Laser cutting machine turbocharging dust removal and noise reduction device

A laser cutting machine, turbocharging technology, applied in laser welding equipment, welding/welding/cutting items, mechanical equipment, etc., can solve the problem of oxidation dust, smoke and airflow impact noise, affecting the operating environment of workers, affecting workers' health, etc. problems, to facilitate collection and recycling, improve the working environment, and reduce noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

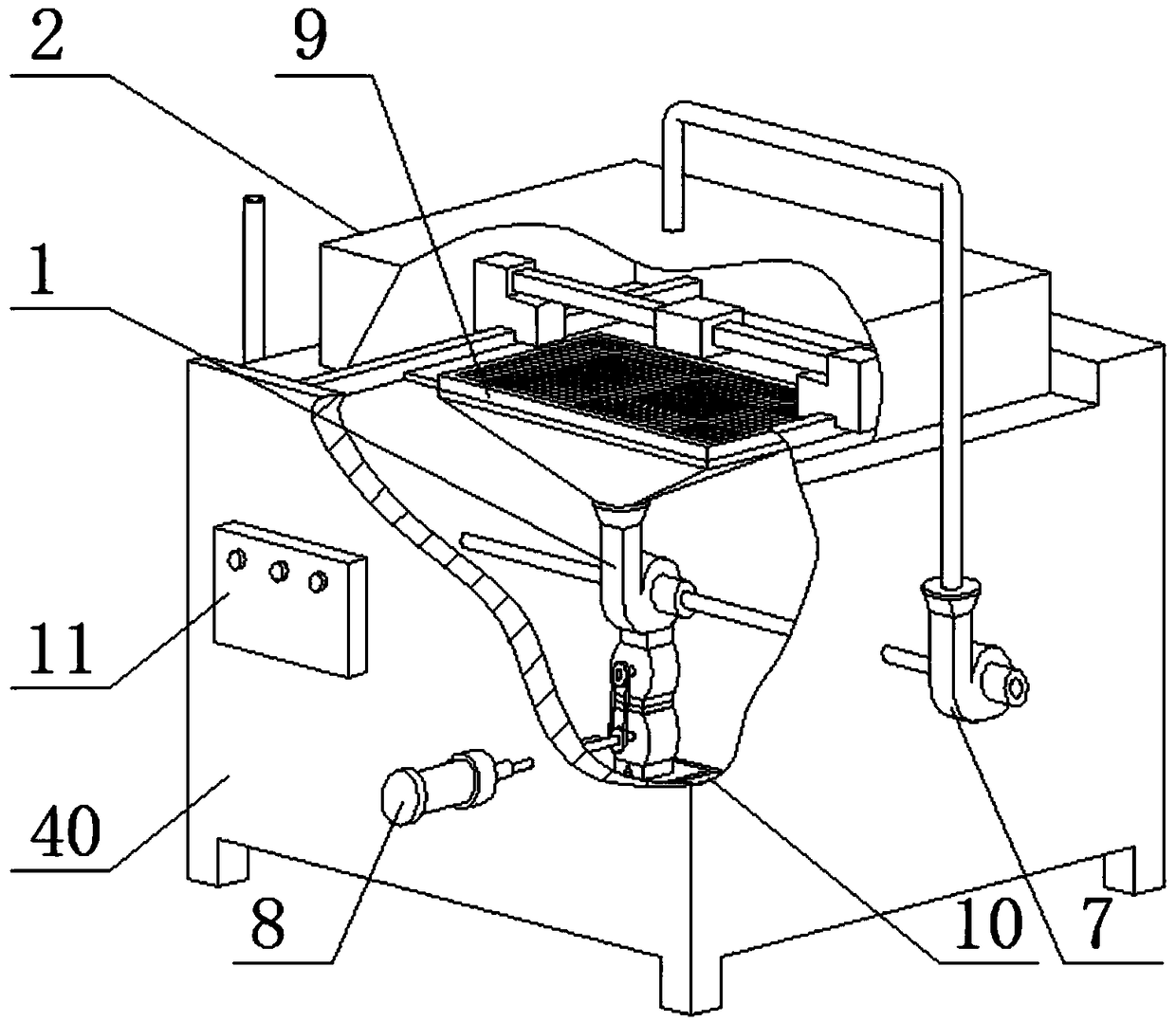

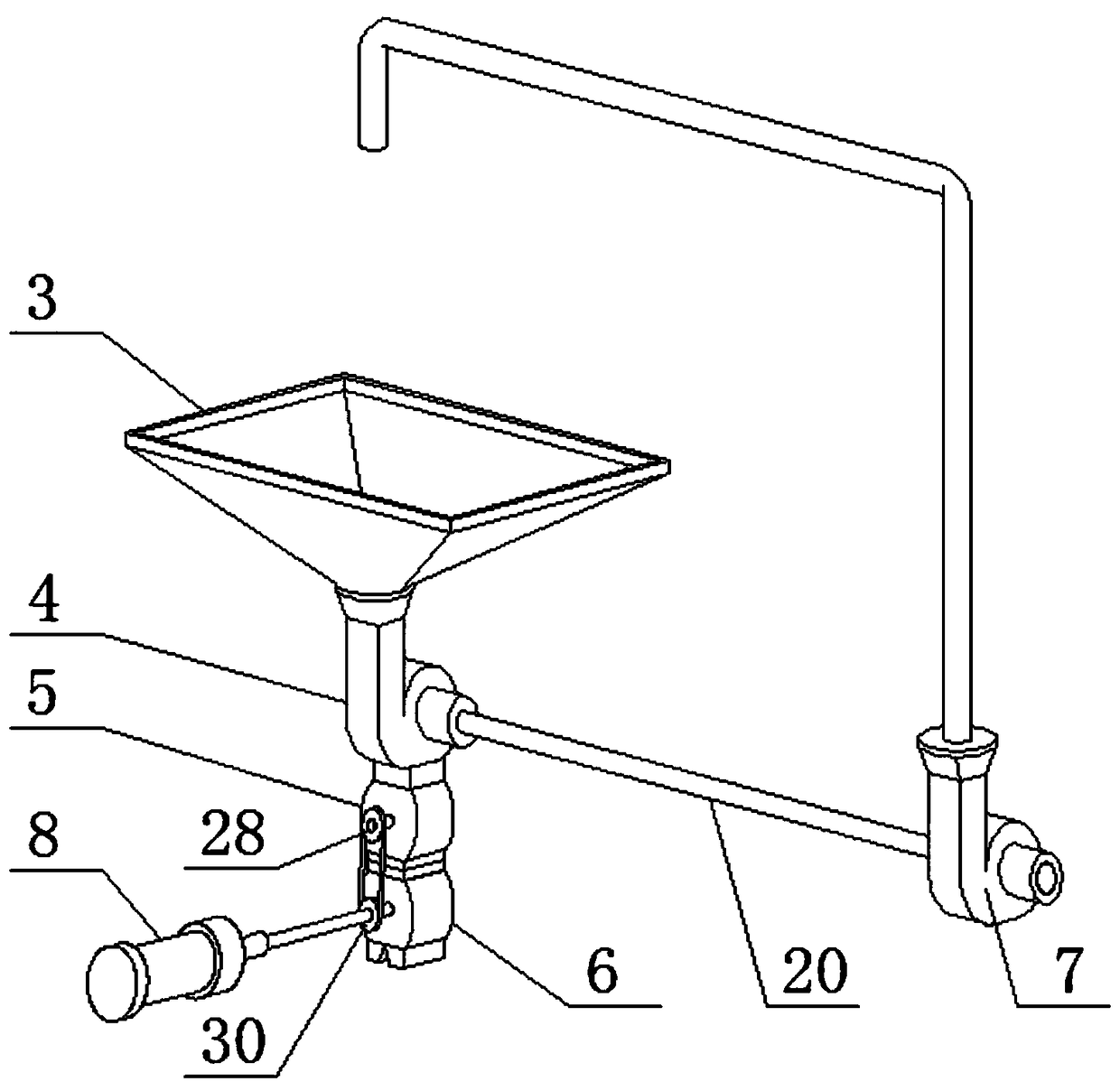

[0029] Examples, see Figure 1-7 , the present invention provides a technical solution:

[0030] A turbocharged dust removal and noise reduction device for a laser cutting machine, comprising a dust removal and noise reduction system 1, a laser cutting machine body 40 and a sealing cover 2 sleeved on the laser cutting machine body 40, the dust removal and noise reduction system 1 passes through a pipeline Connected with the sealing cover 2, the dust removal and noise reduction system 1 includes a shroud 3, a main turbine group 4, a special wind blocker 5, an electromagnetic discharger 6, a secondary turbine group 7, a motor 8, a waste box 10 and a control box 11. The top of the shroud 3 is fixed on the bottom of the support grid 9 on the laser cutting machine body 40, and the main turbine group 4, the special wind choke 5 and the electromagnetic discharger 6 are arranged in sequence from top to bottom In the laser cutting machine body 40, the wind deflector 3, the main turbin...

Embodiment approach

[0032]As a preferred embodiment of the present invention, the first sealing roller 24 includes a bracket 31 and a roller 32, and the roller 32 is provided with rubber.

[0033] As a preferred embodiment of the present invention, the discharge impeller 26 is provided with anchor blades 33 .

[0034] As a preferred embodiment of the present invention, the top of the discharger housing is provided with an eccentric feed pipe 46, and the bottom of the discharger housing is provided with a non-metallic discharge short pipe 34 and a metal discharge short pipe. Pipe 35, waste box 1 36 and waste box 2 37 are arranged on the waste box 10.

[0035] As a preferred embodiment of the present invention, a scraper 38 is provided inside the short metal discharge pipe 35 .

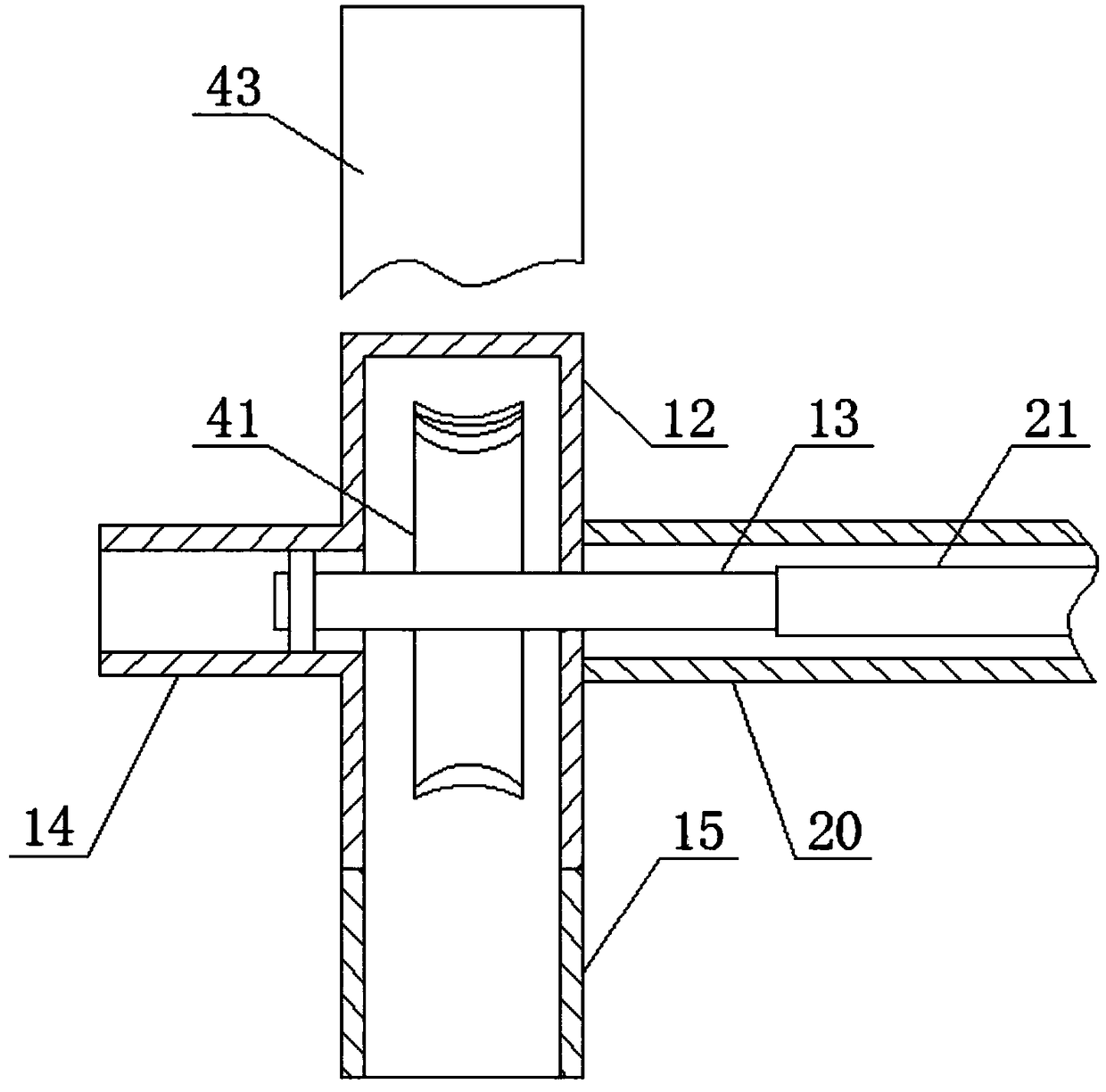

[0036] As a preferred embodiment of the present invention, the electromagnetic drum 22 includes a drum and a coil 39 .

[0037] As a preferred embodiment of the present invention, the first sealing roller 24 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com