Ultra-fine powder classifying device

A classification device and technology of ultra-fine powder, which are applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problems of low classification efficiency, easy to be polluted, unfavorable processing and use, etc. Achieve the effects of high classification accuracy and efficiency, less harm to human health, and convenient collection and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

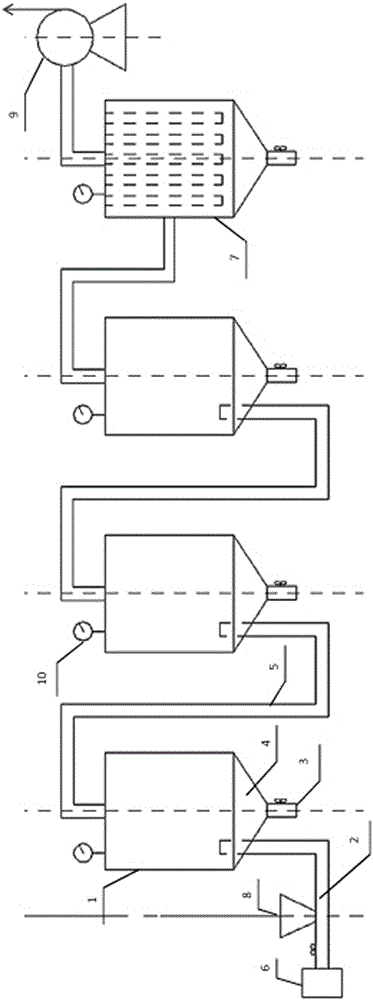

[0013] Such as figure 1 As shown, the present invention provides a kind of superfine powder classification device, which is formed by connecting three dispersion chambers 1 in series through the pipeline 5, the outlet of the former stage dispersion chamber is connected with the entrance of the latter stage dispersion chamber, and each dispersion chamber is provided with There is a pressure gauge 10, the feed port of the first dispersion chamber is externally connected to a feed / air pipe 2, the feed / air pipe 2 is equipped with a feed hopper 8, the inlet of the feed / air pipe is connected to the air compressor 6, and the dispersion chamber 1 Use a plastic bottle with a diameter of φ=150cm, the lower part of the bottle body is a funnel-shaped collection tank 4, and the bottom of the collection tank 4 is provided with a discharge valve 3. The pipeline adopts a plastic pipe with a diameter of φ=5cm, and the last dispersion chamber passes through The pipeline is connected with a dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com