Desulfurization wastewater treatment method

A desulfurization wastewater and treatment method technology, applied in the direction of gaseous effluent wastewater treatment, heating water/sewage treatment, general water supply conservation, etc., can solve problems such as broken equipment, corrosion, etc., achieve low temperature, improve desulfurization efficiency, and make full use of resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

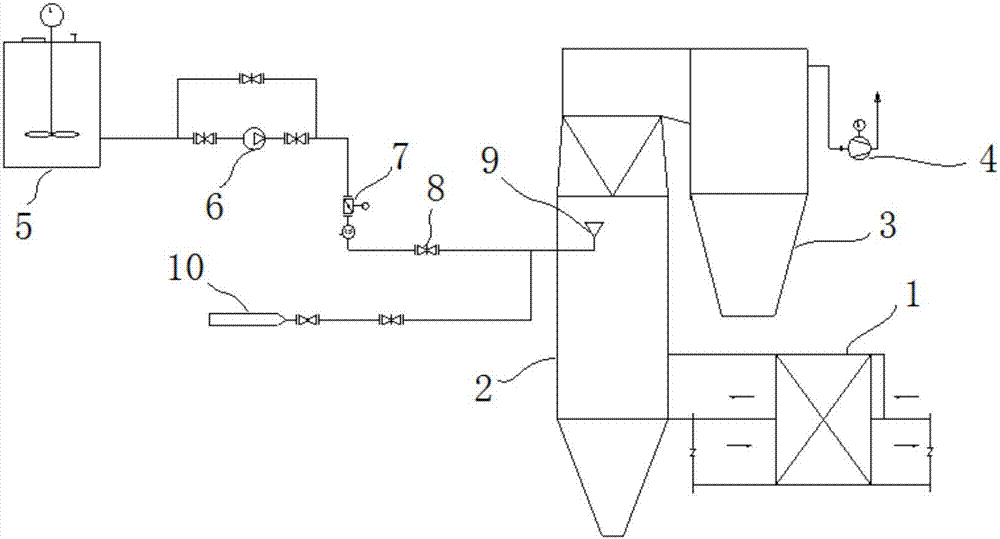

[0044] Such as figure 1 , a desulfurization wastewater treatment device, including a wastewater system, and also includes a phase change generator 2 and a hot air unit, the top of the phase change generator 2 is provided with an outlet, and the bottom of the phase change generator 2 is provided with a solid discharge port , the phase change generator 2 communicates with the hot air unit, and the waste water system communicates with the atomizer 9 inside the phase change generator 2 .

[0045] The hot air output by the hot air unit is mixed with the desulfurization wastewater of the wastewater system atomized by the atomizer 9 to undergo mass heat exchange in the phase change generator 2 to form water vapor and solid particles, and the water vapor passes through the phase change generator 2 The top outlet is discharged, and the solid particles are discharged through the solid discharge outlet at the bottom of the phase change generator 2; the phase change generator 2 provides a...

Embodiment 2

[0047] Such as figure 1 , a desulfurization wastewater treatment device of this embodiment, compared with Embodiment 1, further includes a compressed air unit 10, and the compressed air unit 10 communicates with the atomizer 9.

[0048] The compressed air unit 10 is connected to the atomizer 9, which strengthens the atomization effect of the desulfurization wastewater, and makes the desulfurization wastewater form smaller droplets, so that the hot air and the droplets of the desulfurization wastewater can have a more sufficient mass-thermal reaction. So that the water in the desulfurization wastewater can be more thoroughly formed into water vapor and evaporated.

Embodiment 3

[0050] Such as figure 1 , a desulfurization wastewater treatment device of the present embodiment is further improved on the basis of embodiment 1 or 2, and further includes a gas-solid separator 3 and a fan 4, and the front end of the gas-solid separator 3 is connected to the phase change generator The outlet of 2 is connected, and the rear end of the gas-solid separator 3 is connected with the fan 4.

[0051] After the mass-heat exchange, the impurities and salt in the desulfurization wastewater crystallize to form solid particles. The solid particles include large-particle solids and small-particle solids. Large-particle solids refer to solid particles that fall under the action of hot air and gravity. The solid particles that rise together with the steam, and the large solid particles fall to the solid outlet of the phase change generator 2 under the action of gravity, and the water vapor and small particle solids enter the gas-solid separator 3 from the outlet of the phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com