Patents

Literature

36results about How to "Take full advantage of" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

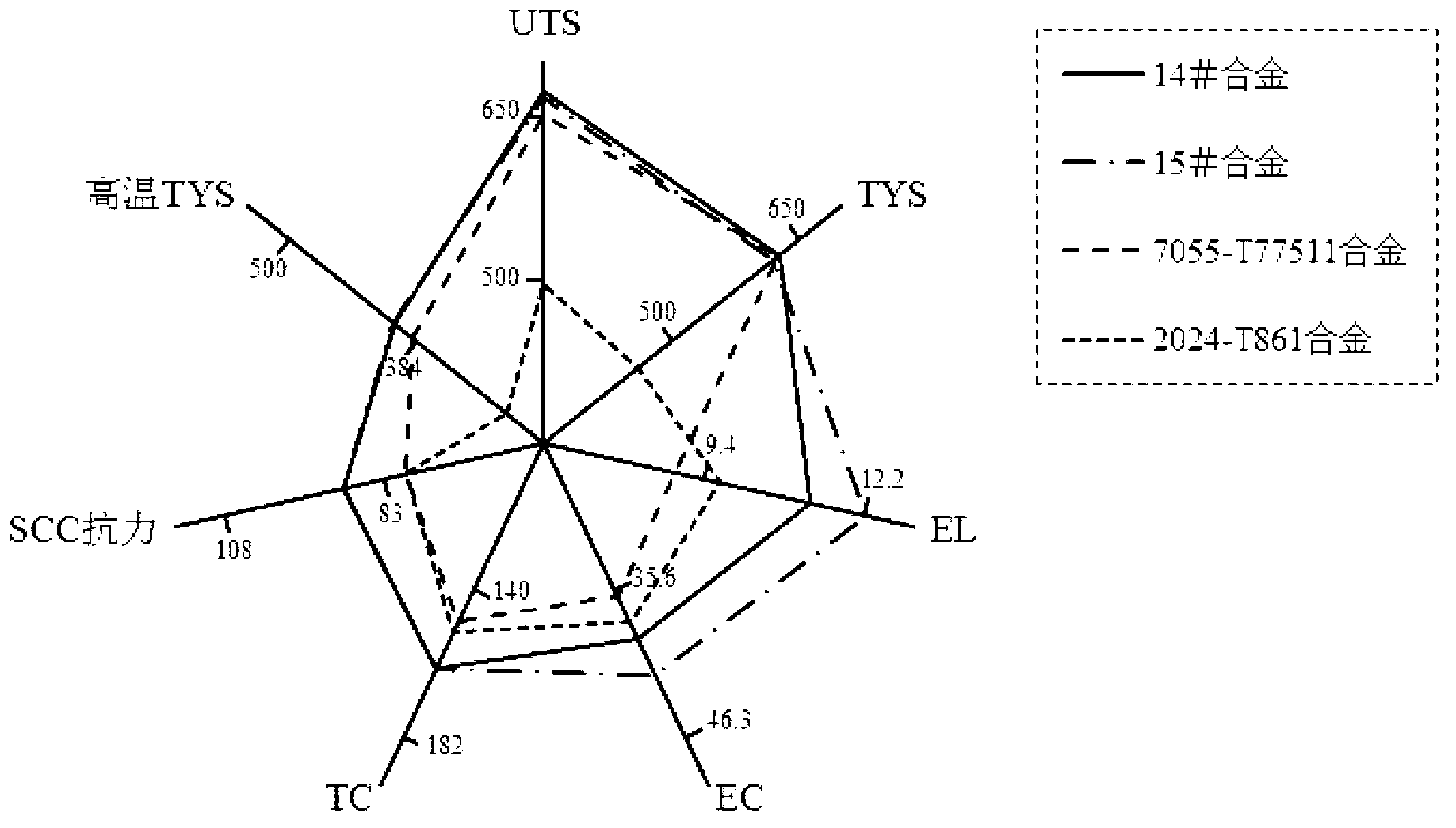

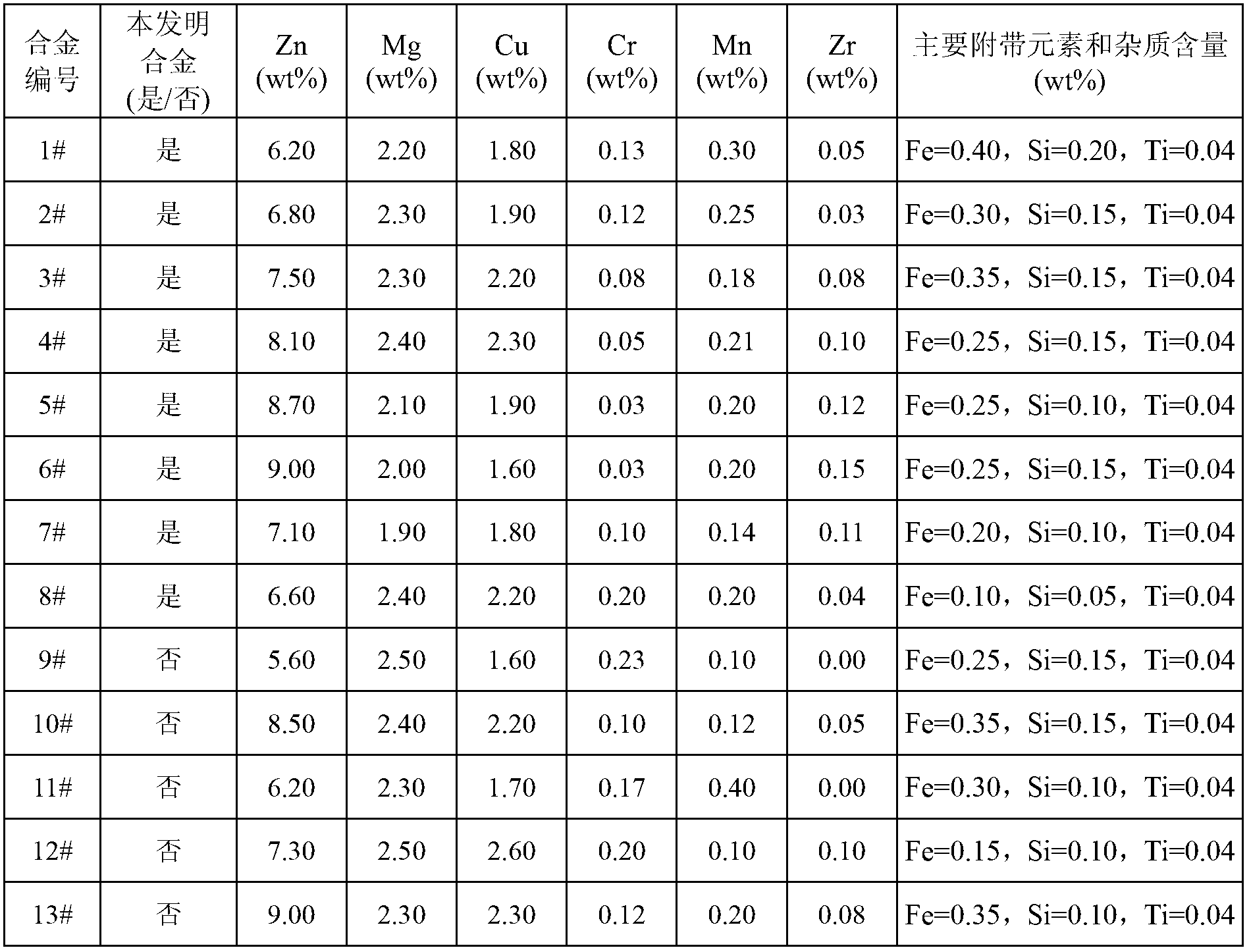

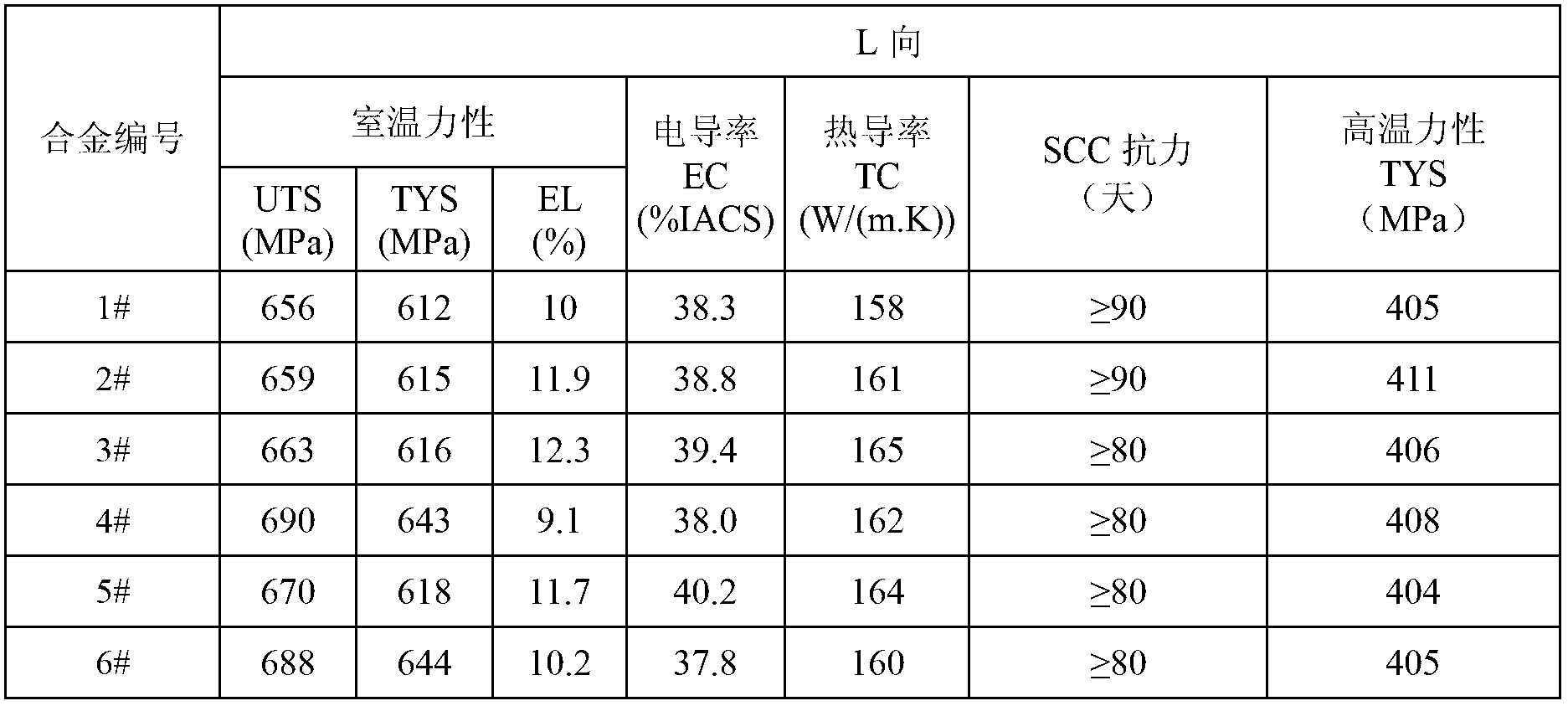

Aluminum alloy product suitable for structure and function integration, and preparation method thereof

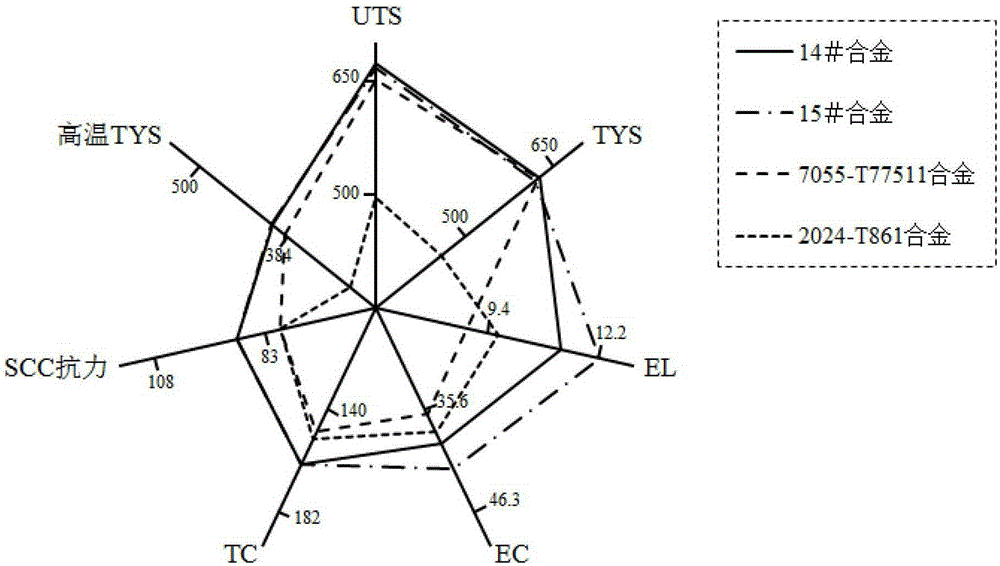

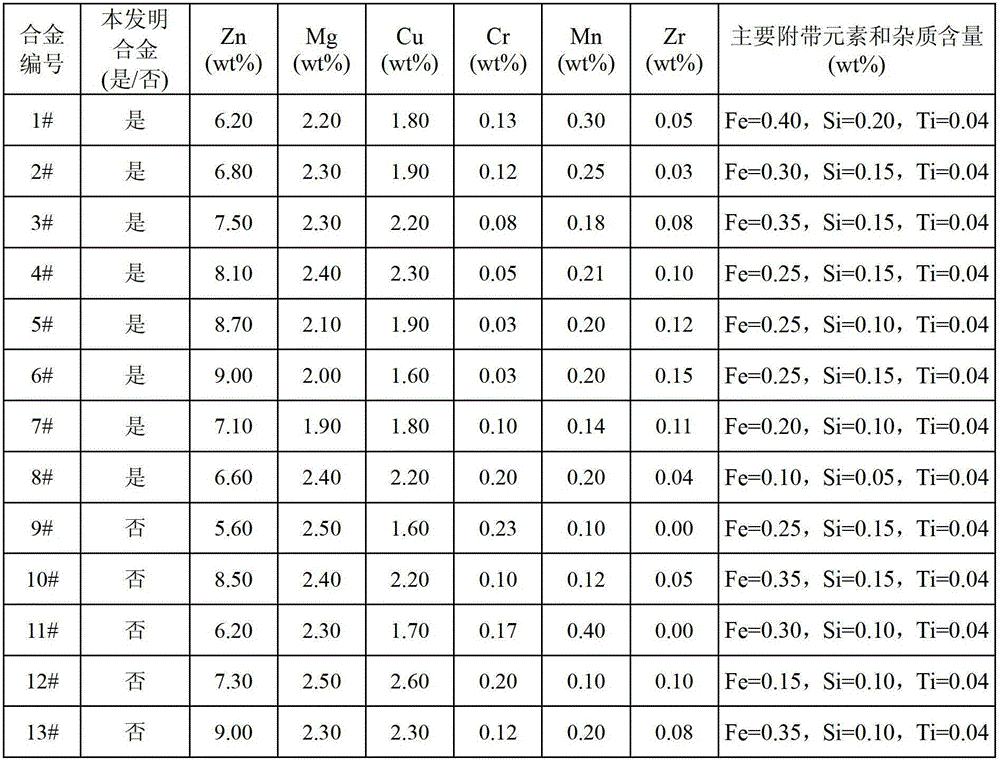

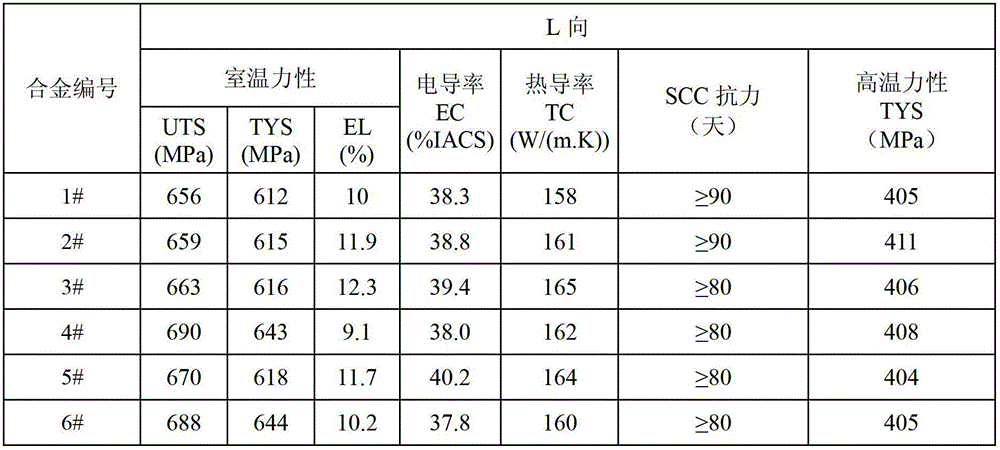

The invention relates to an aluminum alloy product suitable for structure and function integration, and a preparation method thereof. The aluminum alloy product comprises the components of, by weight, 5.5-10.0% of Zn, 1.5-2.8% of Mg, 1.5-2.5% of Cu, 0.01-0.50% of Cr, 0.05-0.50% of Mn, 0.01-0.20% of Zr, and balance of of Al and incidental elements and impurities. In the aluminum alloy product: (a) Zn+Mg+Cu is no lower than 10.0% and no higher than 14.0%; (b) (Zn / Mg)+Cu is no lower than 4.4 and no higher than 6.5; (c) Cr+Mn+Zr is no lower than 0.10 and no higher than 0.60; and (d) the content of Cr is no higher than that of Mn, and content of Mn is no higher than that of Cr+0.20. The aluminum alloy product has high strength, high electric conductivity, and good thermal conductivity. Also, the aluminum alloy product has low residual stress, good surface quality, and good dimensional precision. The invention also relates to a preparation method of the aluminum alloy product.

Owner:GRIMAT ENG INST CO LTD

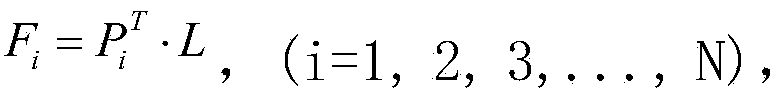

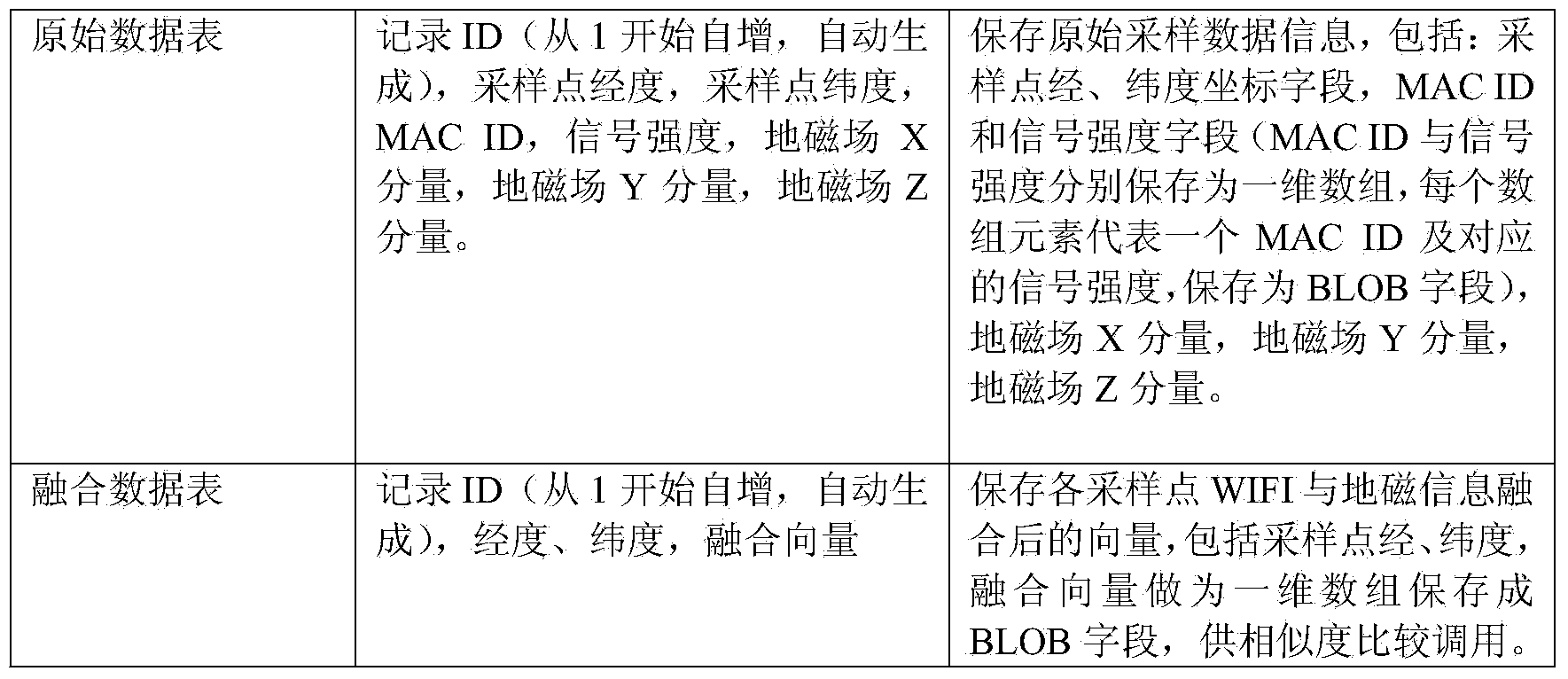

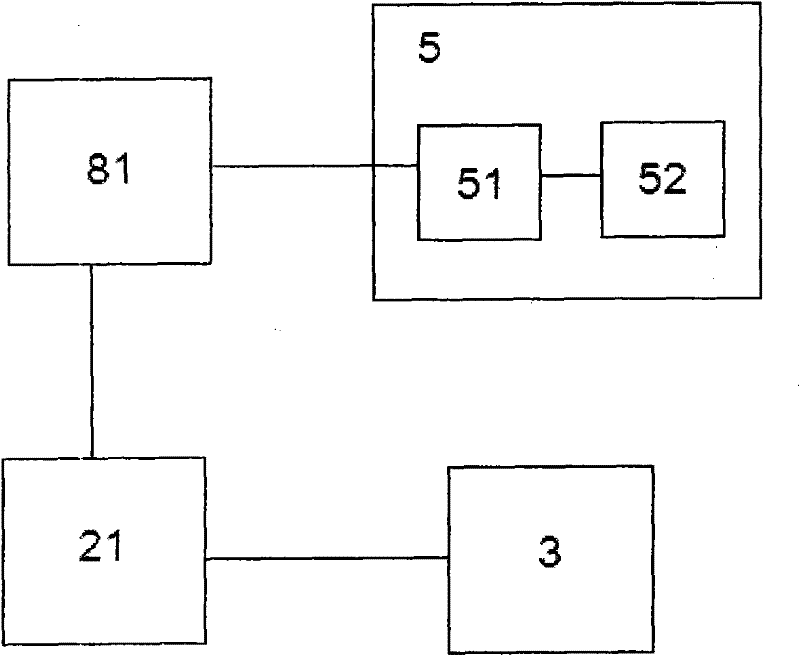

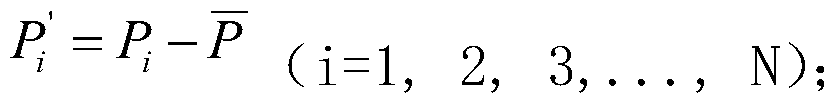

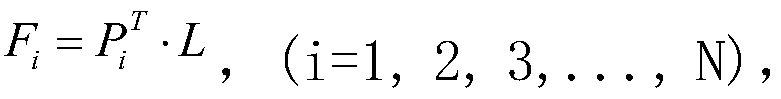

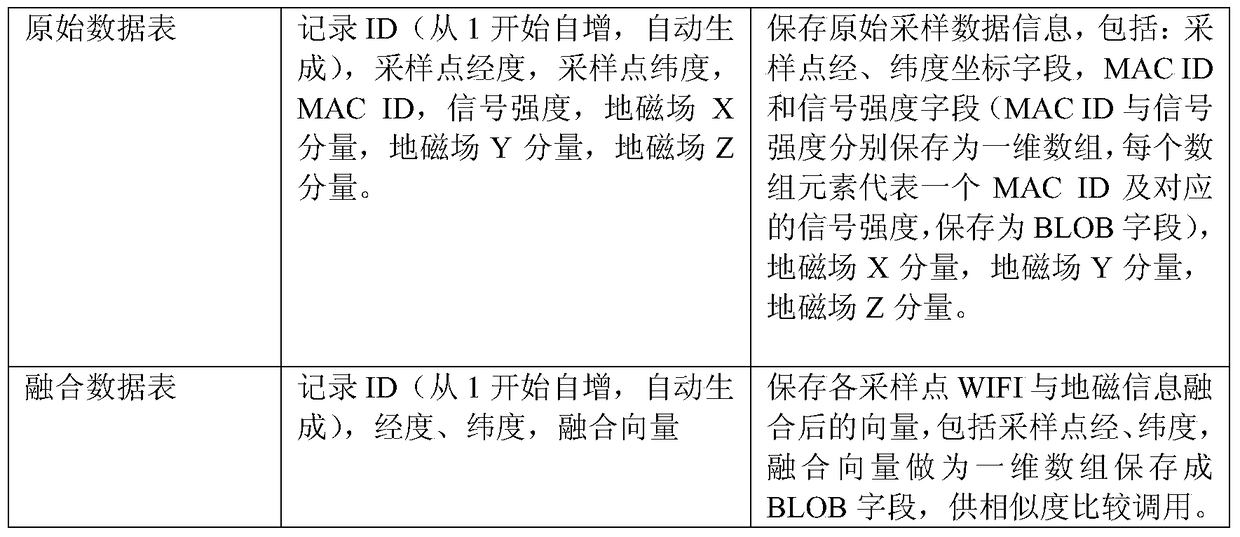

Indoor positioning method combining geomagnetic field and WIFI (wireless fidelity) signals

ActiveCN103630873AThe positioning result is accurateEasy to useNavigation by terrestrial meansPosition fixationSignal strengthHat matrix

The invention relates to the technical field of indoor positioning, in particular to an indoor positioning method combining geomagnetic field and WIFI (wireless fidelity) signals. According to the method, in an offline sampling stage, WIFI signal strength and geomagnetic field information samples are simultaneously collected and are uploaded to a positioning center database, data characteristic fusion and analysis are performed by adopting a principal component analysis method at a positioning center to generate a fusion projection matrix, and all sampling information in the database are projected by the projection matrix to obtain a fusion sample; in an online positioning stage, the vector of WIFI and geomagnetic field intensity information received by a terminal is projected by the fusion projection matrix to generate a fusion vector, and a positioning result is obtained by comparing the fusion vector with the fusion sample in the positioning center database. By adopting the method, accurate positioning combining WIFI and geomagnetic field intensity information can be realized on an existing ordinary smart phone.

Owner:XIAMEN YAXON NETWORKS CO LTD

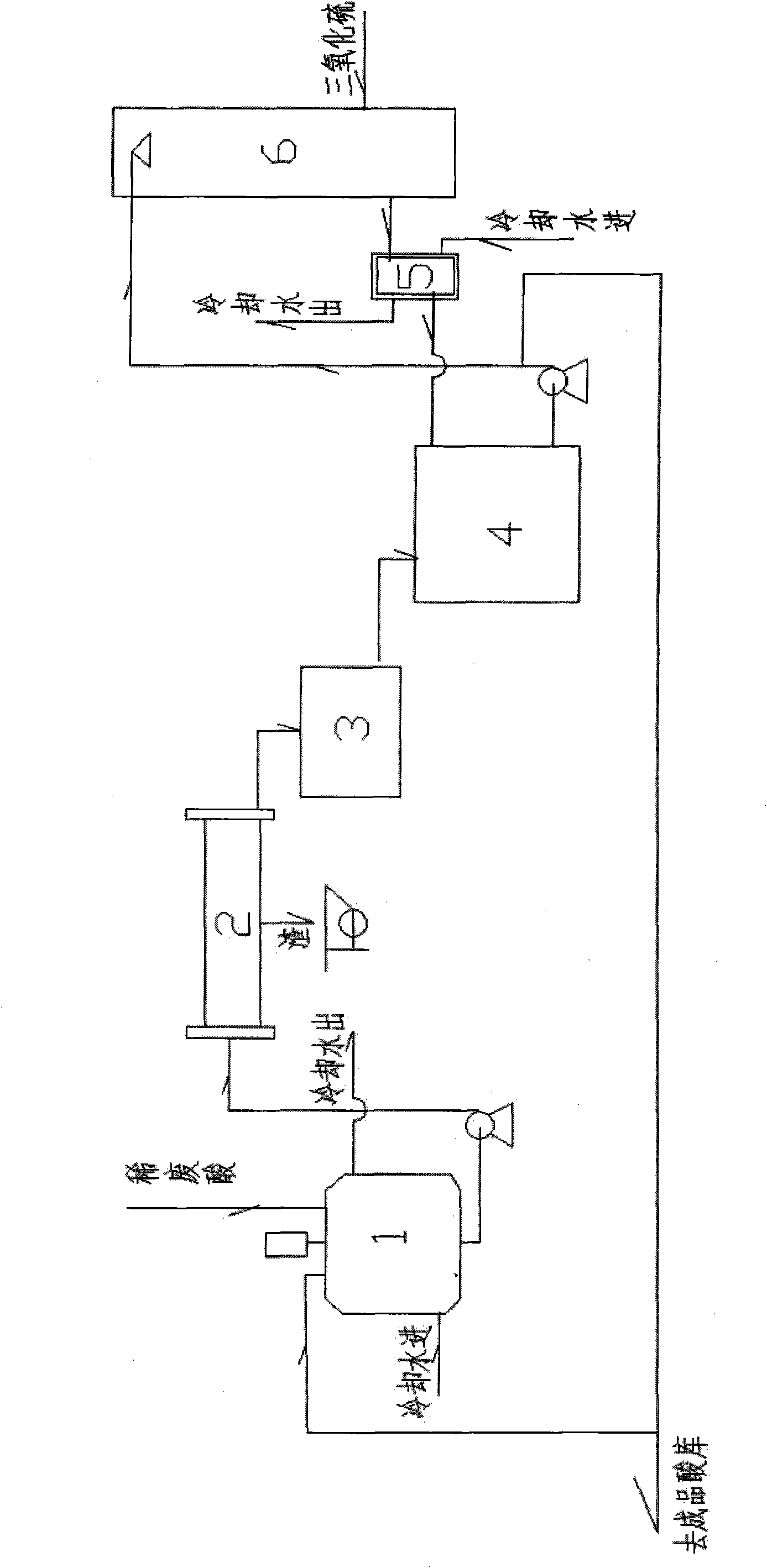

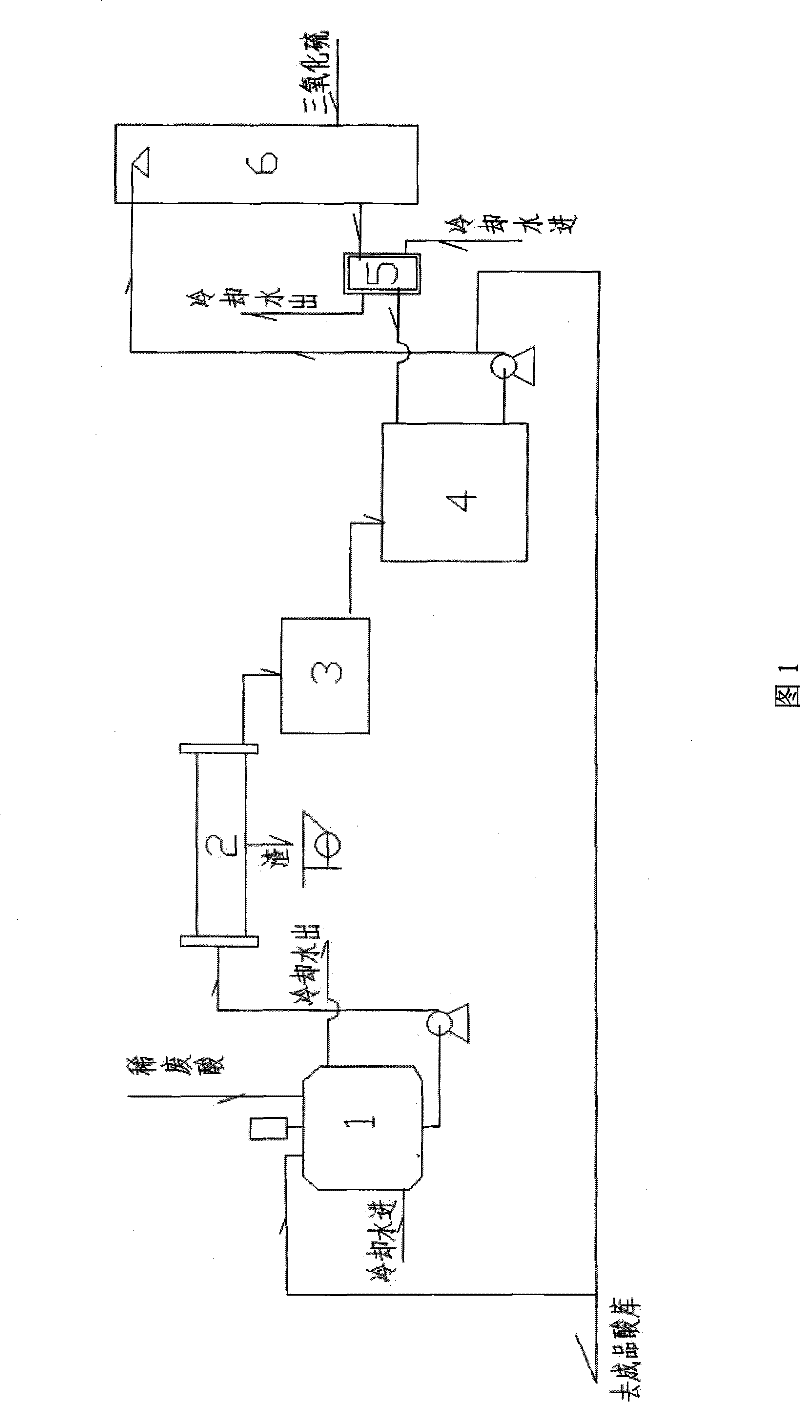

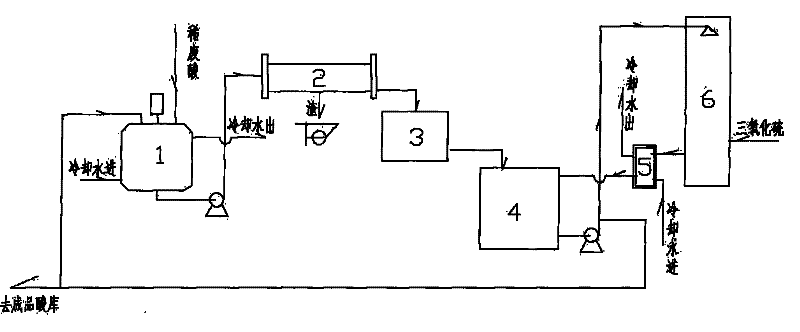

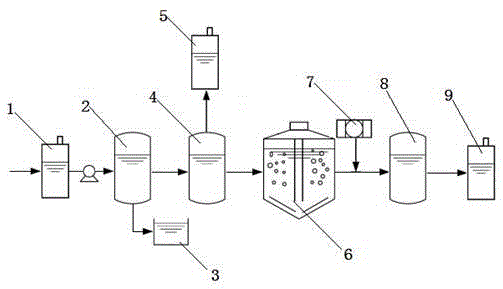

Method and device for producing concentrated sulfuric acid by recycling waste acid from sulfate process titanium dioxide production

ActiveCN101538021ASolving production challenges of reuseIncrease productionSulfur-trioxide/sulfuric-acidSulfurSulfate

The recycling of diluted waste acid produced in the production process of sulfate process titanium dioxide is a bottleneck limiting the development of the sulfate process titanium dioxide. In addition, manufacturers of sulfate process titanium dioxide usually have sulfate acid production devices due to the need of a large amount sulfate acid. The invention relates to a method and a device for producing concentrated sulfuric acid by recycling waste acid from sulfate process titanium dioxide production. The method comprises the following steps: firstly, performing the pre-concentration of the diluted sulfate acid; secondly, removing most impurities carried by the diluted sulfate acid through settlement; and finally, using the sulfate acid subjected to pre-concentration and impurity removal to replace make up water of a sulfate production system, adding the sulfate acid into a sulfate circulating tank of a sulfate acid absorption tower to produce concentrated sulfate acid after sulfate acid absorption tower absorbs sulfur trioxides, and thus recycling the diluted sulfate acid. The method has the advantages of making a plurality of achievements at one time, namely changing pre-concentrated diluted sulfate acid into concentrated sulfate acid without extra energy consumption and equipment addition while reducing the cooling load of sulfate acid flowing out from the tower at the same time.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

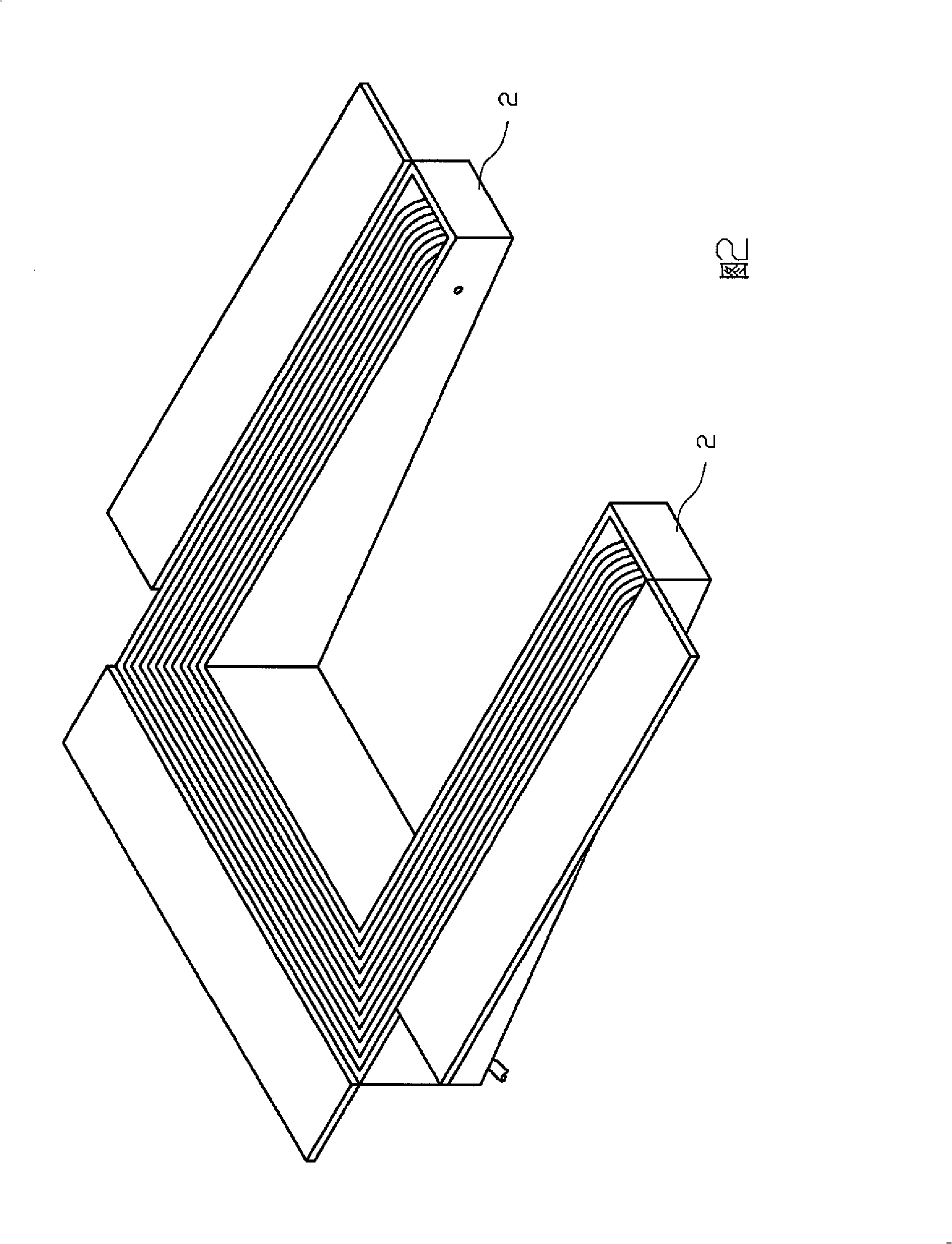

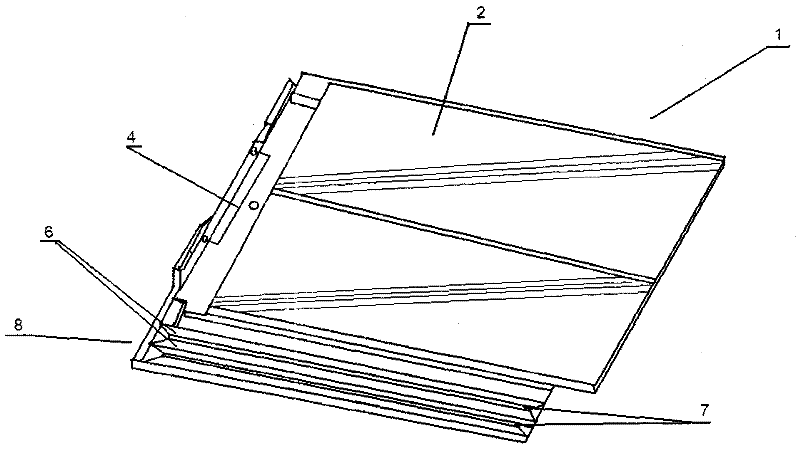

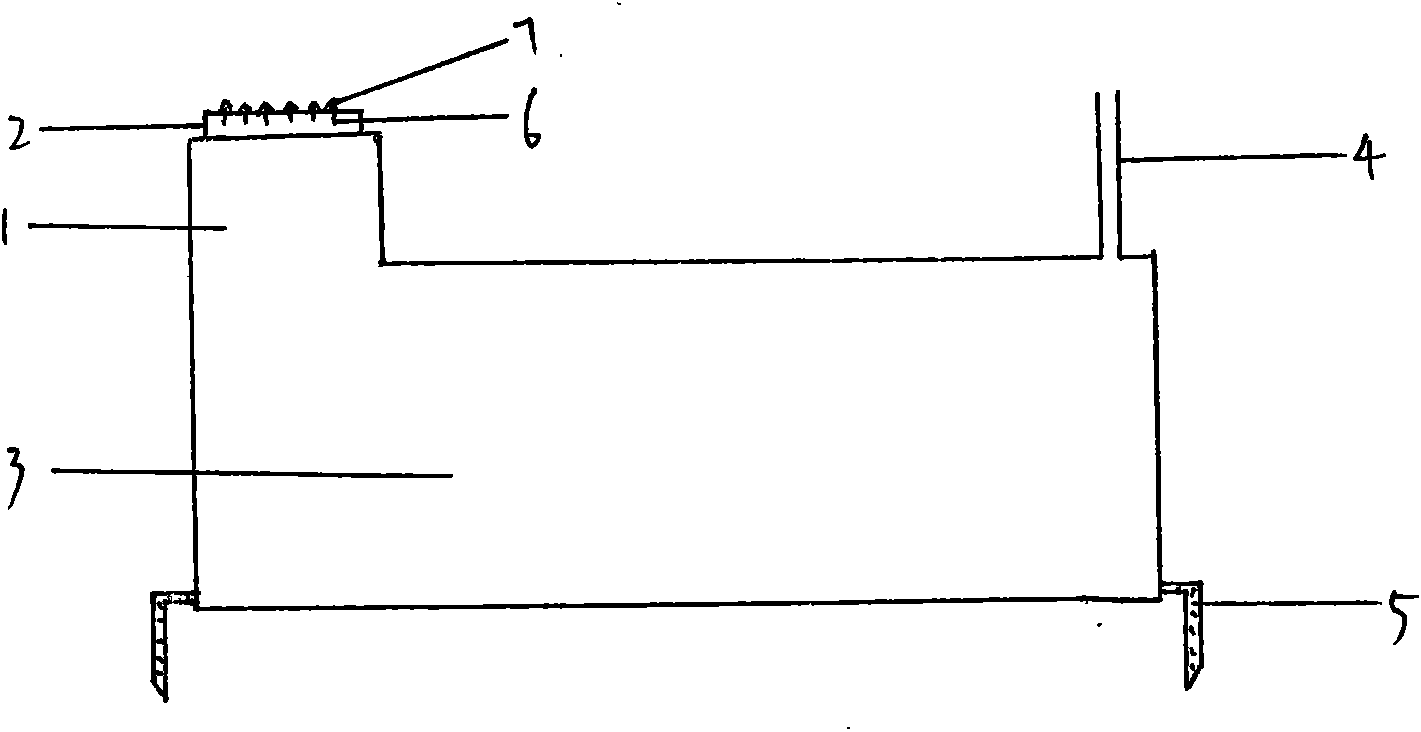

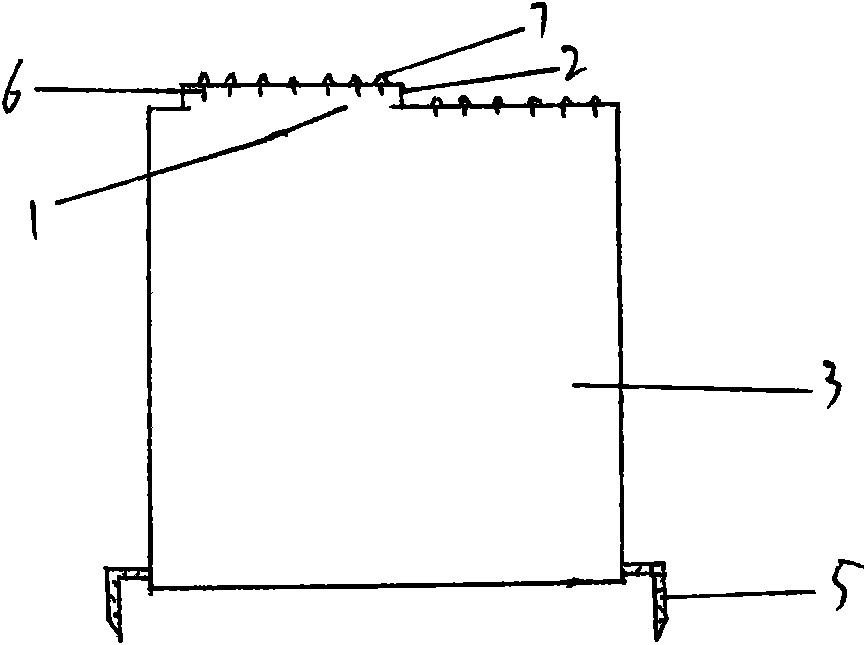

Concealed foldable garage

Owner:任玉明

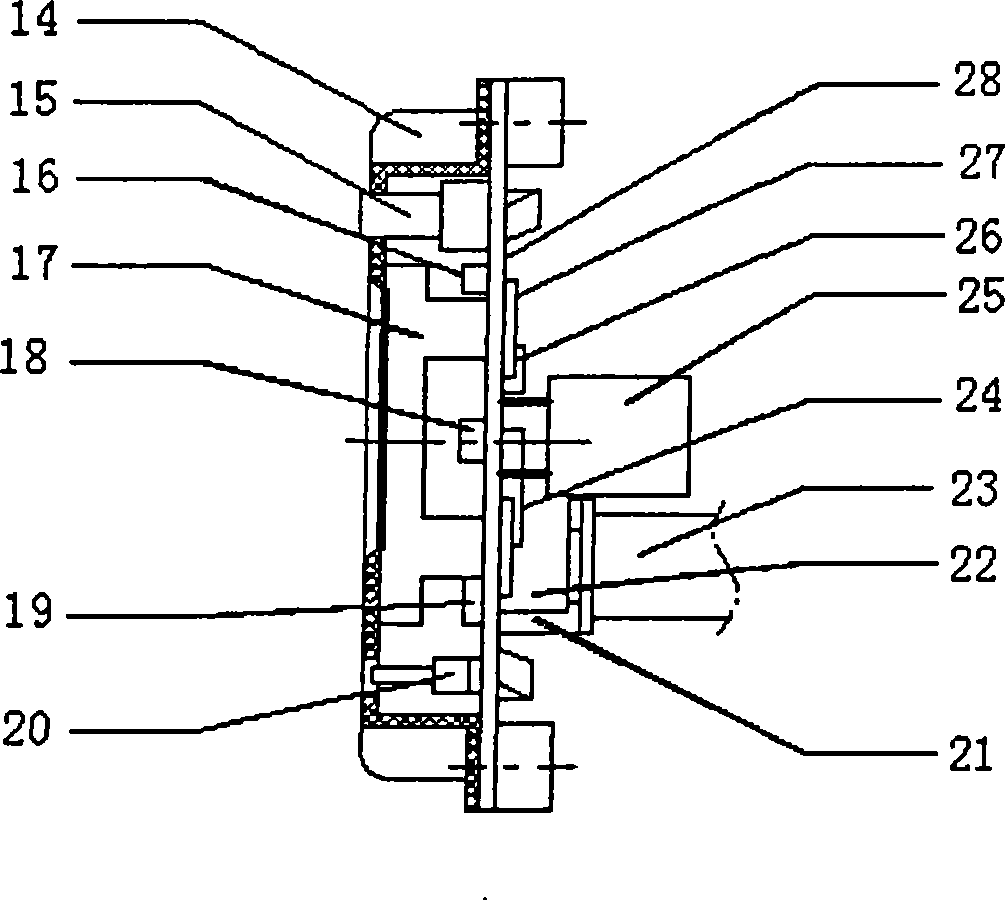

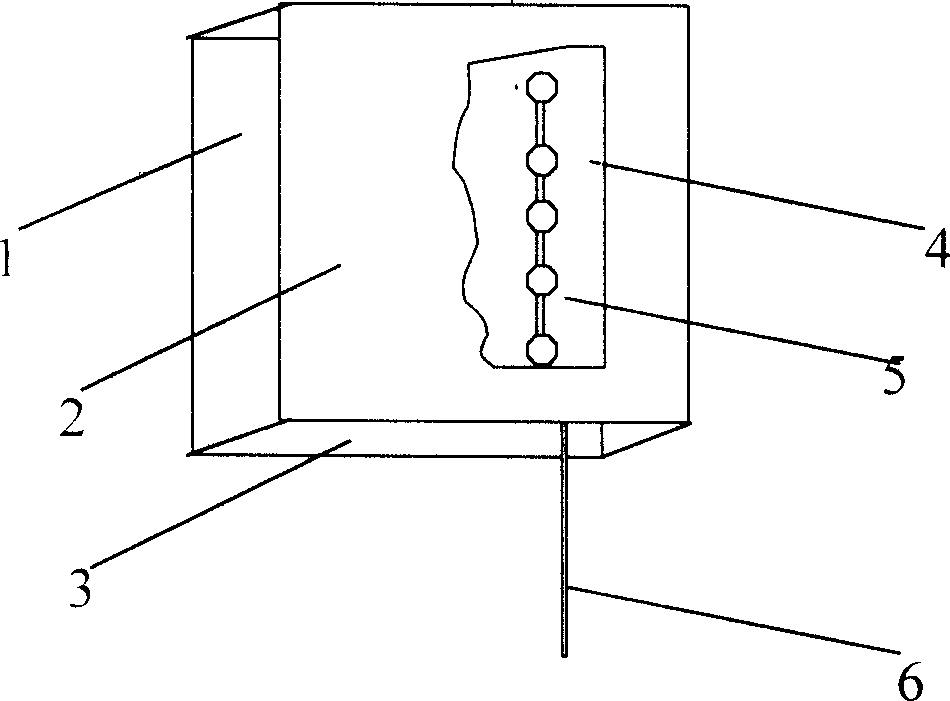

Intelligent pressure transmitter with wide working environment temperature and digital quantity display function

InactiveCN101470038AEnhanced in-place display functionalityTake full advantage ofFluid pressure measurementSignal processing circuitsDisplay device

The invention relates to an intelligent pressure transmitter with wide operating environment temperature and digital amount display, which comprises an electronic box and a pressure sensor, wherein the pressure sensor is mounted under the electronic box, a signal processing circuit board, an OLED display component and a wiring terminal are arranged in the electronic box, and the OLED display component can display a plurality of measurement parameters. The OLED display component can resolve the defects of prior LCD (liquid crystal) display intelligent transmitters which can not display wide temperature range of -40 to +85 DEG C required by users, can not emit light and only can display under backlight condition in dark, to improve the on-site display function of transmitters and completely utilize the advantages of lattice display devices, to obtain in-situ configuration and debugging ability, thereby expanding the application range of the transmitters.

Owner:NO 3 AUTOMATION INSTR & METERS FACTORY SHANGHAI AUTOMATION INSTR & METERS CO LTD

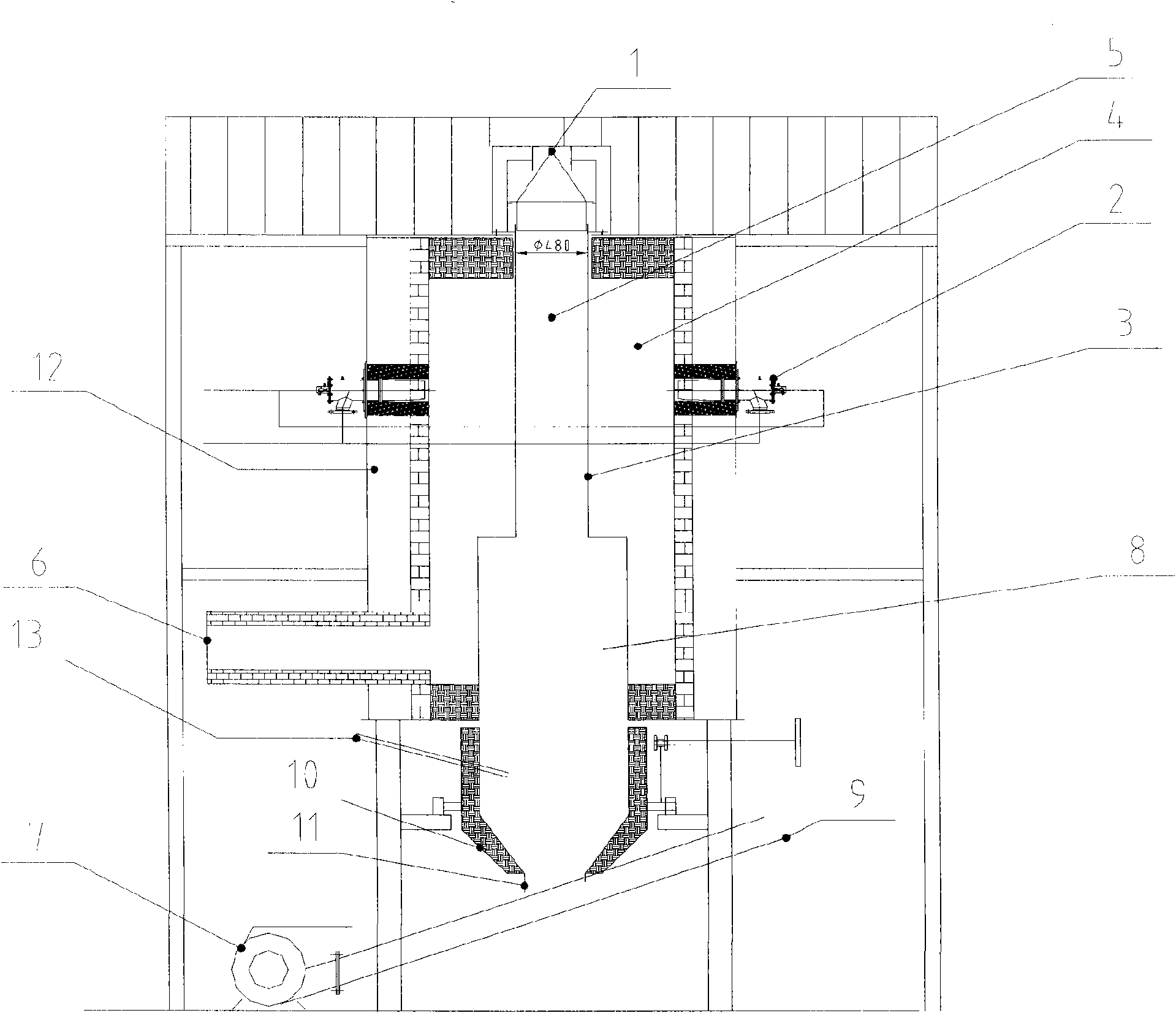

Method for expanding open-bore perlite by gas indirect heating

InactiveCN101643597AEasy to separateSolve the cooling effectIncreasing energy efficiencyIndirect carbon-dioxide mitigationClosed loopPollution

The invention discloses a method for expanding open-bore perlite by gas indirect heating, which heats the open-bore perlite in a gas indirect heating mode. The method comprises the following step: a. a gas indirect heating expansion furnace comprising an expansion cylinder (3) with a small upper cylinder and a big lower cylinder is used; b. the open-bore perlite expands in a high temperature area(5) of the small expansion cylinder in the furnace chamber, so that the perlite micropowder loses crystal water, quickly expands and increases the volume; c. the expanded perlite quickly enters in a low temperature area (8) in the big cylinder to gradually drop temperature without sticking to the wall; d. a draft fan absorbs high temperature waste gas in the furnace chamber through a high temperature flue (6), so that the temperature of the low temperature area in the big cylinder drops, and the form of the perlite is defined; and the discharge end uses a graded closed-loop separating system to ensure no pollution on the environment. The method solves the problem of difficulty in the expansion of the perlite micropowder with 100-250 meshes, has the advantages of short expansion range of balls, quick product discharge, high efficiency, no sticking to the furnace, and low equipment investment, and is suitable for the expansion and the separation of large granules and micro granules.

Owner:LUOYANG ANTUO KILN ENVIRONMENTAL PROTECTION

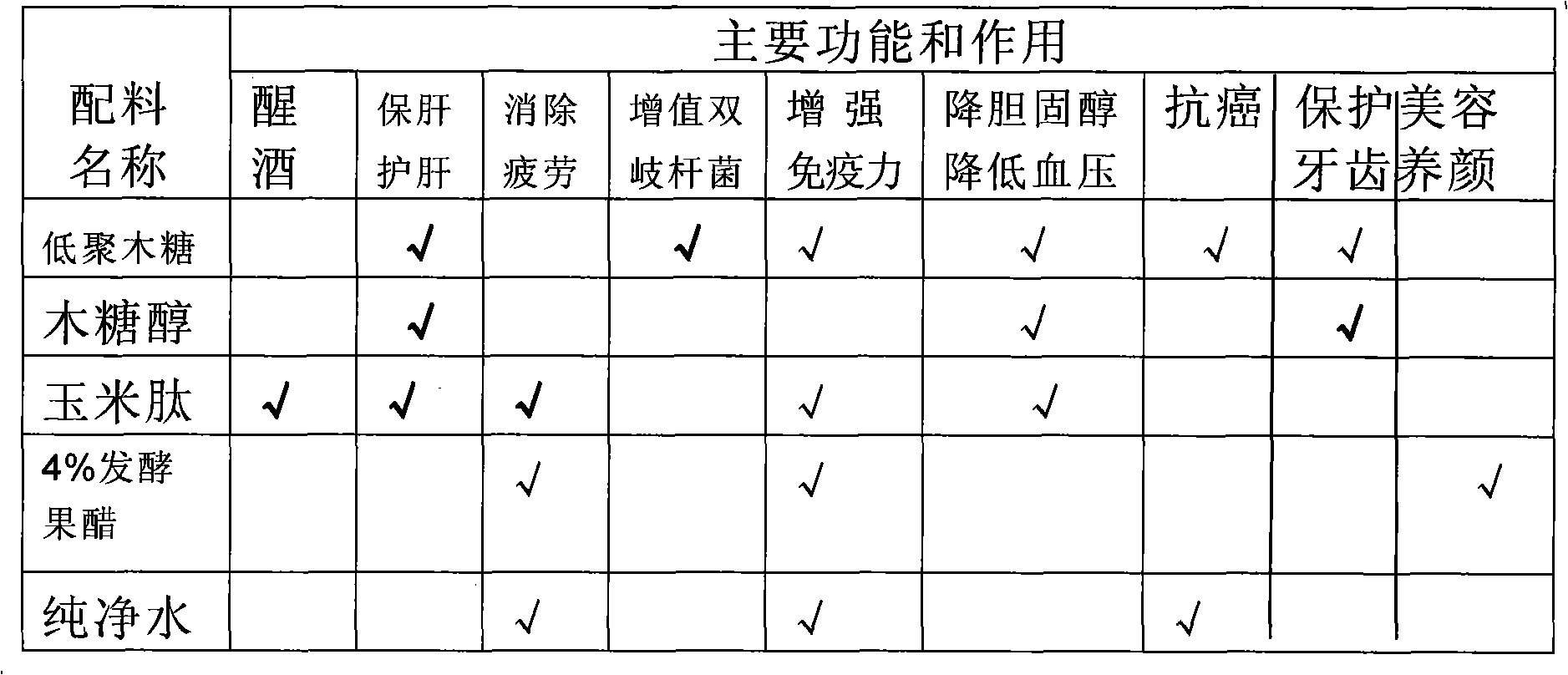

Fruit vinegar beverage containing xylo-oligosaccharide, xylitol and corn peptide

InactiveCN101658314ATake full advantage ofHigh economic valueVinegar preparationFood preparationDiseaseSide effect

The invention relates to a fruit vinegar beverage containing xylo-oligosaccharide, xylitol and corn peptide, belonging to food beverage. The fruit vinegar beverage comprises the components of purifiedwater (63-83%), xylo-oligosaccharide (crystal, 0.5-2%), ylitol (crystal, 10-20%), corn peptide (dry powder, 1.5-5%) and fermented fruit vinegar with the concentration of 4% (5-10%). The components are mixed at the room temperature, sufficiently dissolved, sterilized by a pasteurism and subsequently encapsulated, thus composing the beverage with different component proportions. The fruit vinegar beverage containing xylo-oligosaccharide, xylitol and corn peptide has the advantages of sobering up, protecting liver, beautifying face, eliminating fatigue, reducing blood pressure, reducing cholesterin, reinforcing immunity, stimulating bowels evacuation and the like, has no additives such as sugar, preservative, essence, pigment and the like, has no side effects with proper drinking, and can bewidely applied to general people and special people who drink wine and have the disease of diabetes.

Owner:董路

Intelligent full-automatic earthenware production device

PendingCN107650257ATake full advantage ofSolve the problem of difficult recruitment of front-line workersCeramic shaping plantsAuxillary shaping apparatusTextile printerHuman–machine interface

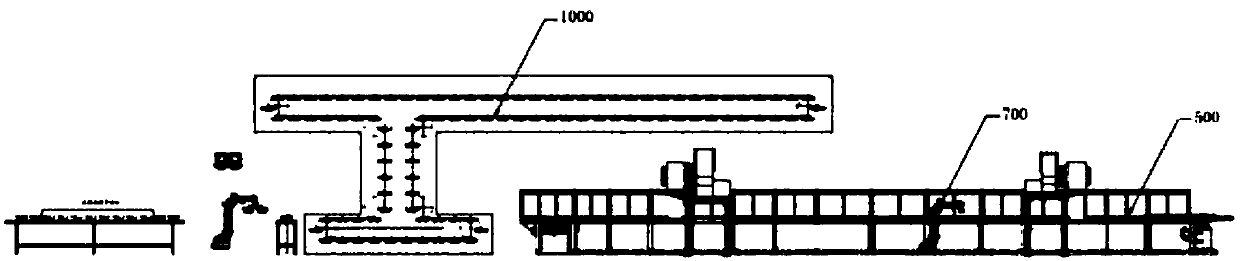

The invention discloses an intelligent full-automatic earthenware production device. The device comprises a mud supply conveying line, a secondary vacuum deairing machine, a mud prepressing device, amolding device, a primary drying line, a mold separation and transfer device, a mold processing device, a 1# fixed-length conveying belt machine, a 2# transfer machine, a secondary drying line, a 3# transfer machine, a 2# fixed-length conveying belt machine, a finishing device and a returned plate drying line. The intelligent full-automatic earthenware production device uses a raw material workshop for conveying mud strips, uses an automatic conveying line for joint, needs no primary producers to finish glazing or printing procedures of the mud strips from the raw material workshop, and uses program control, human-computer interface data setting, PLC control and intelligent alarm voice prompt for setting and control in the whole process.

Owner:ZHIXINLONG TECH (GUANGDONG) CO LTD

An aluminum alloy product suitable for structural and functional integration and its preparation method

The invention relates to an aluminum alloy product suitable for structure and function integration, and a preparation method thereof. The aluminum alloy product comprises the components of, by weight, 5.5-10.0% of Zn, 1.5-2.8% of Mg, 1.5-2.5% of Cu, 0.01-0.50% of Cr, 0.05-0.50% of Mn, 0.01-0.20% of Zr, and balance of of Al and incidental elements and impurities. In the aluminum alloy product: (a) Zn+Mg+Cu is no lower than 10.0% and no higher than 14.0%; (b) (Zn / Mg)+Cu is no lower than 4.4 and no higher than 6.5; (c) Cr+Mn+Zr is no lower than 0.10 and no higher than 0.60; and (d) the content of Cr is no higher than that of Mn, and content of Mn is no higher than that of Cr+0.20. The aluminum alloy product has high strength, high electric conductivity, and good thermal conductivity. Also, the aluminum alloy product has low residual stress, good surface quality, and good dimensional precision. The invention also relates to a preparation method of the aluminum alloy product.

Owner:GRIMAT ENG INST CO LTD

Processing formula and process of biological feed for breeding fly maggots or hermetia illucens

PendingCN112753904AEasy to eatPromote absorptionFood processingAnimal feeding stuffBiotechnologyNutritive values

The invention discloses a processing formula and process of a biological feed for breeding fly maggots or hermetia illucens. According to the processing formula, the formula can give full play to secondary utilization of nutritional ingredients of various waste residues, and a scientific proportion is designed according to the requirements of insects on protein and feeding habits, so that the biological feed contains rich protein; macromolecules such as crude fibers and lignin which cannot be directly absorbed by animals in the waste residues are decomposed into micromolecular nutrient substances and various microelements which can be well eaten and absorbed by the fly maggots and the hermetia illucens under the action of probiotics and enzymes; specific florae are selected inside, and tenebrio molitor and barley worm excrement sand are generally used as a low-price fertilizer or fertilizer pond raw material, but the invention develops a way with a higher additional value for the utilization of the tenebrio molitor and barley worm excrement sand; and meanwhile, a novel treatment auxiliary material with low cost and high nutritional value is provided for many waste residue treatment plants, and the high-quality resource, namely the insect excrement, can be fully combined and utilized.

Owner:广东绿金生物科技有限公司

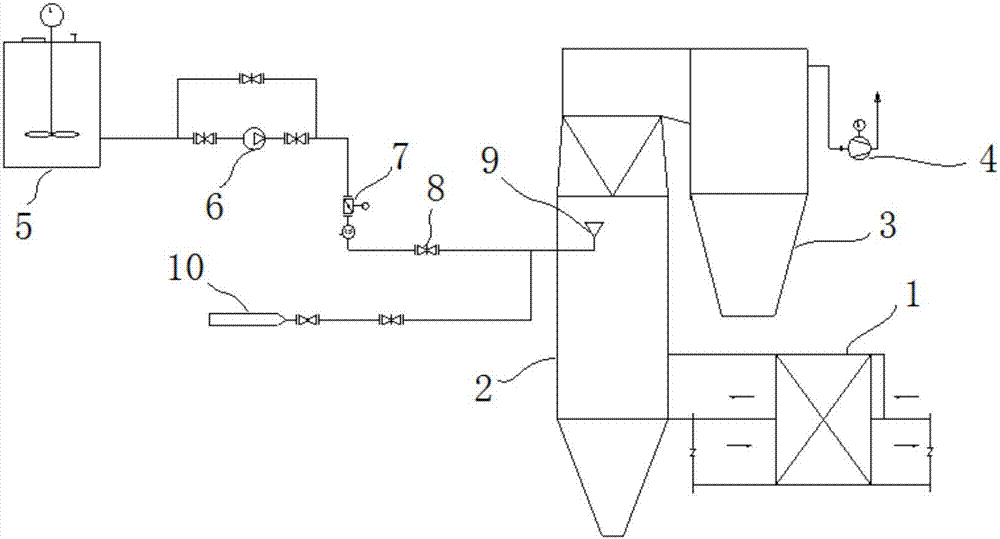

Desulfurization wastewater treatment method

InactiveCN106986401AAchieve pollutionNo corrosion problemsGeneral water supply conservationWaste water treatment from gaseous effluentsGas phasePhase change

The invention discloses a desulfurization wastewater treatment method, and belongs to the field of desulfurization wastewater treatment. A hot air unit introduces hot air into a phase change generator; meanwhile, a wastewater system conveys desulfurization wastewater to an atomizer in the phase change generator for atomization, hot wind formed by the desulfurization wastewater and the hot air is changed into a gas phase from a liquid phase through mass and heat exchange and the gas phase is discharged from an outlet of the phase change generator along with the hot wind; a solid formed by impurity crystal in the desulfurization wastewater enters the hot air unit at a solid outlet of the phase change generator under the action of gravity. According to the desulfurization wastewater treatment method, hot air in the phase change generator and atomized desulfurization wastewater drops are subjected to mass and heat exchange, and the desulfurization wastewater drops are evaporated and crystallized and then subjected to gas-solid separation. The problems that an original desulfurization balance is broken and equipment corrosion is caused in the desulfurization wastewater treatment process in a flue are solved, so that zero pollution and zero emission of the desulfurization wastewater are achieved.

Owner:张玉君

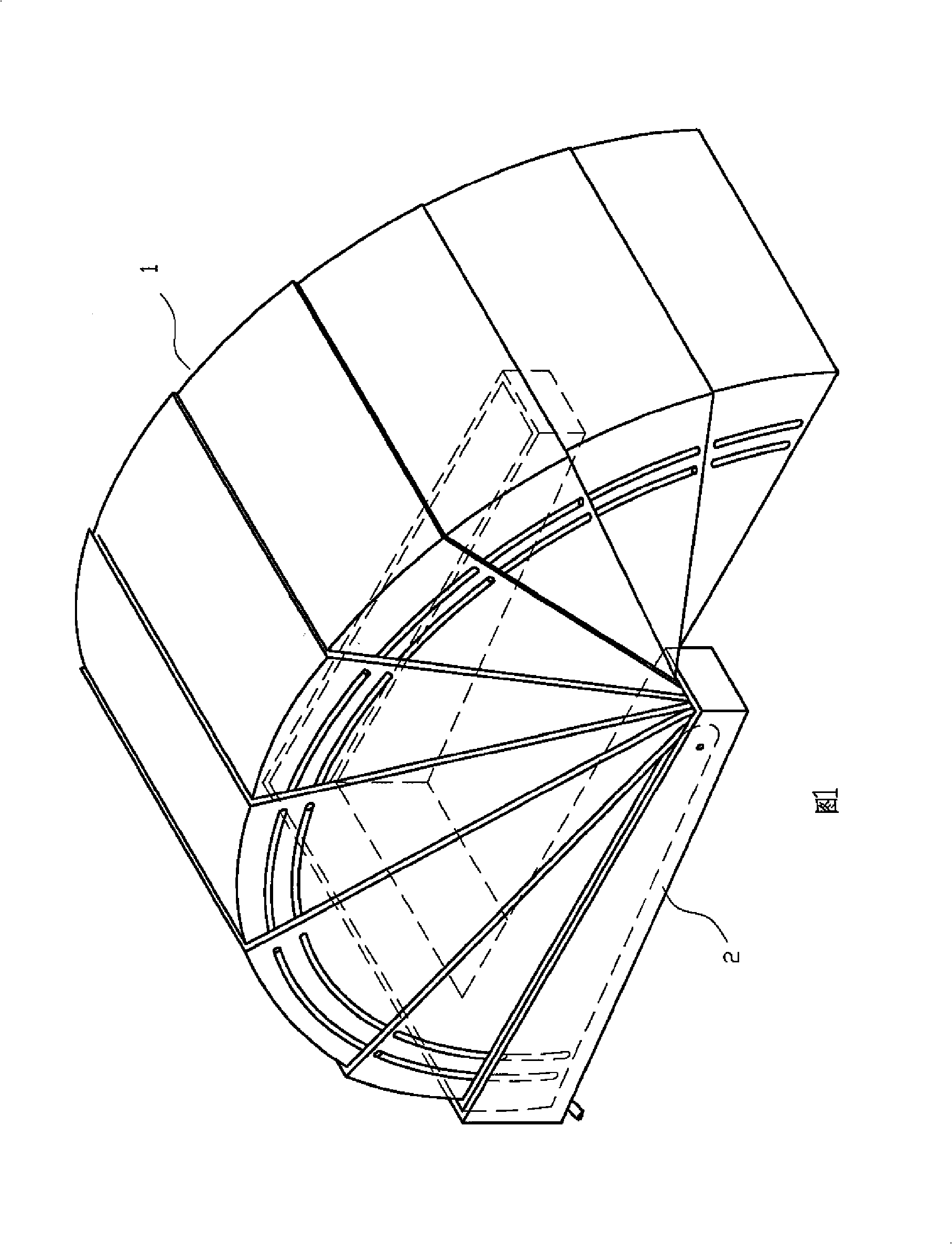

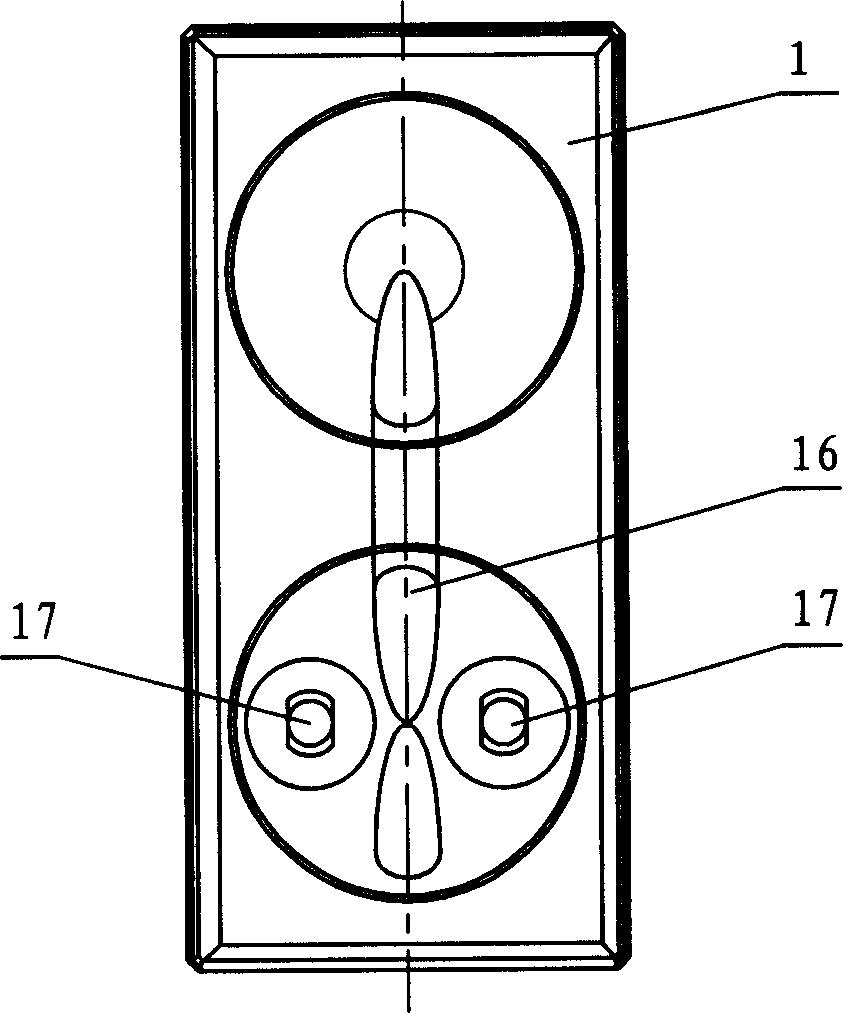

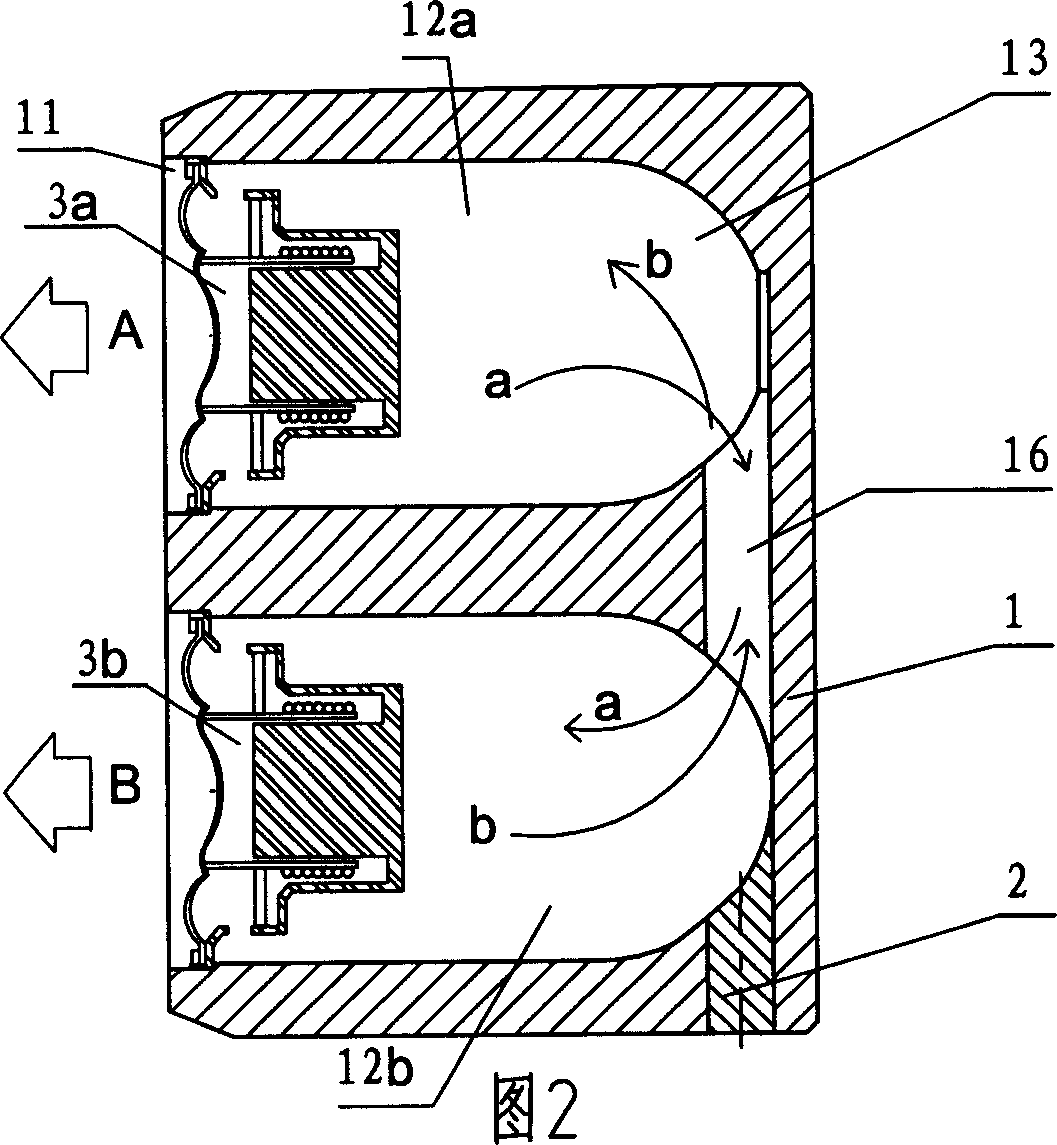

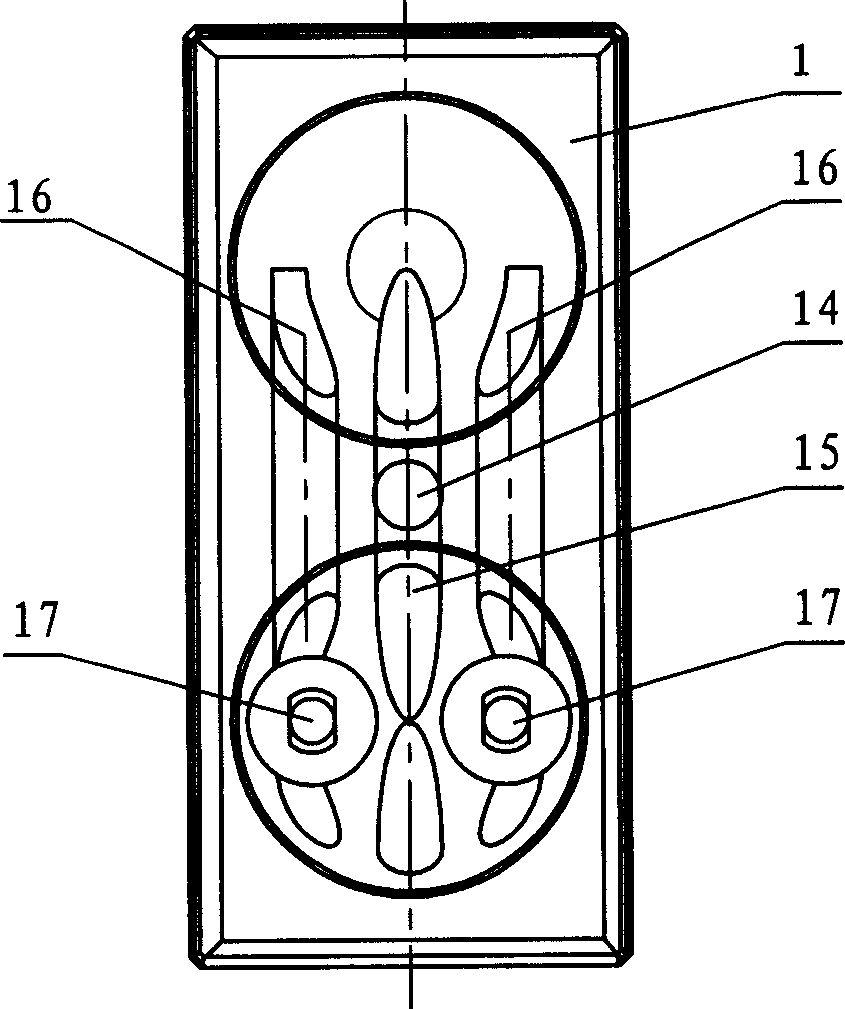

Speaker system

InactiveCN1901752AAchieve resonanceTake full advantage ofFrequency/directions obtaining arrangementsSound boxEngineering

This invention discloses a loudspeaker system including a sound box, at least two loudspeaker sets in the same performance and composed of one or more than one loudspeakers, each set is installed in the open-end of an independent sound chamber in the box, the chambers are in same shape and size, the adjacent chambers are run-through by a connection tube, and the structure of this invention is favorable to realizing resonance of the loudspeaker sets.

Owner:张壮发

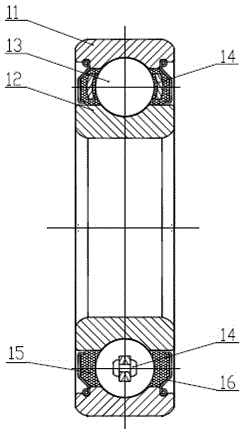

Mixture lubricated rolling bearing and manufacturing method thereof

ActiveCN102588445AOvercome the priceOvercoming the problem of carbon formation at high temperaturesBearing componentsBase-materialsFluid film lubricationPerfluoropolyether

The invention provides a manufacturing method of a rolling bearing which takes mixture of polyethylene oil and solid lubricating material as lubricant and the rolling bearing. The manufacturing method comprises the steps of injecting the lubricant which comprises mixture of polyethylene oil and solid lubricating material micropowder into cavity of the bearing and stamping a dust cap, thus a high temperature resistant sealed bearing is obtained. When the bearing operates at the temperature of being lower than oxidation chain scission temperature of the polyethylene oil, fluid film lubrication is formed; and when the bearing operates at the temperature of being higher than the oxidation chain scission temperature of the polyethylene oil, the polyethylene oil volatilizes, and the fluid film lubrication is changed into solid film lubrication. Compared with the prior art, the invention has the advantages that the problems that perfluoropolyether high temperature lubrication oil has high price and carbon is deposited at high temperature are solved, the problem that solid lubricant is required to be adopted from the start is solved, the bearing can actively realize conversion from fluid lubrication to solid lubrication according to running temperature, respective maximum advantages of the fluid lubrication and the solid lubrication are fully played, operational reliability of the bearing is improved and life of the bearing is prolonged, and the bearing is applicable to various high temperature environments.

Owner:SHANGHAI F&S BEARING TECH

Sweet potato or/and purple sweet potato ball and making method thereof

The invention discloses a sweet potato or / and purple sweet potato ball and a making method thereof. The sweet potato or / and purple sweet potato ball comprises a wrapper and stuffing wrapped by the wrapper, wherein the wrapper is made of sweet potato or / and purple sweet potato wrapper material prepared by pulping sweet potato tubers or / and purple sweet potato tubers. The sweet potato or / and purple sweet potato ball is convenient to eat and has good taste. The stuffing which can be sweetened bean paste or other common stuffing in the prior art, is transported and stored in the way of being frozen at minus 18 DEG C and does not go bad. In the processing process of the sweet potato or / and purple sweet potato ball, most of cells of sweet potato tubers or / and purple sweet potato tubers are broken to release more free starch grains, thereby ensuring the complete utilization of nutrition constituents; and meanwhile, the cohesiveness of the sweet potato or / and purple sweet potato wrapper is increased, therefore the sweet potato or / and purple sweet potato ball can be shaped easily. According to the deep processing method and the finished product, the nutrition constituents of sweet potatoes or / and purple sweet potatoes can be maintained and completely used in the deep processing process and an eating process. The sweet potato or / and purple sweet potato ball has good taste and relatively improved edibleness and can be eaten as staple food; moreover, the value of sweet potatoes or / and purple sweet potatoes is improved; and therefore, the sweet potato or / and purple sweet potato ball has high marketable value.

Owner:赵绪德

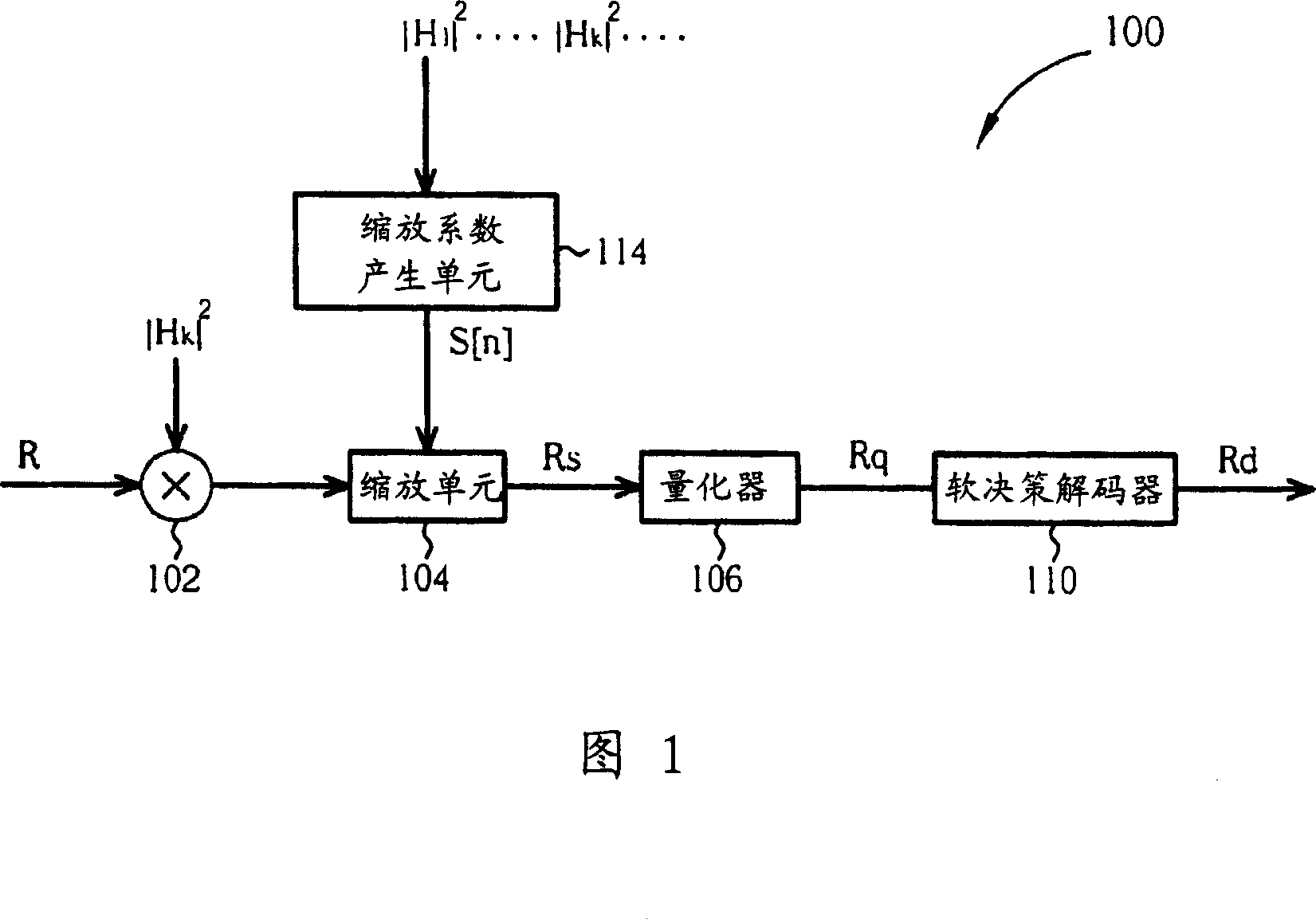

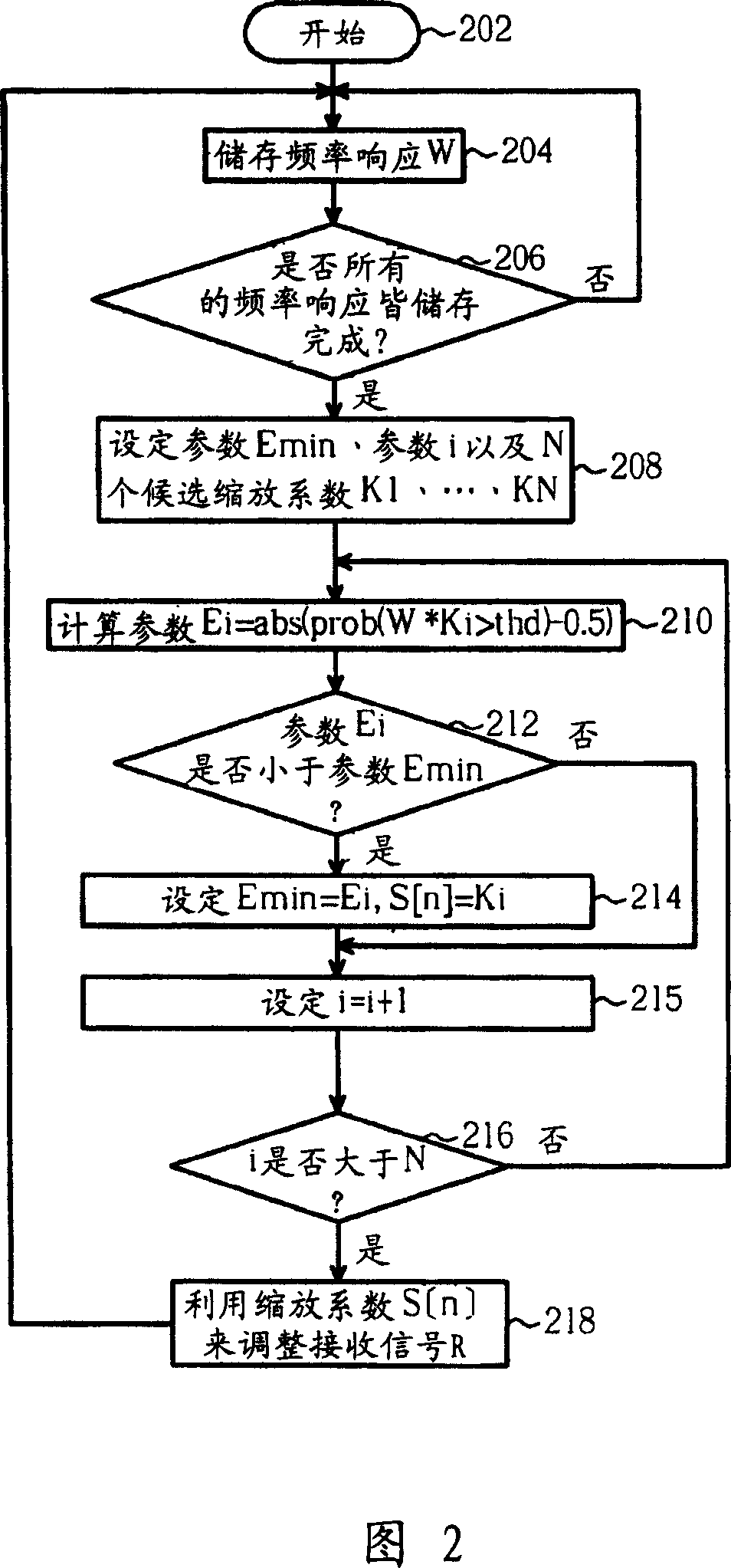

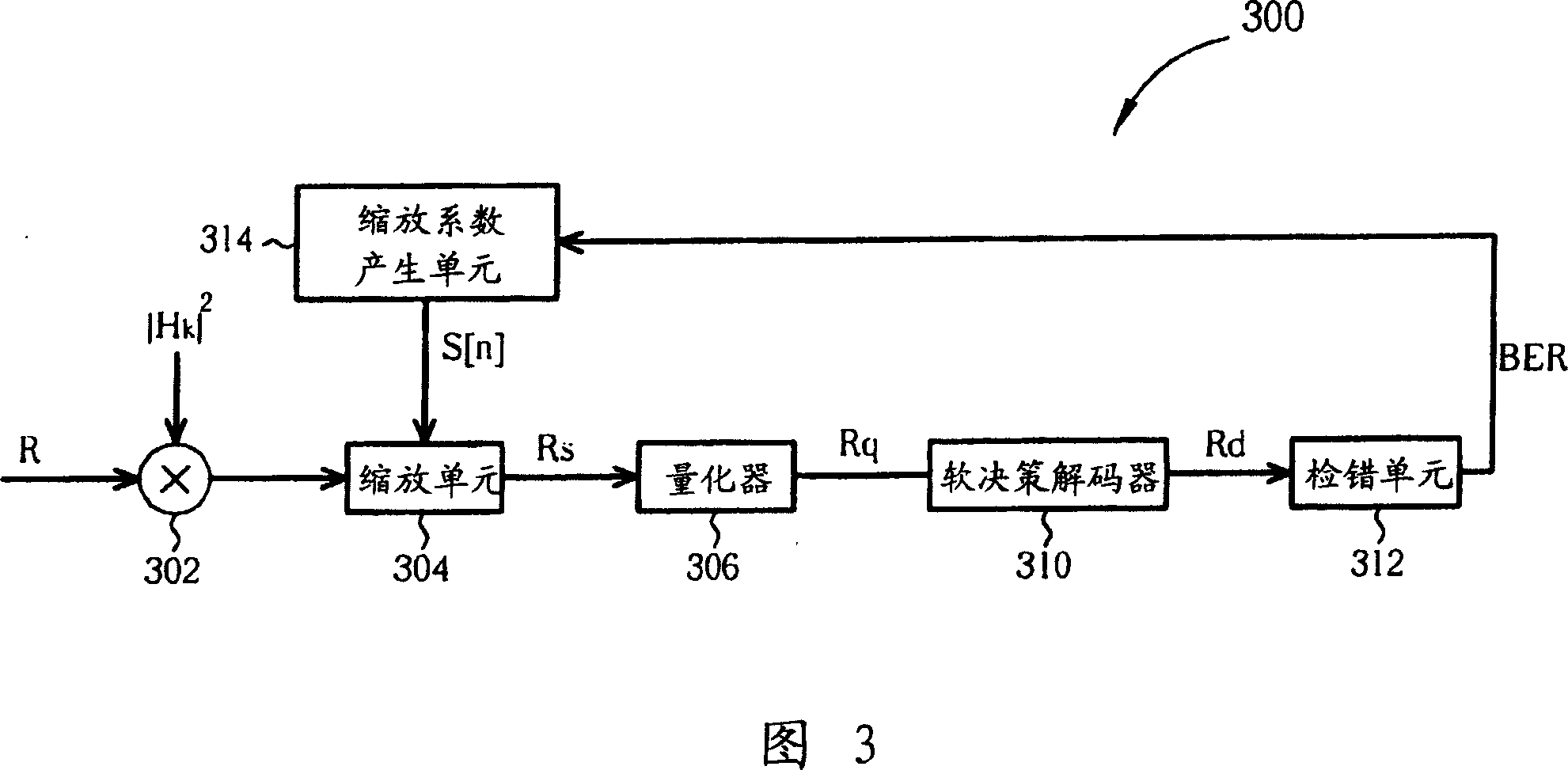

Decoder and relative method

InactiveCN101051843ATake full advantage ofScale the size of the signalCode conversionSystem informationSoft-decision decoder

The decoding unit includes following parts: using scaling coefficient, the scaling unit adjusts received signal in order to output scaled signal; being coupled to the scaling unit, the quantizer is in use for quantizing the scaled signal to generate quantized signal; being coupled to the quantizer, the soft decision decoder is in use for decoding the quantized signal to generate decoded signal; being coupled to the scaling unit, a scaling coefficient generation unit is in use for generating the scaling coefficient based on system information of the decoding unit.

Owner:REALTEK SEMICON CORP

Method and device for producing concentrated sulfuric acid by recycling waste acid from sulfate process titanium dioxide production

ActiveCN101538021BSolving production challenges of reuseIncrease productionSulfur-trioxide/sulfuric-acidSulfurSulfate

The recycling of diluted waste acid produced in the production process of sulfate process titanium dioxide is a bottleneck limiting the development of the sulfate process titanium dioxide. In addition, manufacturers of sulfate process titanium dioxide usually have sulfate acid production devices due to the need of a large amount sulfate acid. The invention relates to a method and a device for producing concentrated sulfuric acid by recycling waste acid from sulfate process titanium dioxide production. The method comprises the following steps: firstly, performing the pre-concentration of the diluted sulfate acid; secondly, removing most impurities carried by the diluted sulfate acid through settlement; and finally, using the sulfate acid subjected to pre-concentration and impurity removal to replace make up water of a sulfate production system, adding the sulfate acid into a sulfate circulating tank of a sulfate acid absorption tower to produce concentrated sulfate acid after sulfate acid absorption tower absorbs sulfur trioxides, and thus recycling the diluted sulfate acid. The method has the advantages of making a plurality of achievements at one time, namely changing pre-concentrated diluted sulfate acid into concentrated sulfate acid without extra energy consumption and equipment addition while reducing the cooling load of sulfate acid flowing out from the tower at the sametime.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

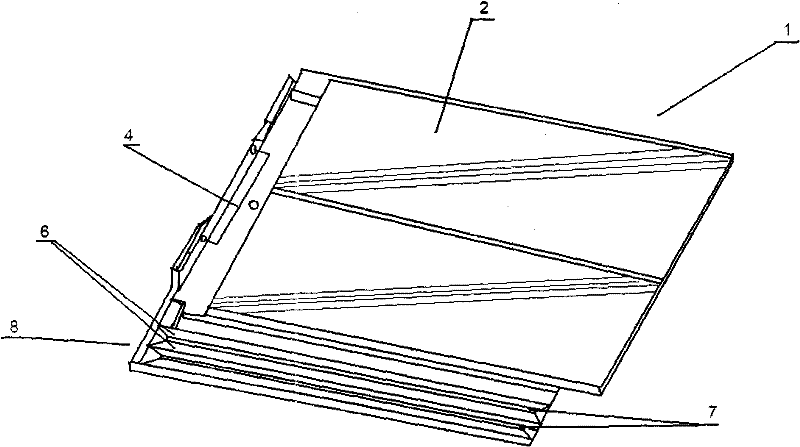

Solar tile system

InactiveCN102345349AWindproofTo prevent rainPhotovoltaic supportsRoof covering using slabs/sheetsStored energyEngineering

The invention discloses a solar tile system, and relates to a solar tile. The solar tile system comprises the solar tile, a line system and a solar tile fixing matrix which is used for fixing more than two solar tiles together, wherein an electric energy output end is arranged on the solar tile; an electric energy input interface which corresponds to the electric energy output end is arranged on the solar tile fixing matrix; a light emitting diode (LED) indicating lamp is arranged on the solar tile; and a power input end of the LED indicating lamp is connected with the electric energy output end of the solar tile. A method for detecting the accuracy of a connecting line of the solar tile comprises the following steps of: connecting an energy consumption element into the line system; connecting the electric energy output end of the solar tile into the electric energy input interface; observing whether the LED indicating lamp is darkened or not; if the LED indicating lamp is darkened, proving that the connection modes are correct; and if the LED indicating lamp is not changed, proving that the connection modes are incorrect, and adjusting the connection modes. In the system, the solar tile can achieve effects of wind prevention, rain prevention and heat insulation and can store energy and generate electricity by fully using solar energy; and the condition of a line can be known at the right moment, so that the function of the system is convenient to implement.

Owner:SHANGHAI SHIGEN ENVIRONMENTAL DESIGN ENG

Integrated crystal electric neon light and its making process

InactiveCN1731008AFree to changeSave resourcesElectric lightingLight effect designsEpoxyEffect light

The present invention relates to one kind of integrated electronic crystal neon light and its making process. The making process includes: 1. casting the casing for crystal neon light with epoxy resin in pattern mold of iron sheet; 2. casting front panel for crystal neon light with epoxy resin on the casing; 3. fixing the LED's as cold light source on the circuit board and leading out the power lines; and 4. casting back cover for crystal neon light with epoxy resin to seal the lighting case and to form the integrated electronic crystal neon light. The integrated electronic crystal neon light has simple making process, low power consumption, high durability, and other advantages.

Owner:潘玉林

Treatment system for effluent discharged by ship

InactiveCN105645689AEmission reductionAchieve sustainable useWater treatment parameter controlFatty/oily/floating substances removal devicesLiquid wasteEvaporation

The invention relates to a treatment system for ship effluent discharged by a ship. The treatment system is characterized by comprising an effluent collecting tank, a pretreatment tank, a sludge tank, an oil and water separator, a waste oil recovering barrel, a membrane bioreactor, an effluent monitoring device, an evaporation and concentration tank and a liquid storage tank. The effluent discharged by the ship is treated in a series of steps to obtain recyclable fresh water, sustainable utilization of resources is effectively achieved, the discharge amount of the effluent to a water body is reduced, and the degree of hazards to the environment by the effluent discharged by the ship is greatly relieved.

Owner:JIANGSU HANTONG SHIP HEAVY IND

Indoor positioning method integrating geomagnetic field and wifi signal

ActiveCN103630873BThe positioning result is accurateEasy to useNavigation by terrestrial meansPosition fixationHat matrixPositional Technique

The invention relates to the technical field of indoor positioning, in particular to an indoor positioning method combining geomagnetic field and WIFI (wireless fidelity) signals. According to the method, in an offline sampling stage, WIFI signal strength and geomagnetic field information samples are simultaneously collected and are uploaded to a positioning center database, data characteristic fusion and analysis are performed by adopting a principal component analysis method at a positioning center to generate a fusion projection matrix, and all sampling information in the database are projected by the projection matrix to obtain a fusion sample; in an online positioning stage, the vector of WIFI and geomagnetic field intensity information received by a terminal is projected by the fusion projection matrix to generate a fusion vector, and a positioning result is obtained by comparing the fusion vector with the fusion sample in the positioning center database. By adopting the method, accurate positioning combining WIFI and geomagnetic field intensity information can be realized on an existing ordinary smart phone.

Owner:XIAMEN YAXON NETWORKS CO LTD

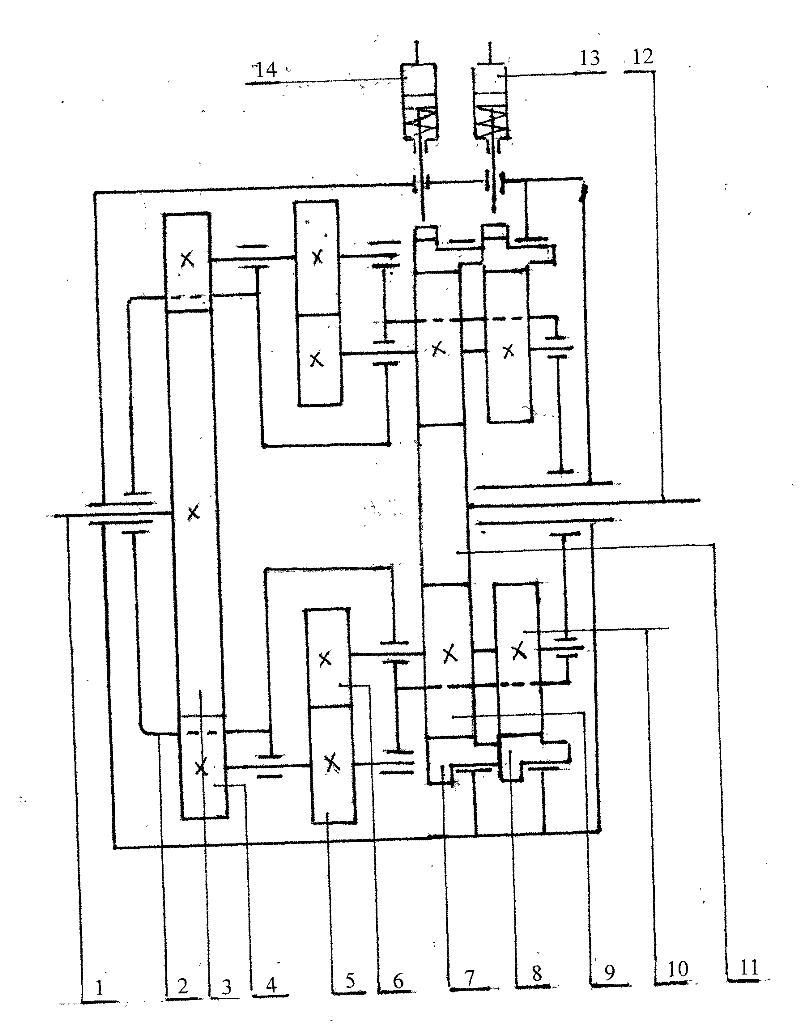

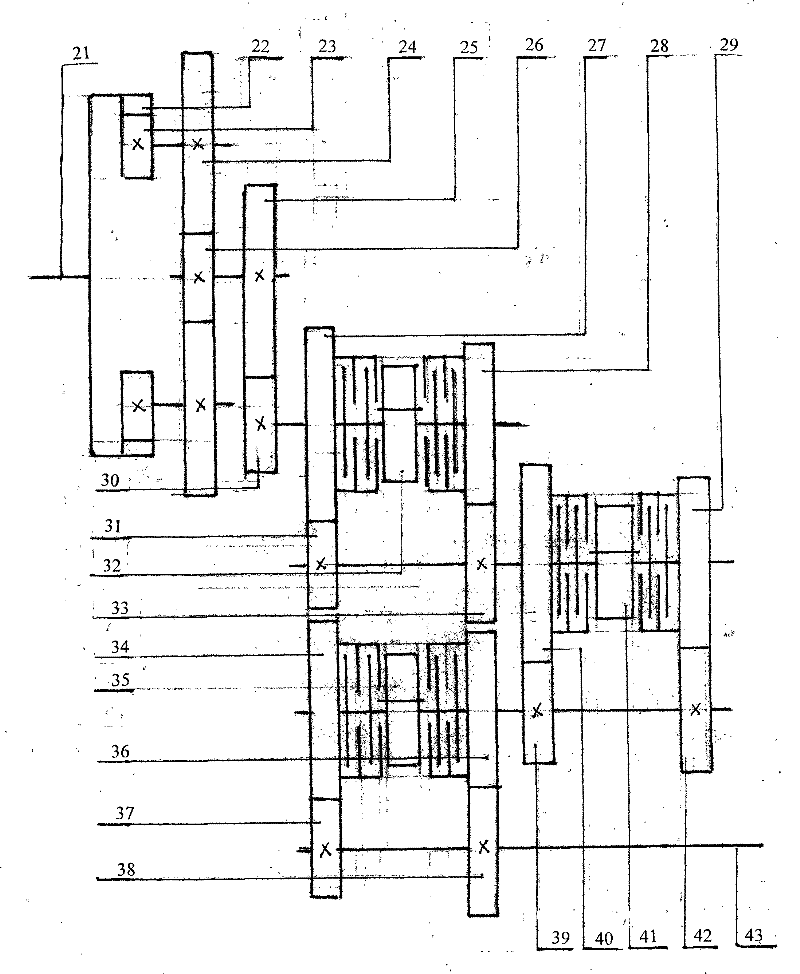

Wind power generation device non self-locking speed change and speed-increasing gearbox

InactiveCN101806280BReduce energy lossImprove efficiencyWind motor controlToothed gearingsAutomatic controlControl system

The invention discloses a wind power generation device speed-increasing gearbox, in particular to a wind power generation device non self-locking speed change and speed-increasing gearbox. The wind power generation device non self-locking speed change and speed-increasing gearbox comprises a speed change and speed-increasing gearbox and a control system thereof and is characterized in that the gear meshing of the speed change and speed-increasing gearbox is in non self-locking meshing, the speed change and speed-increasing gearbox adopts gearbox stepped speed changing and comprises a planetary gear speed change and speed-increasing gearbox and a dead-axle eight-grade speed change and speed-increasing gearbox, and the control system of the speed change and speed-increasing gearbox is a speed-change automatic control system. The wind power generation device has no self-locking speed change and speed-increasing gearbox, the speed-increasing gearbox speed increasing ratio is above 200 so as to widen the velocity space of a wind generating set. The speed-increasing gearbox adopts stepped speed change technology, reduces the energy loss of the power generation device, improves wind power generation device efficiency, saves investment, fully utilizes wind power resource and improves investment rate of return.

Owner:岑益南

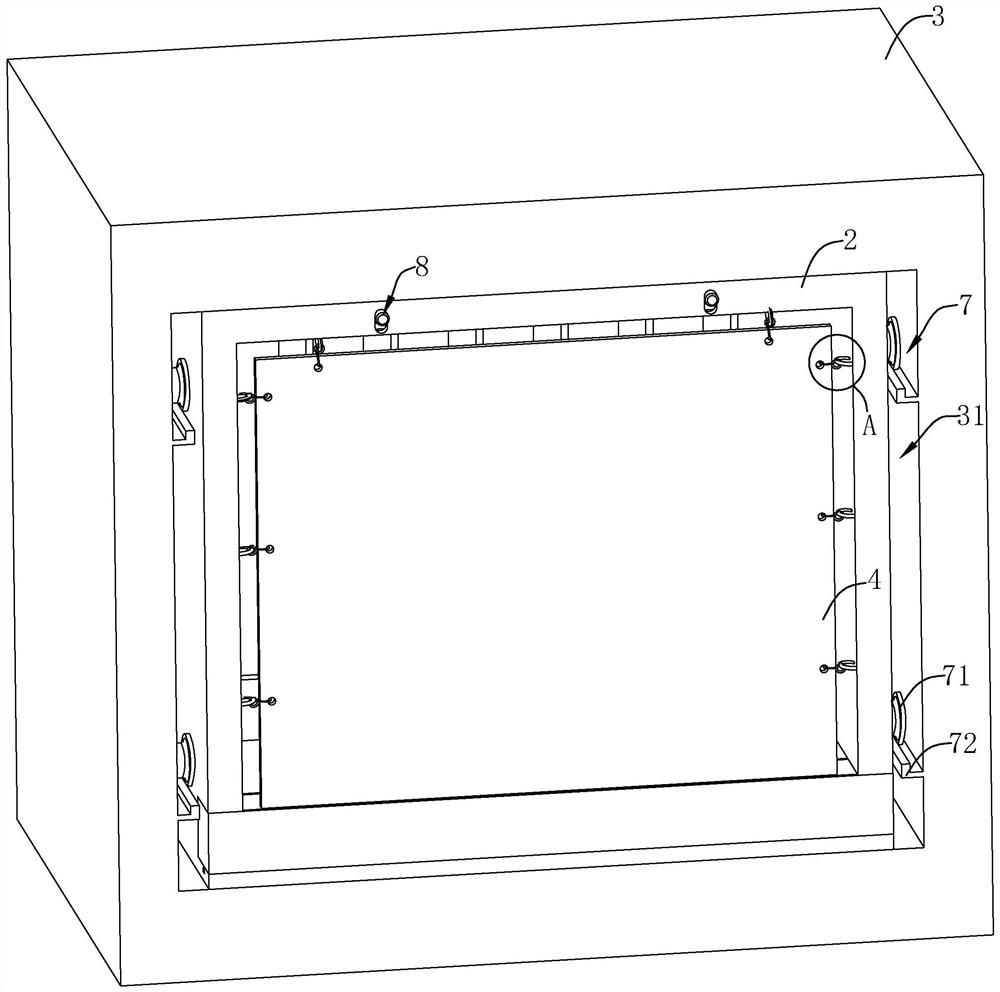

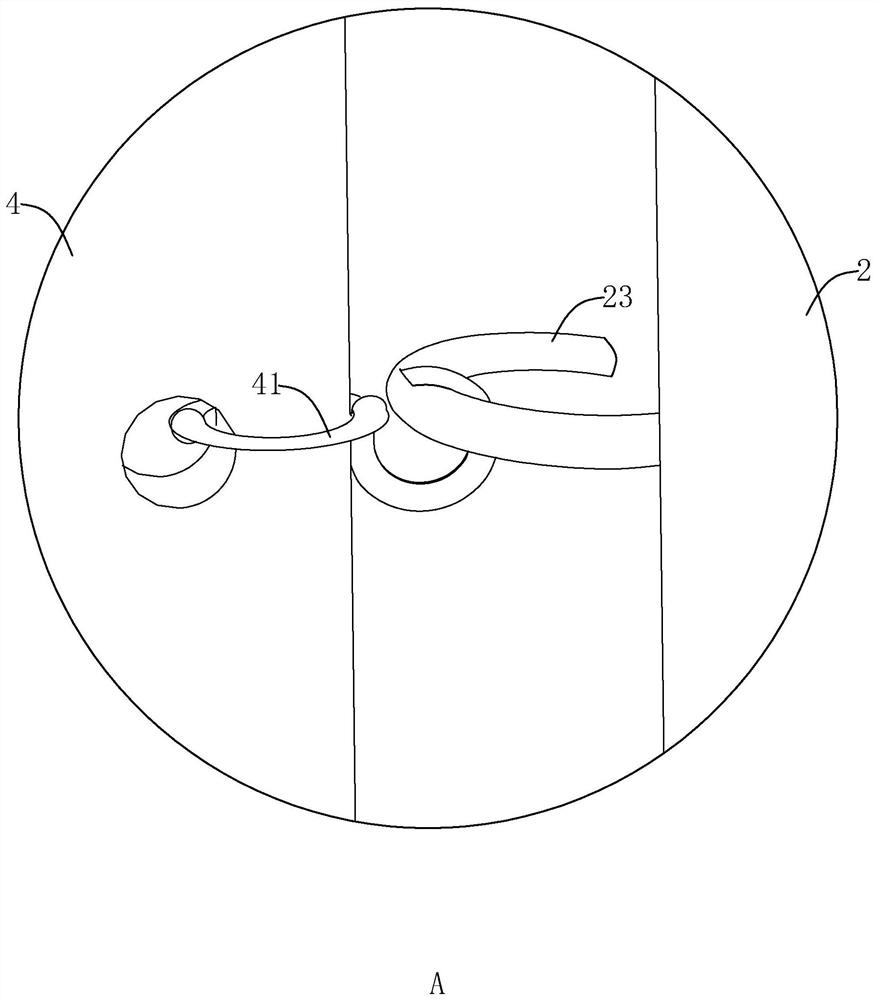

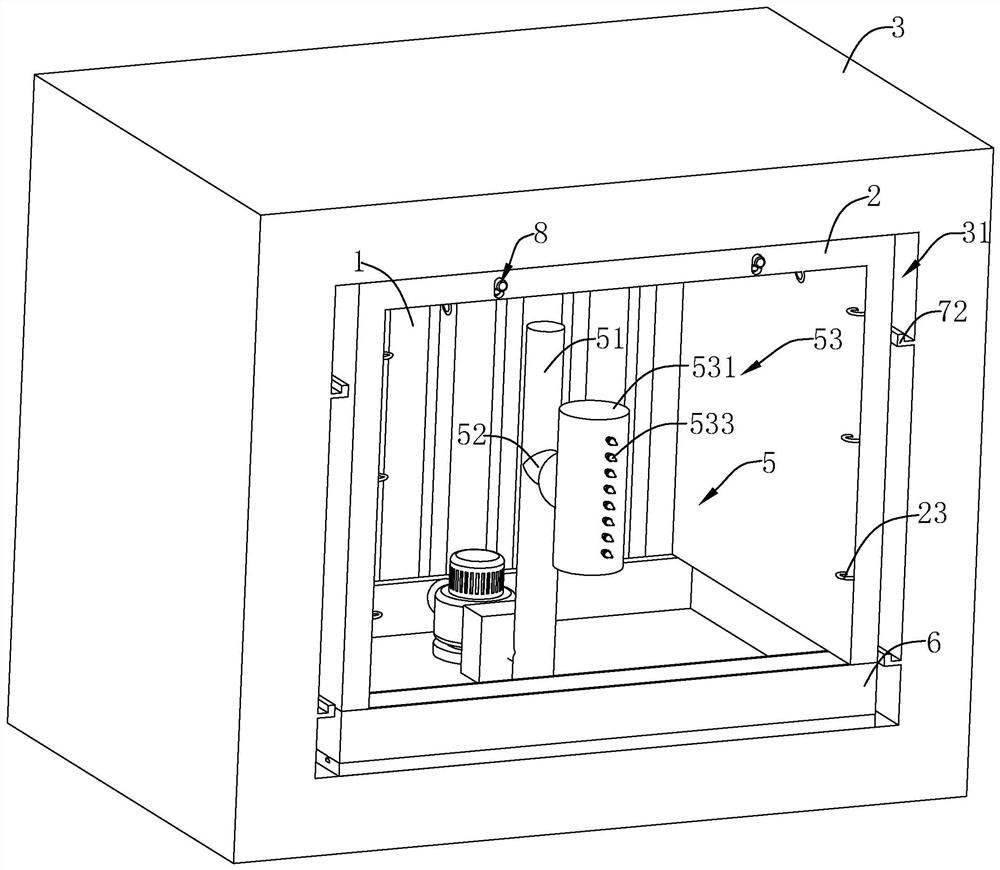

Tap water humidifier for radiator

ActiveCN109855168BAccurate maskingImprove aestheticsMechanical apparatusLighting and heating apparatusThermodynamicsTap water

The invention relates to the technical field of humidifiers, in particular to a tape water humidifier for a heating radiator. The tape water humidifier comprises a box body, water soaking cloth, a water spraying device and a water tank. Two opposite sides of the box body are provided with openings, and the box body is arranged on the outer side of the heat radiator in a covering mode. The water soaking cloth shields the opening of one side, far away from a wall body, of the box body and is flush with a wall surface. The water spraying device is arranged in the box body so as to spray tap waterto the water soaking cloth. The water tank is arranged on a bottom plate of the box body and is located under the water soaking cloth. The water soaking cloth is arranged to change color when meetingwater. A guide assembly for guiding the box body to be accurately arranged on the outer side of the heating radiator in a covering mode is arranged between the box body and a groove wall of a containing groove. The tap water humidifier has the advantages that the tap water humidifier is suitable for reconstruction of old residential communities, tap water can be used as a water source, magnesiumion powder and calcium ion powder in water can be prevented from diffusing into a room along with water vapor, and the safety performance in the using process is improved.

Owner:吕峰

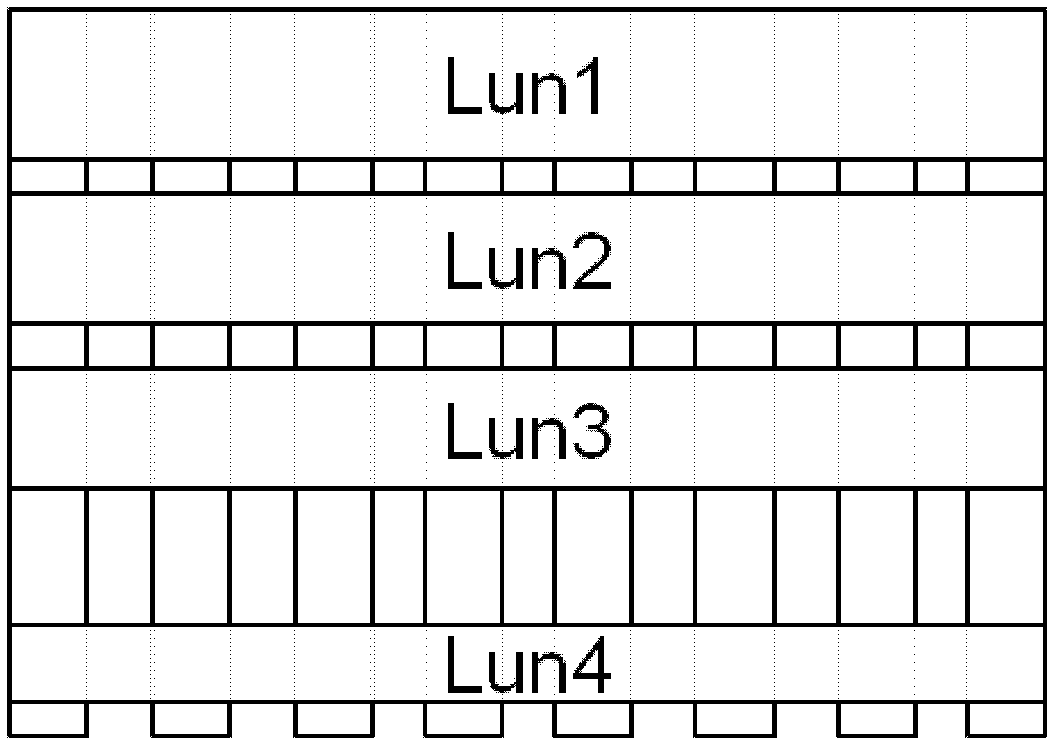

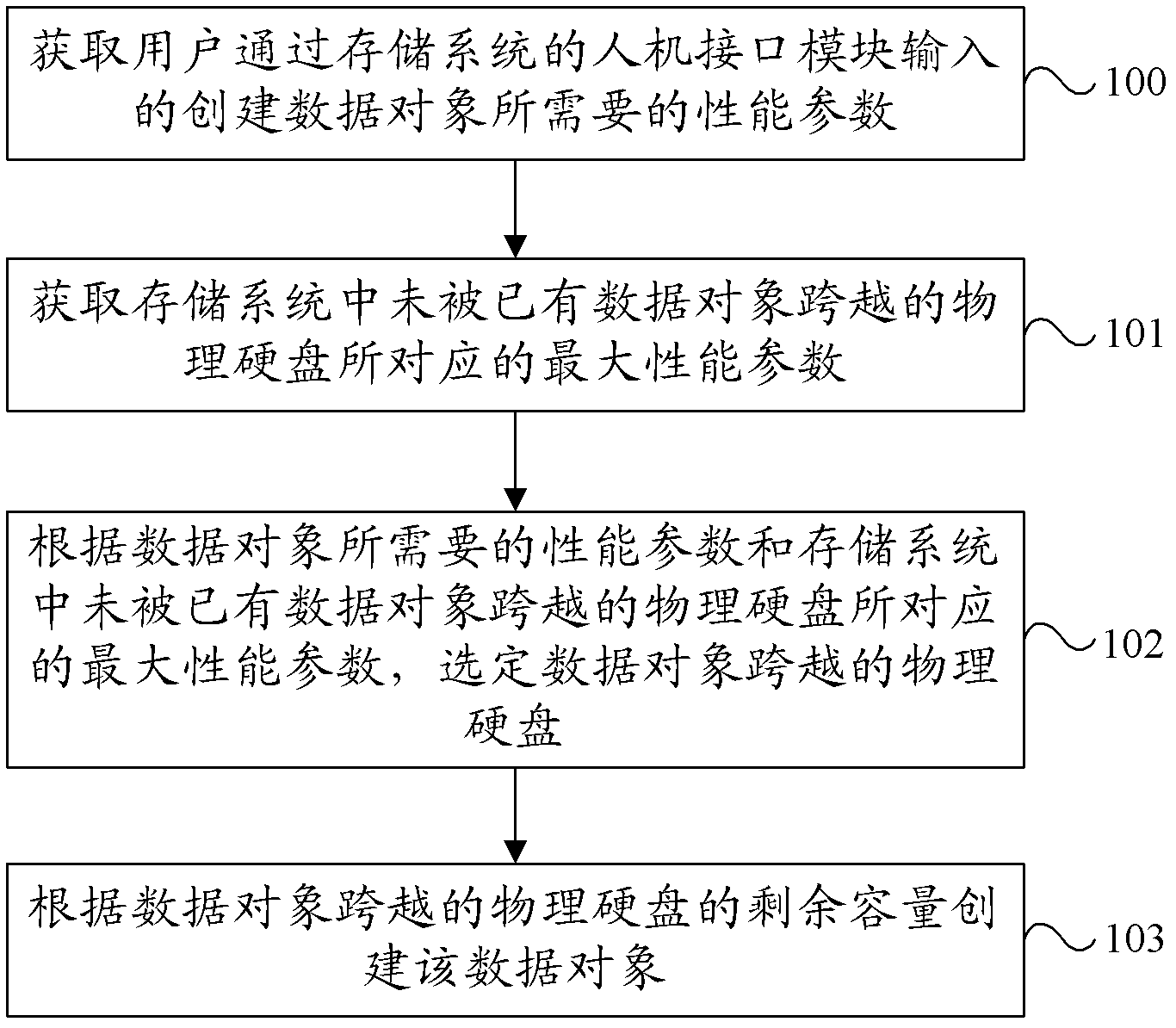

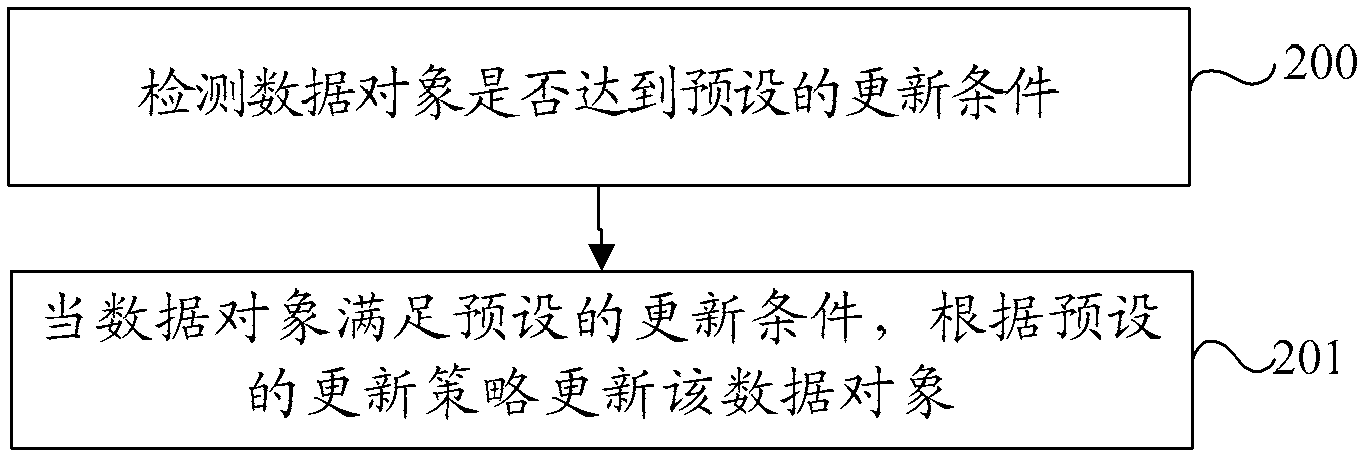

Data object processing method and device

ActiveCN102541470BDefects where changes are distributed in the same wayTake full advantage ofInput/output to record carriersMan machineOperating system

The embodiment of the invention provides a data object processing method and a device. The method comprises the following steps: obtaining the performance parameters which is input through a man-machine interface module of a memory system by a user and is needed by the creation of a data object; obtaining the maximum performance parameter corresponding to a physical hard disk which is not spanned by a preexisting data object in the memory system; selecting a physical hard disk spanned by the data object according to the performance parameters needed by the data object and the maximum performance parameter corresponding to the physical hard disk which is not spanned by the preexisting data object in the memory system; creating a data object according to the spare capacity of the physical hard disk spanned by the data object; and taking the data object as Lun and address areas, files or catalogs of the Lun, corresponding to a user access request. Due to the adoption of the technical scheme of the embodiment of the invention, the physical hard disk resources in the memory system can be utilized sufficiently in a maximum manner.

Owner:CHENGDU HUAWEI TECH

Simple submarine room

InactiveCN101624832ALow costTake full advantage ofArtificial islandsUnderwater structuresSubmarineHuman being

The invention relates to a simple submarine room used for the rest and recreation of human beings. In the invention, a watertight container is made from a waterproof, firm and durable material, a submarine fixer is arranged on the bottom of the container, an outlet position is arranged above the container, a door is arranged at the outlet position, a plurality of vent holes are arranged above the container, the outlet position or the door can be slightly inclined according to the requirement so as to be convenient for draining away rainwater, a waterproof device is arranged outside the vent holes, vent openings can be added in the room if being required, the number of the outlet positions is at least one, the vent openings can be arranged in a large amount or can be not arranged, and stairways are arranged at a doorway position for people to go up and down. The volume, the shape and the size of the room are determined according to the requirement.

Owner:孙图清

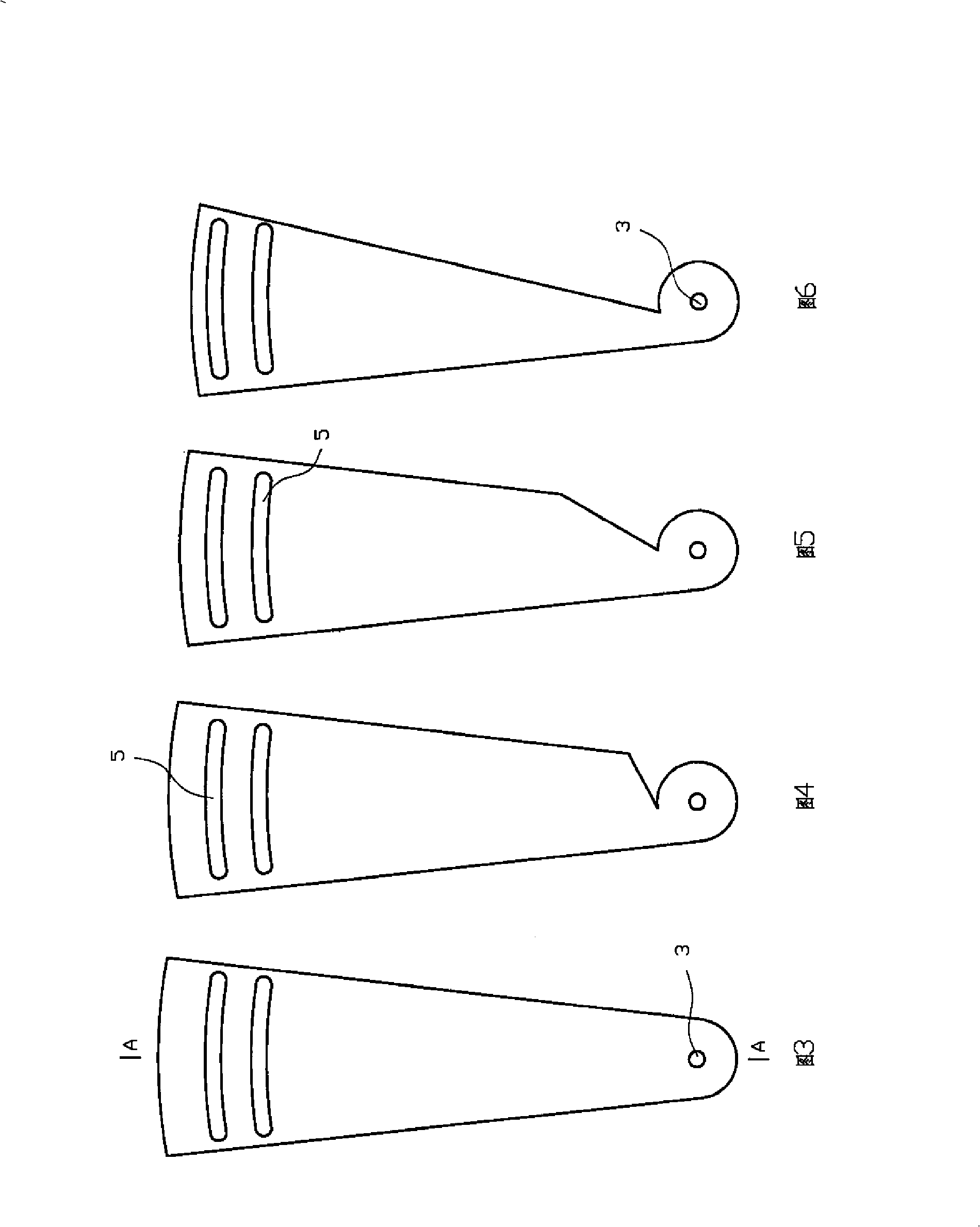

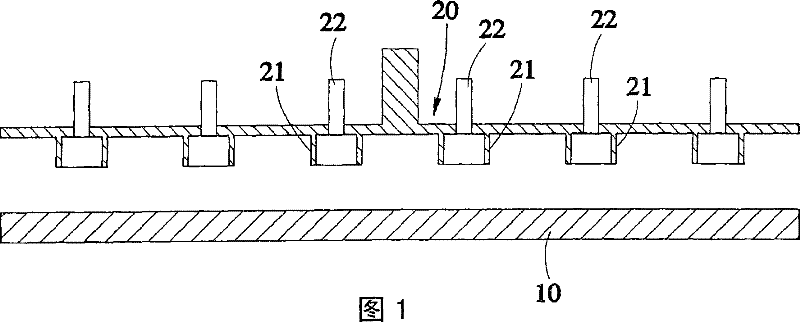

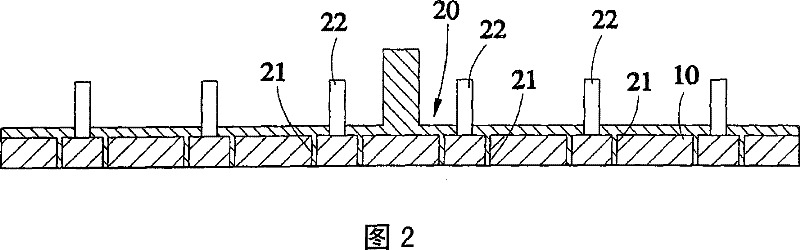

Manufacturing method for permeable granular laminated material

ActiveCN101274505BTake full advantage ofLamination ancillary operationsLaminationBiomedical engineeringGranular material

The invention relates to a production method of a breathable, graininess and expanded laminating material, and the steps of the method are that: an elastic gasket body is prepared and a cutting die is used for trimming. The cutting die is provided with a plurality of cutters which prearrange trimming shapes and the interior of each cutter is provided with a liftout attachment. When in cutting, the cutter can be dropped on a part one of the elastic gasket body in the cutter and then the part one is dragged out so as to cause the elastic gasket body to be divided into an elastic sheet provided with holes with prearranged shapes and a part two of an elastic granular material in each cutter, and then one side of the elastic sheet is laminated with a fabric layer, meanwhile, the cutting die ismoved to another fabric layer to push out the elastic granular material so as to ensure that the elastic granular material can be bonded on the fabric layer, and the other side of the elastic sheet is laminated with a fabric layer while one side of the elastic granular material is laminated with a fabric layer, thus forming the laminating material which is provided with the elastic sheet with holes and the elastic granular material provided with a clearance.

Owner:中良工业股份有限公司

Traditional Chinese medicine composition for treating ulcerative colitis

InactiveCN105267344AStrong targeted curative effectSimple recipeDigestive systemPlant ingredientsUlcerative colitisCodonopsis pilosula

The invention belongs to the technical field of medicine, and particularly relates to a traditional Chinese medicine composition for treating ulcerative colitis. The traditional Chinese medicine composition is prepared from coptis chinensis, mangnolia officinalis, nutmeg, codonopsis pilosula, garden burnet, radix notoginseng, radix paeoniae rubra and semen plantaginis. According to the traditional Chinese medicine composition, syndrome differentiation dosing is carried out, the traditional Chinese medicine composition is simple in component, exact in curative effect and easy to prepare, the medicinal materials are combined and have the remarkable curative effects of clearing heat, removing dampness, promoting qi circulation to relieve pains, achieving astringing and promoting tissue regeneration, the traditional Chinese medicine composition is effective medicine of nursing ulcerative colitis, and the clinical popularizing significance is remarkable.

Owner:QINGDAO MERRITT MEDICAL TECH CO LTD

Manufacturing method of mixture-lubricated rolling bearing and rolling bearing

ActiveCN102588445BImprove operational reliabilityIncreased operating lifeBearing componentsBase-materialsFluid film lubricationChain scission

The invention provides a manufacturing method of a rolling bearing which takes mixture of polyethylene oil and solid lubricating material as lubricant and the rolling bearing. The manufacturing method comprises the steps of injecting the lubricant which comprises mixture of polyethylene oil and solid lubricating material micropowder into cavity of the bearing and stamping a dust cap, thus a high temperature resistant sealed bearing is obtained. When the bearing operates at the temperature of being lower than oxidation chain scission temperature of the polyethylene oil, fluid film lubrication is formed; and when the bearing operates at the temperature of being higher than the oxidation chain scission temperature of the polyethylene oil, the polyethylene oil volatilizes, and the fluid film lubrication is changed into solid film lubrication. Compared with the prior art, the invention has the advantages that the problems that perfluoropolyether high temperature lubrication oil has high price and carbon is deposited at high temperature are solved, the problem that solid lubricant is required to be adopted from the start is solved, the bearing can actively realize conversion from fluid lubrication to solid lubrication according to running temperature, respective maximum advantages of the fluid lubrication and the solid lubrication are fully played, operational reliability of the bearing is improved and life of the bearing is prolonged, and the bearing is applicable to various high temperature environments.

Owner:SHANGHAI F&S BEARING TECH

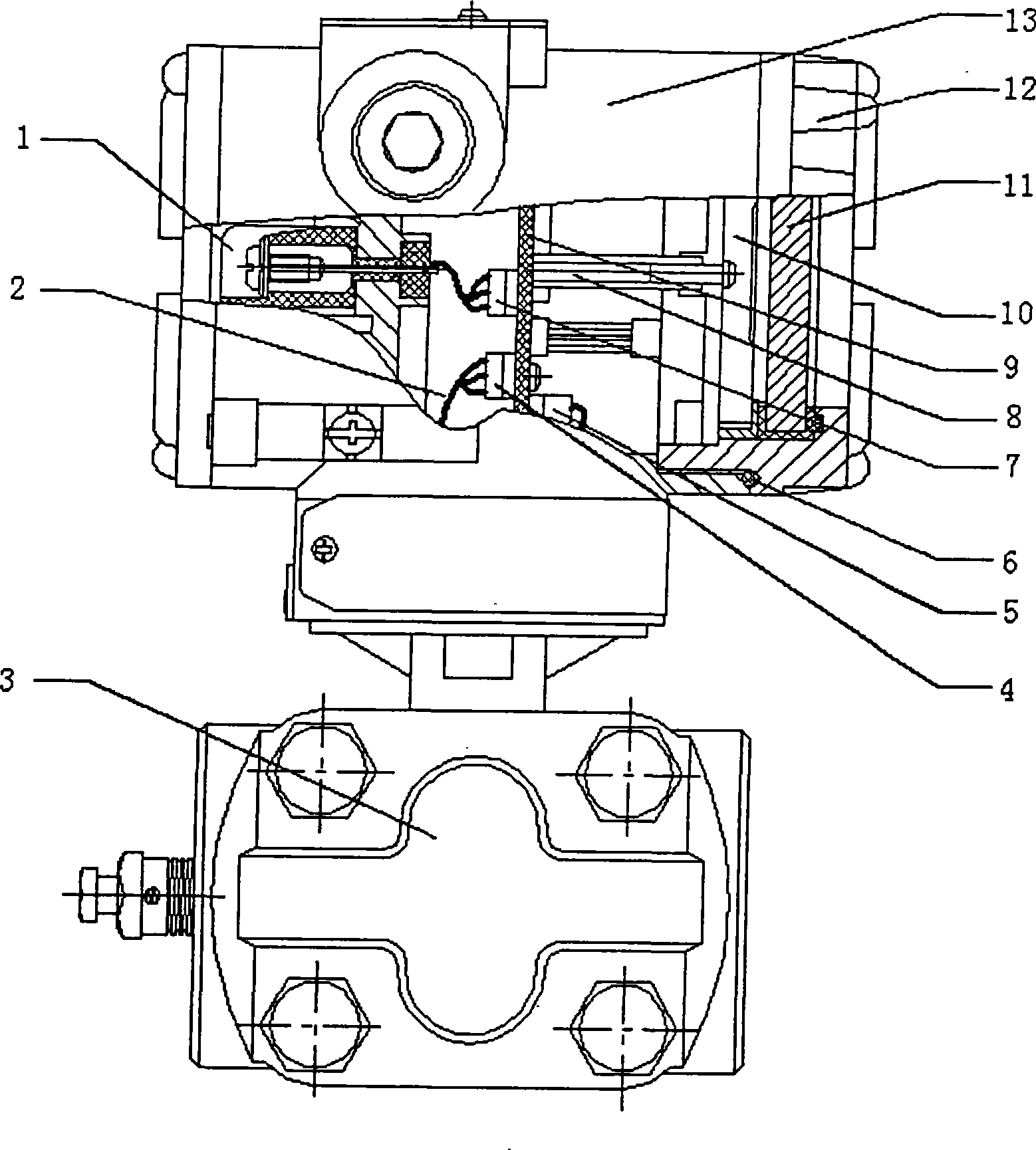

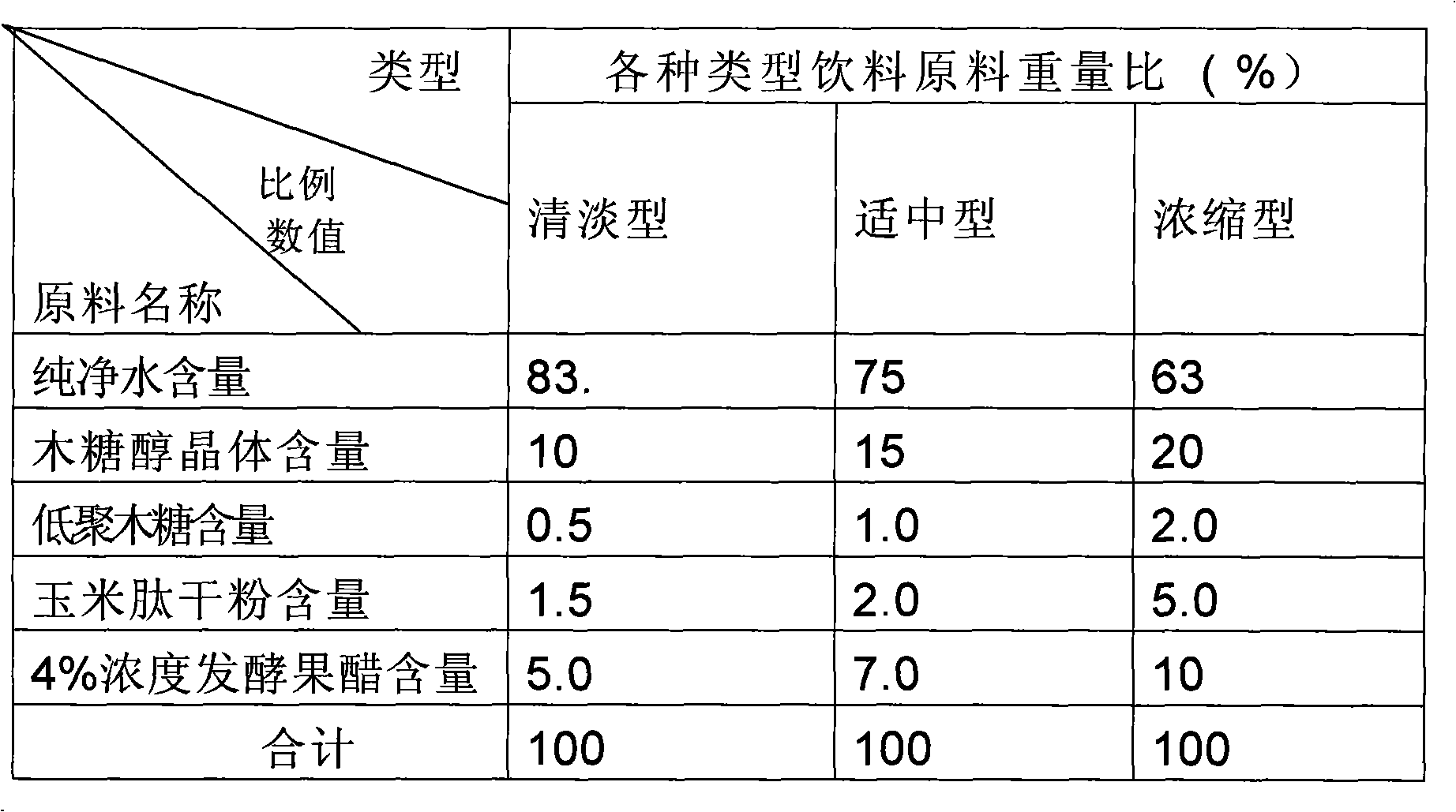

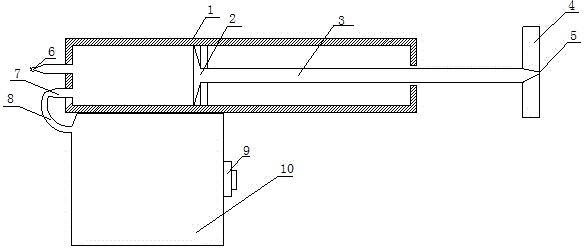

A disposable paint spray gun

The invention provides a disposable paint spray gun comprising a barrel body (1), a piston (2) located in the barrel body (1) and a push rod (3) connected to the piston (2). The tail end of the push rod (3) is provided with a push rod handle (4); a suction hole (5) is formed between the push rod (3) and the push rod handle (4). The bottom of the barrel body (1) is provided with a sprayer (6) and a connector (7). The connector (7) is connected with a paint box (10) via a hose (8). The paint box (10) is provided with a paint adding opening (9). The disposable paint spray gun is simple in structure and low in cost; paint clearing is not needed during use and a new spray gun is used directly, so that the problem that the color mixing caused by incomplete cleaning influences the whole process is solved; the disposable paint spray gun is simple and convenient, and can be operated.

Owner:CHONGQING FEIKAI INFORMATION TECH CO LTD

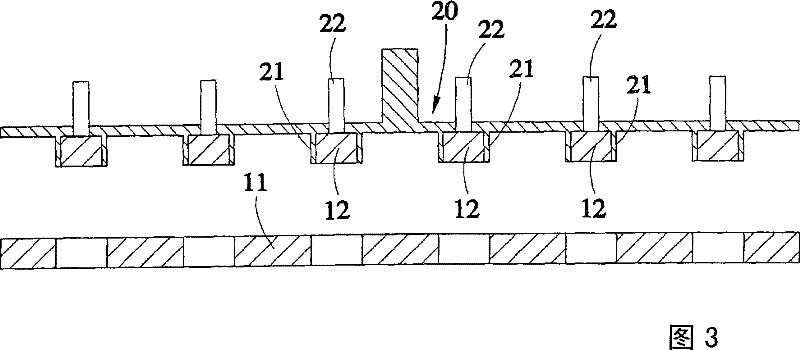

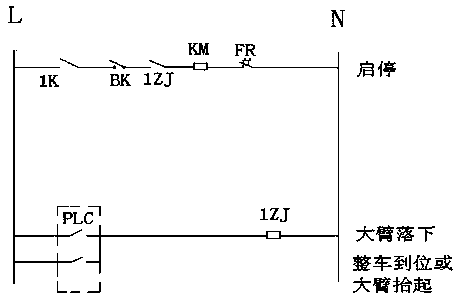

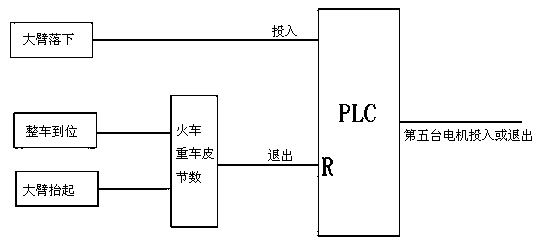

Car dumper re-adjusting machine frequency converter capacity maximum utilization method

InactiveCN108628246ARealize automatic controlSolve Vibration ProblemsProgramme control in sequence/logic controllersFrequency changerLoop control

The invention discloses a car dumper re-adjusting machine frequency converter capacity maximum utilization method. When the output train heavy wagon of the car dumper re-adjusting machine exceeds a specified number of sections, the electric control loop of a standby motor is used for controlling the standby motor to be put into or out to increase the energy of the frequency converter, the electriccontrol loop of the standby motor comprises a PLC, an air switch 1K, a frequency converter switch BK, a relay 1 ZJ, a contactor KM and a thermocouple FR, one end of the air switch 1K is connected with the live wire L, and the other end of the air switch 1K is serially connected with the frequency converter switch BK, the normally-opened end of the relay 1 ZJ, the contactor KM and the thermocoupleFR and then is connected with the null line and the start-stop button of the standby motor at the same time, one end of the PLC is connected with the live wire, and the other end of the PLC is connected with the relay 1 ZJ in series and then is connected with the null line and the signal control end of the car dumper re-adjusting machine, and a contactor KM normally-open switch is arranged in thePLC. According to the invention, the problem that in the prior art, when the capacity of the frequency converter is exceeded at present, and the tripping occurs in the operation is solved.

Owner:SHANXI DATANG INT YUNCHENG POWER GENERATION

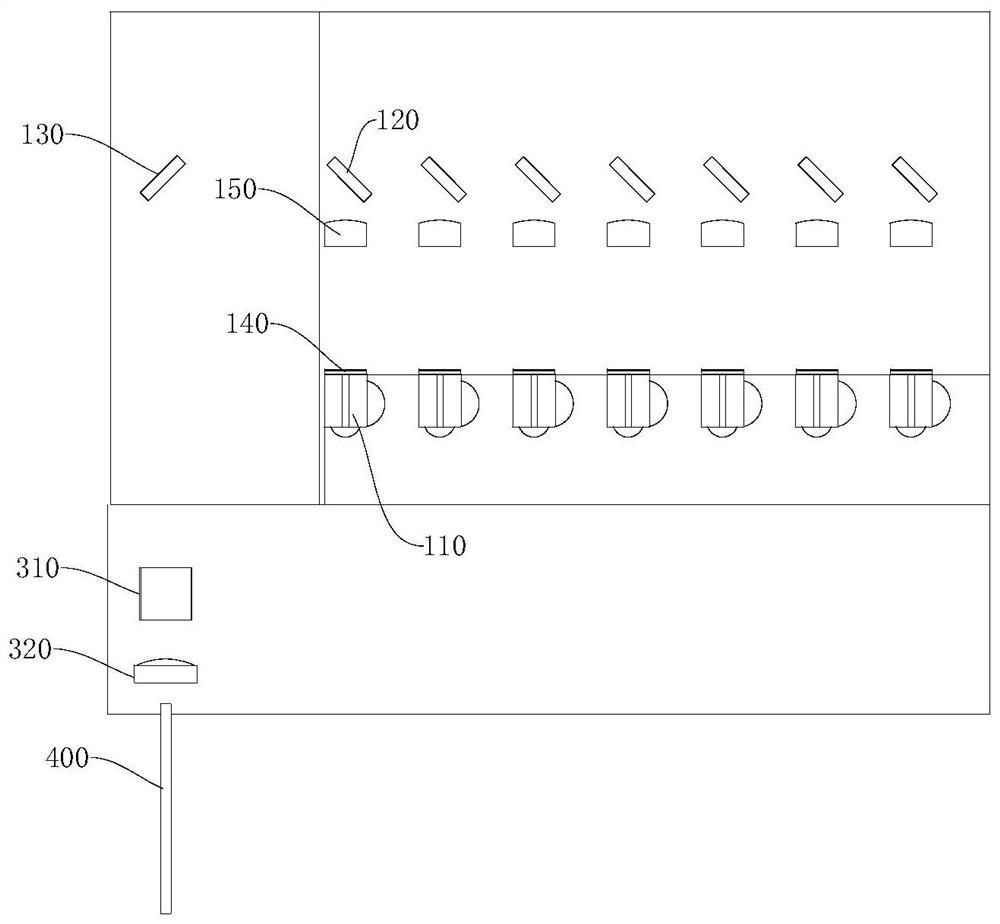

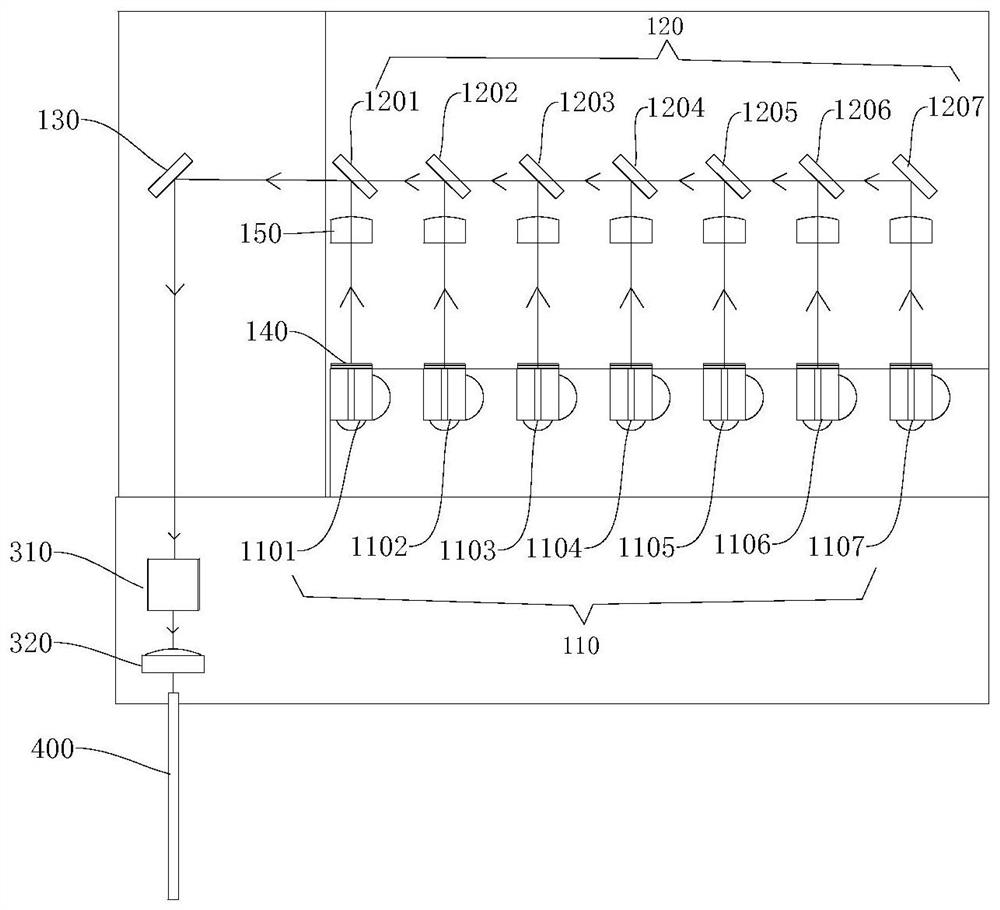

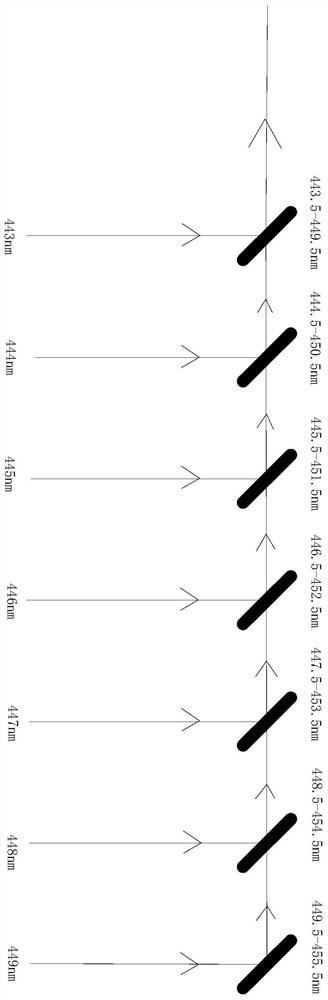

Optical fiber coupling semiconductor laser

PendingCN113794108ACommon accessTo achieve the purpose of coupling multi-wavelength laserSemiconductor laser arrangementsLaser arrangementsErbium lasersLaser beams

The embodiment of the invention belongs to the technical field of semiconductor lasers, and relates to an optical fiber coupling semiconductor laser. The optical fiber coupling semiconductor laser comprises a laser module, a focusing system and an optical fiber, the laser module comprises a light-emitting unit group and a first optical element group, the light-emitting unit group comprises N light-emitting units emitting laser beams with different wavelengths, and the N light-emitting units in the same group are located on the same plane; the first optical element group comprises N first optical elements capable of reflecting the laser with the specific wavelength, the first optical elements and the light emitting units are arranged in a one-to-one correspondence mode, the N first optical elements are arranged in the reflection direction of the laser beams, and the first optical elements can transmit the laser beams reflected by the first optical elements in the same group; and the focusing system and the optical fiber are sequentially arranged on an emergent light path of the multi-wavelength laser. According to the technical scheme provided by the invention, N laser beams with different wavelengths can enter the optical fiber together, so that high-power density output is realized.

Owner:HANS LASER TECH IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com