Integrated crystal electric neon light and its making process

A production process and technology of neon lights, applied in electric light sources, decorative arts, lighting devices, etc., can solve the problems of insufficient light source performance, reduced service life, blurred logos, etc., to achieve full light source performance, durable damage, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

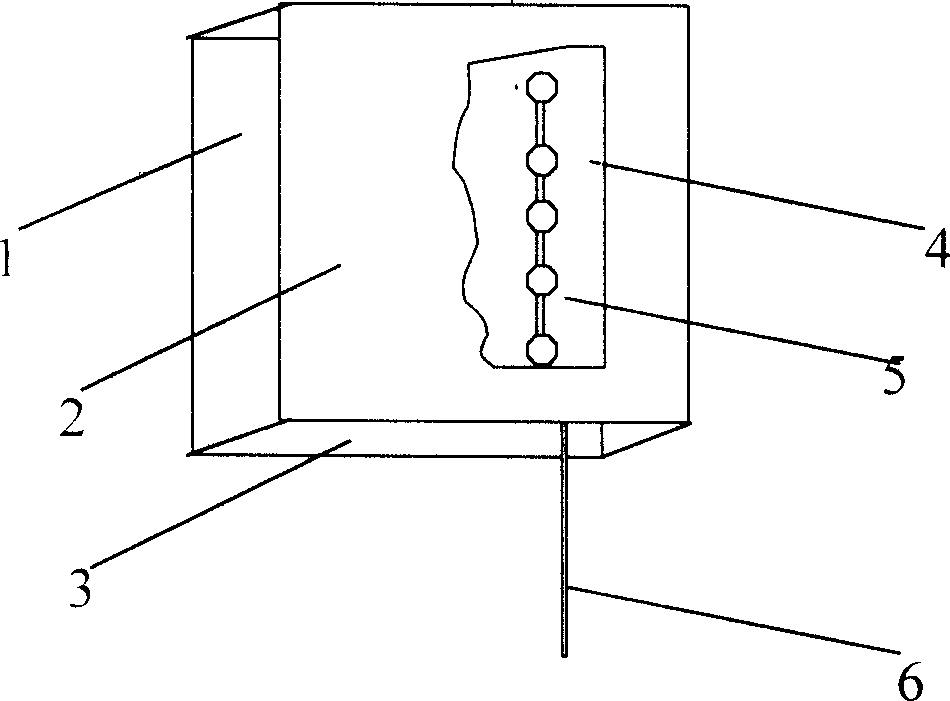

[0011] The manufacturing process of the present invention is as follows: (1) use a thin iron sheet to make a word or a frame of various pattern shapes as a mould, pour the prepared epoxy resin to form the frame shell of the crystal neon lamp, and set it up for the convenient installation of the neon lamp Embedded parts, such as nuts for fixing, etc.; (2) On the frame of the crystal neon lamp that has been made, epoxy resin is used to pour out the front panel of the neon lamp, so that the frame and the front panel form a complete seamless light box; ( 3) Connect and fix the LED, that is, the cold light source light strip, on the wiring board made of transparent material, then place the wiring board with the LED fixed in the crystal neon light box made above and fix it, and lead out the power cord (4) Pouring out the back cover on the crystal neon light box with epoxy resin, and sealing the whole light box to form an integrated crystal electronic neon light.

[0012] The accompa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com