Anti-skid pad and method for producing the same

A production method and technology for anti-skid pads, which are applied to carpets and other directions, can solve the problem that anti-skid pads are difficult to accurately print and color solid patterns, and achieve the effects of bright colors, good product quality and high process efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0024] see Figure 6 Flowchart of the production method.

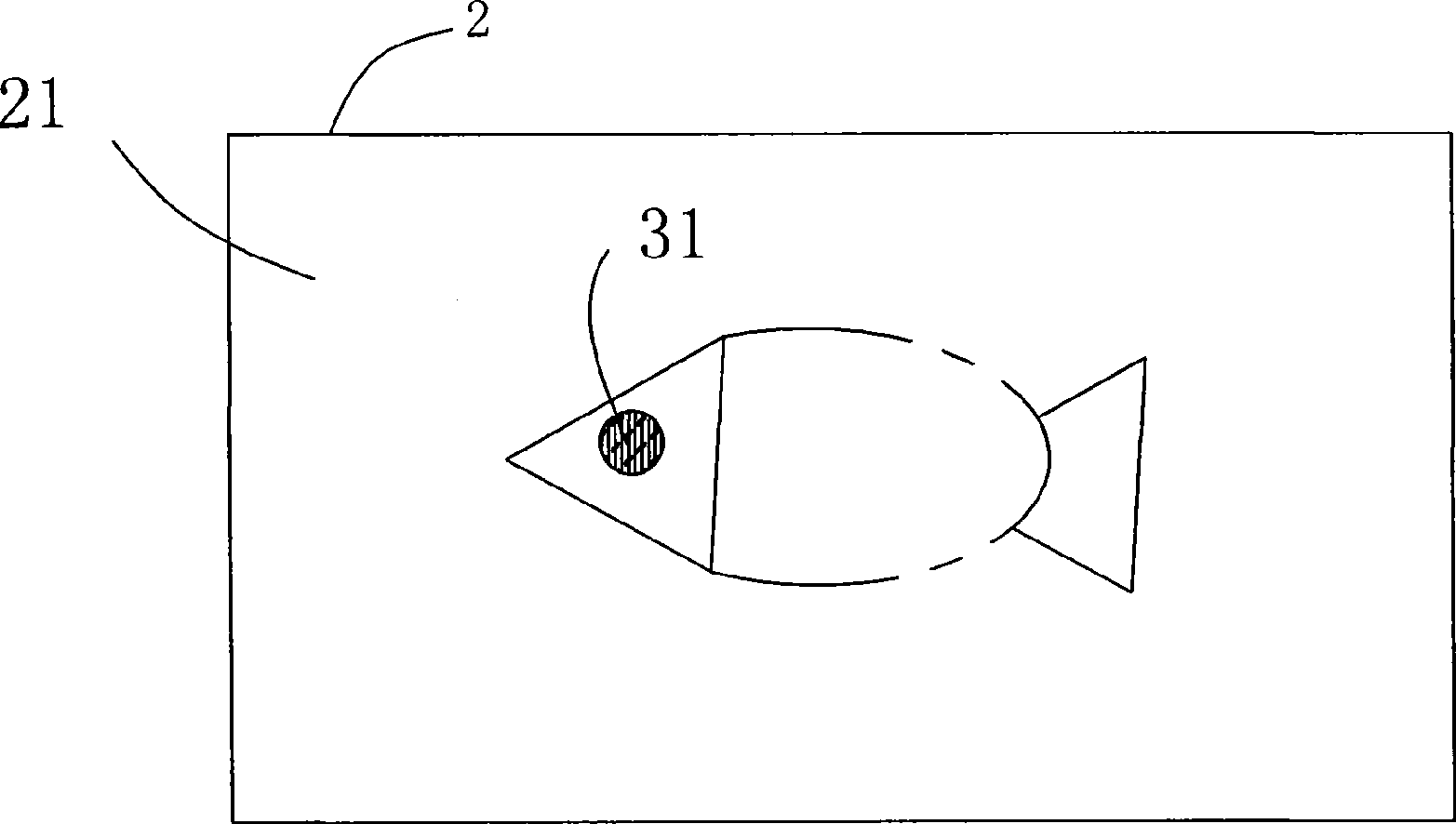

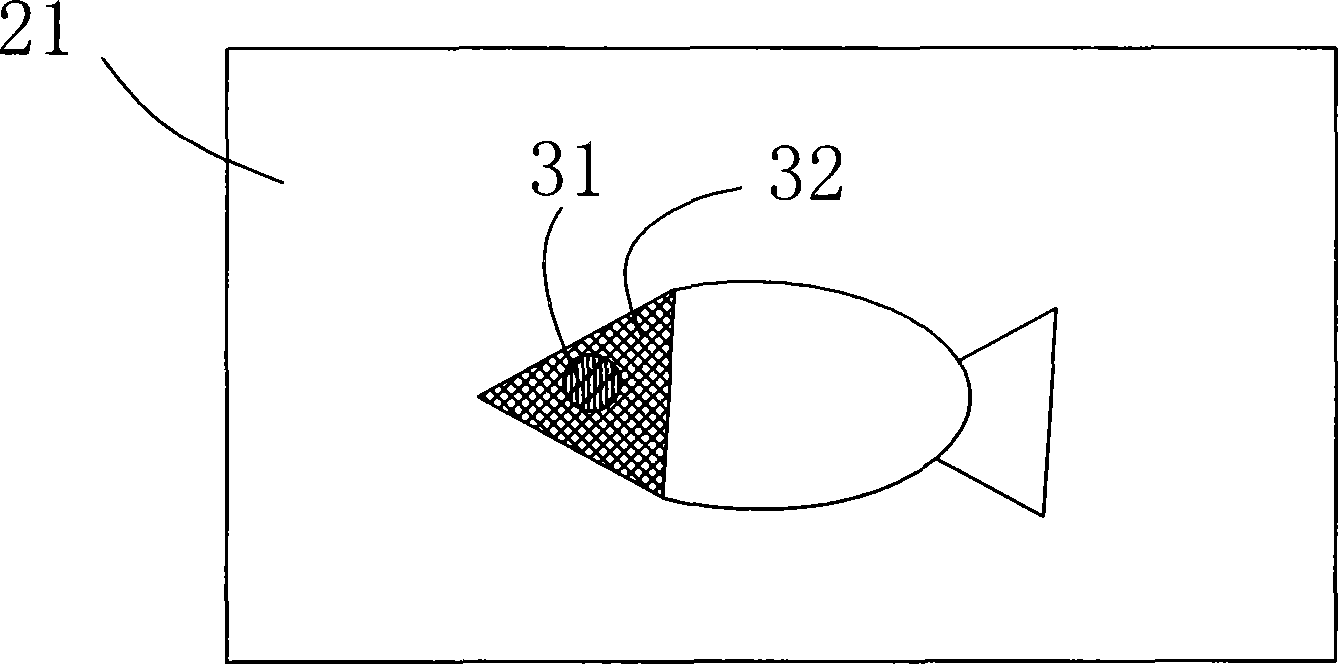

[0025] a. Print patterns on a transparent film made of plastic materials, and cure the printed patterns; the specific curing process can be through heating and curing, or drying the printed patterns naturally, in order to avoid the ink from sticking Infiltration and deformation during the process to ensure the accuracy and delicacy of the printed pattern;

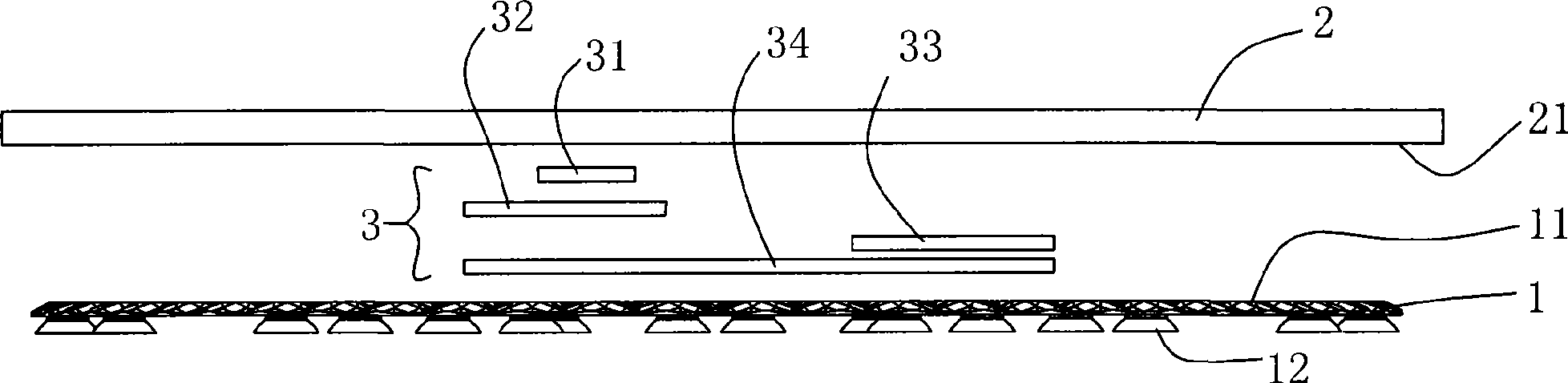

[0026] b. the film 2 is placed between the upper and lower molds of the injection mold for making the anti-slip mat body, so that the side 21 of the film printed with patterns is facin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com