Wind power generation device non self-locking speed change and speed-increasing gearbox

A technology of wind power generation device and gearbox, which is applied to wind turbine components, wind turbines, wind turbine control and other directions, can solve problems such as unsatisfactory growth rate ratio, increase in cost, and reduction in wind energy utilization coefficient, so as to improve the return on investment. speed, widening the speed space, reducing the effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

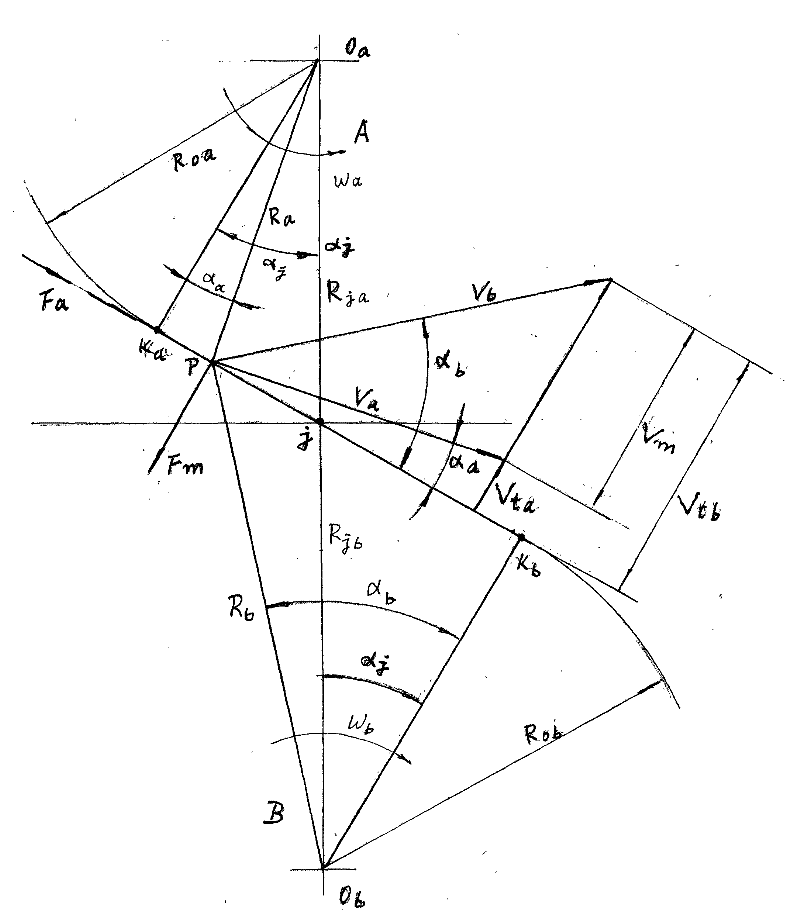

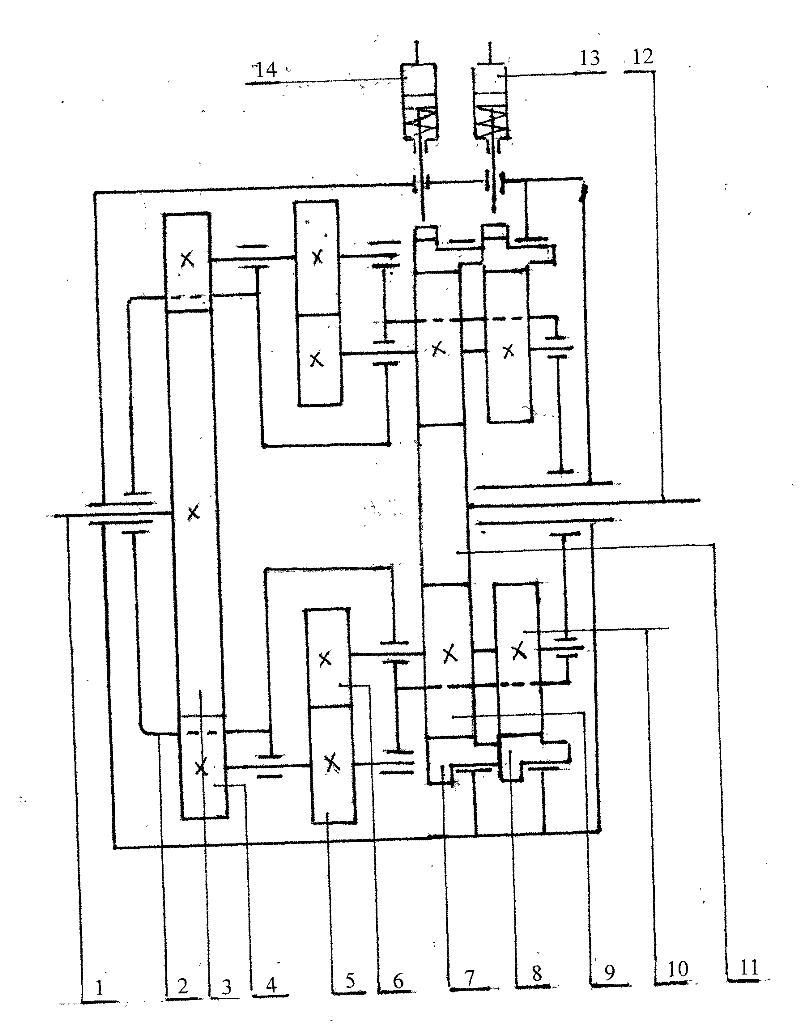

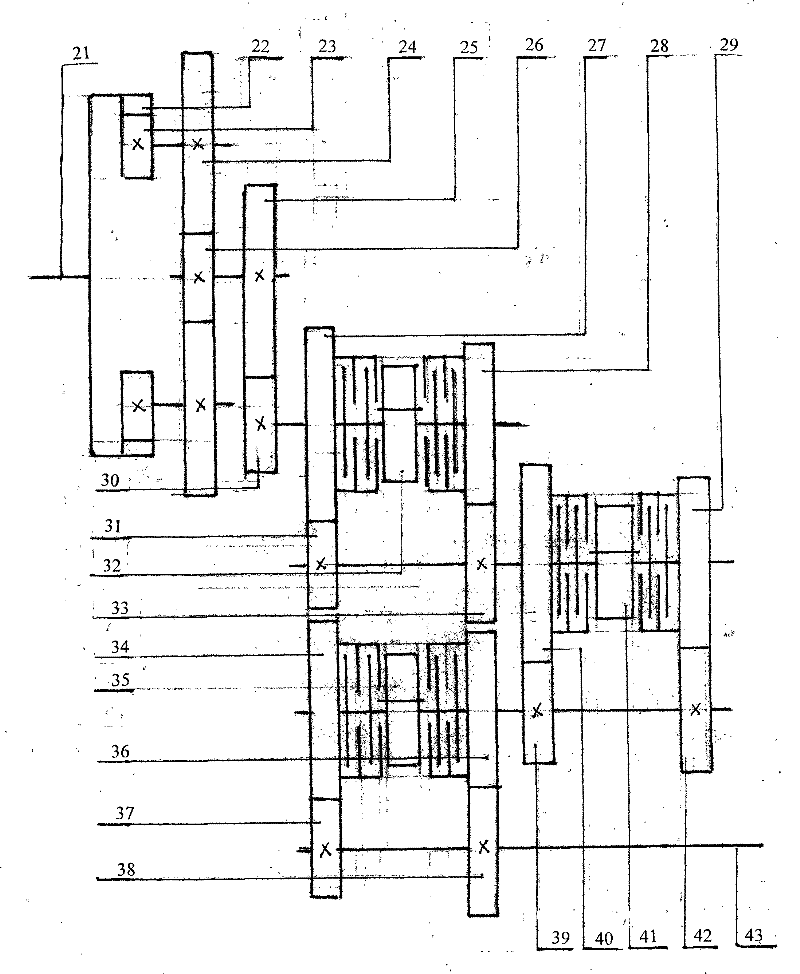

[0034] Accompanying drawing is a kind of specific embodiment of the present invention. The wind power generation device has no self-locking variable-speed speed-up gearbox, including the variable-speed speed-up gearbox and its control system. The radius of the addendum circle of gear B is less than or equal to the pitch circle radius R of the driven gear jb , the variable-speed speed-up gearbox adopts the step-by-step speed change of the gear box. Automatic control system, the common ratio of the graded speed of the variable speed speed-up gearbox Φ is a geometric progression, and the number of stages E is 1, 2, 4, 8 or 16; the planetary gear speed-up speed gearbox is composed of planetary gear X5 and planetary gear Y6 Reverse structure, by transforming the support wheel inner gears 7 and 8 to achieve speed change, the fixed-axis eight-stage variable-speed speed-up gearbox is matched with an induction generator with a slip rate of 10%, realizing full speed regulation, fixed-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com