Method for expanding open-bore perlite by gas indirect heating

An open-pore perlite, gas-fired technology, applied in the field of expansion furnaces, can solve the problems of high efficiency and short expansion stroke of beads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

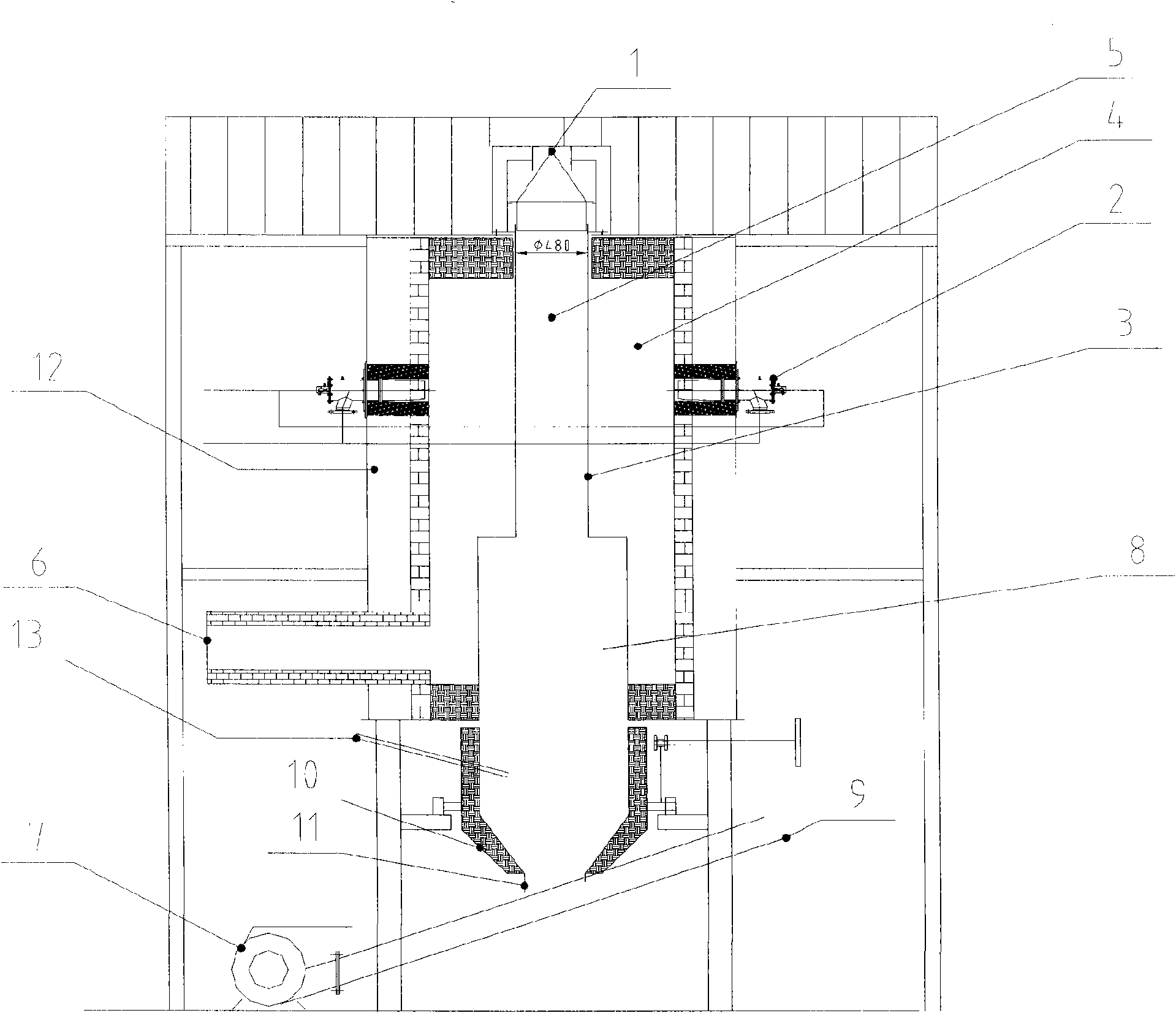

[0034] Such as figure 1Shown in: a kind of gas type indirect heating open-pore perlite expansion method is to use gas indirect heating to heat open-pore perlite, especially suitable for expanding products with open-pore perlite powder below 100-250 mesh, when working, Firstly, the gas-fired indirect heating method is used to manufacture an indirect heating expansion furnace with a large top and a small bottom. The ambient temperature in the high temperature zone 5 of the expanded perlite in the body 4 reaches a high temperature of 1000-1150; conical cylinder.

[0035] Secondly: 1. Utilize the high-temperature flue gas of the combustion chamber 4 on the furnace to heat the air entering the gas burner, that is, exchange heat with the normal-temperature gas delivered by the fan through the heat exchanger at the high-temperature flue 6 outlet of the expansion furnace, and burn the incoming gas. The air in nozzle 2 is heated to over 200 degrees to solve the 2,600 cubic meters of ...

Embodiment approach 2

[0050] Such as figure 1 Shown in: a method of gas-fired indirect heating open-pore perlite expansion, it can also expand the perlite with large particles of 18-40 mesh, the expansion cylinder 3 can also be a conical shape with a small top and a large bottom Cylinder; the method of working is the same as that of the above-mentioned open-pore perlite expansion. When expanding the large-grained perlite, the separation method of the beads adopts an open type, and the switching valve at the blower end is closed, so that the large-grained perlite is separated by the blower through the air separator on the upper part of the discharge channel 9, and the materials of different sizes enter the grading closed-loop separation system. The silo is deposited, and some large-grained perlite is discharged through the end of the silo and collected by the pulse bag filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com