Manufacturing method for permeable granular laminated material

A technology for bonding materials and manufacturing methods, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve problems such as incapable of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0018] An actual manufacturing example is given below to illustrate:

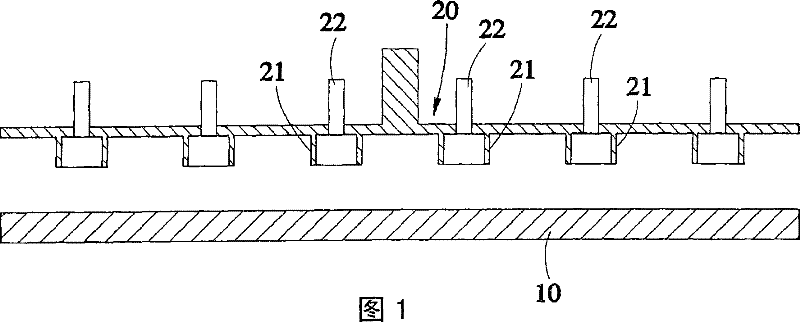

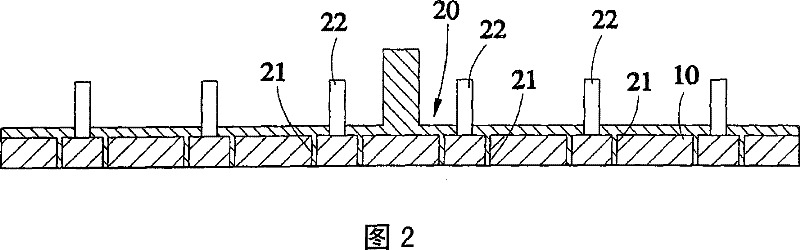

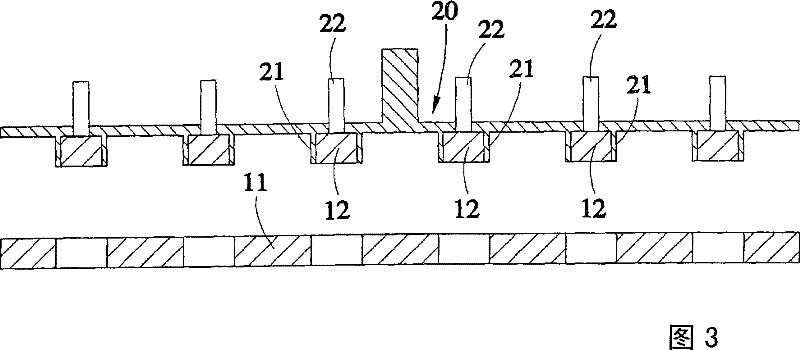

[0019] First prepare a PU foamed elastic pad with a thickness of about 5 mm. Cut the elastic cushion body with a knife die, which is provided with a plurality of circular cutters arranged in a matrix, and each cutter is provided with an ejector device. When the elastic cushion body is cut, the knife The cutting knife of the mold will take out the part of the elastic pad falling in the cutting knife, so that the elastic pad is divided into a 5mm thick elastic sheet with a circular hole and a 5mm thick elastic sheet falling in each cutting knife. Two parts of round elastic pellets.

[0020] Afterwards, hot-melt glue on one side of the elastic sheet, and attach a fabric layer A with a thickness of 1mm, and at the same time, move the knife die to another fabric layer B with a thickness of 1mm that has been hot-melt glued, and then press The ejecting device pushes out the circular elastic granular materials in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com