Manufacturing method of mixture-lubricated rolling bearing and rolling bearing

A technology for rolling bearings and manufacturing methods, applied to bearing components, shafts and bearings, lubricating compositions, etc., can solve the problems of troublesome bearing inner cavity, high cost of lubricant, and limitation of the maximum operating speed of bearings, etc., and achieve high price and wide coverage Application prospect, effect of improving operation reliability and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

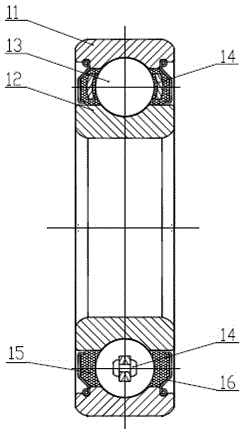

[0035] In this embodiment, polyether oil is selected from polyglycol ether (PAG), and solid lubricating materials are selected from graphite and molybdenum disulfide to make double-sided dust cover sealed deep groove ball bearings, such as figure 1 As shown, the bearing manufacturing process and method are as follows:

[0036] (1) Pour solid lubricating material graphite, molybdenum disulfide micropowder and other fillers and additives into polyglycol ether (PAG), stir and mix evenly to make paste mixture 15 as the lubricant for the bearing;

[0037] (2) The outer ring 11, the inner ring 12 and the rolling elements 13 are all made of bearing steel, and are quenched and tempered according to the operating temperature range of the bearing, and are subjected to chemical heat treatment after machining and forming by grinding and super-precision. In this example In the process, the manganese series phosphating treatment is carried out;

[0038] (3) The retainer 14 is made of medium carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com