Optical fiber coupling semiconductor laser

A fiber-coupled, semiconductor technology, applied in the field of fiber-coupled semiconductor lasers, can solve problems such as low power density and single wavelength, and achieve the effect of increasing optical power density and achieving high-brightness output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

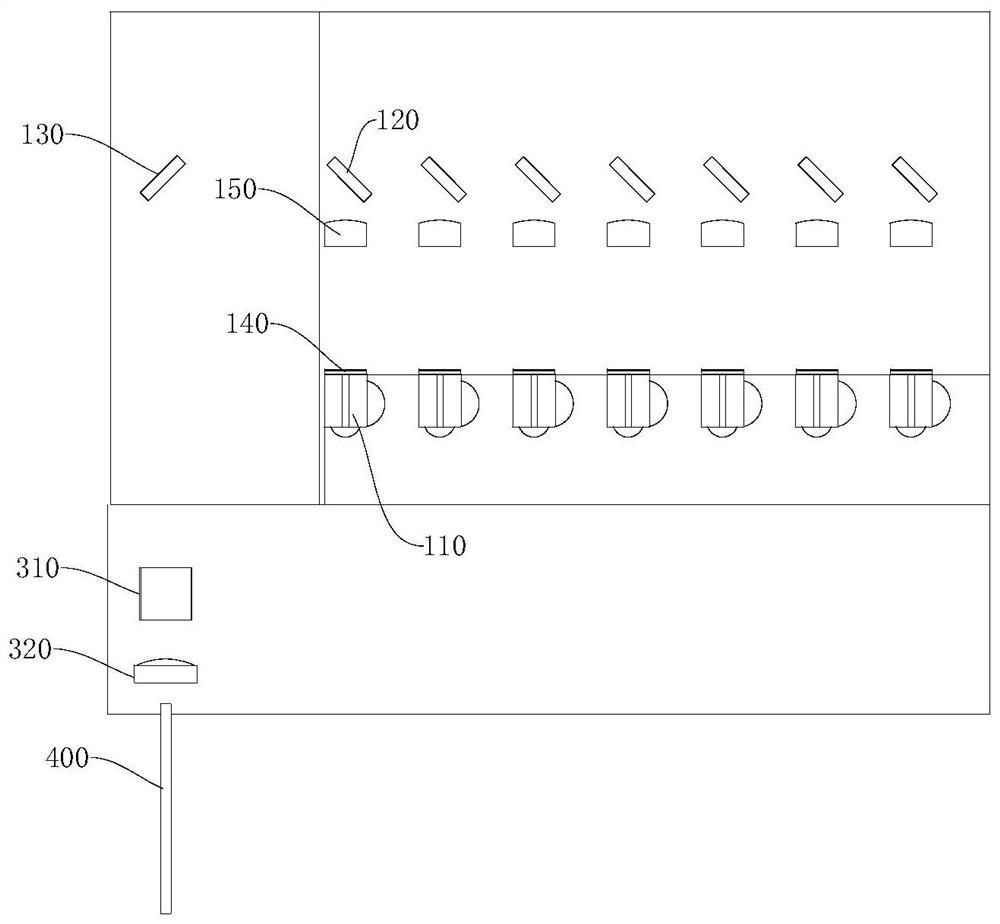

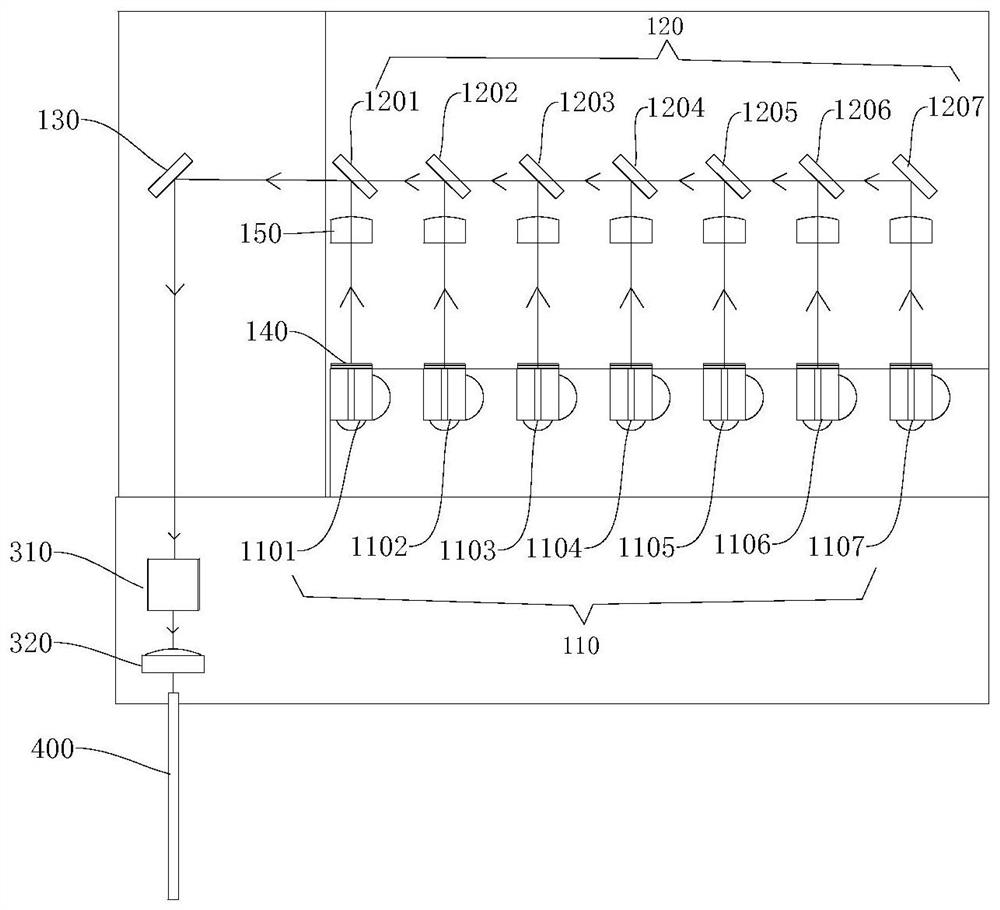

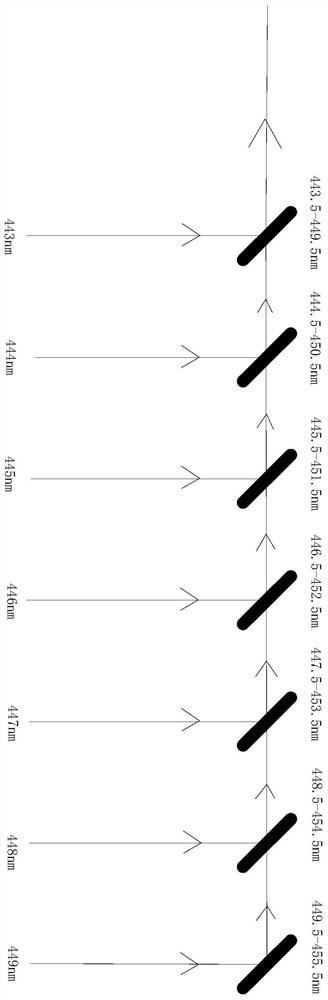

[0071] refer to Figure 1 to Figure 3 , the fiber-coupled semiconductor laser is provided with a laser module, a focusing system and an optical fiber 400 .

[0072] The laser module is provided with a light emitting unit group and a corresponding dichroic mirror group. A light-emitting unit group contains 7 light-emitting units 110 (N=7), which are the first laser chip 1101, the second laser chip 1102, the third laser chip 1103, the fourth laser chip 1104, the fifth laser chip 1105, the Six laser chips 1106 and seventh laser chips 1107. A dichroic mirror group includes 7 dichroic mirrors, namely the first dichroic mirror 1201 corresponding to the first laser chip 1101 and the second dichroic mirror 1202 corresponding to the second laser chip 1102 , the third dichroic mirror 1203 corresponding to the third laser chip, the fourth dichroic mirror 1204 corresponding to the fourth laser chip, the fifth dichroic mirror corresponding to the fifth laser chip 1205. A sixth dichroic ...

Embodiment 2

[0084] refer to Figure 4 to Figure 7 , the fiber-coupled semiconductor laser is equipped with 8 laser modules, a focusing system and an optical fiber 400. The 8 laser modules are respectively the first laser module A, the second laser module B, the third laser module C, and the fourth laser module Module D, fifth laser module E, sixth laser module F, seventh laser module G, eighth laser module H.

[0085] Among them, 8 laser modules are evenly arranged in two rows, and each row is 4 laser modules (that is, M=4), that is, the first laser module A, the third laser module C, the fifth laser module E and The seventh laser module G is located in the same row, and respectively located on 4 steps with decreasing heights. The second laser module B, the fourth laser module D, the sixth laser module F and the eighth laser module H are located in the same row, and are respectively located on four steps with decreasing heights. The first laser module A and the second laser module B are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com