Patents

Literature

81results about How to "Solve freezing problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

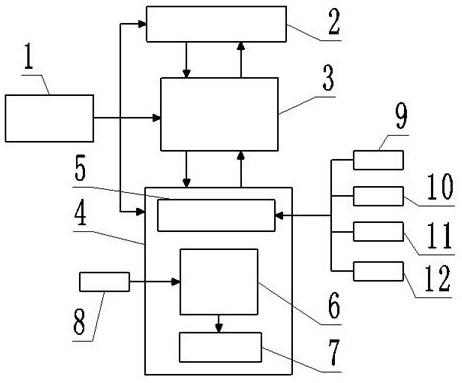

Carbon dioxide foam injecting device of oil well

ActiveCN102747996ASolve freezing problemsGuaranteed foaming effectFlow mixersRotary stirring mixersTemperature controlAutomatic control

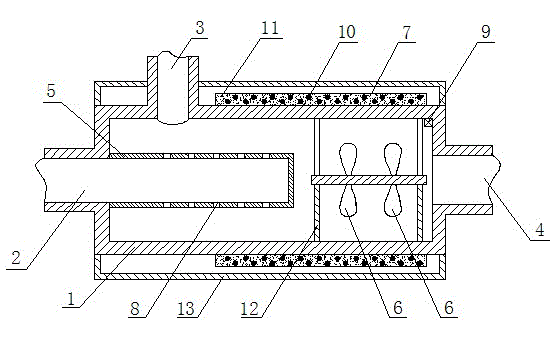

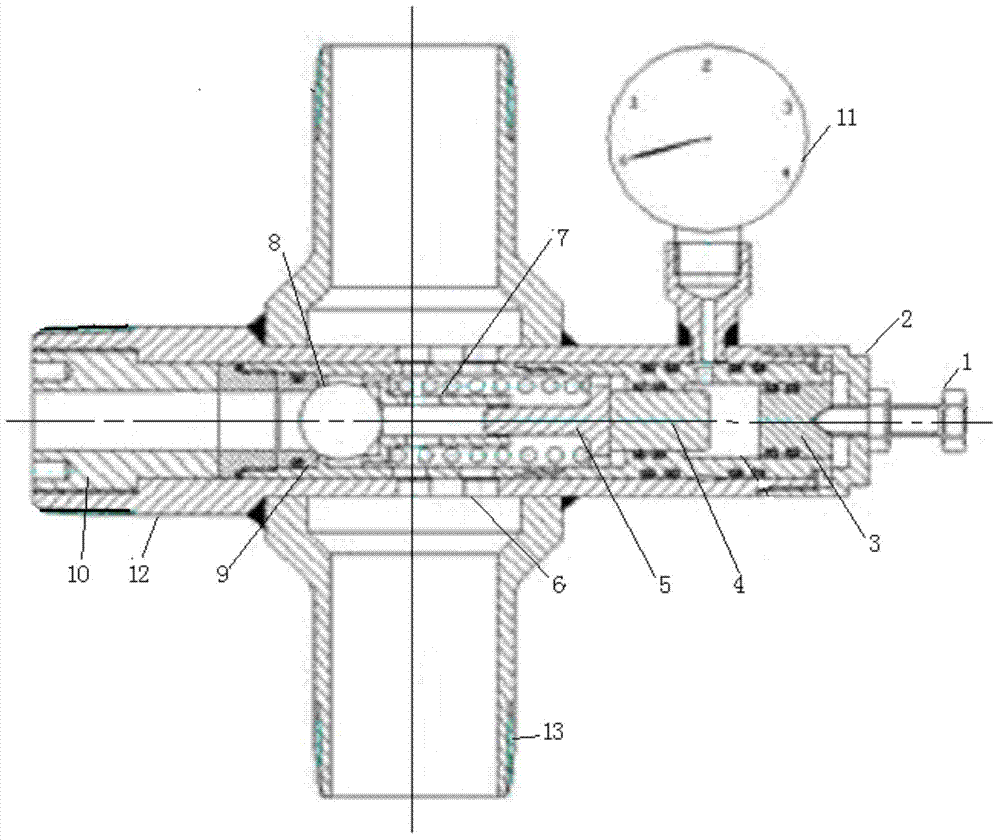

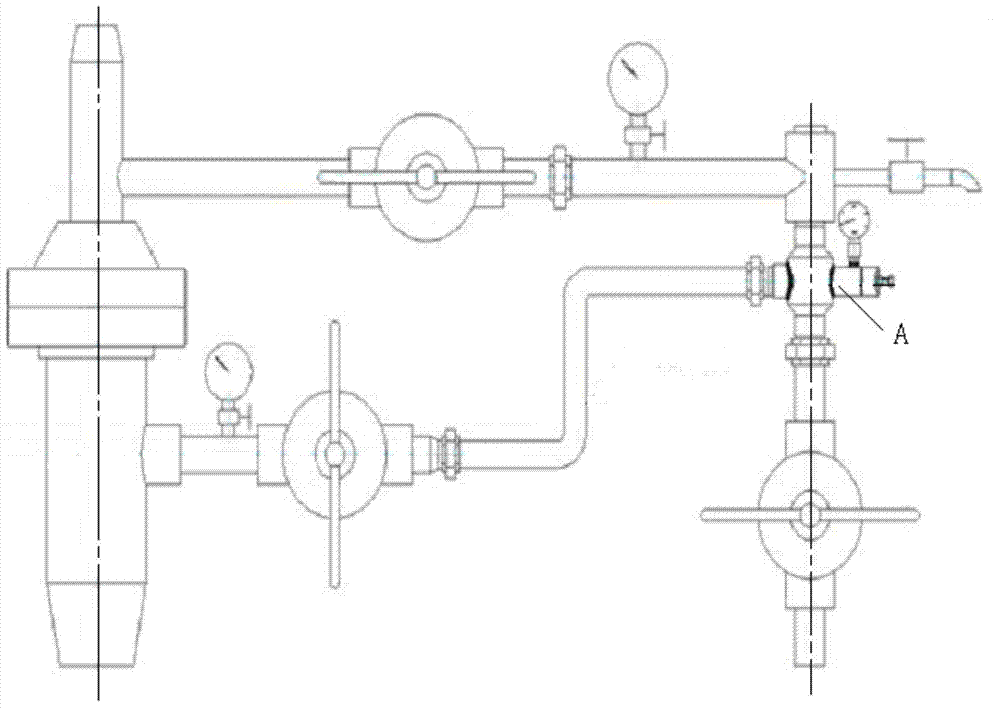

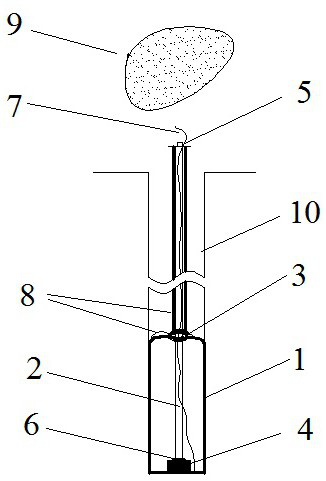

The invention provides a carbon dioxide foam injecting device of an oil well and relates to a mechanical device in an oil mine field. The carbon dioxide foam injecting device is composed of a cylinder body, a carbon dioxide inlet, a dosing port and a mixed liquid outlet. One end of the cylinder body is provided with the carbon dioxide inlet, the other end of the cylinder body is provided with the mixed liquid outlet, a side wall at one end of the cylinder body close to the carbon dioxide inlet is provided with the dosing port. The carbon dioxide inlet in the cylinder body is connected with a spraying pipe, and a stirring paddle is arranged on a fixing frame from the spraying pipe to a mixed liquid outlet space. The carbon dioxide foam injecting device of the oil well is novel in structure, low in construction cost and high-pressure-resisting, the cylinder body is made of stainless steel, and the material is OCr18Ni9 and can bear pressure of 25 MPa. Efficient flame retardant crystallized magnesium oxide is filled in a heater, an electric heat tracing band can heat a system at the temperature of 0-150 DEG C, and a temperature sensor externally-connected temperature control cabinet performs automatic control to a working state of an electric heating pipe. The carbon dioxide foam injecting device solves the problem of frozen blocking in the carbon dioxide foam oil-displacement process and effectively ensures the foaming performance of a carbon dioxide foam system.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

Anti-freezing abrasion-resistant rubber and preparation method thereof

ActiveCN105001469AImprove wear resistanceSolve freezing problemsSynthetic resin layered productsRubber layered productsVulcanizationPolymer science

The invention relates to anti-freezing abrasion-resistant rubber and a preparation method thereof, and belongs to the technical field of rubber products. The rubber comprises 40-80 parts of butadiene rubber, 10-40 parts of butadiene styrene rubber, 10-20 parts of natural rubber, 30-70 parts of reinforcing fillers, 6-13 parts of vulcanizing activators, 0.5-2 parts of vulcanizing agents, 0.5-2 parts of vulcanization accelerators, 5-15 parts of plasticizers, 1-6 parts of anti-aging agents and an ultrahigh molecular weight polyethylene film. By means of preparation, forming, vulcanizing and trimming of the rubber, an anti-freezing abrasion-resistant rubber product is obtained; in the forming process of the rubber, one layer of the ultrahigh molecular weight polyethylene film is attached to and coated on the surface of the rubber, therefore the problem that frozen ice on the surface of the rubber is hard to remove is solved, meanwhile the abrasion-resistant performance of the rubber is improved, and the service life of the rubber product is prolonged. The rubber prepared by the preparation method is tightly attached to the ultrahigh molecular weight polyethylene film, the peel resistance strength reaches up to range from 105 N / cm to 135 N / cm, and the roller abrasion value ranges from 10 mm<3> to 29 mm<3>. Due to the fact that the UHMWPE layer is arranged on the surface of the rubber, the good shock resistance performance and the good corrosion-resistant performance are achieved, and the rubber can be used under the poor environment.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD +1

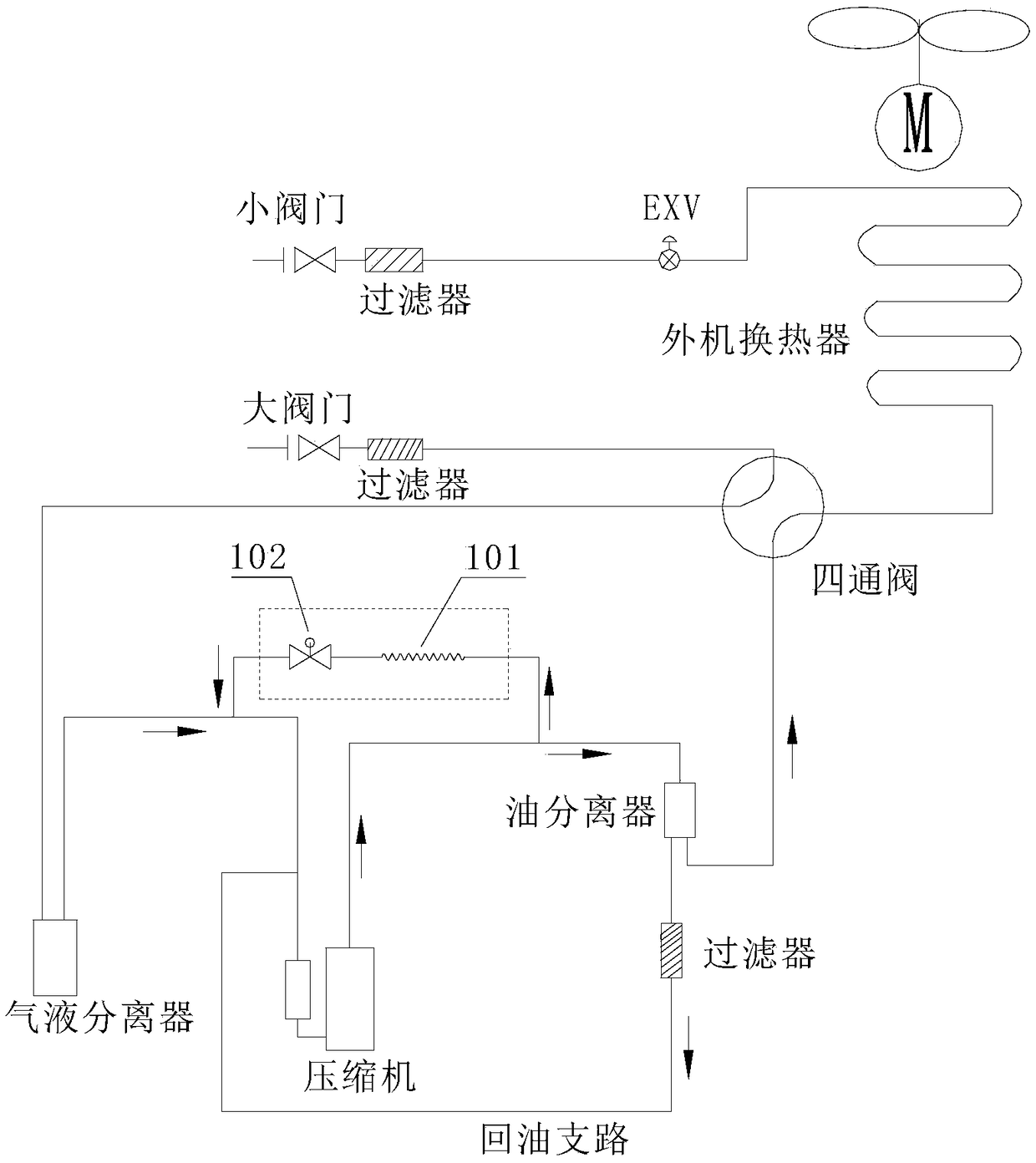

Heat pump defrost control method

InactiveCN107843035AImprove accuracy and timelinessSolve the hard to remove icingCorrosion preventionRefrigeration safety arrangementEngineeringElectrical and Electronics engineering

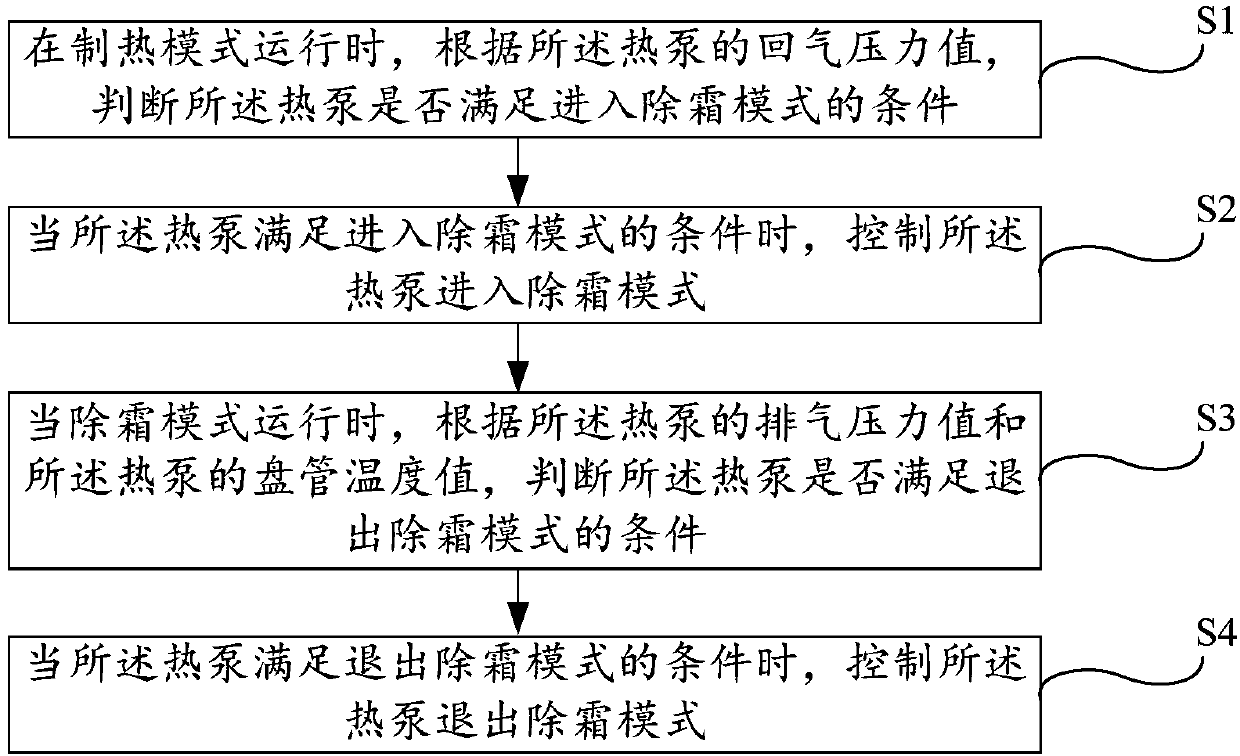

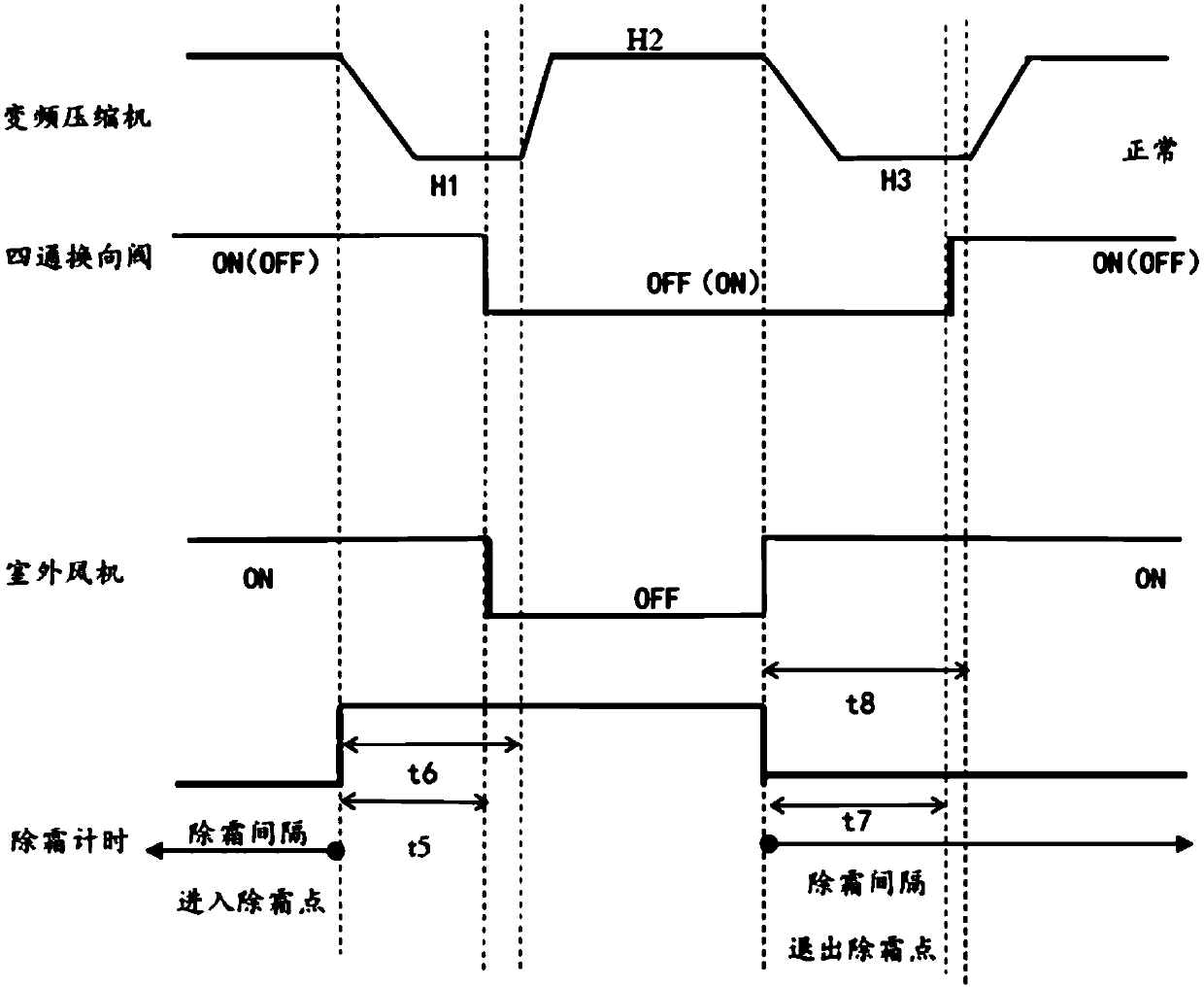

The invention provides a heat pump defrost control method, which comprises the steps of when running at a heating mode, judging whether a condition for entering a defrost mode is met or not accordingto a pressure value of a heat pump; when meeting the condition for entering the defrost mode, entering the defrost mode; when running at the defrost mode, judging whether a condition for exiting the defrost mode is met at the same time according to the pressure value of the heat pump and a coil temperature value of the heat pump; and when meeting the condition for exiting the defrost mode at the same time, exiting the defrost mode. The heat pump defrost control method provided by the invention can be used for effectively judging whether a heat pump unit meets the condition for exiting the defrost mode or not, so that the accuracy and the timeliness in defrosting are improved, and a defrosting effect of the heat pump unit is further improved.

Owner:GUANGDONG PHNIX ENERGY TECH CO LTD

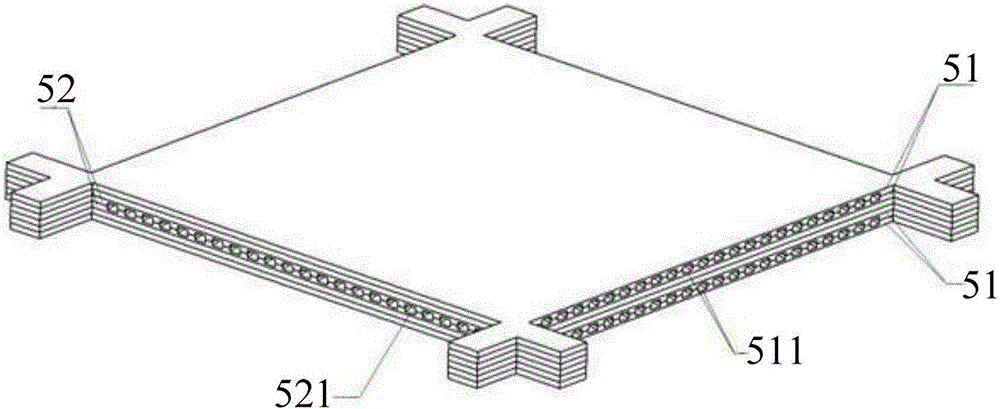

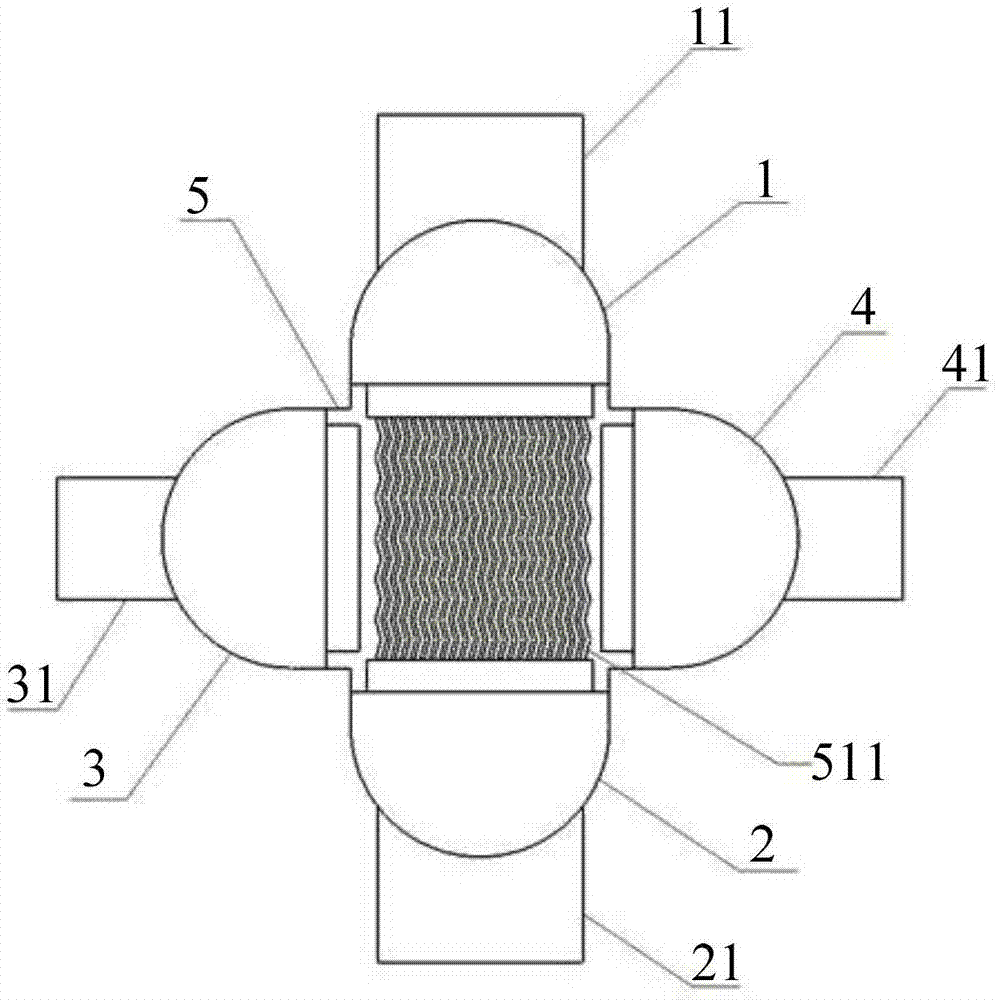

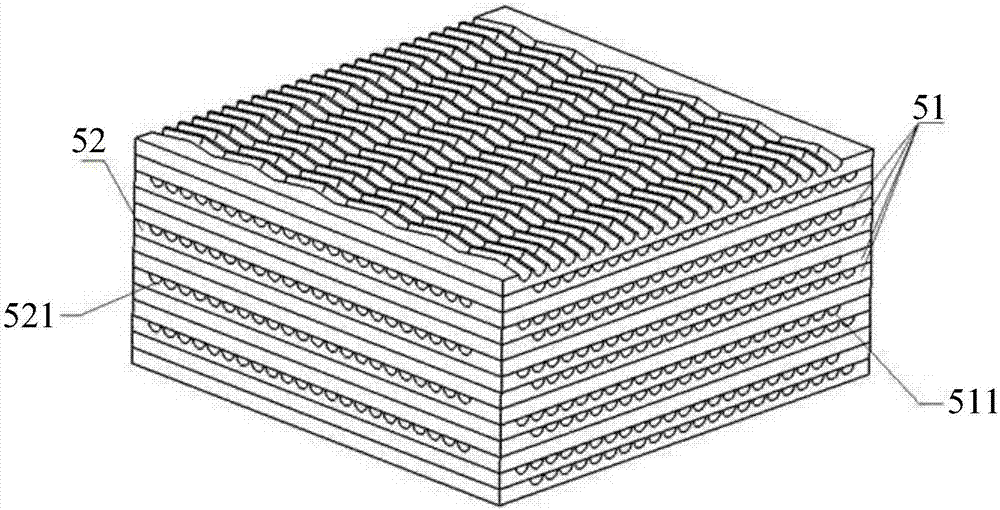

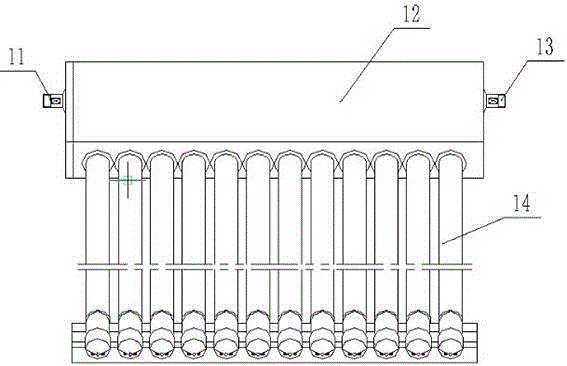

Printed circuit board type molten salt gas heat exchanger

ActiveCN106839833AHeat absorption smoothlySmall sizeCorrosion preventionHeat exchanger fasteningMolten saltEngineering

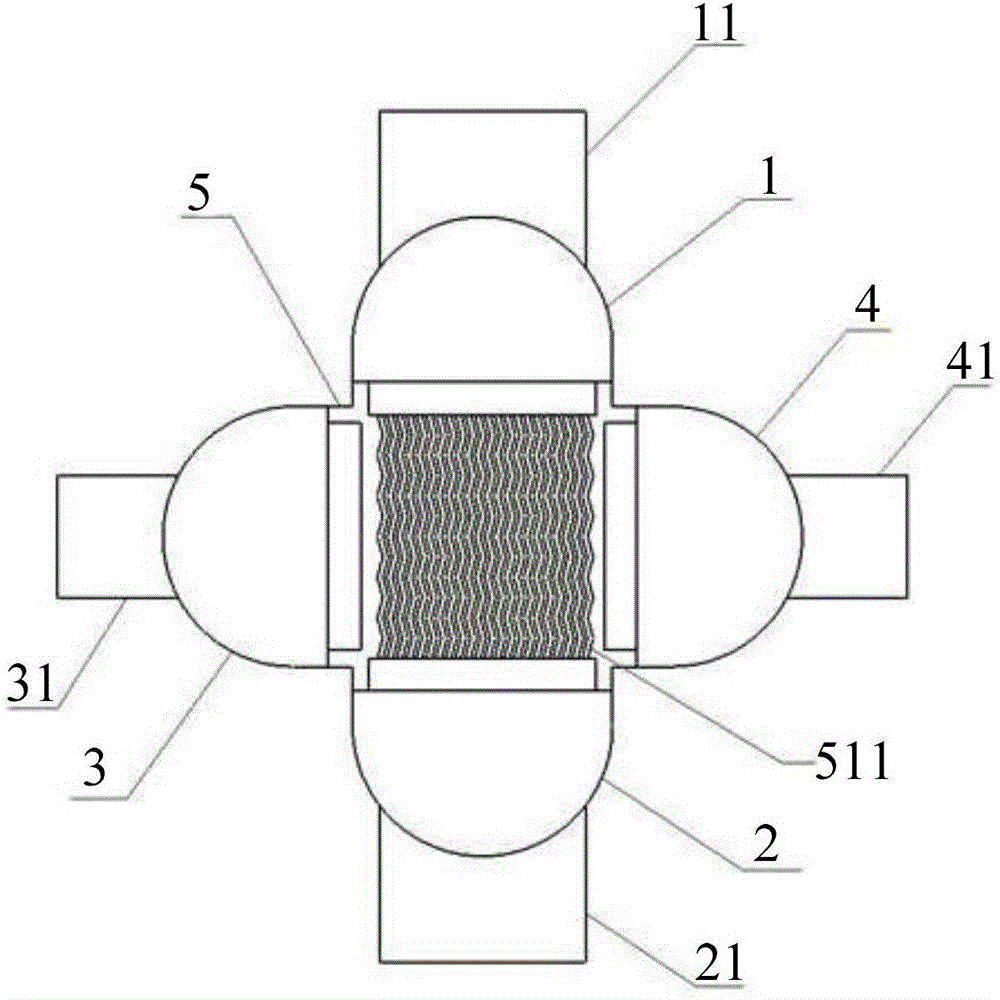

The invention provides a printed circuit board type molten salt gas heat exchanger. The heat exchanger comprises a heat exchange plate core, wherein the heat exchange plate core comprises at least one periodic structure, and the at least one periodic structure comprises a first gas heat exchange plate, a molten salt heat exchange plate and a second gas heat exchange plate which are sequentially stacked; the molten salt heat exchange plate is provided with multiple molten salt flow channels, and each molten salt flow channel extends from a longitudinal first end of the molten salt heat exchange plate to a longitudinal second end of the molten salt heat exchange plate; multiple gas flow channels are formed in each of the first gas heat exchange plate and the second gas heat exchange plate, and each gas flow channel extends from a transverse first end of the corresponding gas heat exchange plate to a transverse second end of the corresponding gas heat exchange plate. Heat exchange is realized in a cross flow manner, space is allocated reasonably, and sensible heat of hot salt is used to a great extent; the periodic curved structures of the flow channels can improve the turbulence of fluids, break heat exchange boundary layers near walls and improve heat exchange efficiency.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

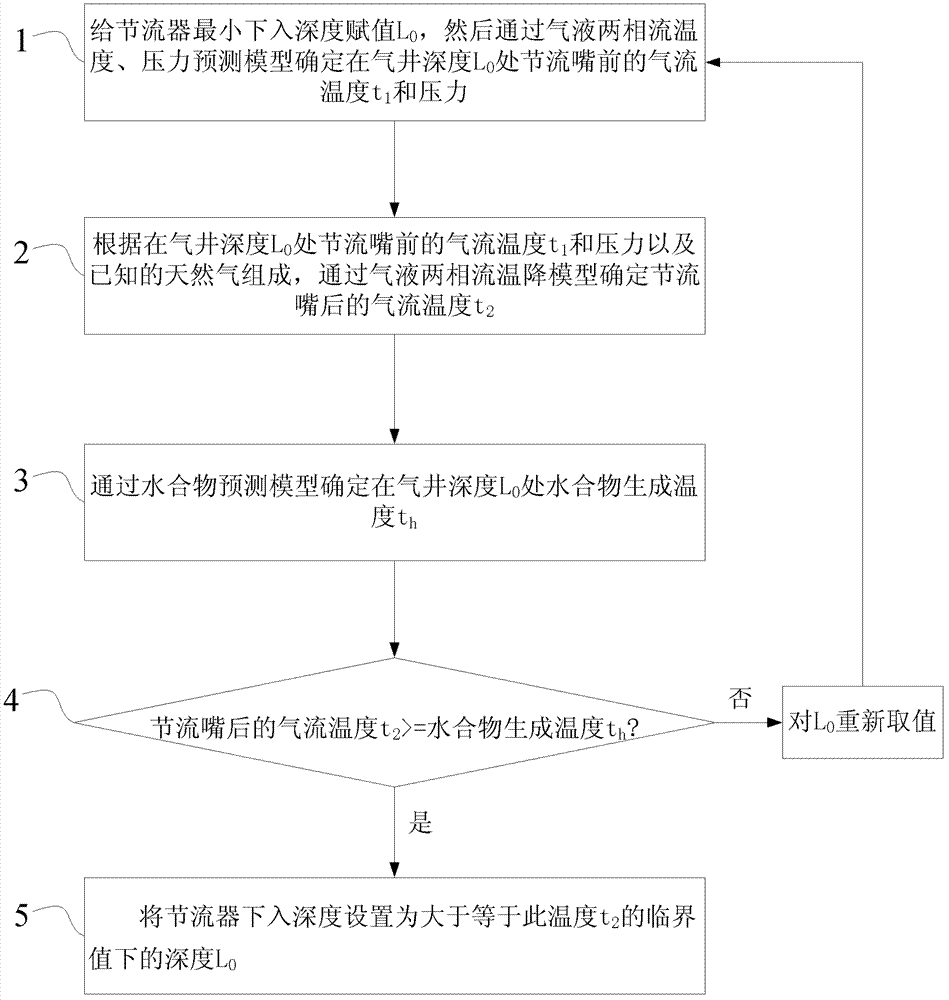

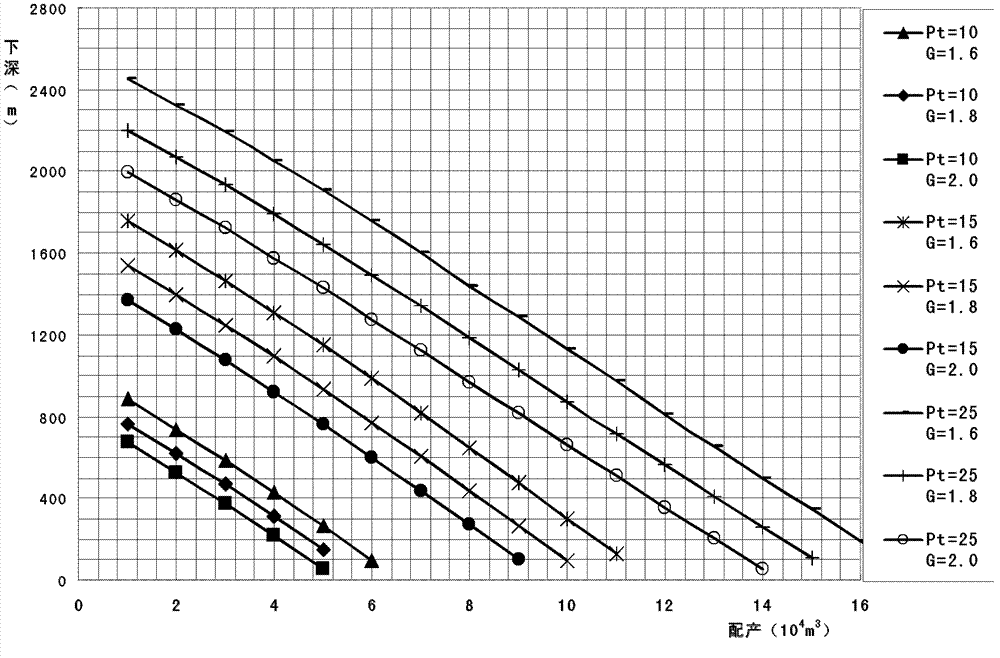

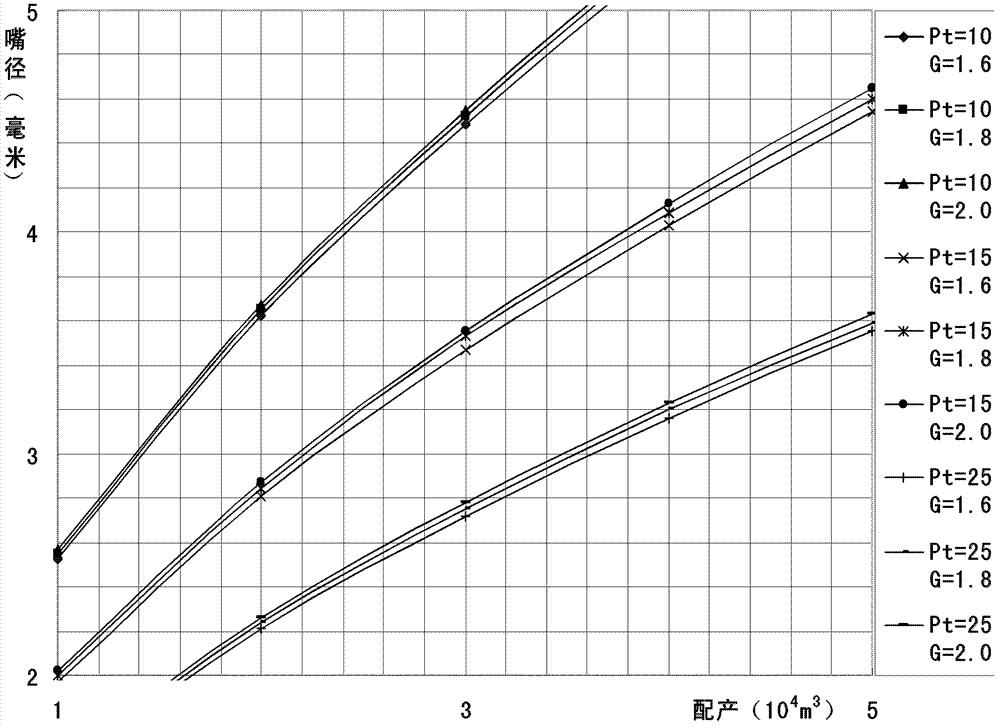

Setting method of underground throttle technological parameter

The invention discloses a setting method of an underground throttle technological parameter. The method comprises setting the depth of setting of an underground throttling device. The specific process comprises that S1, the smallest depth of setting of the throttling device is assigned L0 and temperature t1 and pressure in an upstream of a throttling nipple in the L0 depth position are confirmed through gas-liquid two-phase flow temperature and a pressure prediction model; S2, according to the t1 and the pressure in the L0 position and composition of known natural gas, temperature t2 in a downstream of the throttling nipple is confirmed through a gas-liquid two-phase flow temperature reducing model; S3, aqua-complex generating temperature th in the L0 position is confirmed through an aqua-complex prediction model; S4, if the t2 is lower than the th, the L0 is assigned again and then the steps of S1-S4 are repeated until a critical value that the t2>=th is found; and S5 the depth of setting of the throttling device is set to be more than or equal to the L0 under the critical value of the t2. The setting method of the down hole throttle technological parameter has applicability for both a dry gas pool and a condensate gas pool, important guarantee is offered to efficient development in a condensate gas pool block and the problem that a gas well is frozen and blocked is effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP

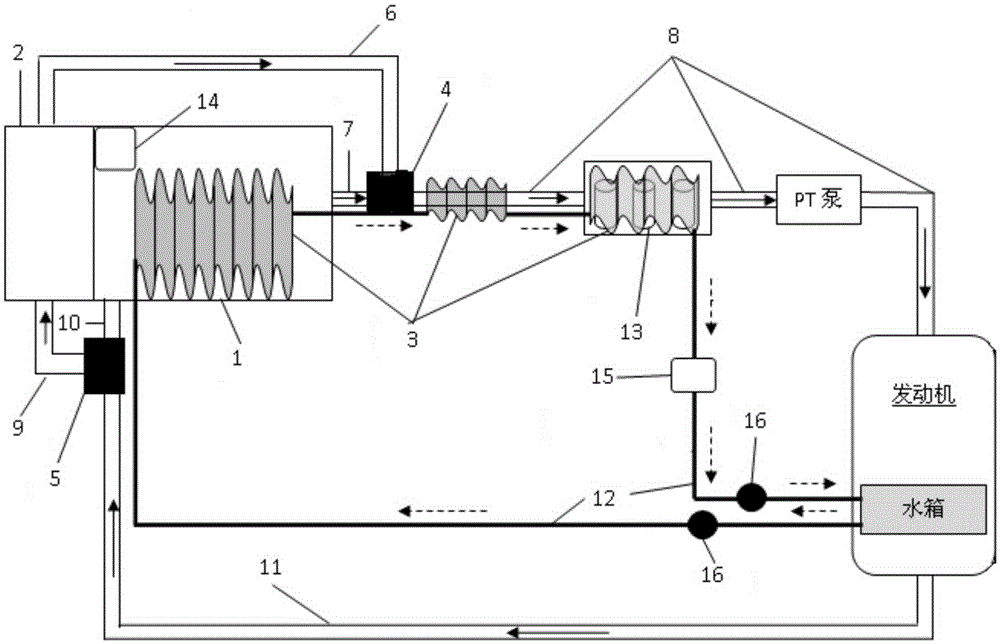

Diesel-type automobile fuel oil preheating device

InactiveCN105402059ALow costReduce cold wearMachines/enginesThermal treatment of fuelSolenoid valveFuel tank

The invention discloses a diesel-type automobile fuel oil preheating device, belonging to the technical field of diesel-type automobile fuel oil preheating. The invention aims to provide the diesel-type automobile fuel oil preheating device which can effectively solve the problems of fuel oil preheating and automobile low-temperature starting, and can lower the fuel oil use cost. The diesel-type automobile fuel oil preheating device comprises a diesel-type automobile main fuel tank, and further comprises a heating fuel oil tank, heat exchangers, a fuel-outlet three-way solenoid valve and a fuel-return three-way solenoid valve, wherein the fuel-outlet three-way solenoid valve is communicated with a heating fuel oil tank fuel outlet pipe and a diesel-type automobile main fuel tank fuel outlet pipe and is connected to a diesel-type automobile main fuel outlet pipe; the fuel-return three-way solenoid valve is communicated with a heating fuel oil tank fuel-return pipe and a diesel-type automobile main fuel tank fuel-return pipe and is connected to a diesel-type automobile main fuel-return pipe; one heat exchanger is arranged in the diesel-type automobile main fuel tank; and the heat exchangers are communicated with a diesel-type automobile water tank through water conveying pipelines. The diesel-type automobile fuel oil preheating device is applicable to use on various diesel-type automobiles.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

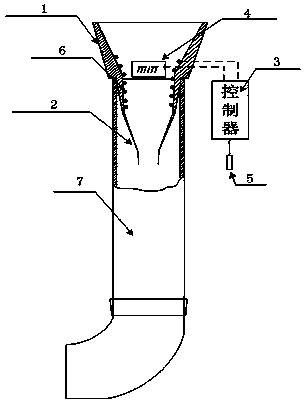

Drain pipe anti-freezing system outside building

ActiveCN104264740ASolve freezing problemsEffective protectionRoof drainageService pipe systemsElectricityFree falling

The invention relates to a drain pipe anti-freezing system. The drain pipe anti-freezing system is formed by a drain pipe water inlet connecting opening, an elastic converged flow guide opening, a controller, electric heaters, a water sensor and an atmospheric temperature sensor; the drain pipe water inlet connecting opening is of an inverted trapezoidal structure; the bottom of the drain pipe water inlet connecting opening is inserted into a drain pipe; the water flowing down is guided to the position of a central axis of the drain pipe through the elastic converged flow guide opening to enable the water flowing down to rapidly fall down to a drain pipe outlet in a free falling body mode, wherein the drain pipe outlet is vertically formed; when the water flowing down is more, the elastic converged flow guide opening can be correspondingly expanded under the action of the water to allow more water to pass through smoothly; the inner wall of the drain pipe water inlet connecting opening is provided with the water sensor and the electric heaters; a signal receiving end of the controller is connected with the water sensor and the atmospheric temperature sensor; an output end of the controller is connected with the electric heaters. According to the drain pipe anti-freezing system, the freezing problem in the drain pipe is solved, the effective protection on the building is achieved, the performance is safe and reliable, and the drain pipe anti-freezing system is particularly suitable for northern area.

Owner:贾书洪

Printed circuit board type fused salt heat exchanger adopting double-layer board arrangement

ActiveCN106895725AHeat absorption smoothlySmall sizeHeat exchanger casingsStationary plate conduit assembliesCause blockagePlate heat exchanger

The invention provides a printed circuit board type fused salt heat exchanger adopting double-layer board arrangement. The printed circuit board type fused salt heat exchanger adopting double-layer board arrangement comprises a shell and a heat change board core arranged in the shell. The heat exchange board core comprises at least one periodical structure. Each periodic structure is composed of a first cold salt heat exchange board, a second cold salt heat exchange board and a hot salt heat exchange board, wherein the first cold salt heat exchange board, the second cold salt heat exchange board and the hot salt heat exchange board are sequentially stacked. Each first cold salt heat exchange board and each second cold salt heat exchange board are provided with multiple cold salt flow channels, wherein the flowing directions of the multiple cold salt flow channels are parallel. Each cold salt flow channel extends from the longitudinal first end of the corresponding cold salt heat exchange board to the longitudinal second end of the corresponding cold salt heat exchange board. Each hot salt heat exchange board is provided with multiple hot salt flow channels. Each hot salt flow channel extends from the transverse first end to the transverse second end of the corresponding hot salt heat exchange board. By the adoption of the printed circuit board type fused salt heat exchanger adopting double-layer board arrangement, it is avoided that fused salt causes blockage of the flow channels in a low-temperature environment, it is also avoided that in a high-temperature environment, the fused salt causes a thermal expansion effect on the flow channels of the heat exchanger, and the service life of heat exchange equipment is prolonged.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

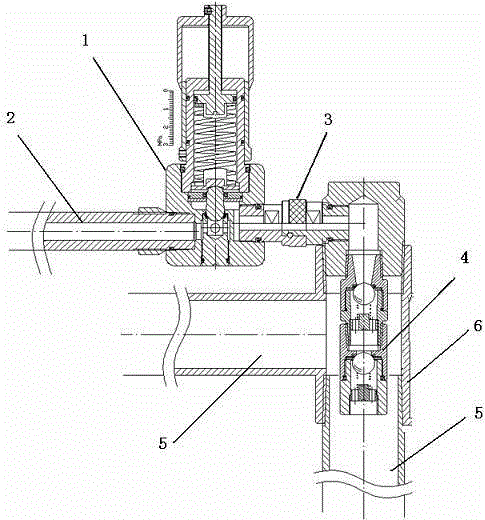

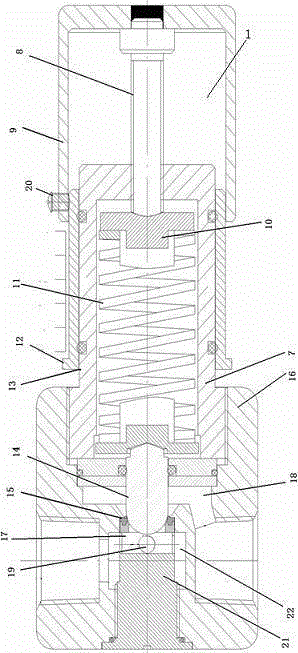

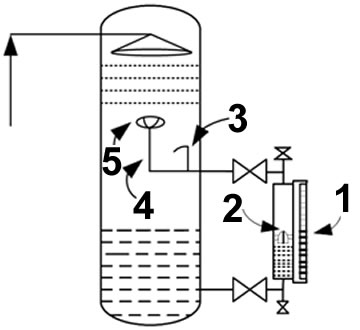

Gas-liquid separation-type casing gas recycling device

The invention relates to a gas-liquid separation-type casing gas recycling device, comprising a constant pressure gas release valve and a check valve, wherein a gas inlet hole is formed in one side of the constant pressure gas release valve; the gas inlet hole is connected with a gas inlet pipeline; a gas exhaust hole is formed in the other side of the constant pressure gas release valve; the gas exhaust hole is connected with a fast joint; the other end of the fast joint is connected with a three-way pipe; the other two ends of the three-way pipe are respectively connected with production process pipelines; the check valve is arranged in the intersection position in the three-way pipe; the constant pressure gas release valve comprises a valve body; the valve body is internally provided with a piston; a valve holder, of which the upper end is provided with a valve ball, is connected below the piston; a valve seat is arranged at the outer side of the valve holder in a sleeving manner; the gas inlet hole is formed in one side of the valve seat, and is communicated with the valve holder which is provided with the valve ball; the gas exhaust hole is formed in the other side of the valve body; the gas exhaust hole is placed above the position where the piston is in contact with the valve holder. According to the gas-liquid separation-type casing gas recycling device, the check valve can prevent crude tar from flowing to the constant pressure gas release valve by means of tracing heat of heat of the field crude tar, so that the gas-liquid separation is realized, and the problem that a constant pressure valve is frozen and blocked in winter is solved.

Owner:PETROCHINA CO LTD

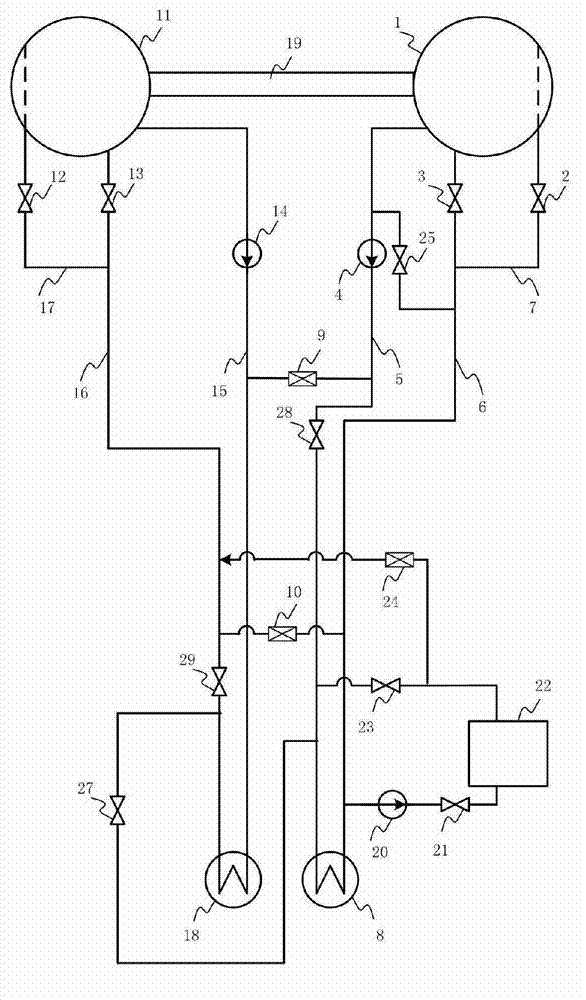

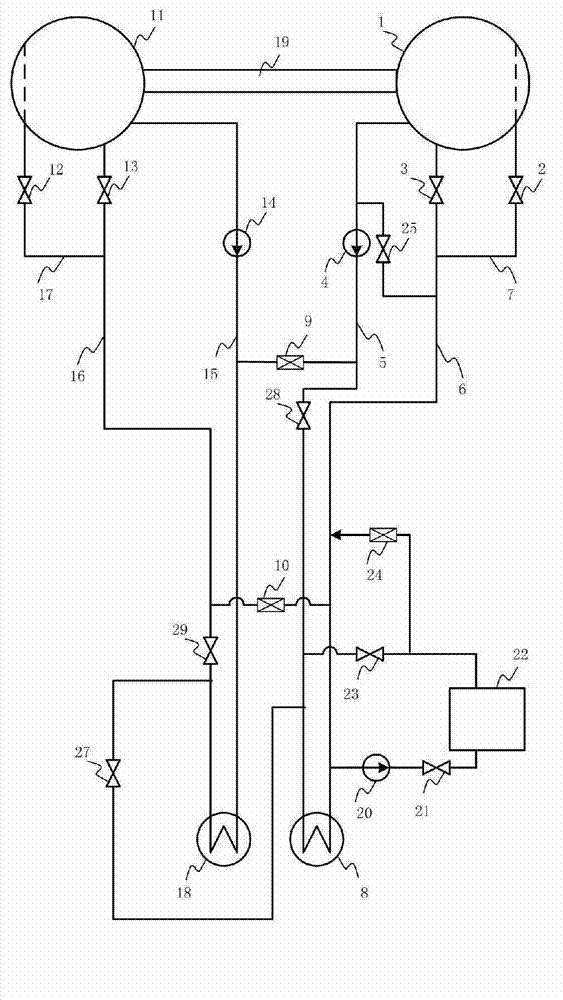

Thermal power plant circulating water system

ActiveCN103034221ASimple structureEasy to adjustTotal factory controlProgramme total factory controlElectricityThermal power station

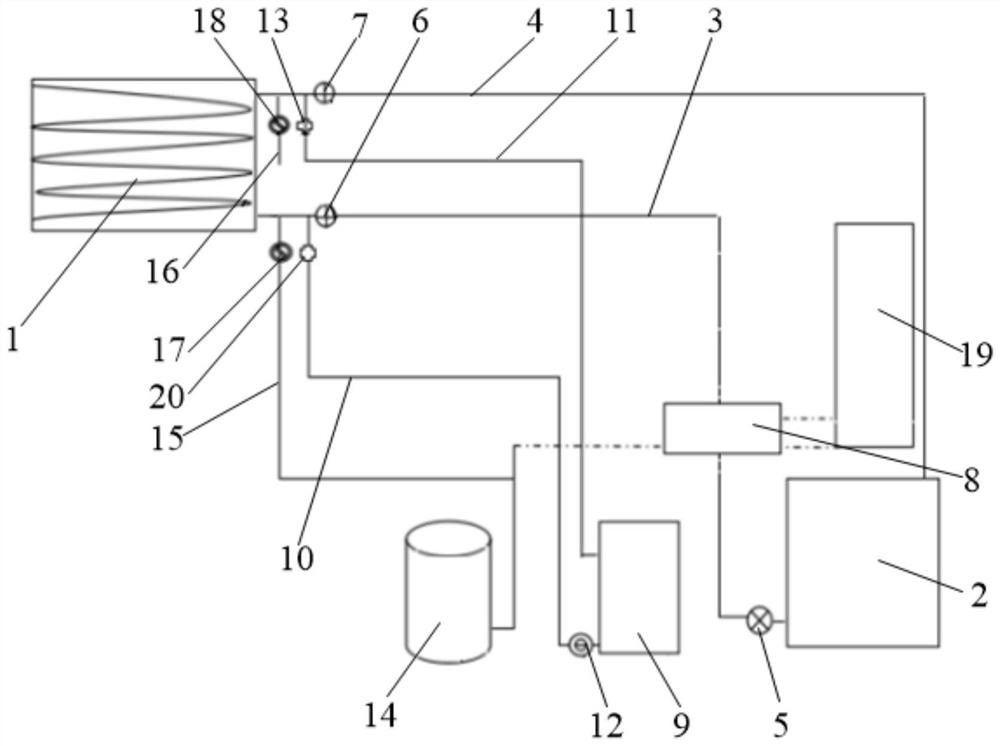

The invention relates to a thermal power plant circulating water system with a function of recycling waste heat. The thermal power plant circulating water system comprises a first unit and a second unit. The first unit comprises a first cooling tower 1, a first circulating water pump 4, a first condenser 8, an icebreaking pipeline valve 2, a circulating water return water main pipe valve 3, circulating water pipeline valve 25 and circulating water supplying main pipe valve 28. The second unit comprises a second cooling tower 11, a second circulating water pump 14, a second condenser 18, a second icebreaking pipeline valve 12, a second circulating water return water main pipe first valve 13 and second circulating water return water main pipe second valve 29. The thermal power plant circulating water system has the advantages of being simple in structure, flexible and convenient to adjust, good in anti-freezing effect, energy-saving and electricity-saving, thoroughly solves the problems of safe and stable operation of the existing thermal power plant circulating water system and freezing of the cooling towers and pools.

Owner:北京华景天润科技有限公司

Access type associated gas recycling device

InactiveCN104514521ASolve the problem of heat absorptionSolve freezing problemsConstructionsFluid removalGas releasePetroleum

The invention discloses an access type associated gas recycling device which is designed for solving the frozen blocking problem of valve core and valve seat as well as completely recycling the associated gas. Valve body of the device is vertically inserted and fixed in a petroleum transmission pipeline; the lower end of the valve body is connected with a lower pressing cap; the middle cylindrical wall is provided with a radial gas vent; the upper end is connected with an upper pressing cap which is provided with an adjusting wheel; the lateral wall of the valve body below the upper pressing cap is provided with a pressure gauge; the valve seat is installed inside the valve body; the lower end of the valve seat is connected with the lower pressing cap; the upper end contacts with the upper pressing cap; the upper portion of the valve seat is hermetically provided with a pressure regulating piston which is connected with the adjusting wheel and a lateral pressure conduction hole corresponding to the pressure gauge; the inner stepped position is hermetically provided with a pressure conduction piston; the lower end of the pressure conduction piston is sequentially connected with a spring seat for containing a spring, and a valve support; the lower end of the valve support is provided with a valve ball. The device is installed and operated inside the petroleum transmission pipeline; the device can be heated with the help of the heat of the crude oil on site, thereby completely solving the problems that heat is absorbed when releasing the gas and the constant pressure vent valve is frozen and blocked in winter.

Owner:PETROCHINA CO LTD

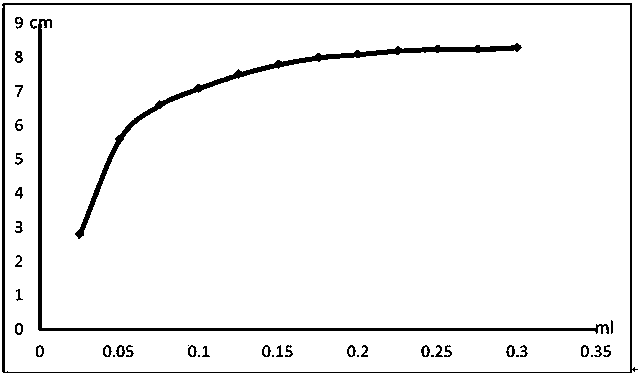

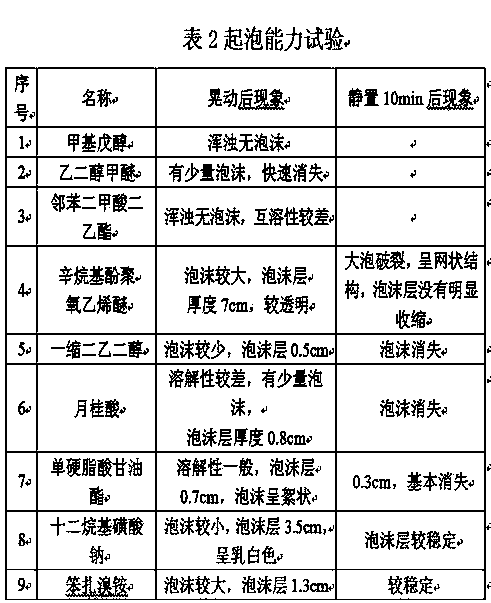

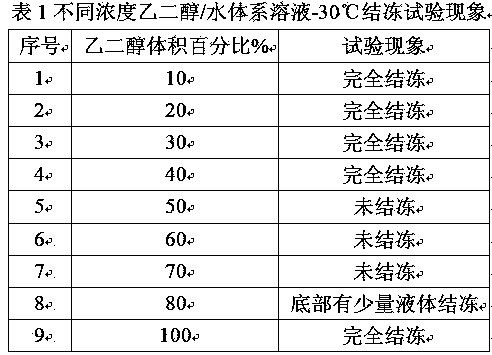

Low-temperature leakage detecting liquid used for air tightness detection of liquid propellant storage and transportation device

InactiveCN104034485AImprove securityImprove work efficiencyDetection of fluid at leakage pointAlkylphenolSolvent

The invention provides a low-temperature leakage detecting liquid used for air tightness detection of a liquid propellant storage and transportation device. The raw constituents of the low-temperature leakage detection liquid are water, a low-temperature solvent, a surfactant, SDS (Sodium Dodecyl Sulfate) and disodium hydrogen phosphate; the raw constituents are mixed uniformly according to a proportion to form the low-temperature leakage detecting liquid. The low-temperature solvent is ethanol or ethylene glycol; the surfactant is any one of octyl alkylphenol polyoxyethylene ether, nonyl phenol polyethenoxy ether and phenethyl phenol polyoxyethylene ether; the SDS serves as an additive agent for improving stability of bubbles, and the disodium hydrogen phosphate serves as a corrosion inhibitor. The low-temperature leakage detecting liquid can be used for air tightness detection of the liquid propellant storage and transportation device in an environment at 0 to -50 DEG C, is strong in bubbling capability, good in air bubble stability and strong in anti-freezing capability, can efficiently solve the problem that a common leakage detecting liquid when being used in a low-temperature environment is frozen, and improves leakage detection reliability and operation safety of the liquid propellant.

Owner:中国人民解放军63605部队

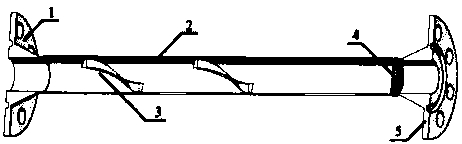

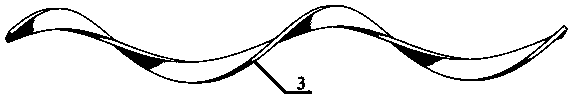

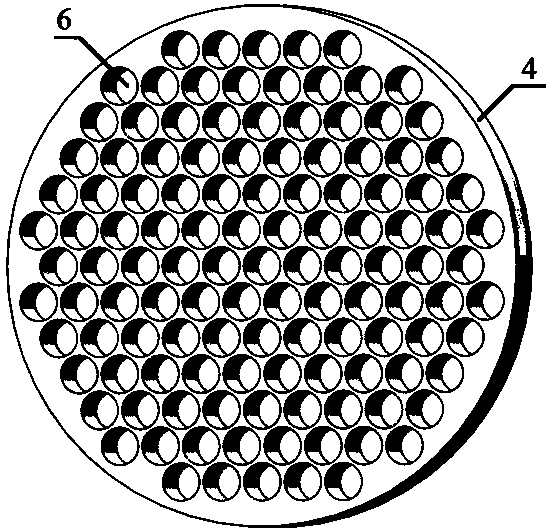

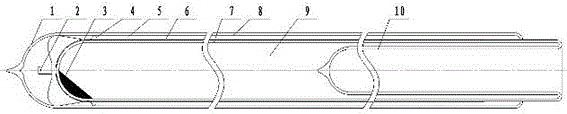

Bond-type gas well opening slow-plugging device and application method thereof

ActiveCN108952617AReduce maintenance difficultyReduce the consumption of manpower and material resourcesWell/borehole valve arrangementsSealing/packingWellheadMaterial resources

The invention provides a bond-type gas well opening slow-plugging device and an application method thereof. The bond-type gas well opening slow-plugging device comprises an oil pipe. A plurality of bond-type vortex generators are mounted in an inner cavity of the oil pipe and fixed to the inner wall of the oil pipe in a linear shape in the axial direction of the oil pipe. The two ends of the oil pipe are connected with a first flange and a second flange correspondingly. A hydrate filtering disc is further arranged in the inner cavity of the oil pipe, arranged in the downstream inner cavity ofthe oil pipe in the mode of being perpendicular to the center axis of the oil pipe, and located downstream the bond-type vortex generators. According to the bond-type gas well opening slow-plugging device and the application method thereof, through the vortex generators at the front end of the oil pipe and the hydrate filtering disc at the rear end of the oil pipe, the phenomena of wellhead frozenblocking and well opening failure due to the fact that a flowmeter flowing channel downstream a gas well wellhead pipeline is plugged by hydrate particles in the well opening process can be relievedand prevented, the gas well opening success rate is increased, the gas well management and maintenance difficulty is reduced, labor and material resources are saved, and the bond-type gas well openingslow-plugging device and the application method thereof have broad application prospects in the field of gas field mining.

Owner:PETROCHINA CO LTD

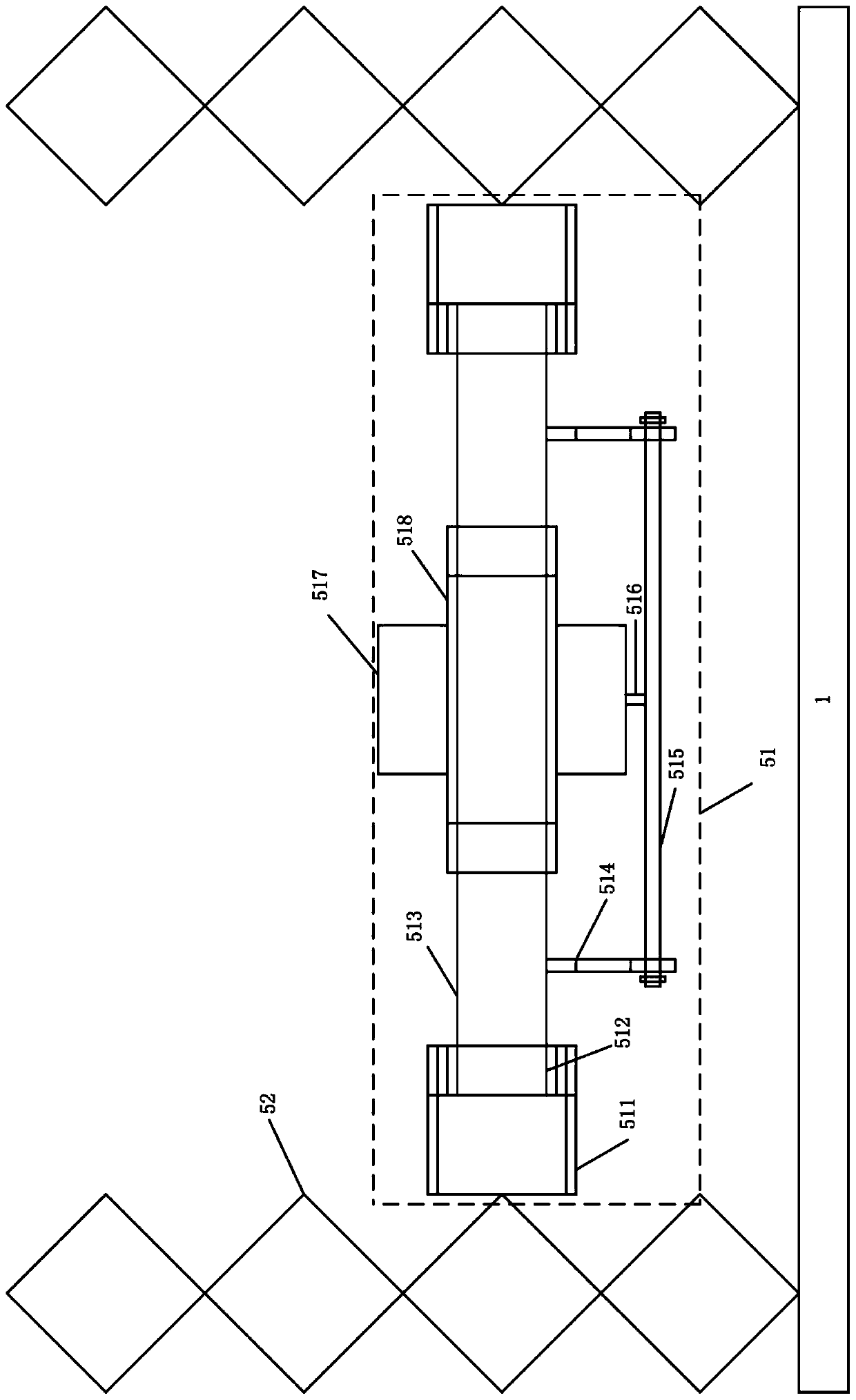

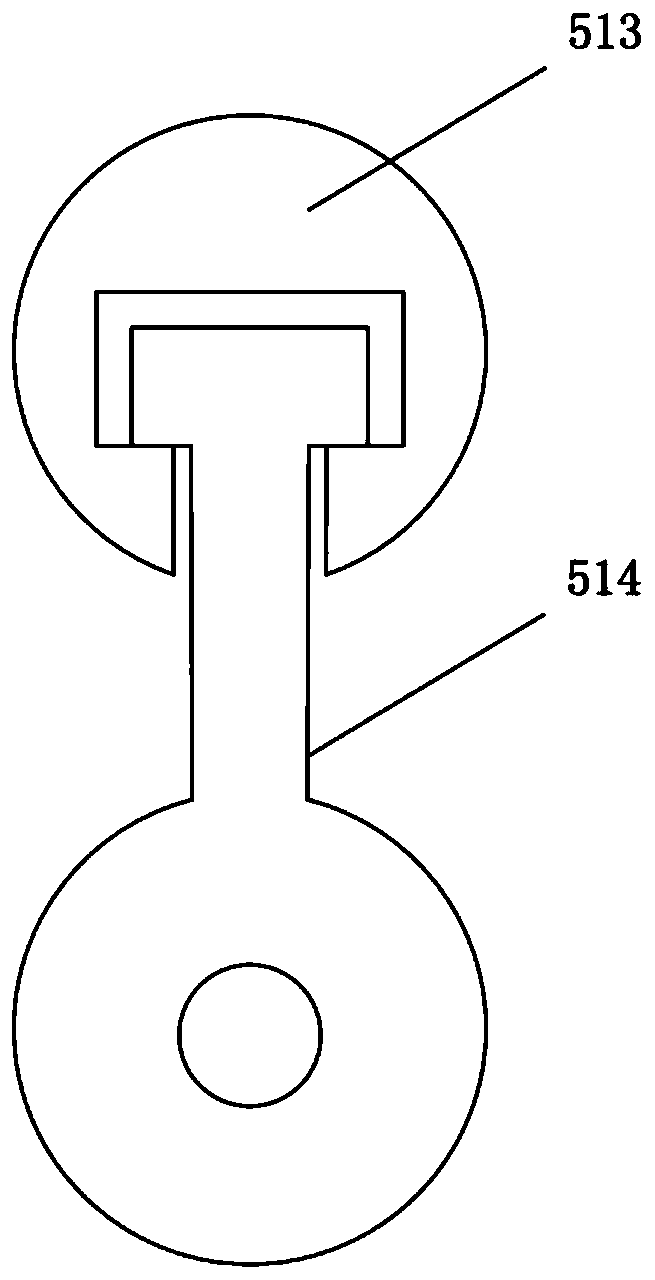

Sprayer

The invention discloses a sprayer, and belongs to the field of environment-friendly engineering machinery. The snow water sprayer is formed by a base (1), a spraying pipeline (2), a drying pipeline (3), a washing pipeline (4), a support device (5), an ice ball groove (6) and a cabin door (7). The base (1), the spraying pipeline (2), the drying pipeline (3), the washing pipeline (4) and the supportdevice (5) are installed in a sprayer cabin. The top of the sprayer cabin is provided with the cabin door (7). The ice ball groove (6) is installed outside the sprayer cabin. The snow water sprayer is specially used for a hot wind quick-freezing-type snow cleaning deicing vehicle, so a technical scheme of the hot wind quick-freezing-type snow cleaning deicing vehicle is more perfect.

Owner:泰州市海通资产管理有限公司

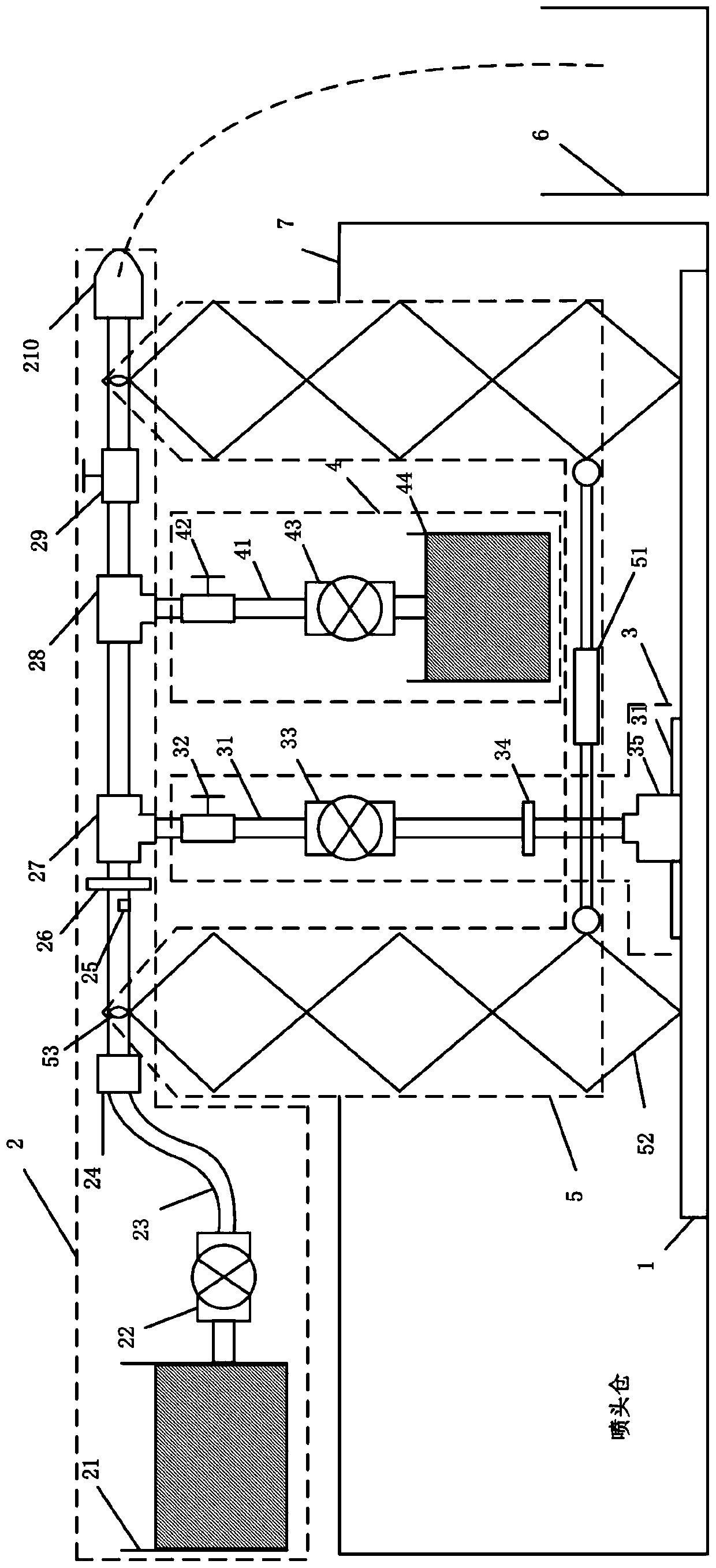

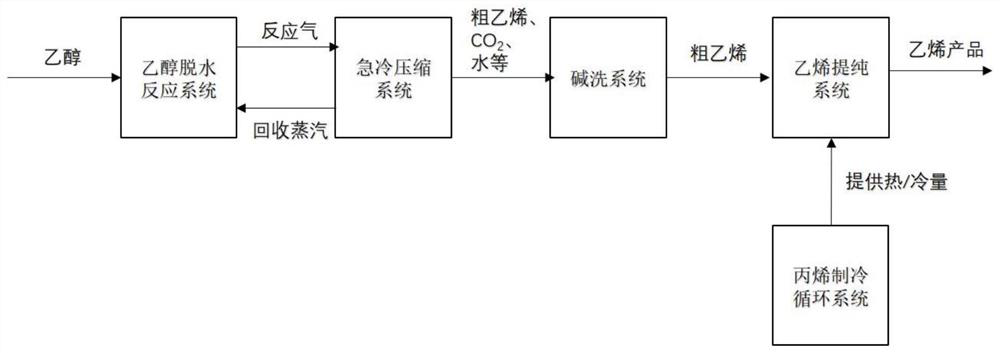

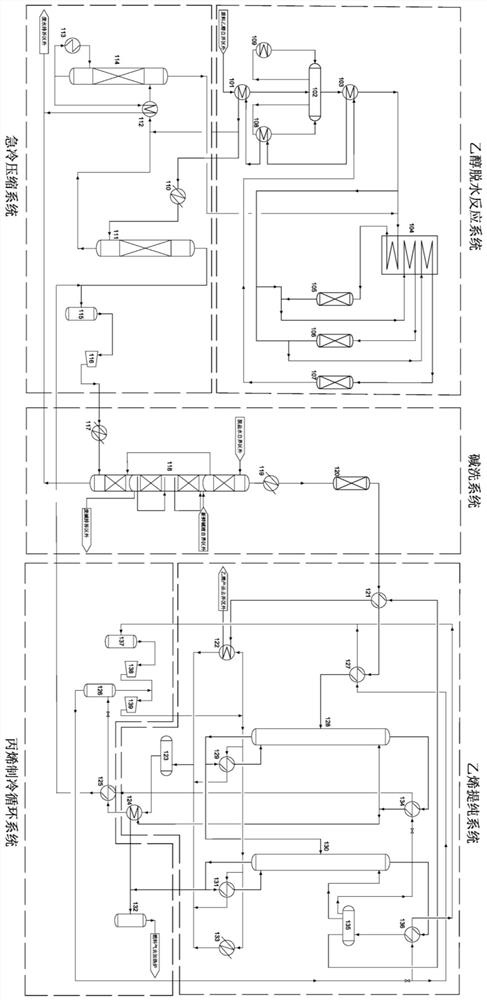

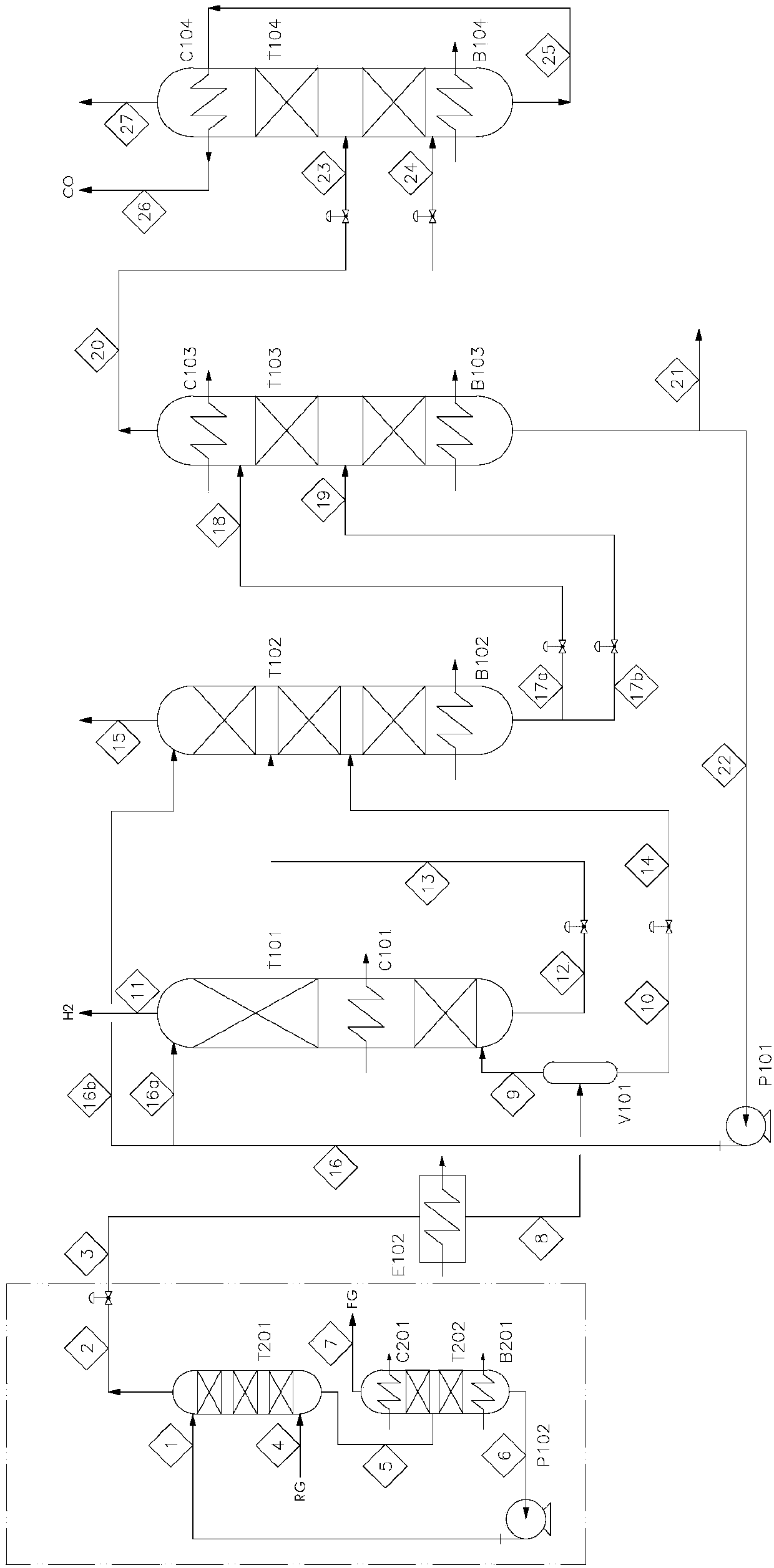

Production process and device for preparing ethylene through dehydration of ethanol

The invention provides a production process and device for preparing ethylene through dehydration of ethanol. According to the invention, an ethanol dehydration reaction system, a quenching compression system, an alkaline tower system, a molecular sieve regeneration system, an ethylene purification system, a propylene refrigeration circulation system and the device are arranged. The production process comprises the following steps: feeding ethanol to the ethanol dehydration system, and carrying out a dehydration reaction to obtain reaction gas; cooling and separating the reaction gas in the quenching compression system, and returning the recovered ethanol to the ethanol dehydration reaction system; feeding crude ethylene, carbon dioxide, water and the like to the alkali washing and molecular sieve system, and removing carbon dioxide and water to obtain crude ethylene; feeding the crude ethylene to the ethylene purification system to obtain an ethylene product; and providing cooling quantity for the ethylene purification system via the propylene refrigeration circulation system. According to the process, gradient utilization of heat of high-temperature reaction product gas is designed; a propylene circulation compression refrigeration system is adopted to provide a low-temperature refrigerant, so energy consumption in the process is effectively reduced; and external water replenishing is canceled while sewage discharge of the system is reduced, so water resource consumption is reduced.

Owner:TIANJIN UNIV

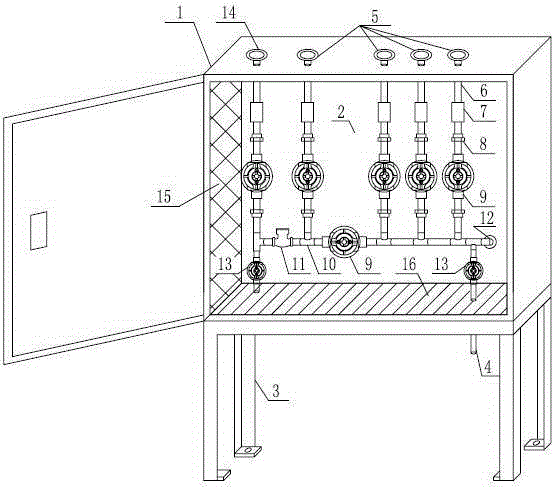

Upper connection type antifreeze integrated service station

InactiveCN106586720AEasy to collectImprove cleanlinessThermal insulationPipe protection by thermal insulationConnection typeThermal insulation

The invention discloses an upper connection type antifreeze integrated service station for the petrochemical industry field. The antifreeze integrated service station includes a box, a partition plate, and support legs; the partition plate is vertically arranged in the box and divides the box into a box front portion and a box back portion which are independent; medium inlets and a condensed water outlet are formed in a box front portion top plate; a liquid collection disc and a drainage pipe are arranged on a box front portion bottom plate; a medium valve group and a condensed water valve group are arranged in the box front portion; and the valve groups vertically communicate with a total pipe. The upper connection type antifreeze integrated service station can prevent rubber pipes from aging due to the fact that heat of steam pipe bakes the rubber pipes; thermal insulation materials are internally arranged on each surface of the box; thermal insulation layers are arranged on the valve groups of the service station; and the problem that pipes of the service station are frozen in cold areas in winder can be solved.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

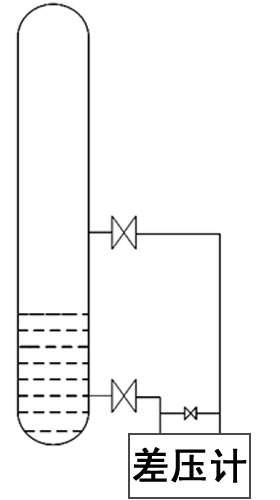

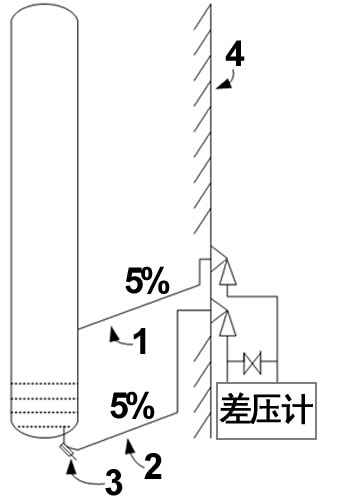

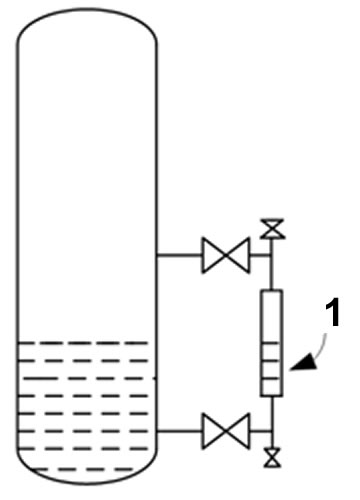

Differential-pressure type anti-freezing liquid level meter

InactiveCN102338652ASolve freezing problemsSolve the temperature change crystallization of the measured mediumLevel indicators by pressure measurementAnti freezingCooling tower

The invention provides a differential-pressure type anti-freezing liquid level meter. A positive-phase pressure-guiding pipeline of a differential pressure gauge is led out of a cooling tower at a certain height, and is led from the inner wall of an equipment container to the bottom part thereof; a measured medium is not in direct contact with a positive pressure chamber of the differential pressure gauge, and air or nitrogen in the remained gap is used for pressure conduction; and quantitative anti-freezing liquid is filled into the part of the positive-phase pressure-guiding pipeline out ofa stop valve of the cooling tower. By adopting the differential-pressure type anti-freezing liquid level meter, the problems that the positive-phase pressure-guiding pipeline is frozen and blocked and the measured medium is crystallized or condensed after being subjected to temperature changes are effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP

Pre-washing technology and device used for cryogenic separation of synthesis gas

PendingCN109628186AAvoid cloggingReduce freezingGas treatmentGaseous fuelsSyngasSeparation technology

The invention discloses a pre-washing technology and device used for cryogenic separation of synthesis gas. The pre-washing technology includes the steps that after the synthesis gas is pre-cooled, pre-washing is conducted through a pre-washing agent to remove unsaturated hydrocarbon and macromolecule saturated hydrocarbon, and finally purified raw material synthesis gas is obtained; the purifiedraw material synthesis gas is subjected to follow-up synthesis gas cryogenic separation; the ice point of the pre-washing agent is lower than the operation temperature of the follow-up synthesis gas cryogenic separation technology. On the basis of current methane washing, carbon monoxide washing and partial condensation synthesis gas cryogenic separation technologies, the novel pre-washing technology used for synthesis gas cryogenic separation is adopted, and unsaturated hydrocarbon and macromolecule saturated hydrocarbon in the raw material synthesis gas are removed in advance to be preventedfrom entering the downstream and blocking downstream equipment or downstream pipelines. The on-line rate of a cold box for the cryogenic separation technology is increased, and meanwhile the safety of the cold box can be improved to solve the problem that the cold box is blocked under freezing.

Owner:BEIJING PETROCHEM ENG

Whole-glass heat pipe vacuum solar collector

InactiveCN106016776ASolve freezing problemsSolar heating energySolar heat devicesEngineeringVacuum tube

A whole-glass heat pipe vacuum solar collector comprises a header and a whole-glass heat pipe vacuum solar collecting pipe with one end inserted in the header and connected with the header in a sealed manner; an inner container is arranged in the header; the whole-glass heat pipe vacuum solar collecting pipe comprises a hood glass pipe, an inner glass pipe connected in the hood glass pipe in a sleeved manner, and a condensation pipe connected in the inner glass pipe in a sleeved manner; the hood glass pipe, the inner glass pipe and the condensation pipe are each provided with a semispherical closed end and an open end; a vacuum interlayer is arranged between the hood glass pipe and the inner glass pipe; the outer wall of the inner glass pipe is plated with a solar selective absorption coating; the inner glass pipe and the condensation pipe are closed to form an evaporation segment which is filled with a heat transfer working medium; and the heat transfer work medium penetrates the pipe wall of the condensation pipe to heat water in the inner container. The whole-glass heat pipe vacuum solar collector solves the problem that because water passes through the interior of a common whole-glass vacuum pipe, damage is easily caused in winter.

Owner:SHANDONG HUAYU UNIV OF TECH

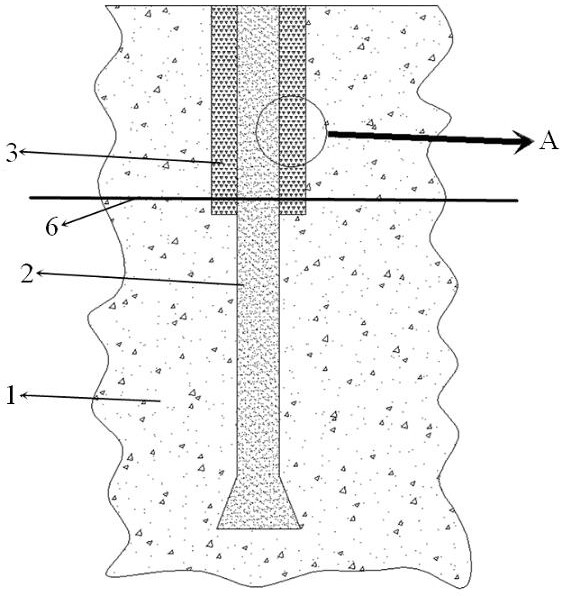

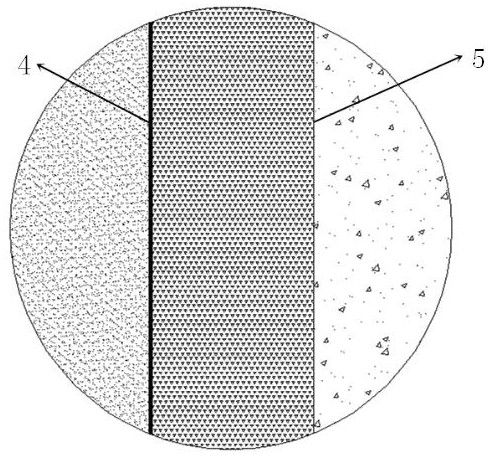

Frost-uplifting resistant structure of pile foundation in permafrost region and construction method thereof

The invention relates to a frost-uplifting resistant structure of a pile foundation in a permafrost region. The frost-uplifting resistant structure comprises the pile foundation placed in a permafrostlayer, and is characterized in that a casing is arranged on the position, at the upper limit of frozen soil, of the pile foundation, and a protective layer is arranged on the hole wall of the position, where the casing is located, of the pile foundation; and a non-frost-heaving filling material with the shrinkable volume is arranged between the protective layer and the casing. The invention further discloses a construction method of the structure. According to the frozen and uplift resistant structure, the frozen and uplift resistant effect is good, the cost is low, the construction is simple, and the problem of freezing and uplifting of the pile foundation in the permafrost region can be effectively solved.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

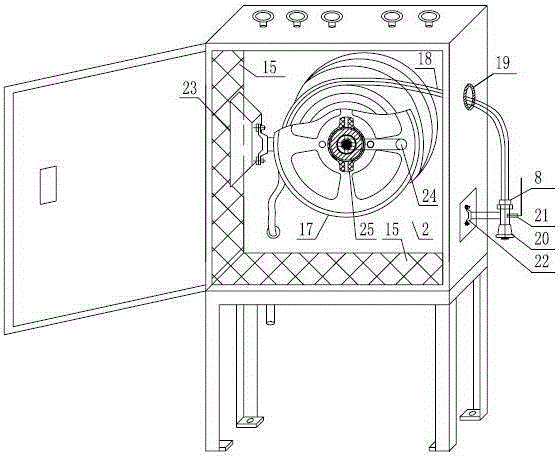

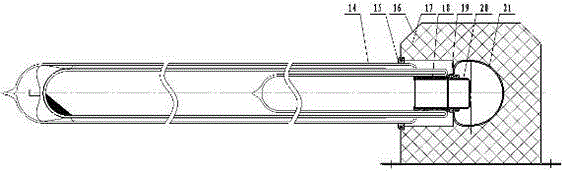

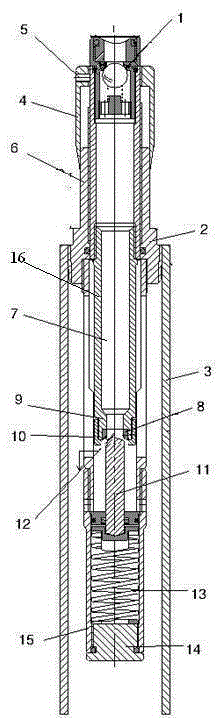

Plug-in anti-frozen-blocking casing gas recovery device

ActiveCN105257255APrevent inflowSolve the problem of heat absorptionFluid removalWell/borehole valve arrangementsElectrical conductorGas release

The invention provides a plug-in anti-frozen-blocking casing gas recovery device which comprises an oil pipe, a constant-pressure gas relief valve and a pressure conductor, wherein the lower end of the constant-pressure gas relief valve is inserted into the oil pipe; a pressure regulating cap is arranged at the upper end of the constant-pressure gas relief valve; the upper end of the pressure regulating cap is fixedly connected with the upper end of the pressure conductor; the pressure conductor penetrates through the constant-pressure gas relief valve and extends into the oil pipe; the interior at the lower end of the constant-pressure gas relief valve is sleeved by an inner pipe to form an gas inlet cavity; the upper end of the gas inlet cavity is connected with a one-way valve through a screw thread; a gas vent is formed in the lower end of the inner pipe, and communicated with the oil pipe. The device integrates the constant-pressure gas relief valve and the one-way valve, and is mounted in a wellhead oil pipe of an oil well; the constant-pressure gas relief valve can be subjected to heat tracing by virtue of crude oil heat on site, and condensation water can be discharged when the constant-pressure gas relief valve is opened for gas discharge through adoption of such a sleeving manner that the valve seat is mounted above a relief piston, so that the problems of heat absorption during gas relief and frozen-blocking in winter can be completely solved; meanwhile, the one-way valve can prevent crude oil from flowing into a casing pipe.

Owner:PETROCHINA CO LTD

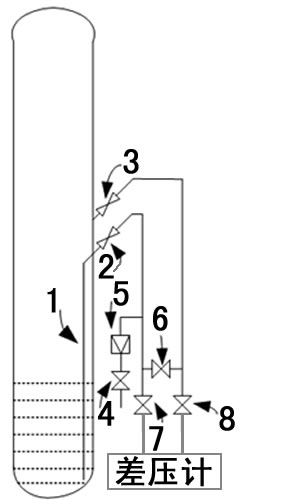

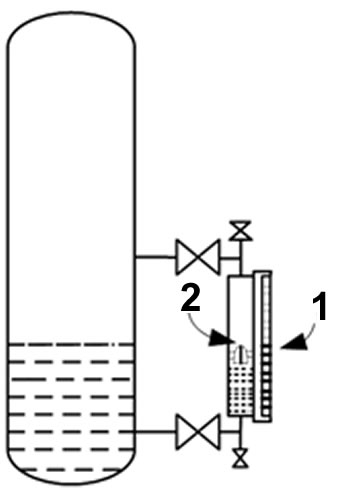

Measured medium flowing type anti-freezing liquidometer device

ActiveCN102338650ASolve the freezing problemSolve freezing problemsMachines/enginesLubrication indication devicesAnti freezingEngineering

The invention belongs to the technical field of metering and particularly relates to a measured medium flowing type anti-freezing liquidometer device. On the basis of the conventional glass tube type liquidometer or the conventional magnetic turning column type liquidometer, a negative pressure guide tube of the liquidometer extends into a container of equipment; and an air guide tube (3), a flowlimiting tube (4), a receiving disk (5) and the like are added. The measured medium flowing type anti-freezing liquidometer device is characterized in that: a medium in the container of the equipmentis always in a flowing state in the liquidometer; and the problems of freezing and blocking of the liquidometer in winter can be solved.

Owner:CHINA PETROLEUM & CHEM CORP

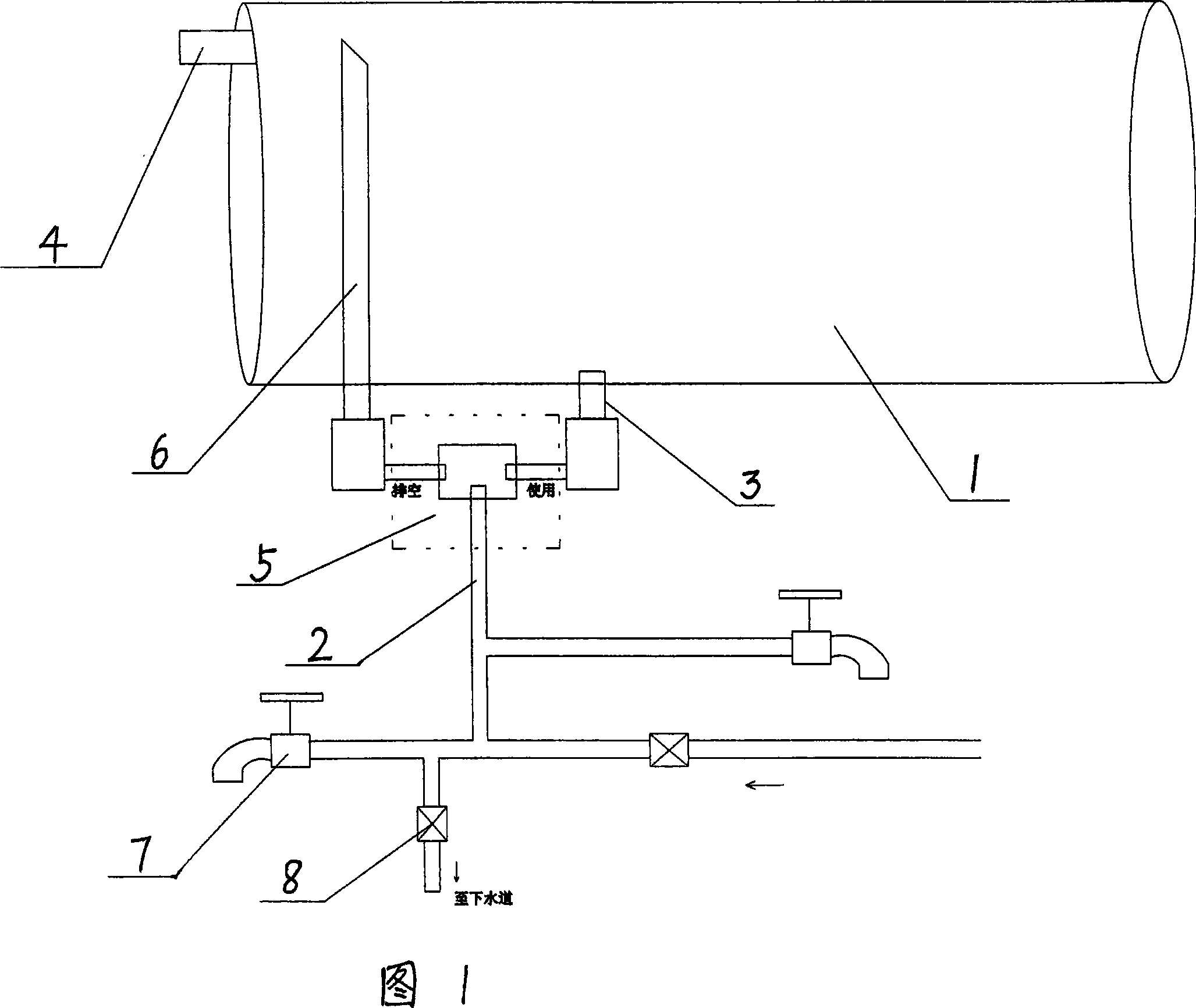

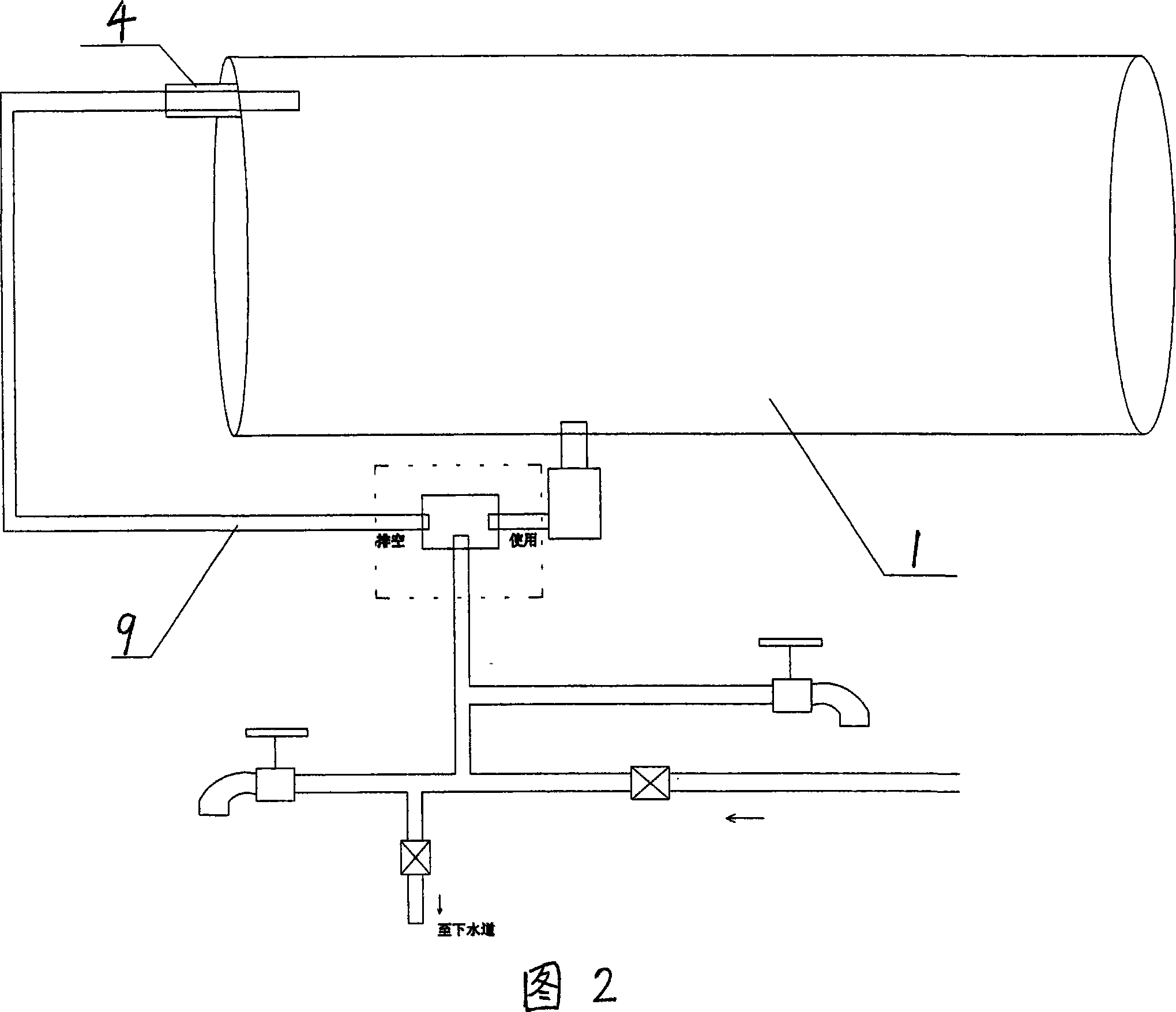

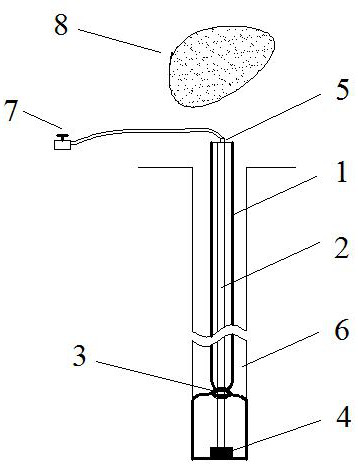

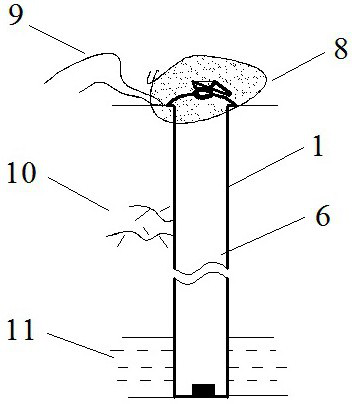

Intelligent exhaust water takeout device for solar water heater

InactiveCN101074788ASolve freezing problemsSolar heat devicesDomestic hot-water supply systemCold winterSolar water

The invention discloses a solar water heater for the water emptying intelligent devices. It includes storage tank (1), main pipeline (2), as well as linking hose (3), linking hose (3) connect with the bottom of storage tank (1), on the side of storage tank (1) a meeting has a stomata ( 4), referred to the water emptying device fixing with three and two valve (5), the end of three and two valve (5) is connected with trachea (6), the top of trachea (6)is higher than the maximum surface location of storage tank (1),and the other end connects linking host(3),another end connects the top of the main pipeline(2). Because the invention can guarantee inlet and outlet pipe road is completely drained, intelligent controlled can be achieved, a good solution to the freezing cold winter plugging the pipeline, also make full use of the thermal water emptying in the pipeline.

Owner:江苏光芒新能源股份有限公司

Method for preventing blast hole from freezing

PendingCN112378301ASolve the technical problems of frozen icePrevent flowBlastingRubber materialRubber ring

The invention discloses a method for preventing a blast hole from freezing. Based on the principle, after each blast hole is drilled, the blast hole is immediately subjected to full-closed treatment by using a closed barrel, so that an external water source and air cannot enter the blast hole. The general method comprises the following steps that firstly, a cylindrical closed barrel made of a rubber material, wherein the diameter is smaller than that of a blast hole; an inflation connector is installed at one end of a high-pressure-resistant high-strength hose with the diameter of 2 cm, a guide balance lead block is installed at the other end of the high-pressure-resistant high-strength hose, then the hose penetrates into the closed barrel and is fixed, and the end of the guide balance lead block is fixed to the bottom of the closed barrel; a damping rubber ring is prepared, and the damping rubber ring is arranged at the position, above the guide balance lead block, of the closed barrel in a sleeving mode; the blast hole is cleaned after being drilled; then, the closed barrel is led into the blast hole, uniform-speed inflation is conducted, the closed barrel expands to reach a holeopening, and the closed barrel is clamped through calipers; and a plastic sand bag is used for pressing the hole opening, and then full-closed treatment of the blast hole is completed. According to the method, a water source causing blast hole freezing can be effectively blocked, and the technical problem of blast hole freezing in blasting construction in plateau alpine regions is fundamentally solved.

Owner:LIAONING INST OF SCI & TECH

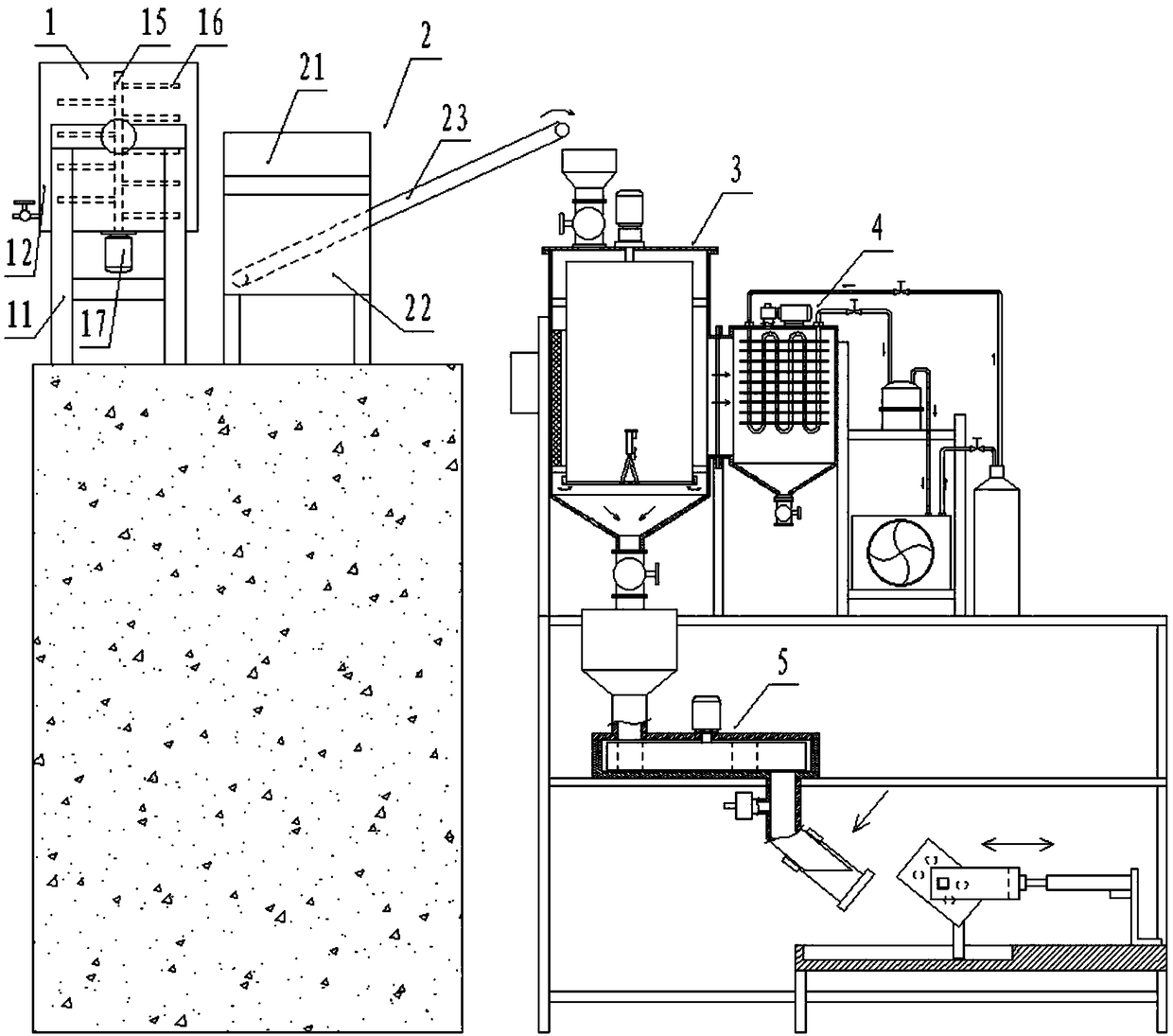

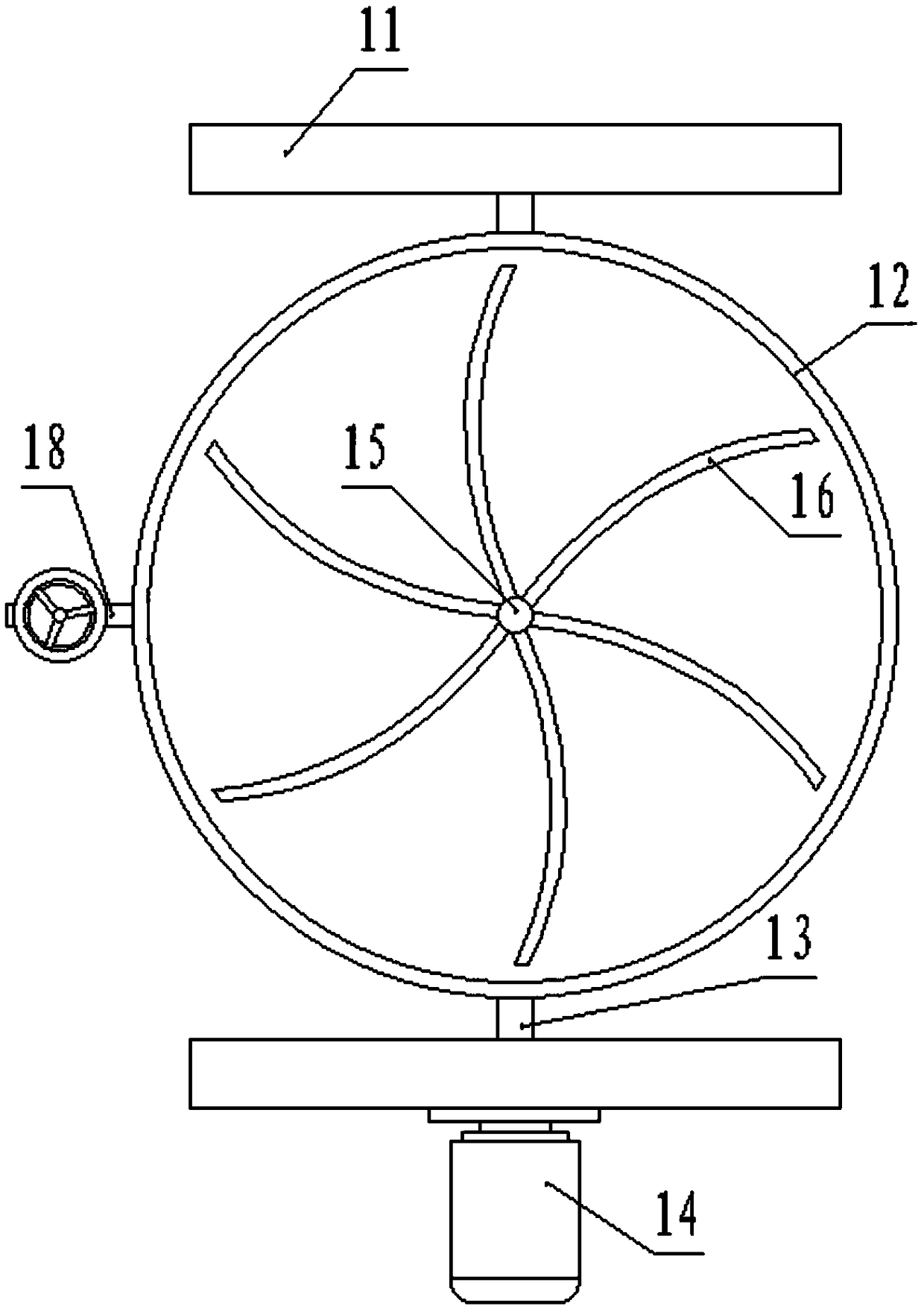

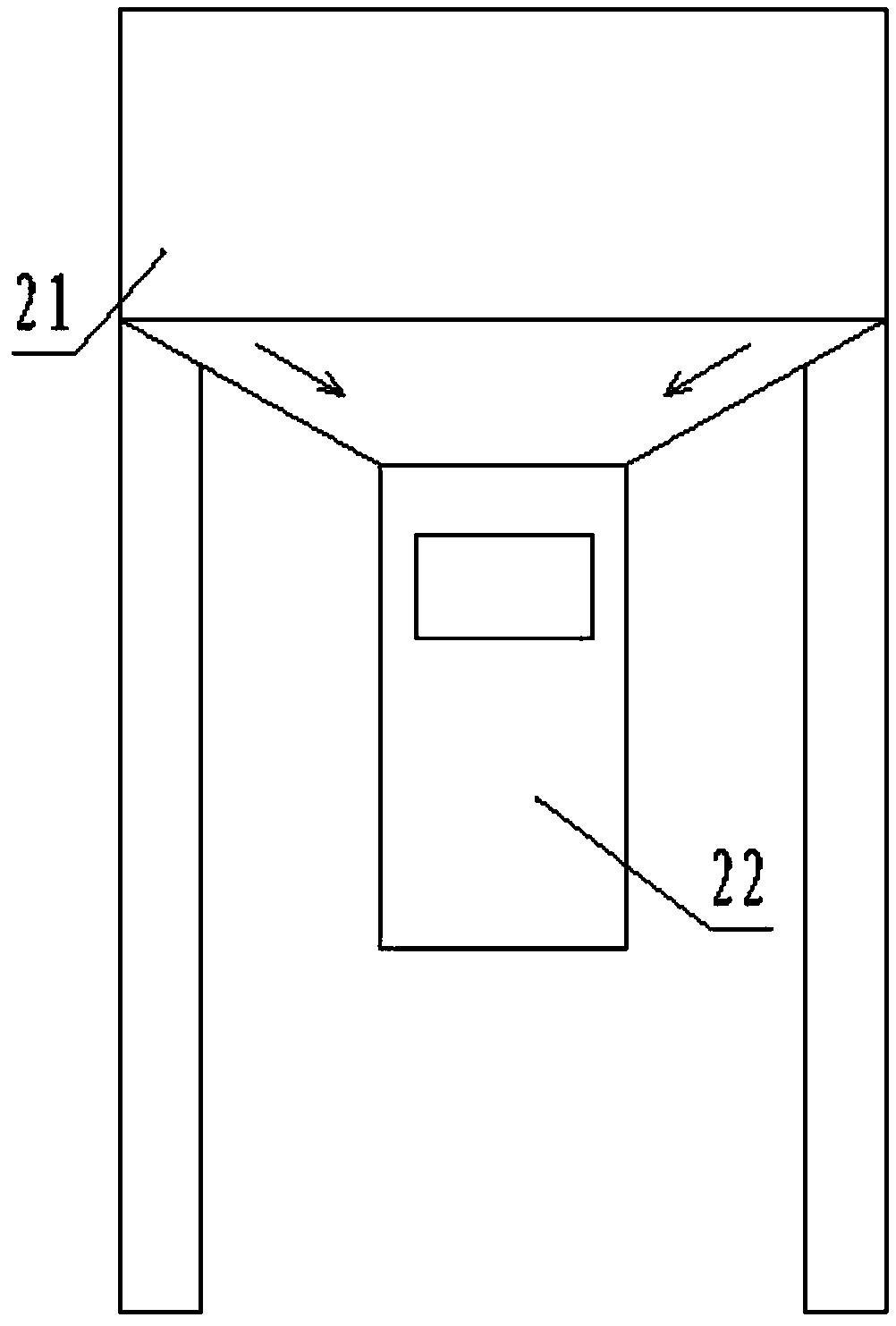

Processing comprehensive treatment equipment for tetrastigma hemsleyanum diels et gilg tea

The invention discloses processing comprehensive treatment equipment for tetrastigma hemsleyanum diels et gilg tea. The processing comprehensive treatment equipment comprises a cleaning device, a conveying device, a drying device, a freezing device and a packaging device; tetrastigma hemsleyanum diels et gilg is cleaned in a cleaning barrel on the cleaning device by stirring; after cleaning through the cleaning barrel, materials are poured to the conveying device; the drying device comprises a drying outer barrel and a drying inner barrel, the drying inner barrel is used for freezing and drying the tea and meanwhile facilitating feeding and discharging, the drying outer barrel communicates with the freezing device and is used for providing the negative pressure environment and the sublimation temperature and meanwhile capturing sublimed moisture; and the packaging device controls the tea amount intermittently through a packaging rotating disc in the packaging device and conducts vacuumizing packaging sealing. According to the processing comprehensive treatment equipment for the tetrastigma hemsleyanum diels et gilg tea, pesticide residue on the surface of tea leaves is removed through the cleaning device, feeding is achieved through the conveying device, the loss of heat sensitive substances in the tetrastigma hemsleyanum diels et gilg tea is reduced by the drying device through low-pressure freezing, and the packaging device conducts quantitative and vacuum bagging treatment on the tetrastigma hemsleyanum diels et gilg tea.

Owner:赵小林

Intelligent well opening heating switch pressure adjusting system

InactiveCN111980625ALow costSave normal production timeInsulationWell/borehole valve arrangementsFlow transducerTerminal equipment

The invention discloses an intelligent well opening heating switch pressure adjusting system. The system comprises a power supply system, a control room operation control platform and a needle valve;the power supply system is electrically connected with the control room operation control platform, the needle valve and a 4G communication and remote terminal unit respectively; the control room operation control platform communicates with the needle valve via the 4G communicate and remote terminal unit; a needle valve controller, an electromagnetic heating controller and an electromagnetic heater are fixedly installed on the needle valve; the needle valve controller is electrically connected with a casing pressure transducer, an oil pressure transducer, a flow transducer and a pipe pressuretransducer respectively; and the electromagnetic heating controller is electrically with a temperature transducer and the electromagnetic heater respectively. The system is scientific and reasonable in structure, convenient and reliable to use and suitable for promotion and use.

Owner:盘锦华晨石油装备制造有限公司

Device for preventing blast hole from freezing

The invention discloses a device for preventing a blast hole from freezing. The device is composed of a sealing barrel, an inflation hose, a damper, a guide balance lead block, an inflation connector,a magnetic attraction connector, a safety rope, a tightening bag and a sealing sand bag. When the device is used, the device is straightly placed into the blast hole to be sealed, then constant-speedinflation is conducted, inflation is stopped after the volume of the sealing barrel is expanded to exceed the opening of the blast hole by 5-10 cm, the sealing barrel is clamped through calipers, then the sealing sand bag is pressed at a hole opening of the blast hole, and then the whole sealing treatment of the blast hole is completed. At the moment, the sealing barrel is tightly attached to thehole opening, the hole bottom and the whole peripheral wall of the blast hole, external surface water, rock mass crack water, rock mass seepage water and other water sources and air cannot enter theblast hole, and ice cannot be frozen naturally when no water exists. When the blast hole is filled with powder, the sealing sand bag is removed, and the sealing barrel is taken out for powder fillingoperation. According to the device, the blast hole can be sealed in an omnibearing manner, a water source causing blast hole freezing is effectively blocked, and the technical problem of blast hole freezing in blasting construction in plateau alpine regions is fundamentally solved.

Owner:LIAONING INST OF SCI & TECH

Anti-freezing device of closed cooling tower

PendingCN114018071ASolve freezing problemsSimple structureTrickle coolersWater circulationEngineering

The invention discloses an anti-freezing device of a closed cooling tower. The anti-freezing device comprises a cooling tower radiator coil tube, and further comprises a cooling water circulating device, an anti-freezing solution circulating device and a purging device, wherein the cooling tower radiator coil tube is connected with the cooling water circulating device through a circulating water pipeline, the cooling tower radiator coil tube is connected with the anti-freezing solution circulating device through an anti-freezing solution pipeline, the purging device is connected with the cooling water circulating device through an anti-freezing solution pipeline, and the purging device is connected with the circulating water pipeline and the anti-freezing solution pipeline through purging pipelines. According to the invention, the anti-freezing requirement of a copper coil pipe in the closed cooling tower in winter can be effectively met.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Heating constant-temperature system for hot water pipeline

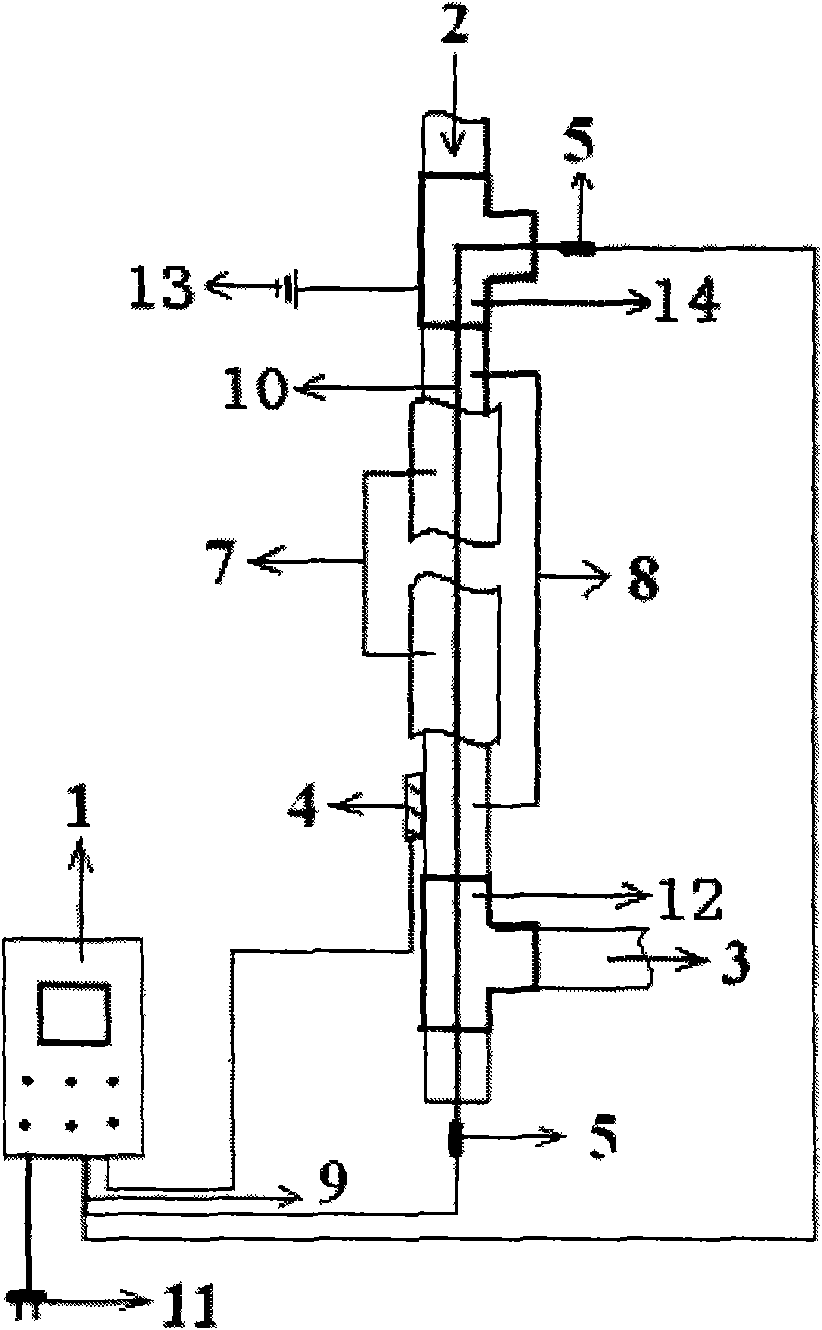

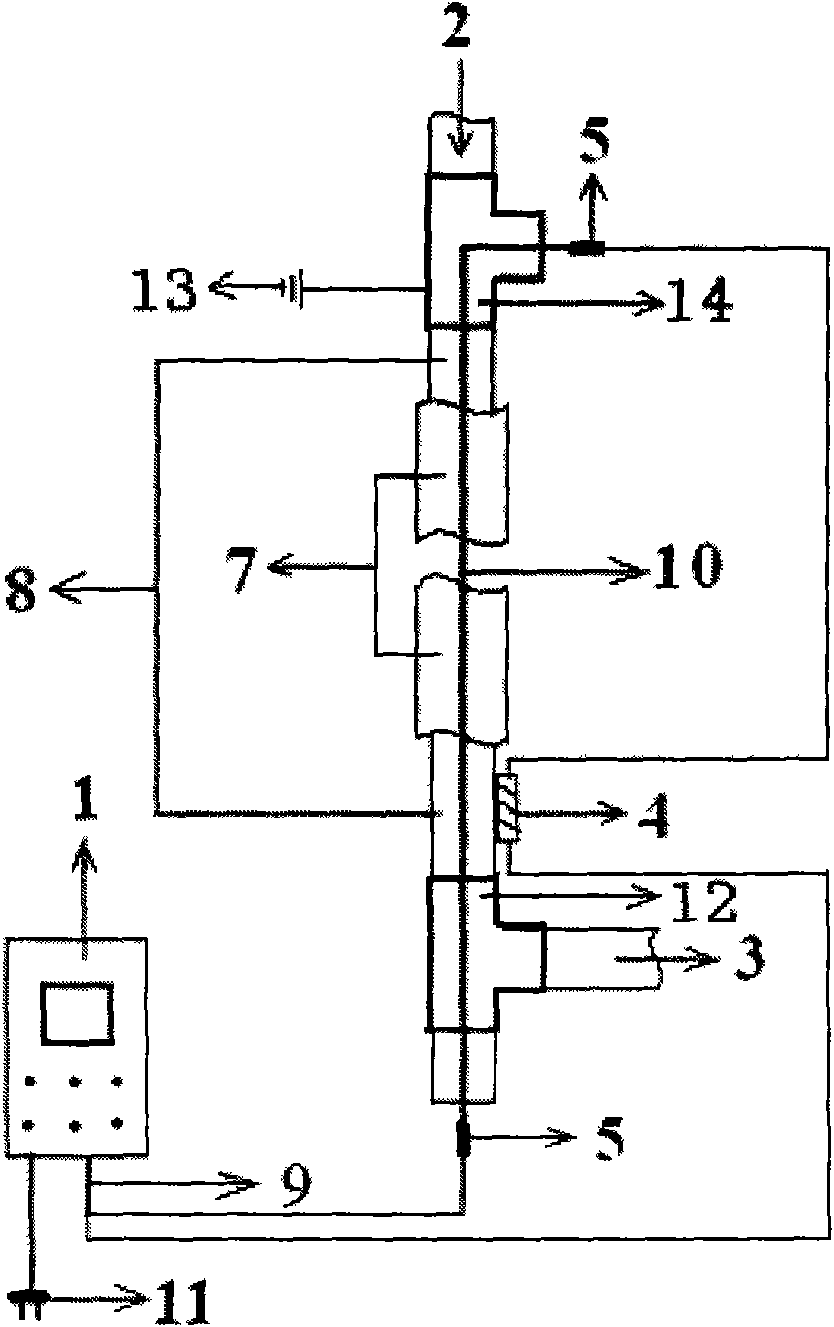

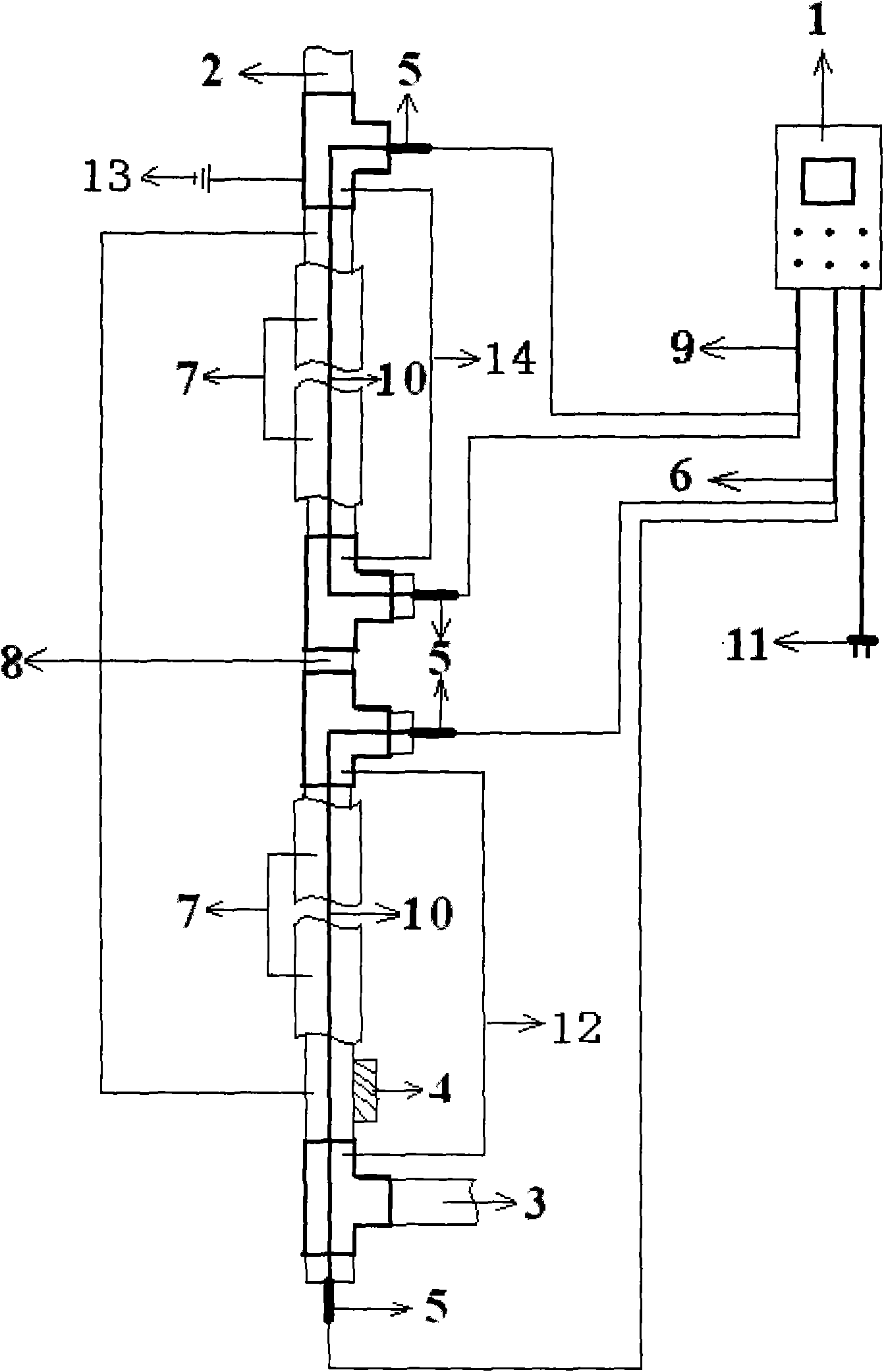

InactiveCN101886842ASolve freezing problemsConstant water temperatureWater heatersSolar waterSmart control

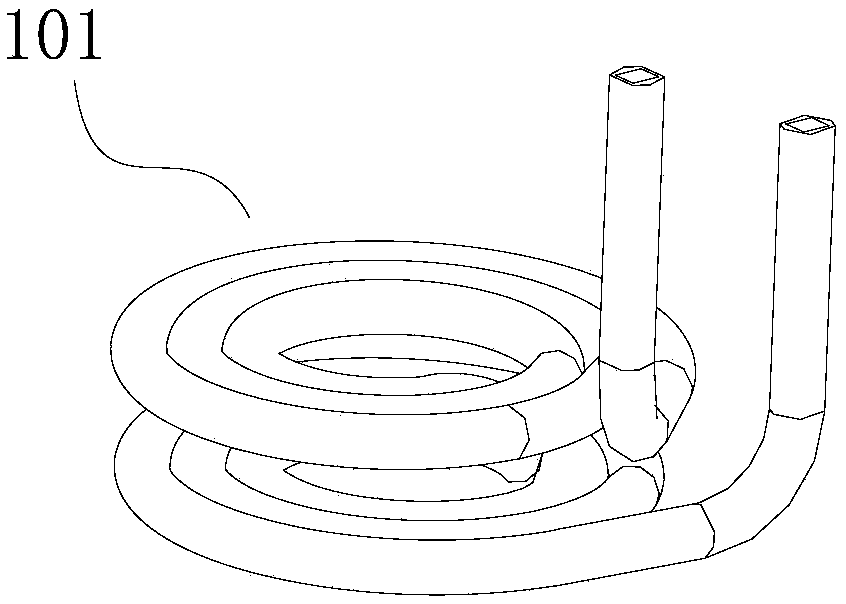

The invention discloses a heating constant-temperature system for a hot water pipeline, which mainly comprises an intelligent controller 1, a water inlet 2, a water outlet 3, a temperature sensor or a temperature control switch 4, a binding post 5, a heat preservation pipe 7 of the hot water pipeline, a hot water pipeline 8, power leads 6 and 9 of an insulating heating wire, an insulating heating wire 10, tee joints 12 and 14, a power line 11 of the intelligent controller and a ground wire 13. The intelligent controller 1 is mutually connected with the insulating heating wire 10, the temperature sensor or the temperature control switch 4, the binding post 5 and the power leads 6 and 9; and the hot water pipeline 8 is mutually communicated and connected with the tee joints 12 and 14, the water inlet 2 and the water outlet 3 respectively. The temperature sensor or the temperature control switch 4 is arranged at any place of the hot water pipeline 8; the heat preservation pipe 7 is sleeved outside the hot water pipeline 8; and the ground wire 13 is connected with the tee joint 12 or the tee joint 14. The heating constant-temperature system for the hot water pipeline mainly solves the problem that once the hot water stops flowing in the hot water pipeline for a period of time, the temperature of the hot water in the hot water pipeline drops as the temperature-constant effect of the hot water pipeline is unsatisfactory, and particularly in a solar water heater / solar water heating system, the hot water pipeline made of a plastic material can be blocked or even frozen and cracked in the cold weather in the conventional hot water pipeline.

Owner:周强高

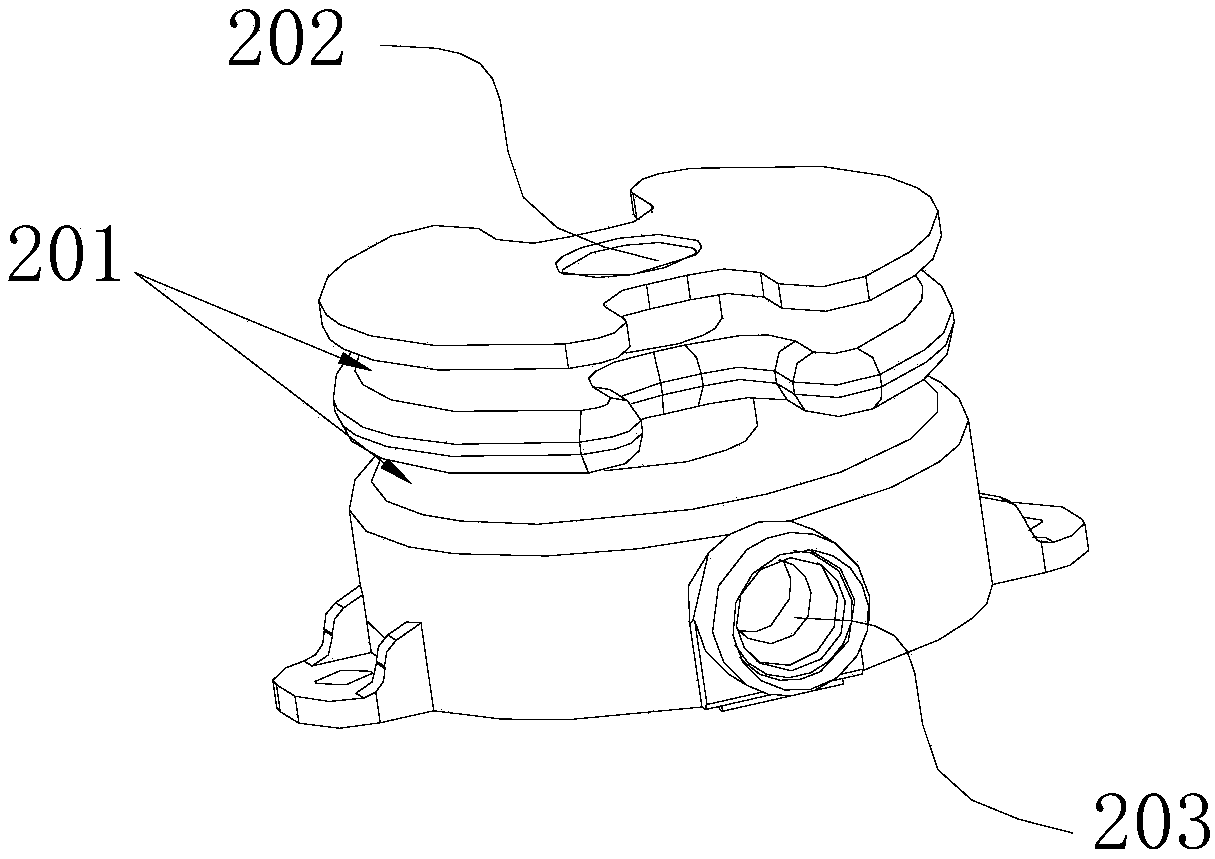

Water pump anti-freezing device of air conditioning unit and anti-freezing water pump

PendingCN109405257APrevent freezingEfficient dischargeCondensate preventionPump componentsImpellerAnti freezing

The invention relates to a water pump anti-freezing device of an air conditioning unit and an anti-freezing water pump. The anti-freezing device comprises a heat exchange pipe, an air inlet pipe and an air outlet pipe, wherein the heat exchange pipe winds around a water pump, one end of the heat exchange pipe is connected with an exhaust end of a compressor of the air conditioning unit through theair inlet pipe, and the other end of the heat exchange pipe is connected with an air suction end of the compressor of the air conditioning unit through the air outlet pipe. The device can solve the problem that a water pump impeller is frozen in a low-temperature severe environment, the normal operation of an air conditioner heating mode is guaranteed, and water generated in a defrosting and deicing process can be effectively discharged in time; and a branch pipe flows through a water pump port from a high-temperature high-pressure part of a refrigerant circulation system, the internal energyof the air conditioning unit is well utilized, no extra heating unfreezing device is added, the structure of the air conditioning unit is slightly changed, the machining is simple, and the cost is low.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com