Method for preventing blast hole from freezing

A blasthole and orifice technology, which is applied in the field of engineering blasting construction, can solve the problems of not fundamentally solving the problem of freezing of blastholes, failure to solve the problem of freezing of blastholes, and difficulty in implementing blastholes, etc., to achieve the solution of freezing of blastholes, The effect of simple structure and small labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

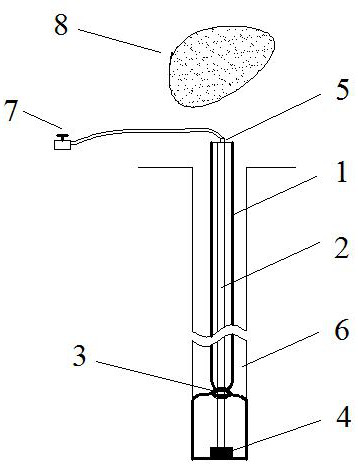

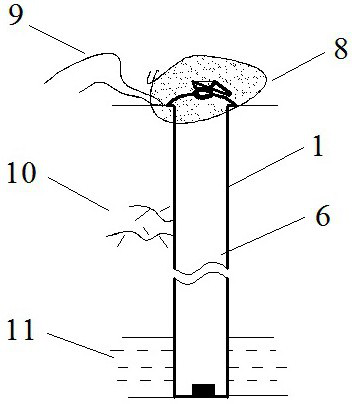

Image

Examples

Embodiment Construction

[0011] Taking the open-pit blasting construction at an altitude of about 5,270 meters in a plateau high-altitude area as an example, the specific working conditions are: the rock mass joints and fissures in the blasting area are relatively developed, and the rock's Platts coefficient is f=6-10. The hole diameter is 120mm, the hole depth is 14.5m, the hole distance is 6 meters, the row distance is 4.5 meters, the holes are arranged in a triangle, the filling height is 4.5-5 meters, the plateau type emulsion explosive is used, the ordinary plastic nonel millisecond delay detonator is used, and the average explosive unit consumption is 0.40kg / m 3 about. The freezing situation is that after one or a few days after drilling all the blastholes in the blast area, the phenomenon of freezing will appear in the hole when the powder is charged. Ice, and in severe cases, almost the entire borehole in the blast zone is frozen. Illustrate the concrete method of the present invention with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com