Semiconductor device and method for manufacturing same

一种半导体、器件的技术,应用在半导体器件及其制造领域,能够解决难以具有较大截面积等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

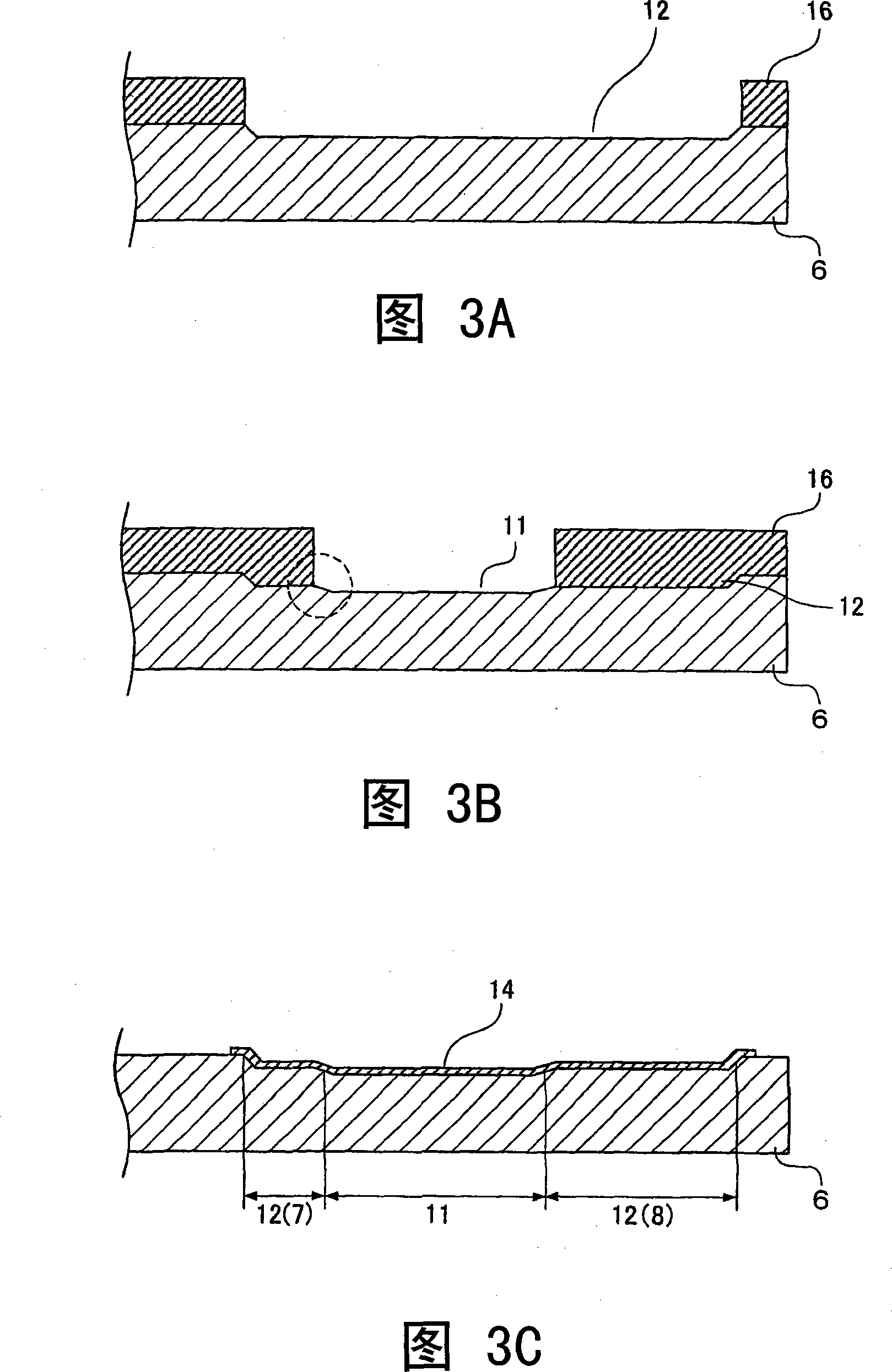

[0040] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

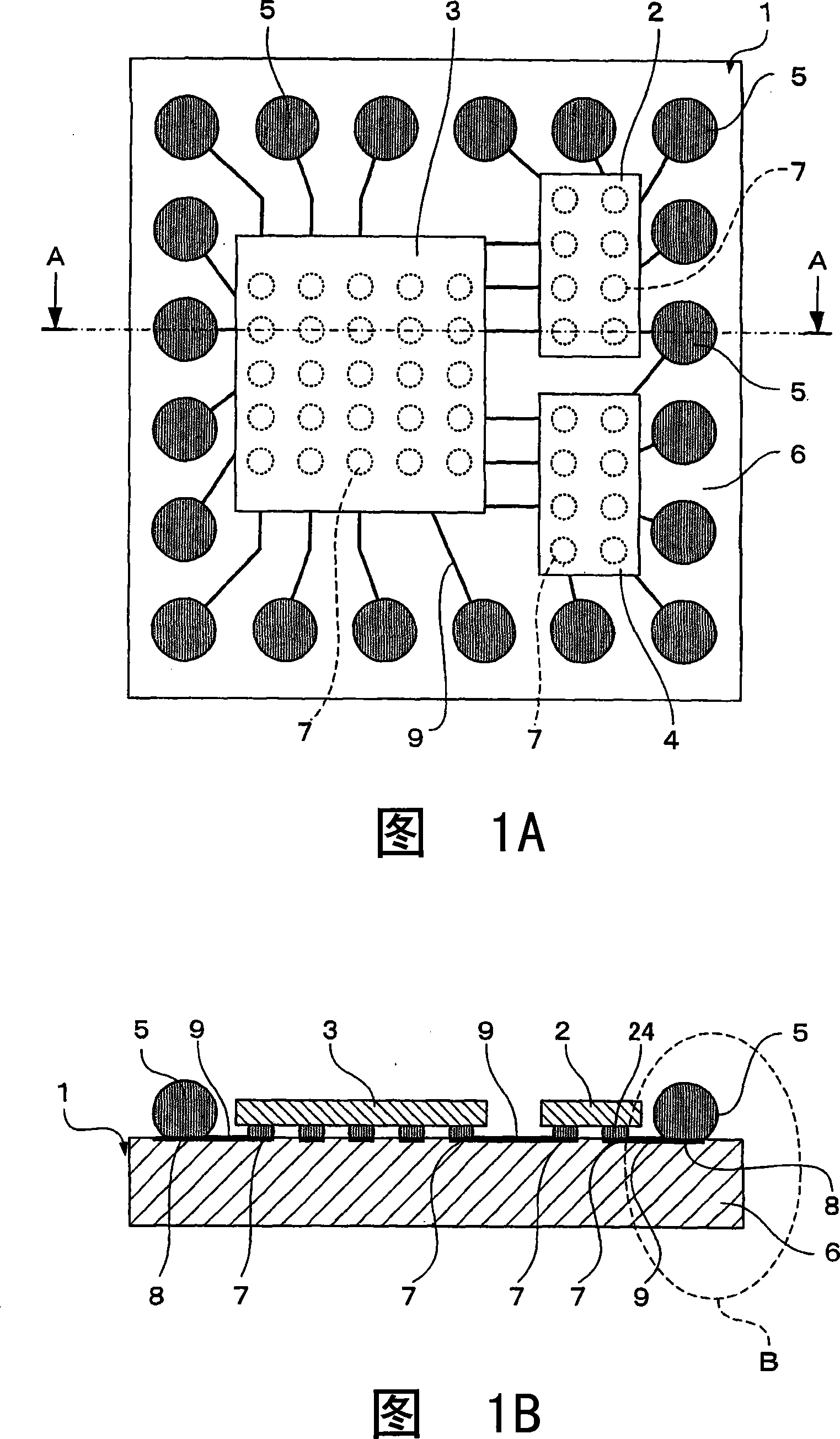

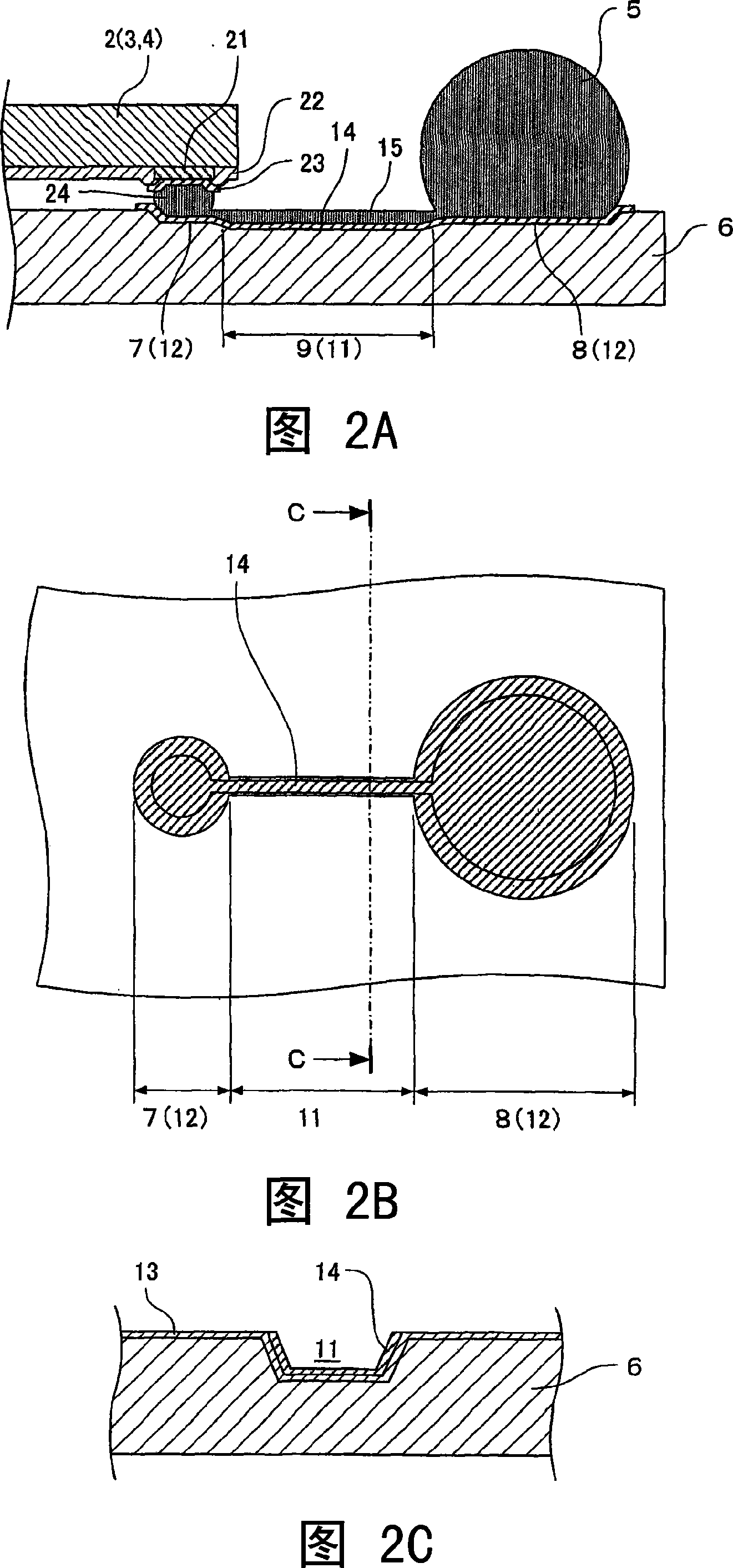

[0041] The semiconductor device shown in Fig. 1 and Fig. 2 has: wiring substrate 1; IC chips 2, 3, 4; Understand that shown is less than actual).

[0042] The structure of the wiring substrate 1 is that, on the surface of the silicon wiring substrate 6, there are a plurality of connection terminals 7 arranged in the central region, a plurality of external connection terminals 8 arranged in the peripheral region, and connections between the connection terminals 7 and the outside. The conductor wiring 9 to which the terminal 8 is connected. The plurality of connection terminals 7 are arranged in three predetermined areas on the wiring board 1, and the IC chips 2, 3, and 4 are mounted in the respective areas. The aforementioned solder balls 5 are formed on the external connection terminals 8 .

[0043] Here, the wiring board (hereinafter referred to as silicon wiring bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com