Carbon dioxide foam injecting device of oil well

A carbon dioxide, injection device technology, used in mixers with rotary stirring devices, transportation and packaging, wellbore/well components, etc. Low problems, to achieve the effect of novel structure, guaranteed foaming performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

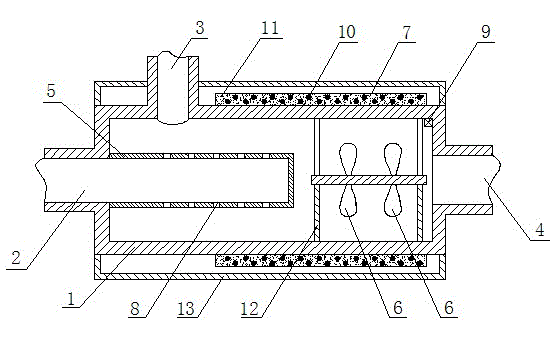

[0011] Attached below figure 1 To the oil well carbon dioxide foam injection device of the present invention, be further explained:

[0012] The oil well carbon dioxide foam injection device of the present invention is composed of a cylinder body 1, a carbon dioxide inlet 2, a dosing port 3 and a mixed liquid outlet 4, and one end of the cylinder body 1 is provided with a carbon dioxide inlet 2, and the other end is provided with a mixed liquid outlet 4 A dosing port 3 is provided on the side wall of the cylinder body 1 near the end of the carbon dioxide inlet 2; the carbon dioxide inlet 2 in the cylinder body 1 is connected to the spray pipe 5, and the spray pipe 5 is densely covered with spray ports 8, so that the liquid carbon dioxide can be sprayed. Effect.

[0013] A stirring paddle 6 is arranged on the fixed frame 12 in the space between the spray pipe 5 and the mixed liquid outlet 4 . The stirring paddle fully stirs the foaming agent entering the dosing port and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com