Patents

Literature

36results about How to "Guaranteed foaming effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

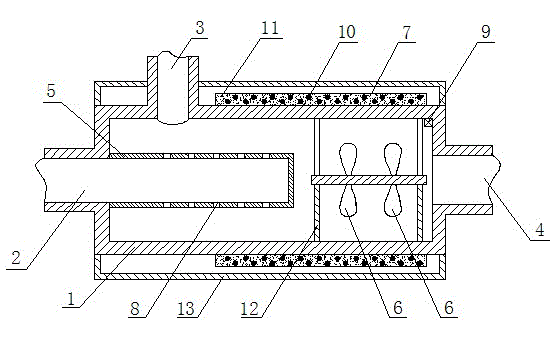

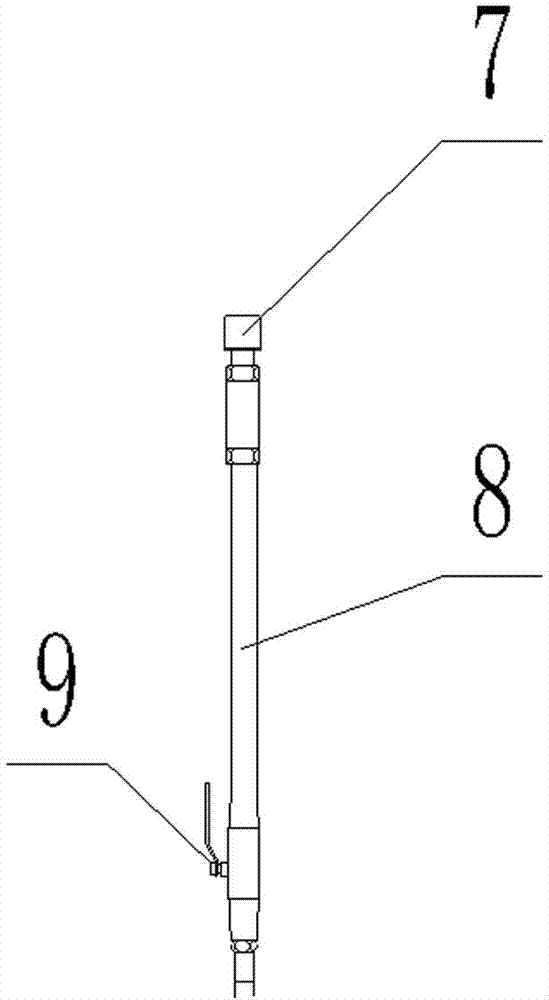

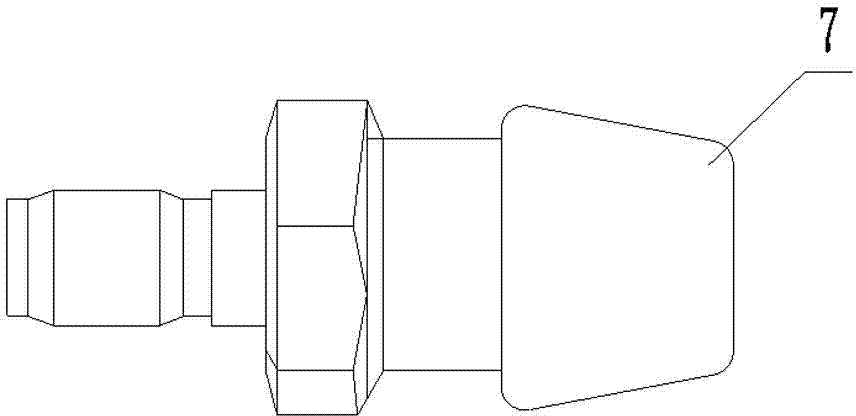

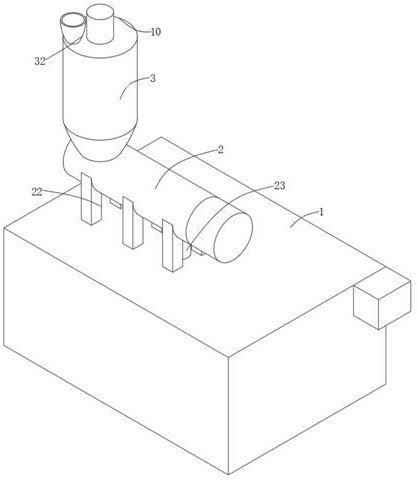

Carbon dioxide foam injecting device of oil well

ActiveCN102747996ASolve freezing problemsGuaranteed foaming effectFlow mixersRotary stirring mixersTemperature controlAutomatic control

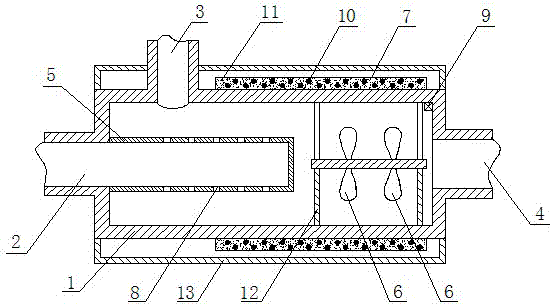

The invention provides a carbon dioxide foam injecting device of an oil well and relates to a mechanical device in an oil mine field. The carbon dioxide foam injecting device is composed of a cylinder body, a carbon dioxide inlet, a dosing port and a mixed liquid outlet. One end of the cylinder body is provided with the carbon dioxide inlet, the other end of the cylinder body is provided with the mixed liquid outlet, a side wall at one end of the cylinder body close to the carbon dioxide inlet is provided with the dosing port. The carbon dioxide inlet in the cylinder body is connected with a spraying pipe, and a stirring paddle is arranged on a fixing frame from the spraying pipe to a mixed liquid outlet space. The carbon dioxide foam injecting device of the oil well is novel in structure, low in construction cost and high-pressure-resisting, the cylinder body is made of stainless steel, and the material is OCr18Ni9 and can bear pressure of 25 MPa. Efficient flame retardant crystallized magnesium oxide is filled in a heater, an electric heat tracing band can heat a system at the temperature of 0-150 DEG C, and a temperature sensor externally-connected temperature control cabinet performs automatic control to a working state of an electric heating pipe. The carbon dioxide foam injecting device solves the problem of frozen blocking in the carbon dioxide foam oil-displacement process and effectively ensures the foaming performance of a carbon dioxide foam system.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

Spray hard phenolic foam

InactiveCN102268172ASmooth surface High tensile strengthHigh compressive strengthFireproof paintsPhenolformaldehyde foamPolymer science

The invention discloses a hard phenolic foam composition, a sprayed hard phenolic foam coating, a preparation process and an application. The rigid phenolic foam composition is obtained by mixing composite phenolic resin and mixed acid in a mass ratio of 1-10:1. The above-mentioned hard phenolic foam composition is completely atomized and mixed uniformly at a pressure of 100-200kg and a temperature of 20-50°C, sprayed from a spray gun, and evenly sprayed on the wall to form a spray-coated hard phenolic foam Insulation. The obtained spraying hard phenolic foam coating can be applied to the field of waterproof, fireproof or thermal insulation materials.

Owner:田瑞军

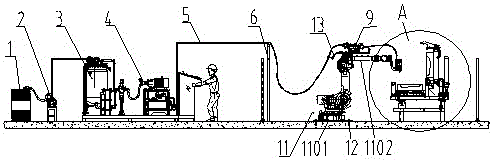

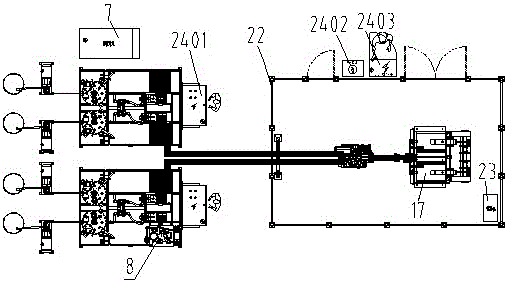

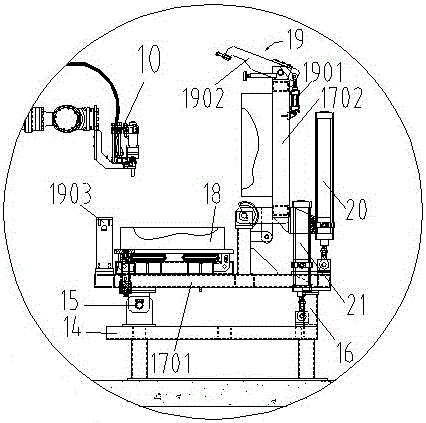

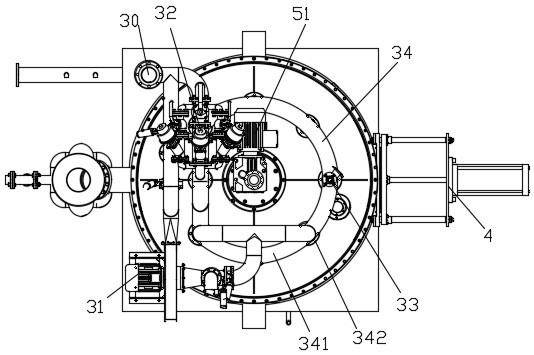

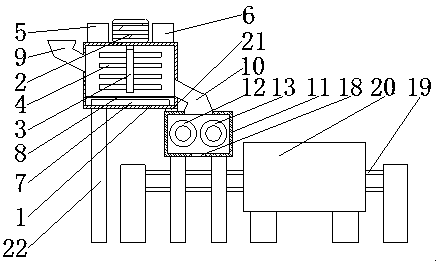

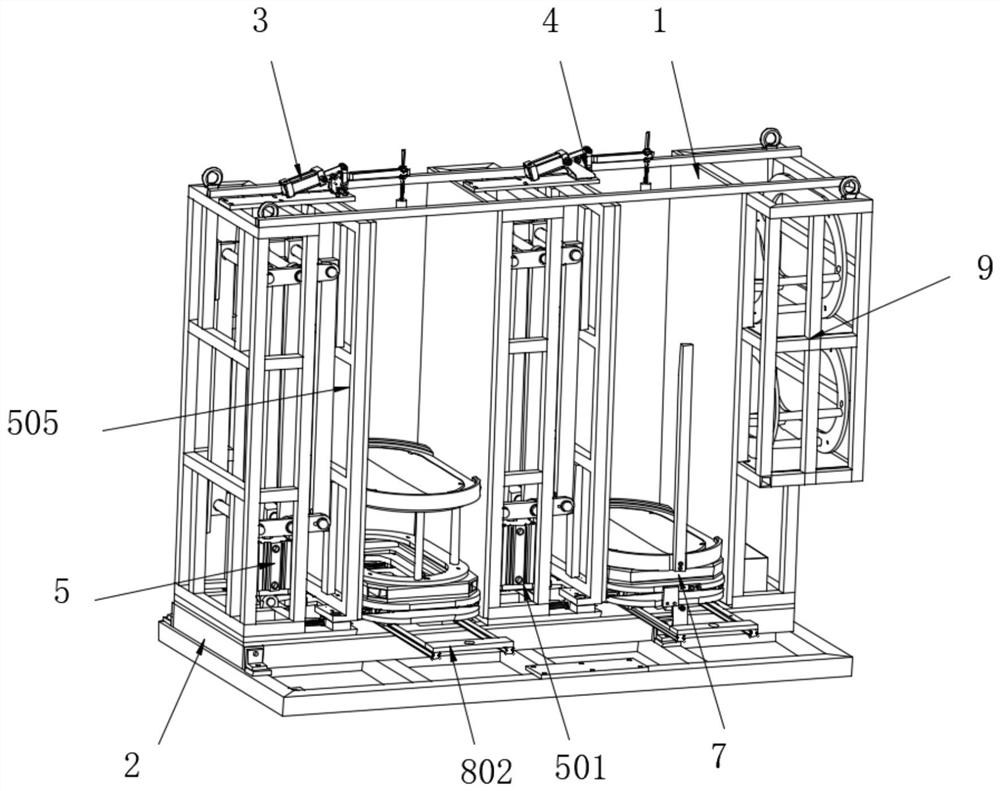

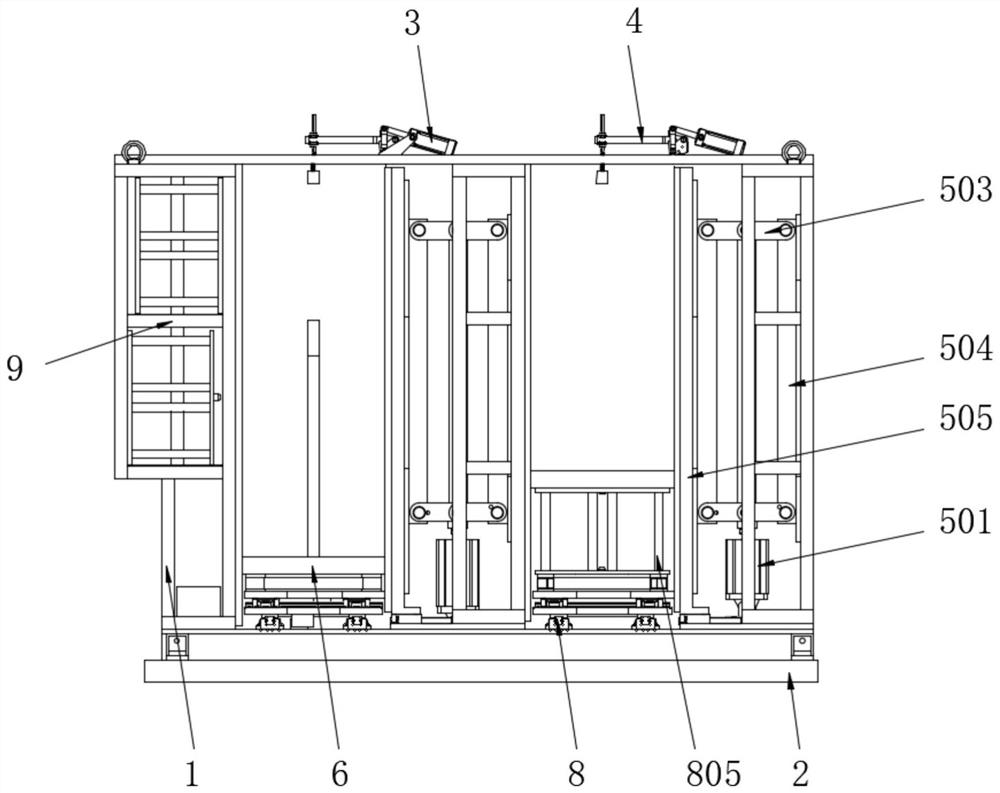

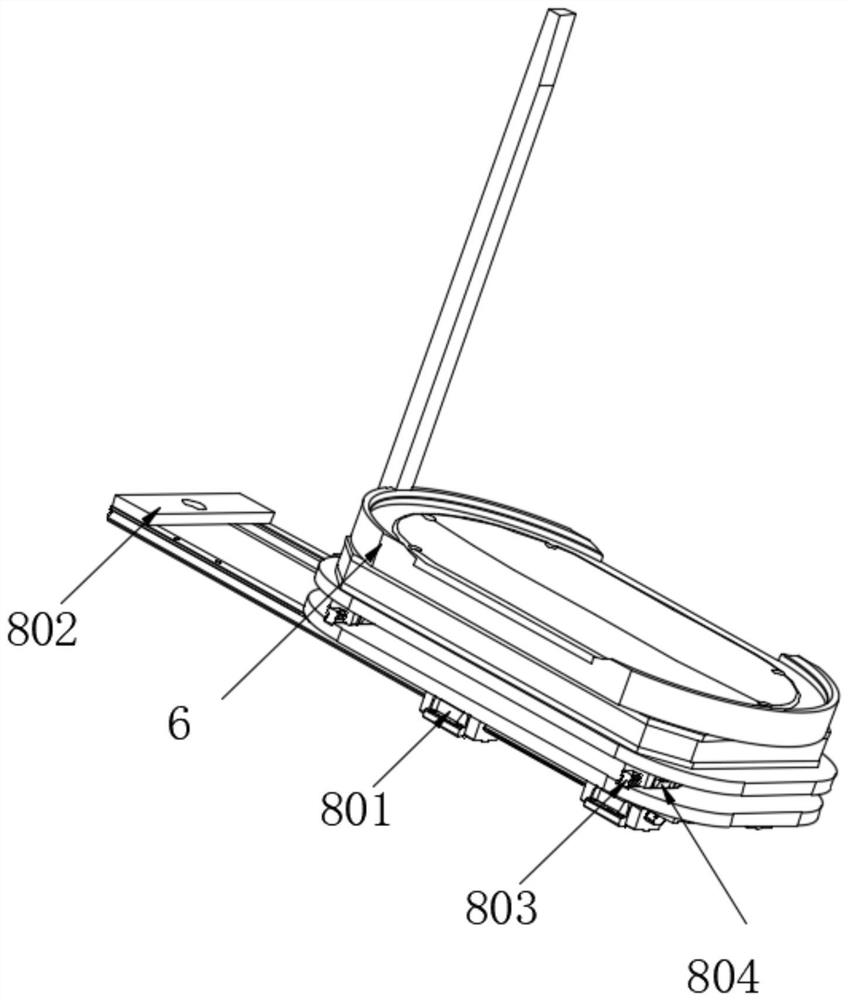

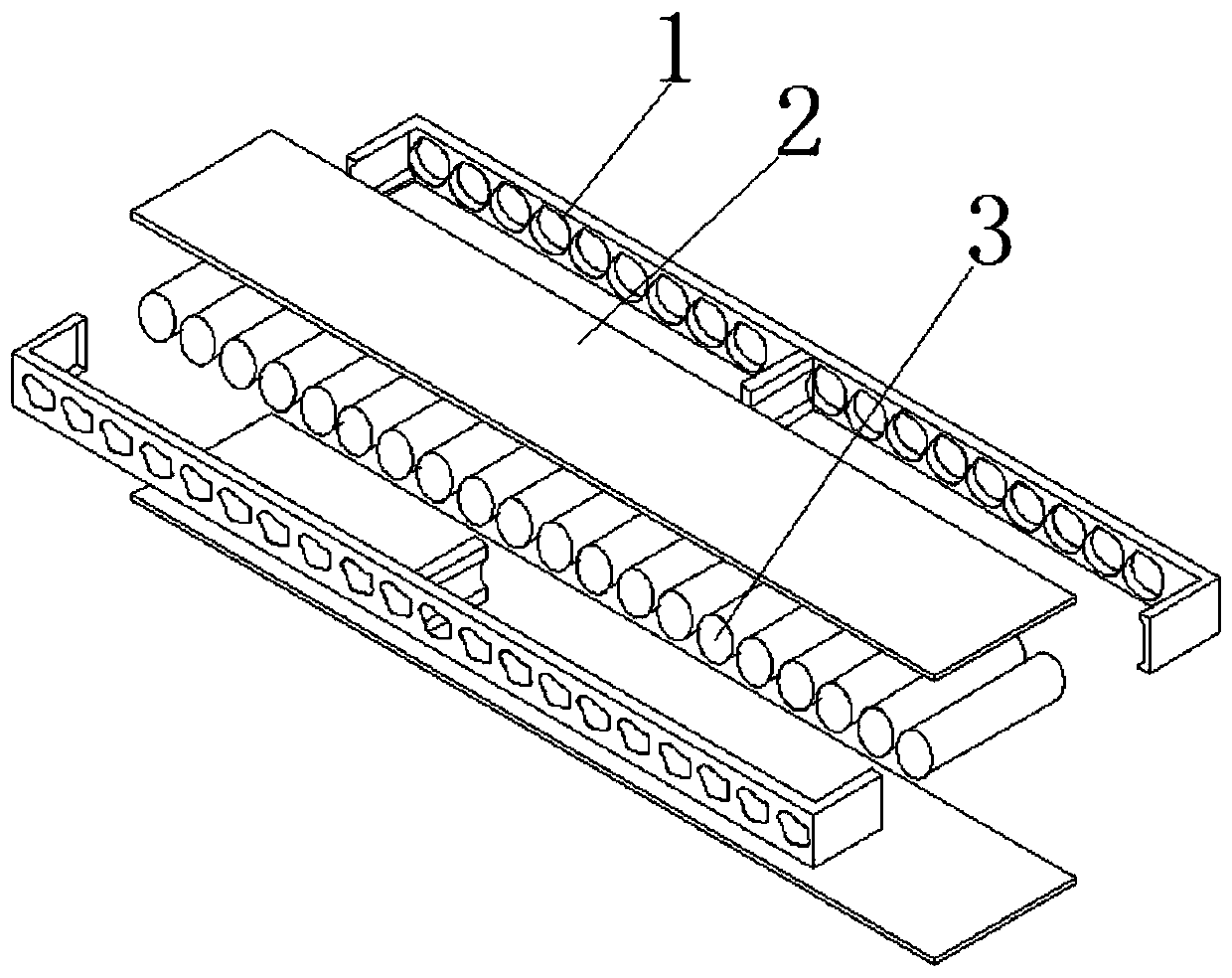

Auto pillow foaming experiment line

PendingCN106738579AGuaranteed foaming effectShorten the trial production cycleDomestic articlesProduction lineRobotic arm

The invention relates to the field of auto pillow production lines, in particular to an auto pillow foaming experiment line which is characterized by comprising a two-component high-pressure foaming machine of a foaming material, a manipulator for adjusting a filling position, a foaming die set for shaping the foaming material, a safety device for safety protection, and an electric control system for controlling operation of the experiment line, wherein the safety device is arranged around the manipulator and the foaming die set; the electric control system is arranged on one side of the safety device; the two-component high-pressure foaming machine comprises a raw material barrel, a feeding pump, a raw material tank, a metering unit, a connecting pipeline, a mixing head control valve bank and a mixing head sequentially connected; the manipulator comprises a base arranged on the ground and a manipulator arm arranged on the base; and the foaming die set comprises a die set support, a die set, a die-sinking and die-assembling air cylinder and a foaming die. The auto pillow foaming experiment line can shorten the trial production period of new products of an auto pillow and reduces the cost.

Owner:WUHAN ZHENGWEI MACHINERY

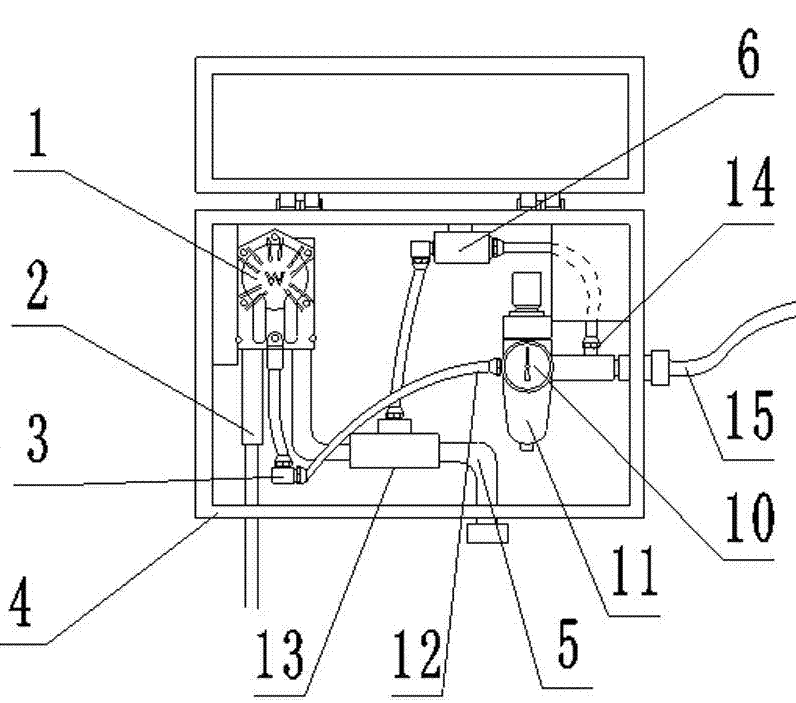

Novel bubble spraying machine and disinfecting method thereof

InactiveCN104492626AAvoid safety hazardsImprove securityLiquid spraying apparatusDiaphragm pumpSpray nozzle

The invention discloses a novel bubble spraying machine and a disinfecting method thereof. An air source is connected with a pressure stabilizing valve through a branch air outlet pipe, the branch air outlet pipe is connected with a gas-liquid mixing pump through a branch capacity regulation valve, a pressure gauge is mounted on a pressure gauge filter connected with a pneumatic diaphragm pump connecting pipe, the pneumatic diaphragm pump connecting pipe is connected with a pneumatic diaphragm pump through an air pipe buffering joint, a liquid inlet pipe and a liquid outlet pipe are arranged at two ends of the pneumatic diaphragm pump respectively, the liquid outlet pipe is connected with a spray gun, the spray gun comprises a spray gun rod and a spray nozzle, a spray gun valve is arranged on the spray gun rod, the internal angle of the spray nozzle is in the shape of a long curve and cuts through to an outlet, and the outlet of the spray nozzle is wedge-shaped. The novel bubble spraying machine has the advantages that the novel bubble spraying machine is good in bubble generation effect, high in adhesive force, long in action time, good in cleaning and disinfecting effect, uniform in bubble generation and large in sector; liquid medicine dosage can be reduced greatly, and disinfection cost is reduced; efficiency is improved, labor intensity of workers and labor cost are reduced, and morbidity of chickens is lowered.

Owner:青岛阿普曼生物科技有限公司

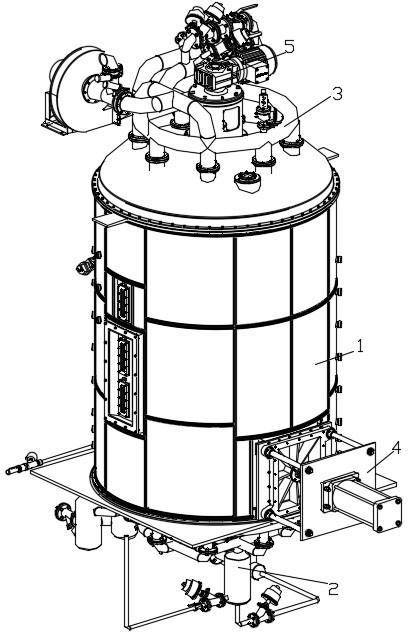

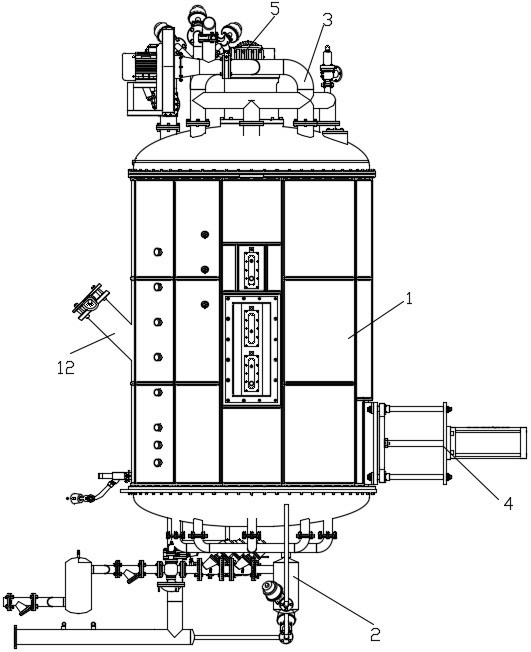

Foaming device achieving porous air intake and exhaust and foaming method of foaming device

The invention relates to a foaming device achieving porous air intake and exhaust and a foaming method of the foaming device. In order to solve the problems that in the prior art, a foaming device is low in foaming efficiency and high in energy consumption, according to the technical scheme, the foaming device achieving porous air intake and exhaust comprises a foaming barrel, an air intake mechanism, an exhaust mechanism, a material door cylinder and a stirring mechanism; a feeding opening is formed in the foaming barrel; the air intake mechanism is mounted at the bottom of the foaming barrel; the exhaust mechanism is mounted at the top of the foaming barrel; the material door cylinder is mounted at a material door of the foaming barrel; the air intake mechanism comprises a main air intake pipe, a first filter, a second filter, a first steam pocket, a second steam pocket, a third steam pocket, a pressure reducing valve, a steam proportional valve, an air proportional valve and a porous air intake pipeline; the main air intake pipe is connected with the first filter; the first filter is connected with the first steam pocket and the second steam pocket; the first steam pocket and the second steam pocket are connected in parallel; and the second filter is connected with the first steam pocket and the second steam pocket. The foaming device is high in foaming efficiency and achieves energy saving and environment protection.

Owner:HANGZHOU FUYANG DONGSHAN PLASTIC MACHINERY

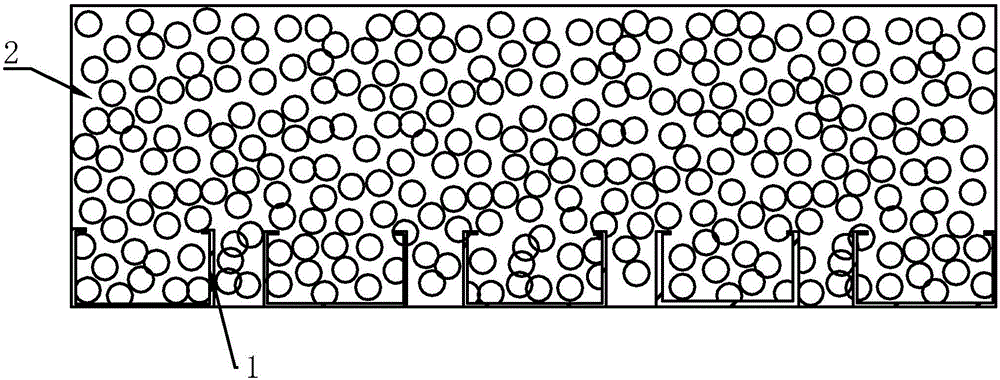

Structure and manufacturing technology of cement foaming wall, and foaming cement slurry formulation used for wall

The invention discloses a structure and a manufacturing technology of a cement foaming wall, and a foaming cement slurry formulation used for the wall, and solves problems in the prior art that strength and toughness of a cement foaming wall are not enough, and investment of necessary devices on site is reduced. The main points of the technical scheme are performing pouring uniformly on foaming cement slurry in a mold which is uniformly provided with lightgage steel joists, and the cement slurry carrying out chemical foaming in the mold. The equipment cost by using physical foaming in the prior art is saved, and adding of the lightgage steel joists, a cement reinforcing agent, reinforced fibers and other materials makes the strength and toughness of a manufactured wall improved.

Owner:BEIJING HUAYUANJIAYE BUILDING MATERIAL CO LTD

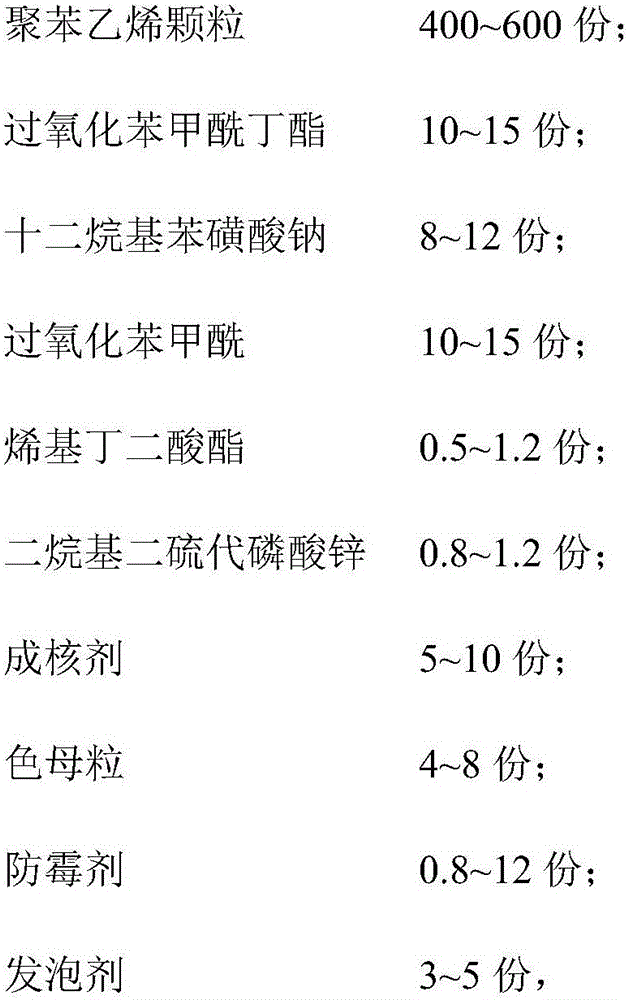

Economical polystyrene heat-preservation extruded board and preparation method thereof

The invention discloses an economical polystyrene heat-preservation extruded board. The economical polystyrene heat-preservation extruded board is prepared from the following components in parts by weight: 400 to 600 parts of polystyrene particles, 10 to 15 parts of butyl peroxybenzoate, 8 to 12 parts of sodium dodecylbenzene sulfonate, 10 to 15 parts of benzoyl peroxide, 0.5 to 1.2 parts of alkenyl succinate, 0.8 to 1.2 parts of zinc dialkyl dithiophosphate, 5 to 10 parts of a nucleating agent, 4 to 8 parts of color master batch, 0.8 to 12 parts of a mildew-proof agent and 3 to 5 parts of a foaming agent, wherein the polystyrene particles are formed by mixing new polystyrene materials, polystyrene recycled materials and polystyrene waste materials and the mixing ratio is 1 to 2 to 2. The new polystyrene materials, the recycled materials and the waste materials are mixed to form a main material, so that the production cost of enterprises is greatly reduced and the economic benefits are improved.

Owner:南京欧格节能环保科技有限公司

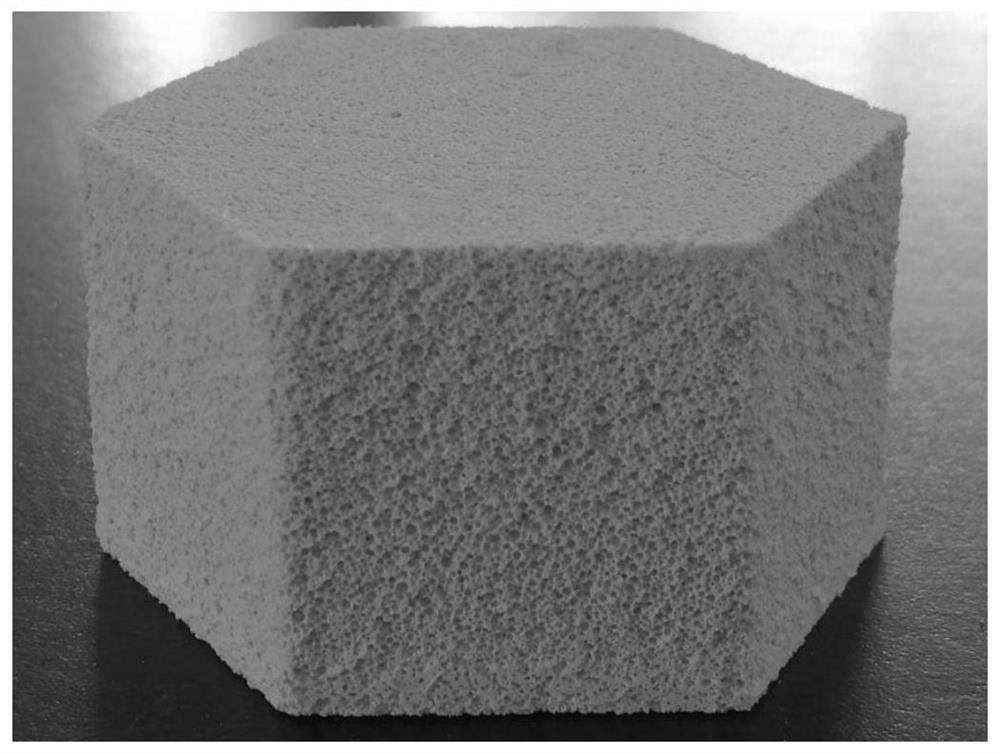

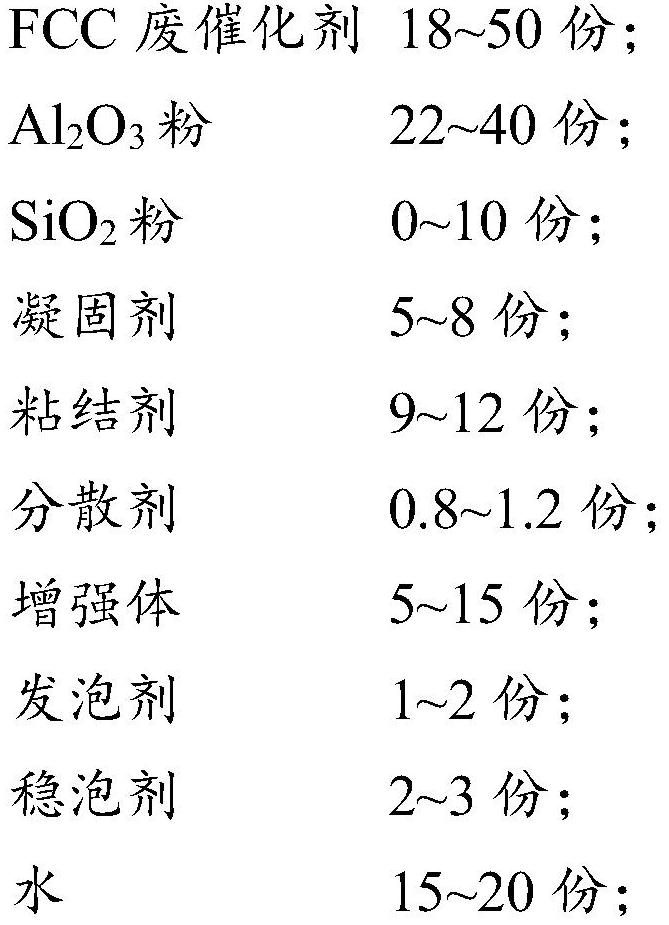

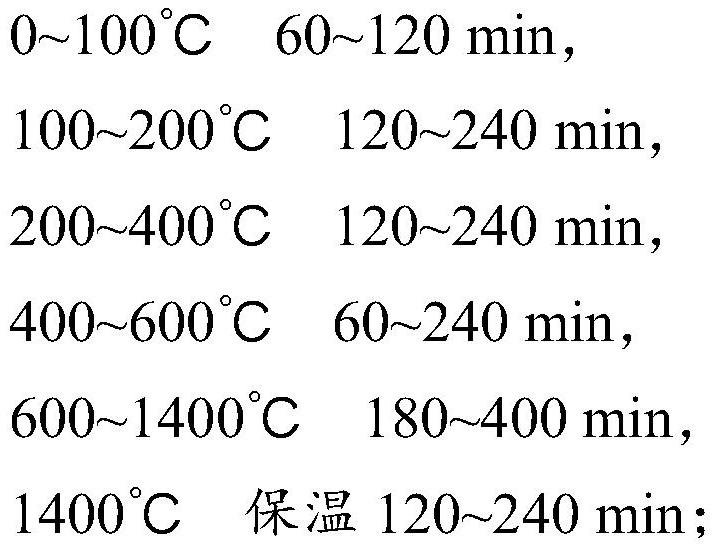

A kind of high temperature resistant foamed ceramics prepared by FCC waste catalyst and preparation method thereof

The invention belongs to the technical field of inorganic fire-resistant and heat-insulating materials, and in particular relates to a high-temperature-resistant foamed ceramic prepared from FCC waste catalyst, which is prepared from the following raw materials in parts by mass: 18-50 parts of FCC waste catalyst; Al 2 o 3 Powder 22~40 parts; SiO 2 0-10 parts of powder; 5-8 parts of coagulant; 9-12 parts of binder; 0.8-1.2 parts of dispersant; 5-15 parts of reinforcement; 1-2 parts of foaming agent; 2-3 parts of foam stabilizer ; 15-20 parts of water and a pH regulator. The present invention uses FCC waste catalyst, Al 2 o 3 Powder and SiO 2 The powder is the ceramic base material, and the ratio is optimized. The high-temperature-resistant foam ceramics obtained have a higher service temperature and a lower thermal conductivity, and realize efficient recycling and reuse of FCC spent catalysts.

Owner:JIANGSU HIGH TECHNO THERMAL EQUIP CO LTD

Automatic foaming production line for car mats

The invention discloses an automatic foaming production line for car mats. The automatic foaming production line comprises a stirring tank; the axis at the top of the stirring tank is fixedly connected with a first motor; an output end of the first motor penetrates through the top of the stirring tank and extends to the inner cavity of the stirring tank; the bottom of the output end of the first motor is fixedly connected with a transmission rod; and stirring rods are fixedly connected with two sides of the surface of the transmission rod. Through cooperative using of the stirring tank, the first motor, the transmission rod, the stirring rod, a vulcanizing agent cabin, a foaming agent cabin, a heating block, a bottom plate and a feeding pipe, rubber materials can be dynamically vulcanized,so that the foaming effect is better ensured, rubber compounds can be pre-formed and then the forming work of rubber products is better ensured; and vulcanization and foaming are carried out on the pre-formed rubber products through a conveyer belt and a drying box, so that the foaming quality is better ensured, the working difficulty is reduced, the production cost is reduced and the product yield is improved.

Owner:吴燕

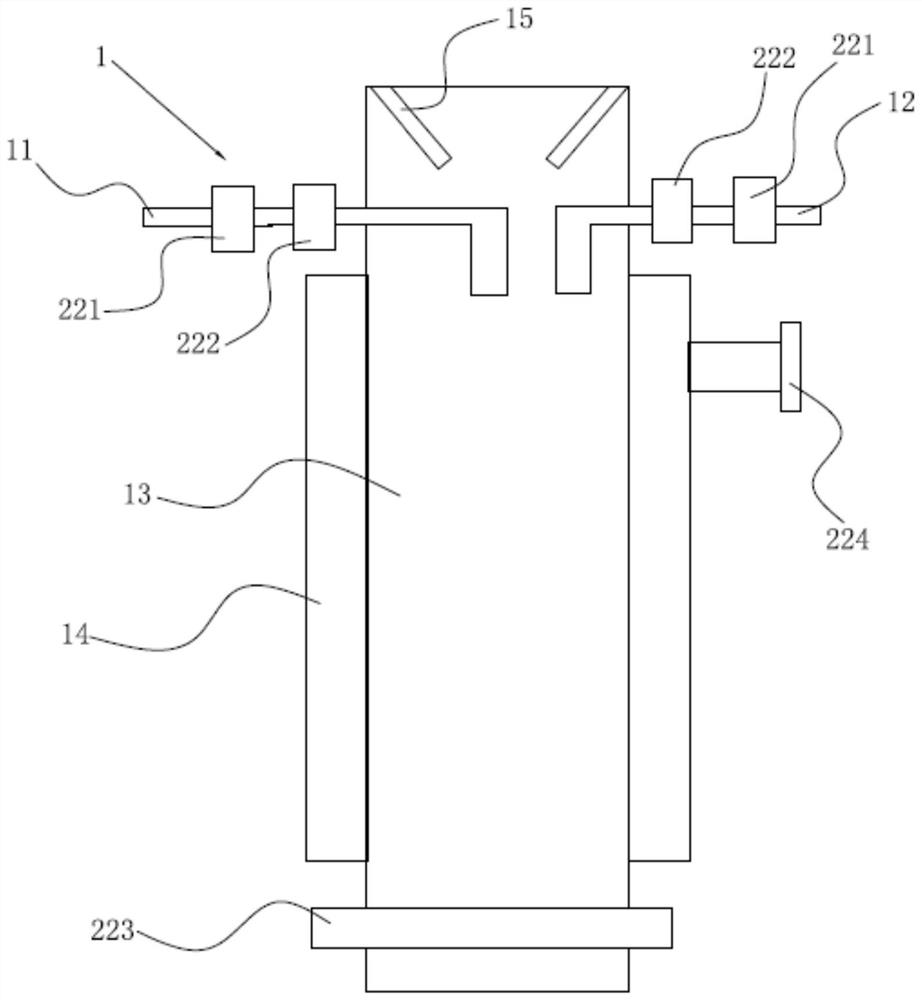

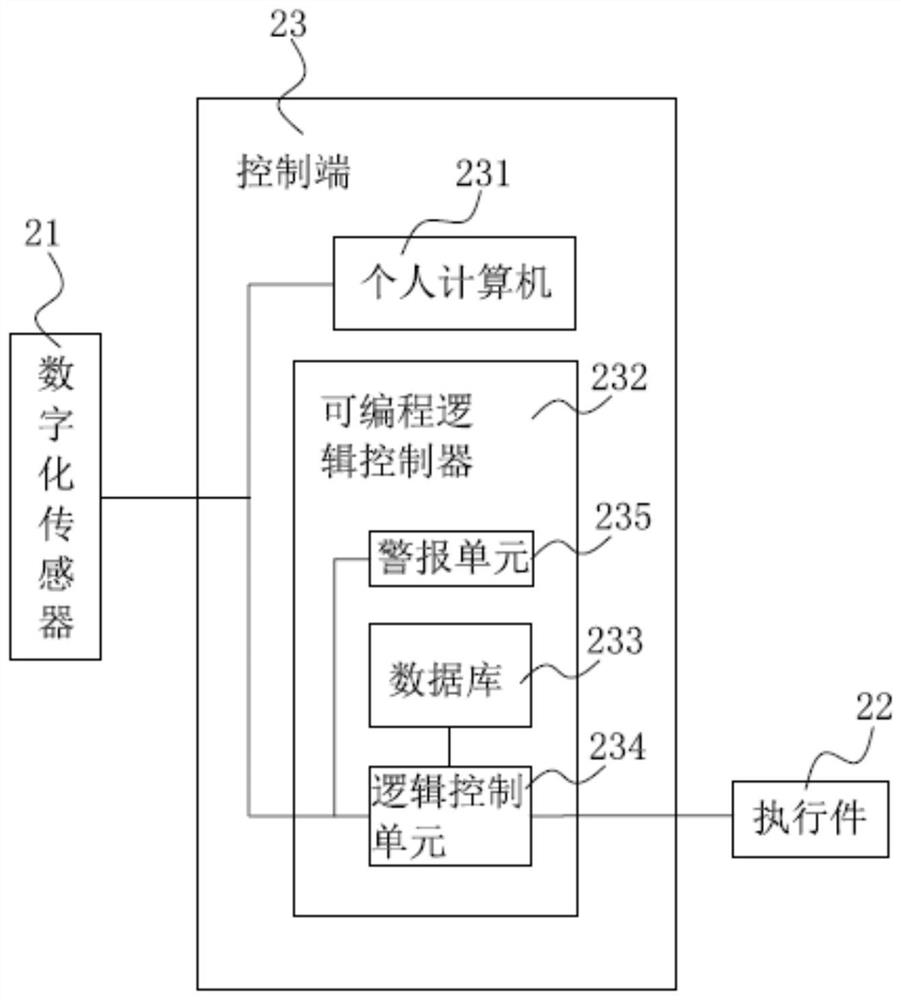

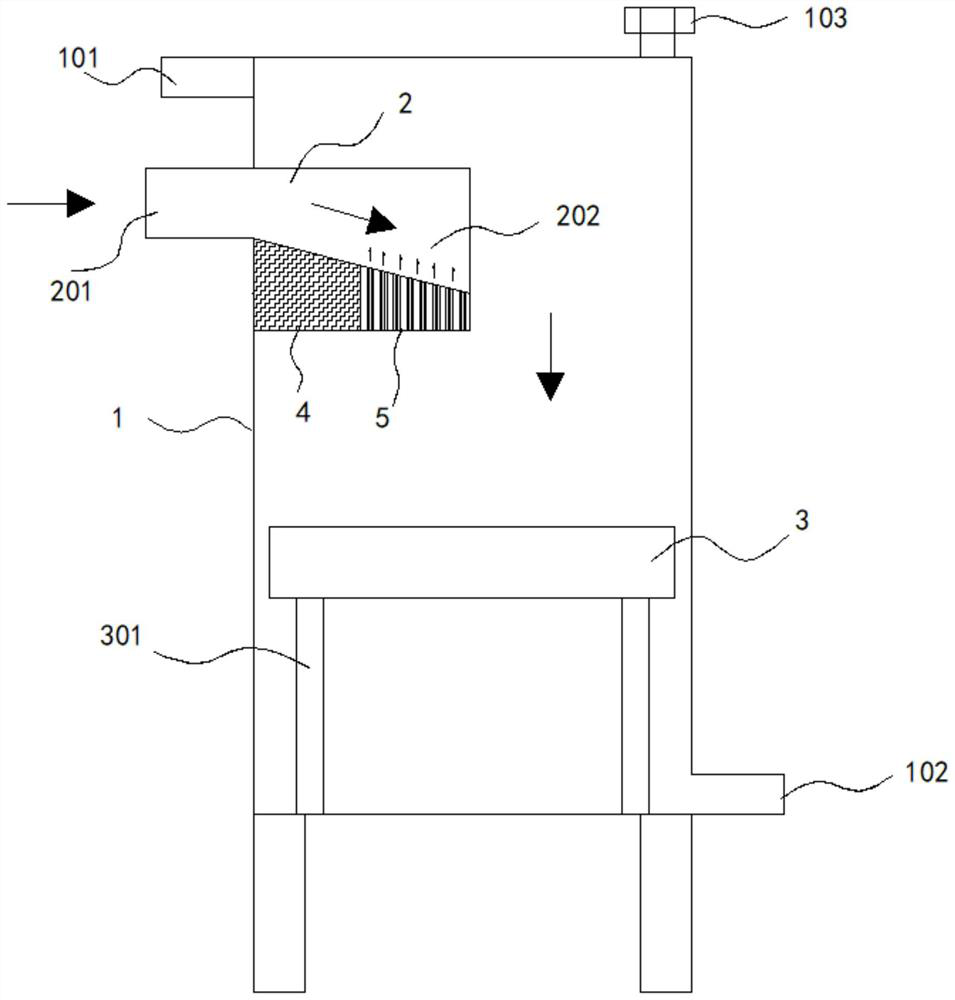

Asphalt foaming device and asphalt foaming method

InactiveCN111622048AGuaranteed foaming effectRealize automatic adjustmentRoads maintainenceInstrument controlProcess engineering

The invention relates to the technical field of road equipment, and particularly relates to an asphalt foaming device and an asphalt foaming method. In order to solve the problems in the prior art that instrument control is not accurate enough, asphalt is aged, and the foaming quality of the asphalt is greatly reduced, the asphalt foaming device is characterized by comprising a circulation pipeline for inputting air, water and the asphalt and outputting the foamed asphalt obtained through adjustment, and a control subsystem, wherein the control subsystem comprises at least one group of digitalsensors which are arranged at the tail end of the circulation pipeline and are used for detecting index real-time data of the foamed asphalt obtained by adjustment, an execution piece which is arranged on the circulation pipeline and controls the circulation state of the circulation pipeline, and a control end which is connected with the digital sensors, compares the index real-time data detectedby the digital sensors with the corresponding index target data, and controls the execution piece to act so as to output the foamed asphalt obtained by adjustment with the index real-time data according with the index target data requirement.

Owner:ROAD & BRIDGE INT +1

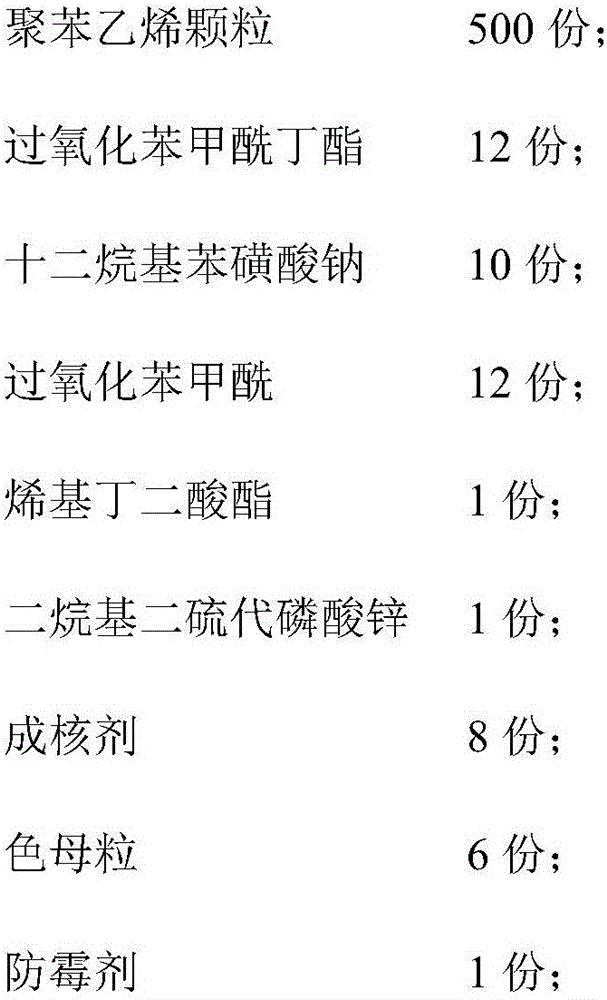

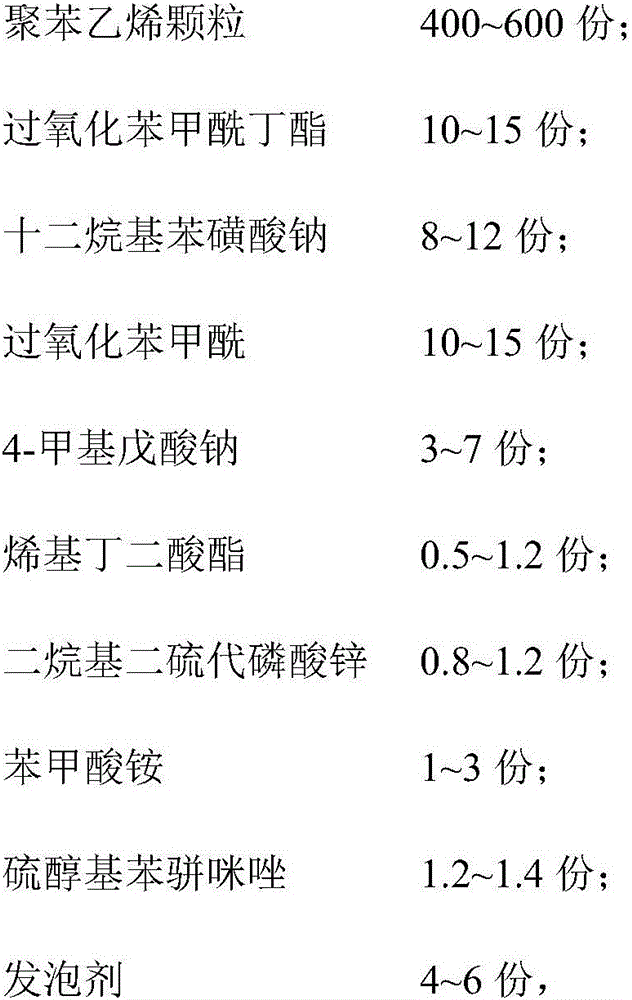

Polystyrene thermal-insulation plastic extrusion plate similar to EPS plate and preparation method thereof

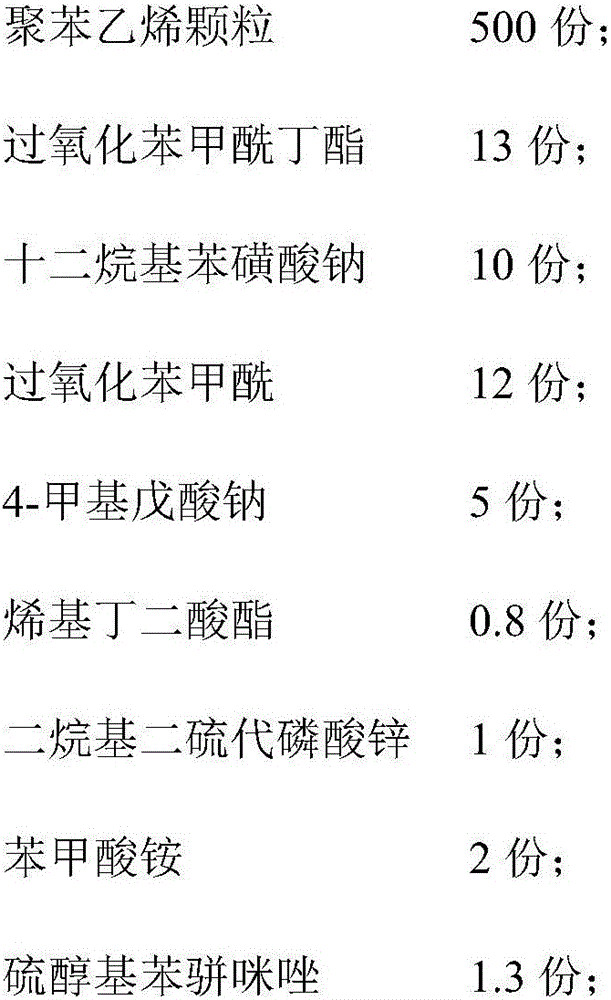

The invention discloses a polystyrene thermal-insulation plastic extrusion plate similar to an EPS plate and a preparation method thereof. The polystyrene thermal-insulation plastic extrusion plate is prepared from the following components in parts by weight: 400-600 parts of polystyrene particles, 10-15 parts of benzoyl butyl ester peroxide, 8-12 parts of sodium dodecyl benzene sulfonate, 10-15 parts of benzoyl peroxide, 3-7 parts of 4-methyl sodium valerate, 0.5-1.2 parts of alkenyl succinate, 0.8-1.2 parts of zinc dialkyl dithiophosphate, 1-3 parts of ammonium benzoate, 1.2-1.4 parts of thiol benzimidazole and 4-6 parts of a foaming agent, wherein the polystyrene particles are mixed by polystyrene fresh materials, polystyrene reclaimed materials and polystyrene waste. By controlling the reaction temperature of the material and an adding proportion of a nucleating agent, the plastic extrusion plate is guaranteed to not get black; and meanwhile, the raw materials are not added with color master batches, so that the plate color is not deepened, and the appearance of the plate is similar to the that of the EPS plate; and the plate is white, clean and environmentally-friendly.

Owner:南京欧格节能环保科技有限公司

Carbon dioxide foam injecting device of oil well

ActiveCN102747996BSolve freezing problemsGuaranteed foaming effectFlow mixersRotary stirring mixersTemperature controlAutomatic control

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

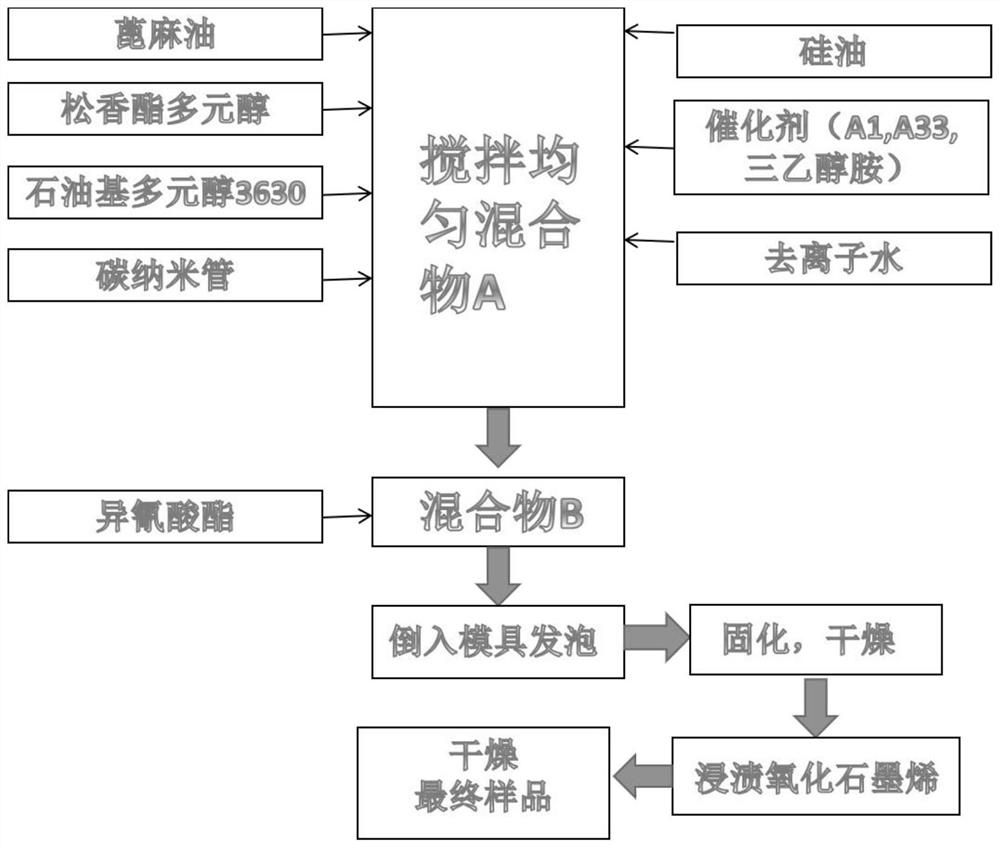

A hybrid plant-based polyurethane porous material impregnated with carbon nanotubes and graphene oxide and its preparation method

Owner:JILIN UNIV

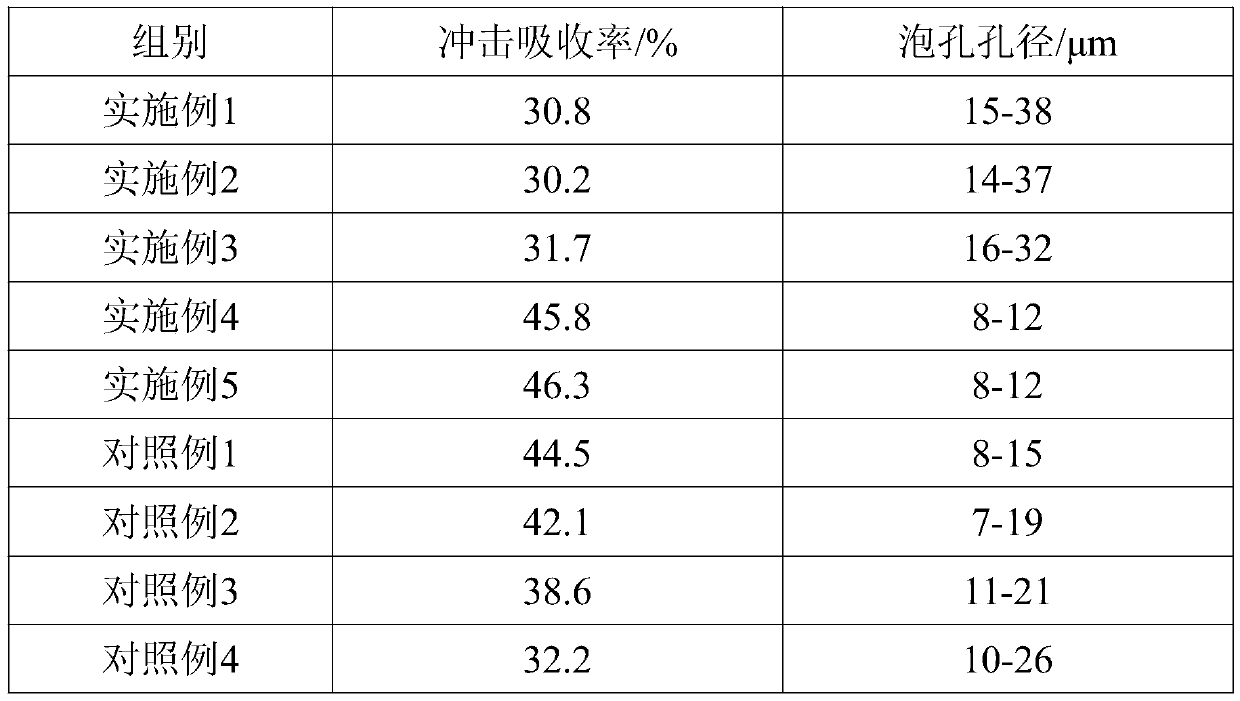

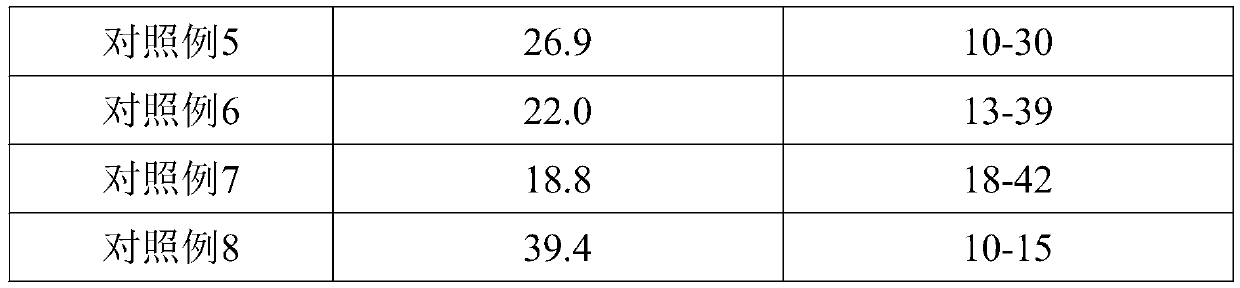

Machining technology for submerged-arc welding straight seam steel pipe of shock absorption structure

The invention discloses a machining technology for a submerged-arc welding straight seam steel pipe of a shock absorption structure, and relates to the technical field of straight seam submerged-arc welding steel pipes. The machining technology includes the following steps that (1) the submerged-arc welding straight seam steel pipe is machined; (2) shock absorption materials are machined; and (3)the shock absorption structure is formed. By adoption of the machining technology, the produced shock absorption materials are coated on the submerged-arc welding straight seam steel pipe to form theshock absorption structure, and therefore the shock absorption performance of the submerged-arc welding straight seam steel pipe is excellent; and meanwhile, the using amount of metal magnesium and aluminum is reduced, and the shock absorption performance of the shock absorption materials is enhanced while cost is reduced.

Owner:HEFEI ZIKING PIPE INC

Method for fabricating non-woven paper ripple foaming wallpaper

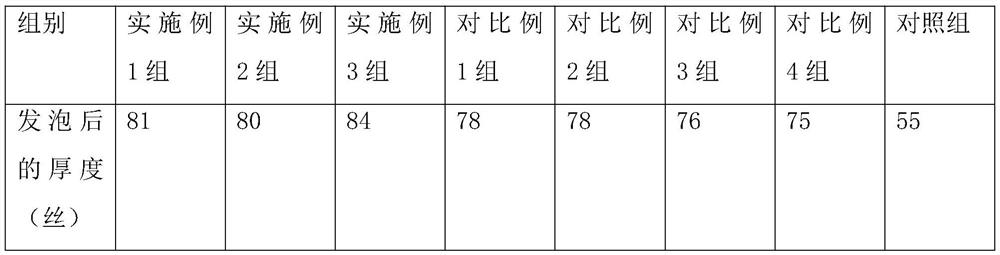

ActiveCN105040523AGuaranteed to meet the requirementsGuaranteed foaming effectSpecial paperPaper/cardboardPlasticizerPolyvinyl chloride

The invention discloses a method for fabricating non-woven paper ripple foaming wallpaper. According to the method, relatively environment-friendly non-woven paper is selected as a base material for non-woven paper ripple foaming; a printing material is a ripple foaming material of changing the melting point; and the melting point is 180 degrees and is consistent with that of polyvinyl chloride (PVC). In order to ensure the ripple foaming height, a PVC paint is printed by two laser gravures to ensure that the height of the PVC printing layer reaches the requirements; finally a laser gravure ripple foaming material is printed on the PVC printed layer again; by the characteristic that the melting point of the PVC is the same as that of the ripple material, an organic matter and a plasticizer in the PVC fully volatilize; and the PVC and the ripple material are foamed together to ensure the foaming height and the foaming effect of the ripple material. Compared with traditional PVC ripple foaming, the non-woven paper ripple foaming procedures are reduced; a coating process flow is not needed; printing and foaming are directly carried out on a gravure press; and the wallpaper does not contain the organic matter or the plasticizer, so that the method is relatively environment-friendly.

Owner:上海希尔彩印制版有限公司

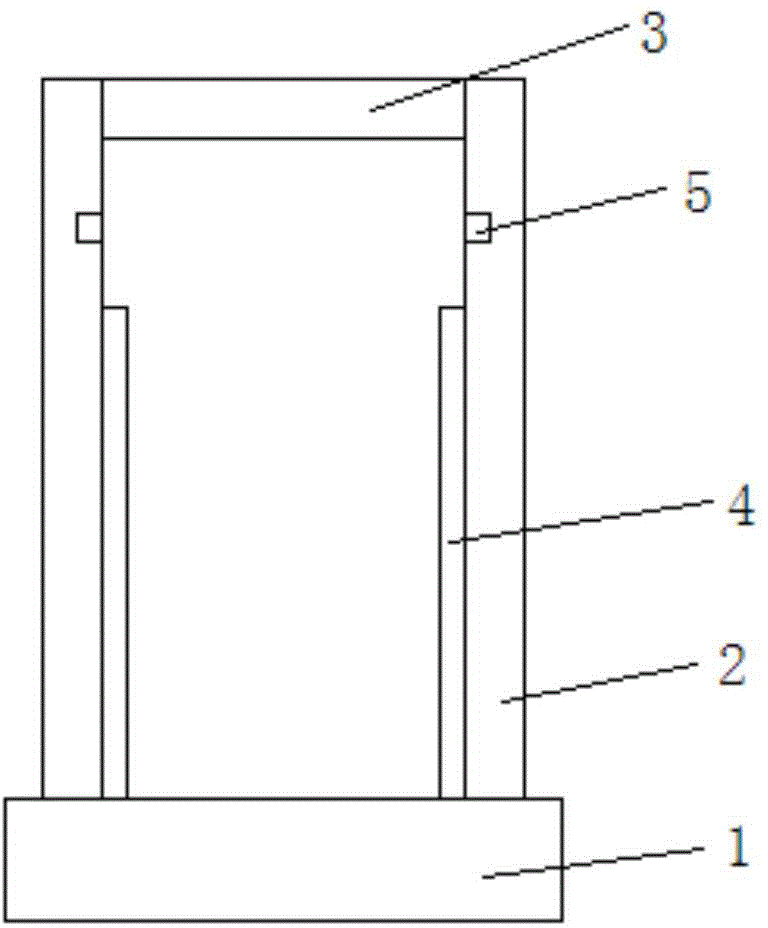

Solar collector header foaming rack

The invention discloses a solar collector header foaming rack which comprises a base and fixing plates, wherein the fixing plates are vertically arranged on two sides of the base; a connecting rod is arranged at the upper ends of the fixing plates on the two sides; two positioning plates matched with a header are arranged on the fixing plates; grooves matched with the end cover of the header are formed in the upper ends of the fixing plates. The solar collector header foaming rack has a simple and reasonable structure; during the use, the distance between the positioning plates is adjusted according to the size of the header, and the header is positioned and fixed on the base; the parts, protruding out relative to the body of the header, of the end cover of the header are placed in the grooves to improve the stability of the header and effectively prevent the header from inclining during foaming, so that the foaming effect and the product quality are improved; besides, the solar collector header foaming rack is convenient to adjust and mount.

Owner:ANHUI SHUNDA NEW ENERGY TECH DEV

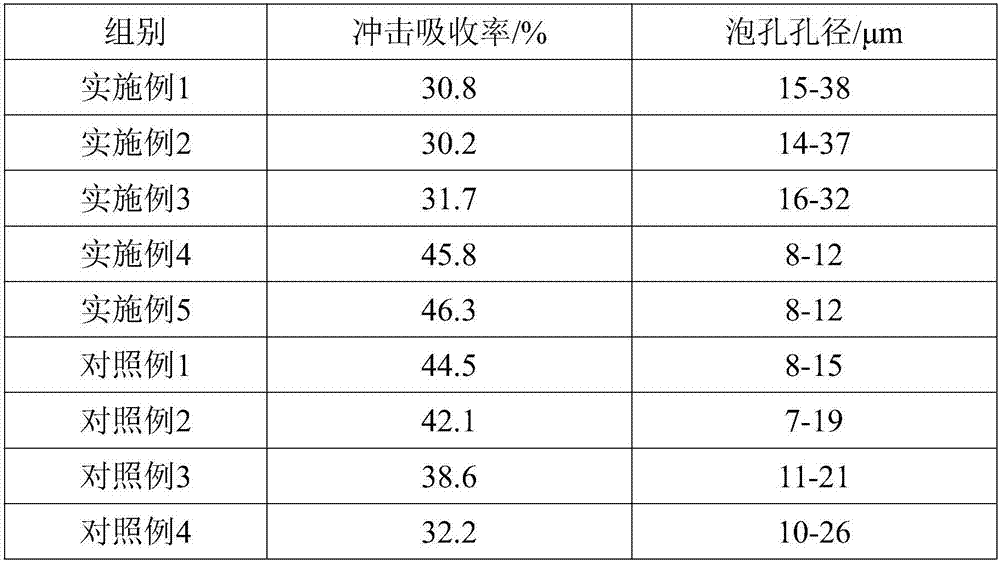

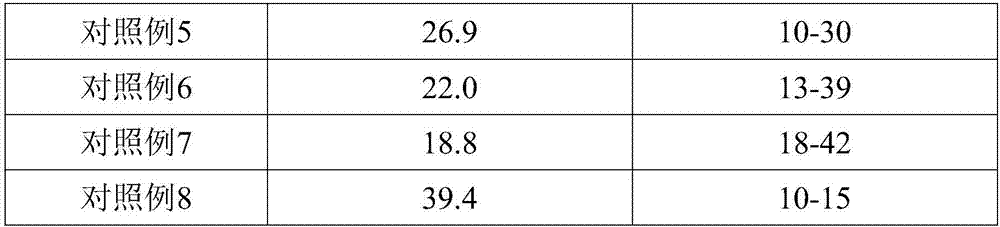

A Processing Technology of Submerged Arc Welded Straight Seam Steel Pipe with Shock Absorbing Structure

The invention discloses a processing technology of a submerged arc welded straight seam steel pipe with an impact absorption structure, relates to the technical field of straight seam submerged arc welded steel pipes, and comprises the following steps: (1) processing the submerged arc welded straight seam steel pipe, (2) impacting Processing of absorbent materials, (3) Forming of impact-absorbing structures. In the present invention, the shock absorbing material is coated on the submerged arc welded straight seam steel pipe to form a shock absorbing structure, thereby endowing the submerged arc welded straight seam steel pipe with excellent shock absorption performance; at the same time, the amount of metal magnesium and aluminum is reduced, and the cost is reduced. At the same time, the shock absorbing performance of the prepared shock absorbing material is enhanced.

Owner:HEFEI ZIKING PIPE INC

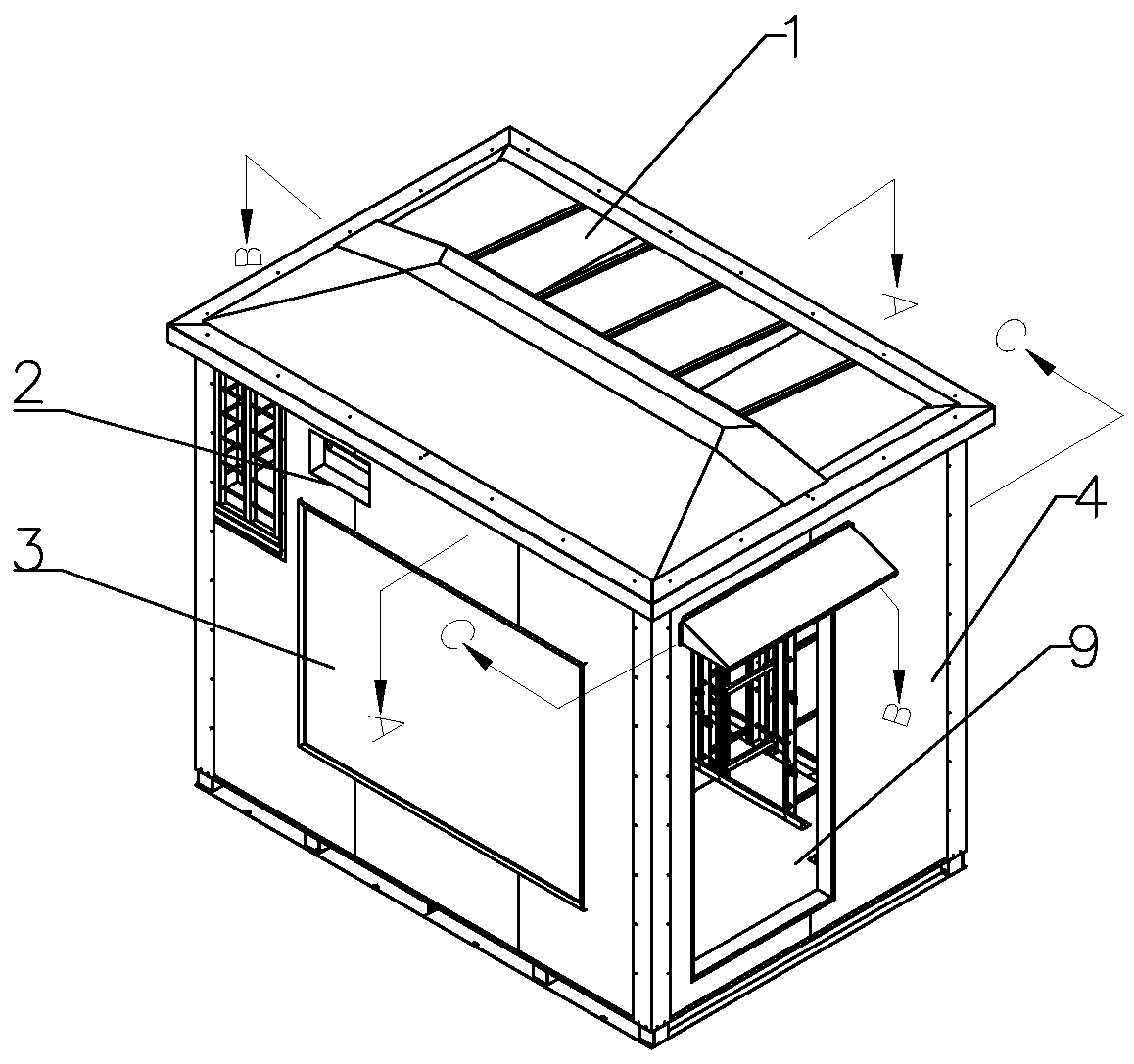

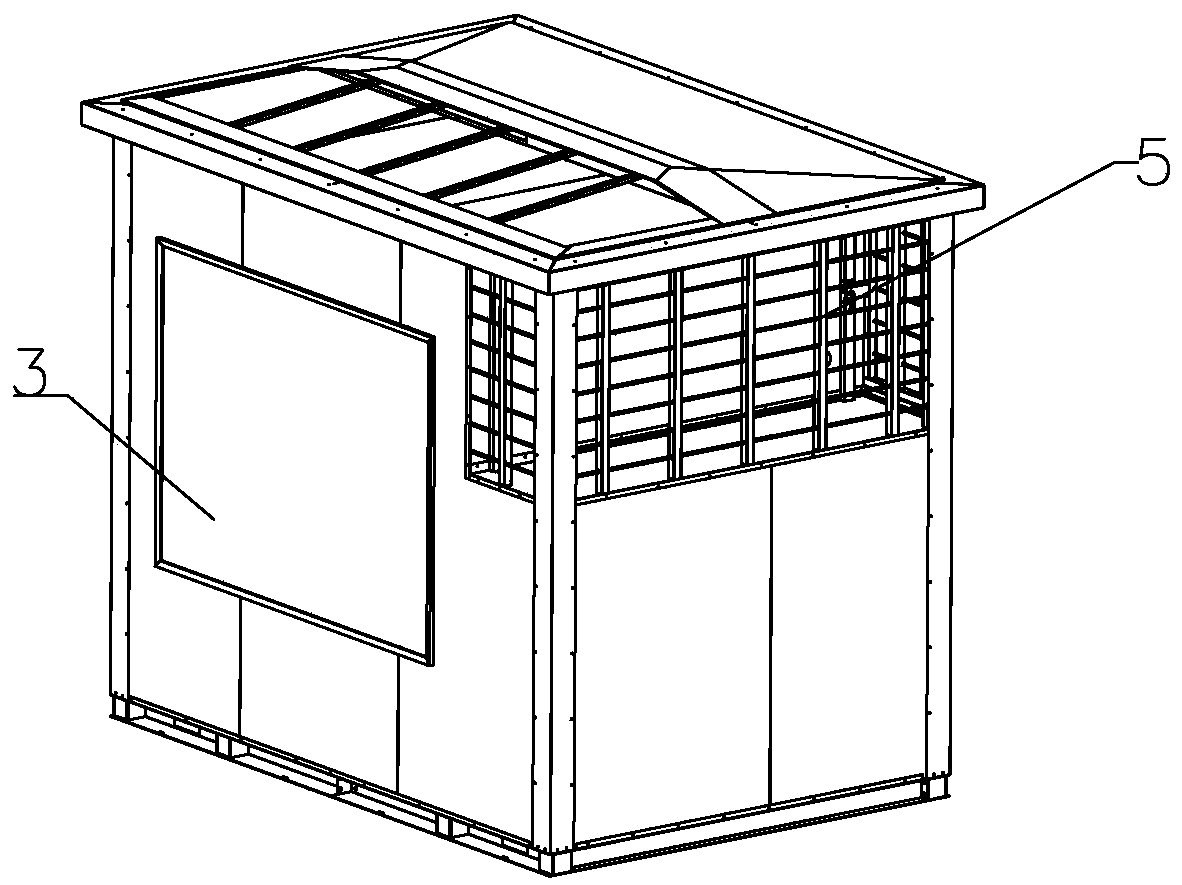

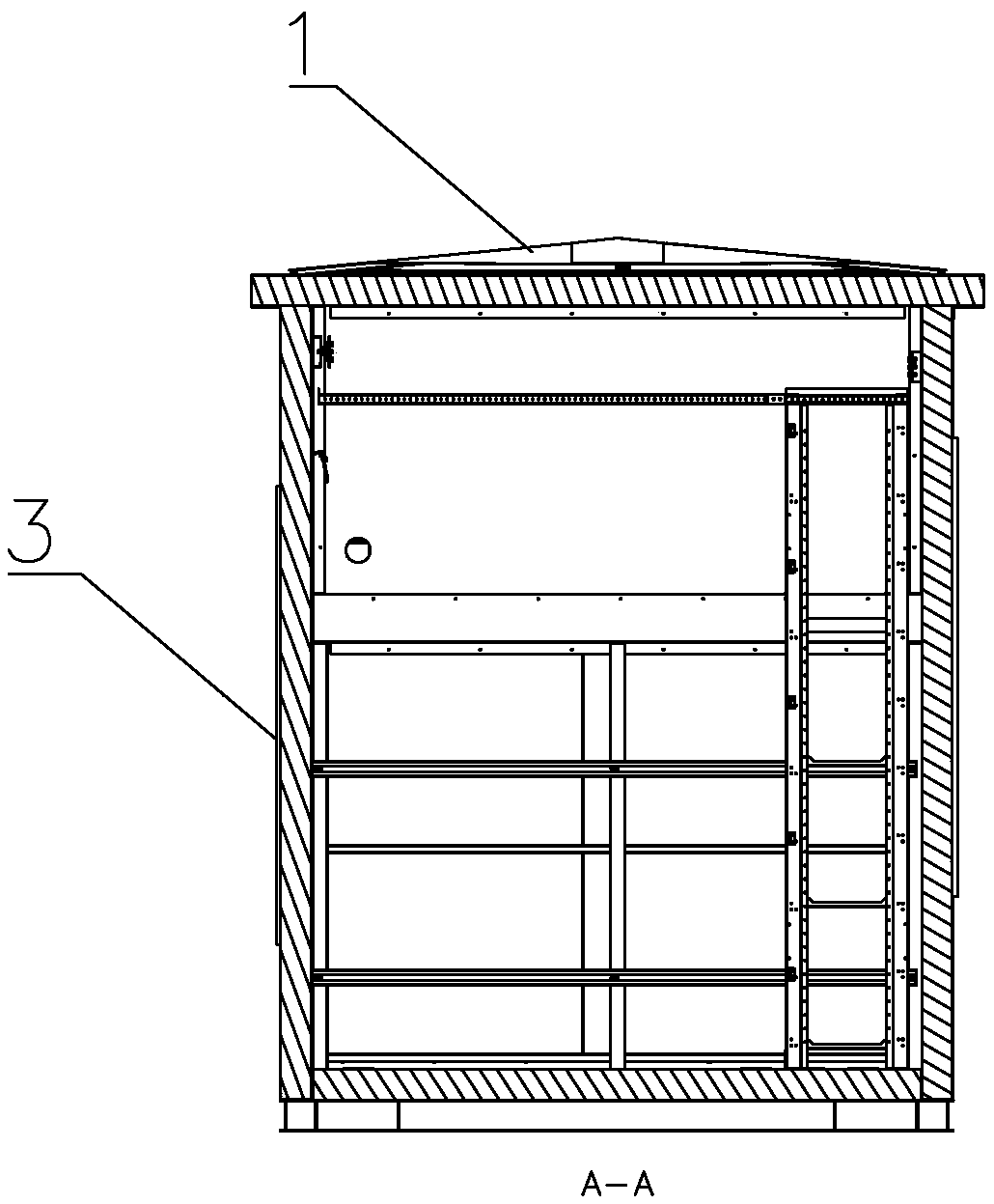

A solar multifunctional outdoor computer room

ActiveCN107165440BReduce shear heatHigh hardnessPhotovoltaic supportsBatteries circuit arrangementsEngineeringMechanical property

The invention relates to the technical field of outdoor machine rooms, in particular to a solar multifunctional outdoor machine room. The solar multifunctional outdoor machine room comprises a machine room body and a solar assembly, and the machine room body comprises side plates, a top plate, a bottom plate and a frame assembly; and the frame assembly comprises a bottom frame, a top frame and a plurality of stand columns, the top plate is fixed to the top frame, the bottom plate is fixed to the bottom frame, the side plates are arranged between adjacent stand columns, the solar assembly comprises solar panels and a solar device controller, and the solar panels are arranged on the top plate. Each side plate comprises an external panel layer, a first bonding layer, a thermal preservation layer, a second bonding layer and an internal panel layer from outside to inside, and reinforcement frameworks are arranged in the thermal preservation layers. According to the solar multifunctional outdoor machine room, solar energy can be utilized for supplying power in a power failure condition so that normal operating of the outdoor machine room can be guaranteed, the construction period is short, the investment cost is low, the structure is compact, and assembling is convenient; and the outdoor machine room has the good mechanical property, corrosion resistance and flame resistance, good heat preservation and insulation properties, and long service life.

Owner:GUANGDONG HIWAVE TECH

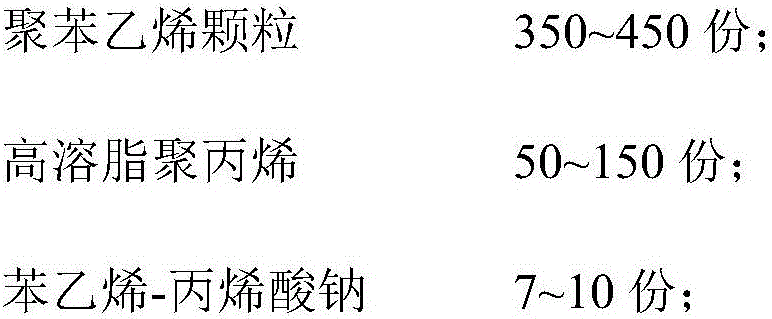

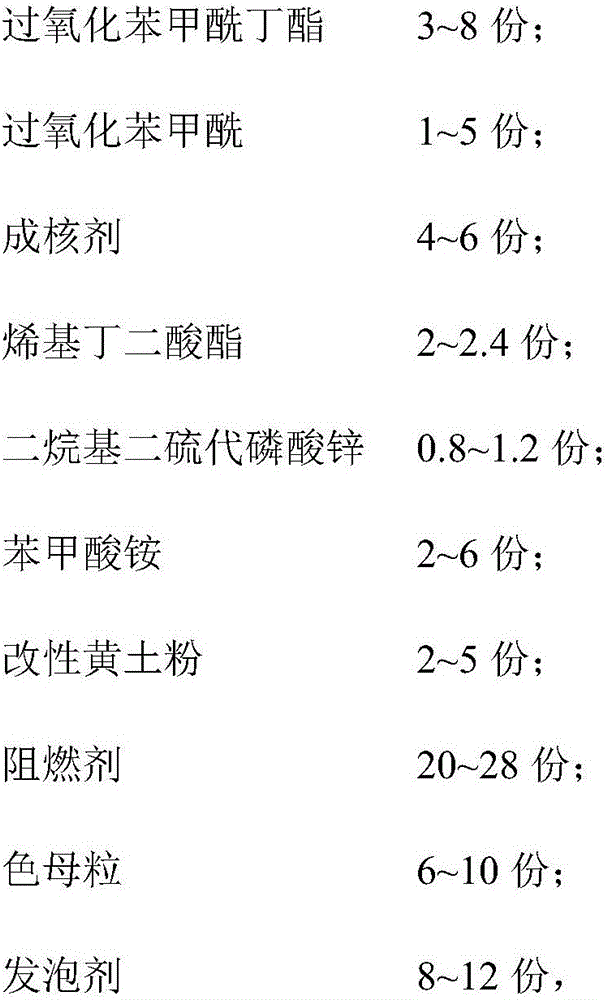

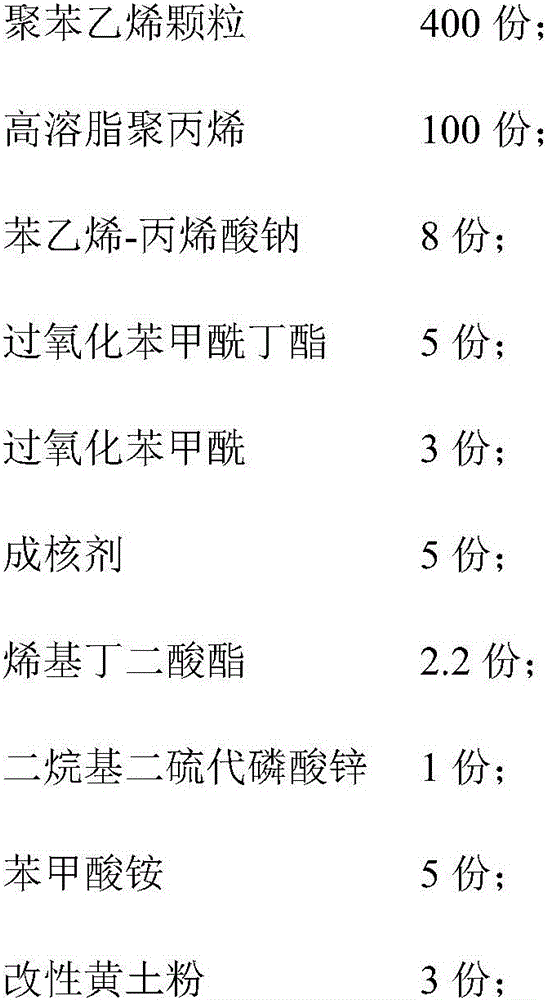

Polystyrene/polypropylene blended heat preservation extruded sheet and preparation method thereof

InactiveCN105860310ADoes not affect physical propertiesDoes not affect specific gravityBenzoyl peroxideSuccinic acid

The invention discloses a polystyrene / polypropylene blended heat preservation extruded sheet. The polystyrene / polypropylene blended heat preservation extruded sheet is prepared from, by weight, 350-450 parts of polystyrene granules, 50-150 parts of high fat soluble polypropylene, 7-10 parts of styrene-sodium acrylate, 3-8 parts of benzoyl peroxide butyl ester, 1-5 parts of benzoyl peroxide, 4-6 parts of a nucleating agent, 2-2.4 parts of alkenyl succinic acid ester, 0.8-1.2 parts of zinc dialkyl dithiophosphate, 2-6 parts of ammonium benzoate, 2-5 parts of modified loess powder, 20-28 parts of fire retardant, 6-10 parts of color master batches and 8-12 parts of a foaming agent. In the formula, high fat soluble polypropylene and other materials are mixed with polystyrene raw materials, a small number of leftover materials are added, and the sheet with the thickness being 10 cm or above can be produced; the sheet can reach national B1-level fire rating by adding a small quantity of the fire retardant, and the physical performance of the sheet is not affected.

Owner:南京欧格节能环保科技有限公司

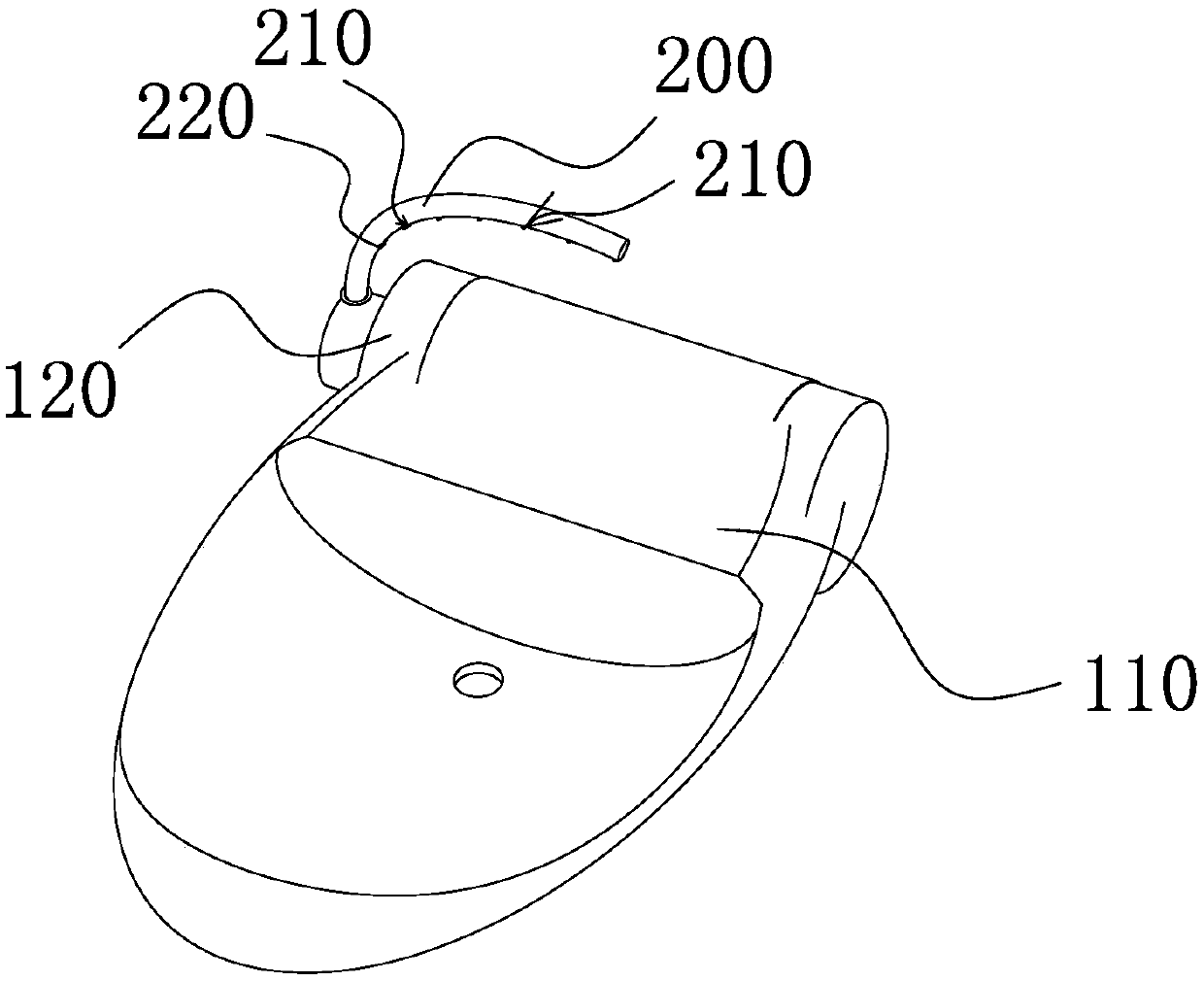

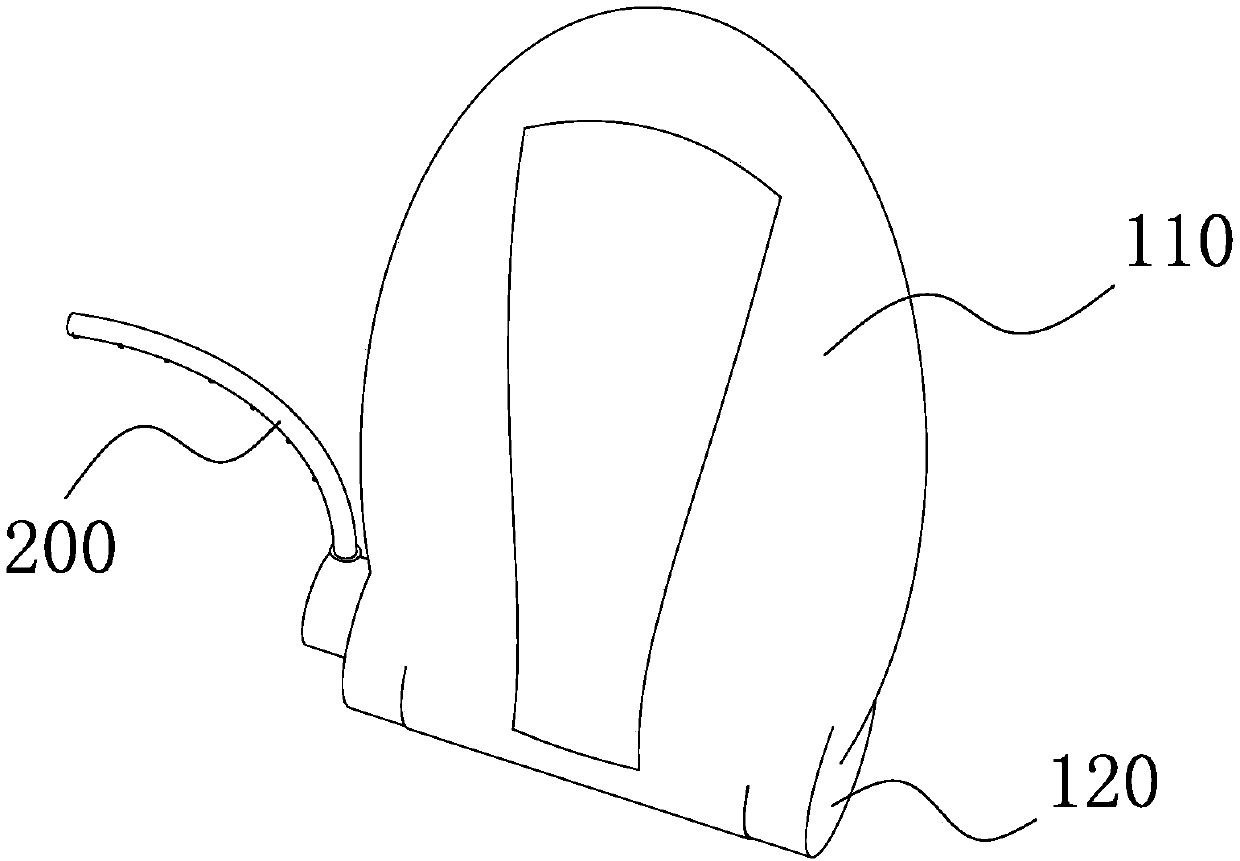

Head washing basin

PendingCN109680764AFully cleanedWater flow covers a wide and uniform areaDomestic plumbingEngineeringMechanical engineering

The invention provides a head washing basin. The head washing basin is provided with a head washing faucet, and the head washing faucet comprises a faucet body; the faucet body is configured to be ofa structure which is curved or bent in the preset direction; a plurality of water outlet areas distributed in the preset curving or bending direction are arranged on the inner side of the faucet body;each water outlet area is provided with at least one water outlet; a plurality of splicing structures which are spliced end to end are arranged from the middle section of the faucet body to the tailend of the faucet body; one water outlet area is arranged at each splicing structure; and a foaming structure is arranged between at least two of the splicing structures, wherein the foaming structureis detachably arranged between the splicing structure located at the tail end of the faucet body and the adjacent splicing structure. The washing head basin has the advantages of being ideal in cleaning effect and convenient to use.

Owner:NINGBO OULIN IND CO LTD

Cement foam wall structure and manufacturing process

Owner:BEIJING HUAYUANJIAYE BUILDING MATERIAL CO LTD

Preparation method of gray cast iron inoculant

The invention discloses a preparation method of a gray cast iron inoculant. The preparation method comprises the following steps: smelting proportioned raw materials, foaming and cooling to obtain a foaming material; crushing the foaming material into particles of 1-2mm, and then putting the particles into a closed container; air in the closed container is pumped out, then inert gas is filled, and the pressure is increased to 0.2 MPa or above; injecting a molten film-forming agent into the closed container, so that the surfaces of the foaming material particles are coated with the film-forming agent, and curing the film-forming agent to obtain a cured material; and crushing the cured material to obtain the gray pig iron inoculant with the particle size of 2-6mm. According to the preparation method, the foaming material particles have a thinner wall type and a hollow internal structure, when the foaming material particles are put into molten iron to be used as a nucleating agent, the foaming material particles can be more rapidly fused into the molten iron, the longer inoculation time is obtained, release of gas in the hollow structure can drive the nucleating agent to be rapidly dispersed in the molten iron, and therefore the foaming material particles are more stable in performance. And the mixing uniformity is improved, and the casting quality is improved.

Owner:GUANGXI UNIV

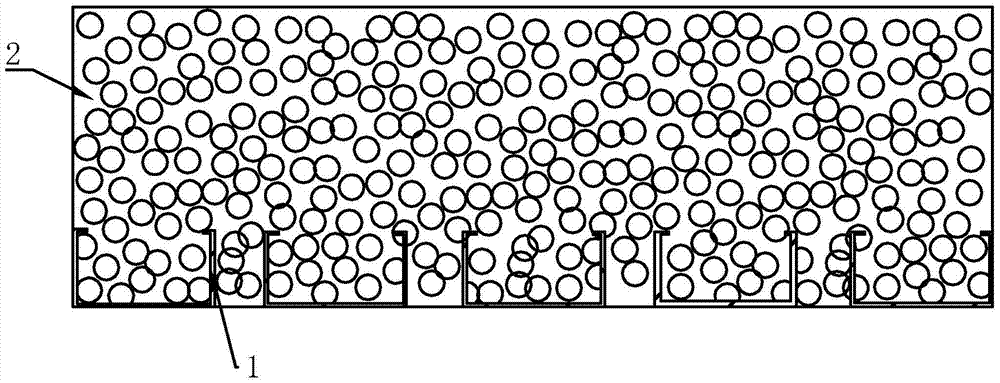

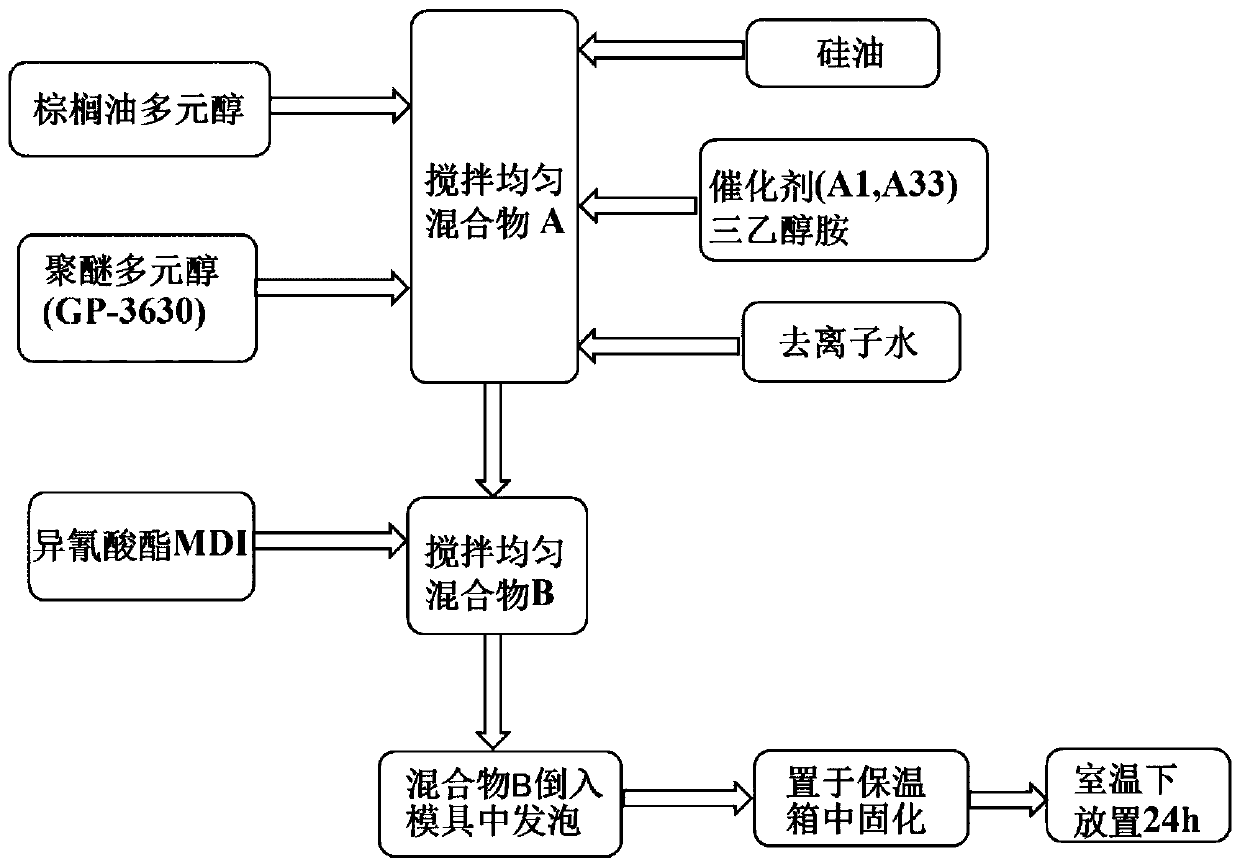

A kind of palm oil-based polyurethane porous material and preparation method thereof

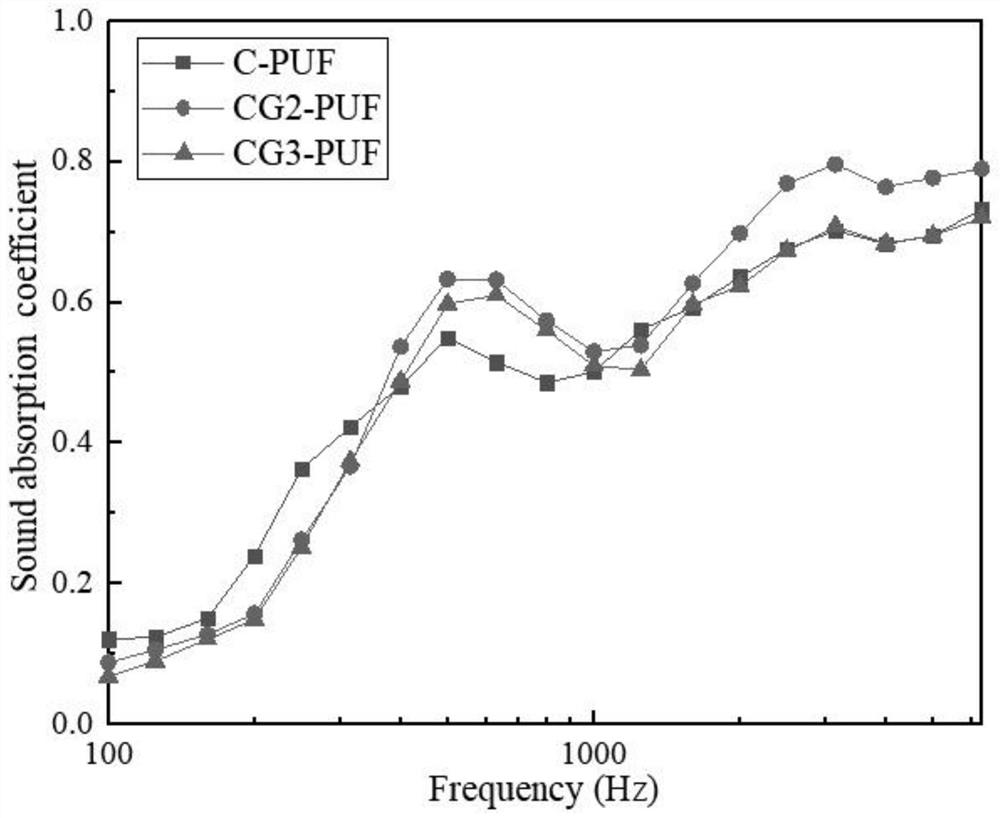

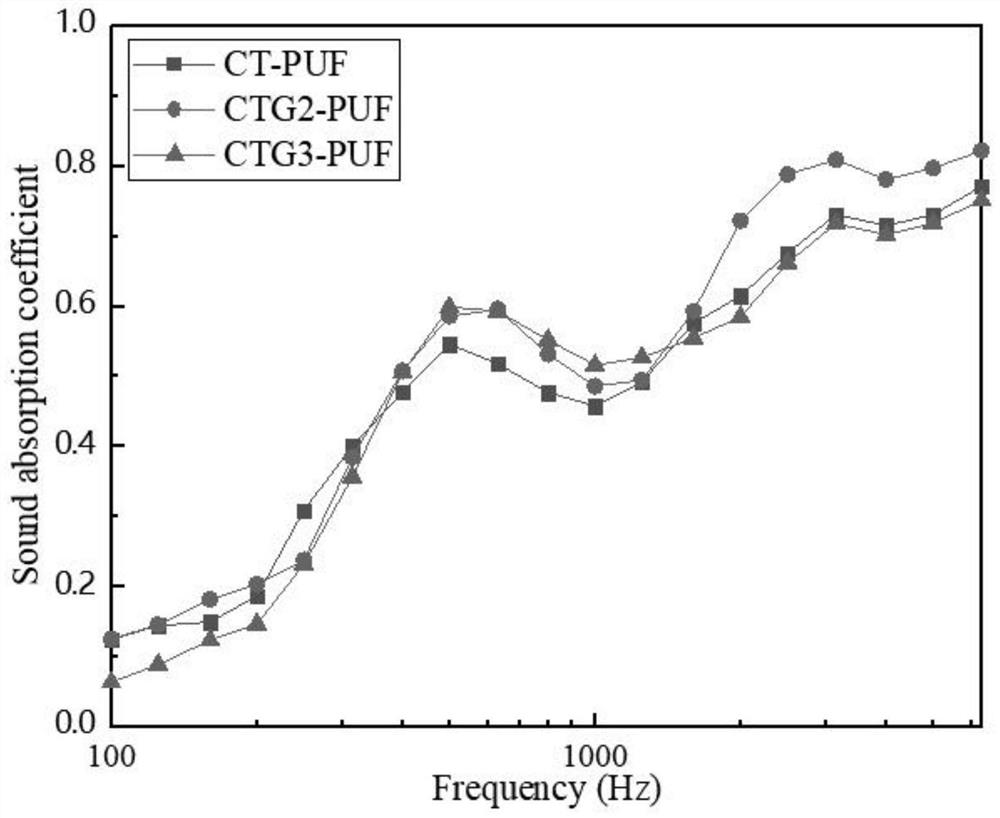

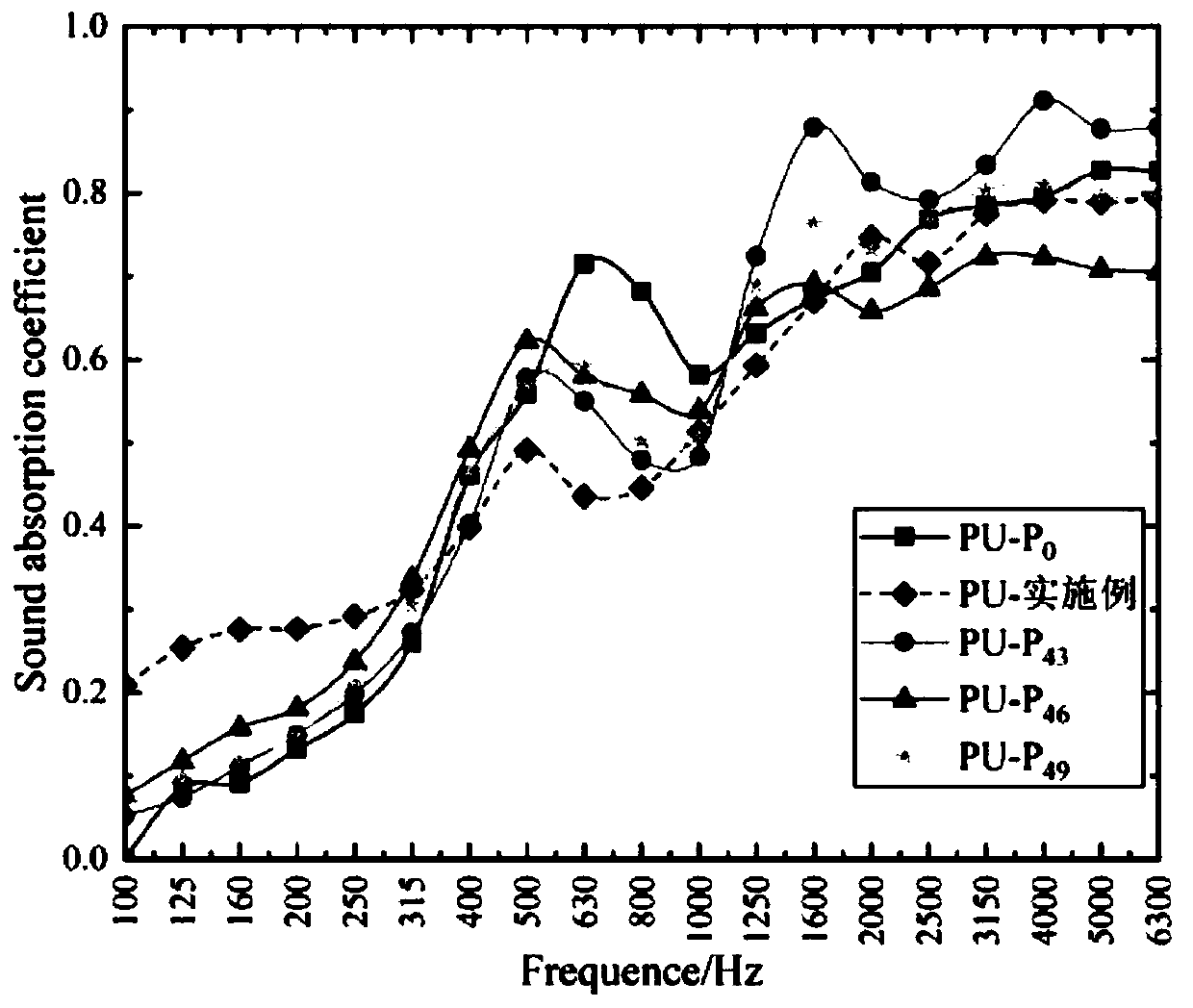

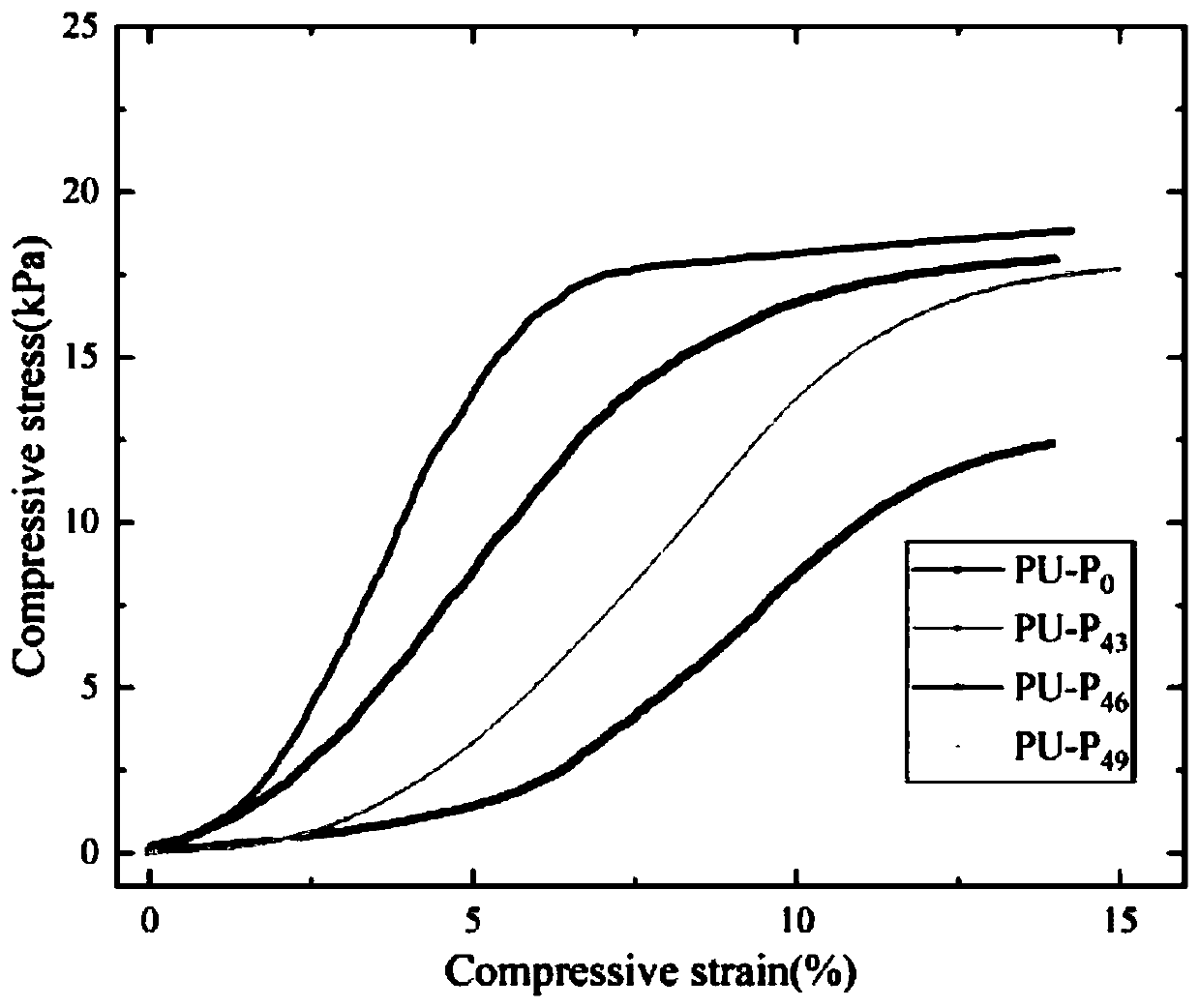

ActiveCN110117352BExcellent low frequency sound absorption performanceEasy to compressPtru catalystHydroxyl value

The invention discloses a palm-oil-based polyurethane porous material. The palm-oil-based polyurethane porous material is prepared from, by weight, 43-49 parts of palm oil polyalcohols, 51-57 parts ofpolyether polyalcohols, 0.6 part of a foam stabilizer, 2.5 parts of triethanolamine, 0.05 part of a catalyst A1, 1.0 part of a catalyst A33, 2.5 parts of deionized water and 30-35 parts of polymericMDI, wherein the hydroxyl value of the palm oil polyalcohols is within the range of 170-200 mg KOH / g. According to the palm-oil-based polyurethane porous material, the palm oil polyalcohols are utilized for replacing petroleum polyalcohols to prepare the polyurethane sound absorbing material, the environmental pollution is reduced, and the material has a better low-frequency sound absorbing effectand better compression performance. The invention further provides a preparing method of the palm-oil-based polyurethane porous material.

Owner:JILIN UNIV

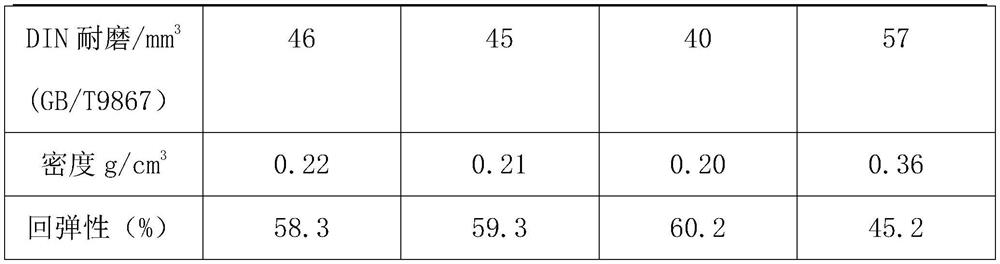

Wear-resistant shoe outsole and preparation method thereof

ActiveCN114702737AImprove wear resistanceGood weather resistanceSolesPolymer sciencePolyethylene glycol

The invention discloses a wear-resistant shoe outsole and a preparation method thereof. The wear-resistant shoe outsole comprises a wear-resistant layer and an insole compounded on the wear-resistant layer, the wear-resistant layer is prepared from butadiene styrene rubber, natural rubber, brominated butyl rubber, glycerol monostearate, methylpropanediol, dicumyl peroxide, polyethylene glycol, modified glass fibers, polydimethylsiloxane, polyethylene wax, modified bentonite and calcium stearate, and the shoe outsole prepared by the application is good in wear resistance and weather resistance, soft and comfortable, good in wear resistance, good in wear resistance, good in wear resistance, good in wear resistance, good in wear resistance and good in wear resistance. The wear resistance of the shoe outsole is improved by limiting the substructure of the shoe outsole and arranging the wear-resistant layer; and the elastic midsole is arranged to ensure the wearing comfort of the outsole.

Owner:达州市嘉源体育用品有限公司

Master batch for reducing foaming temperature and application thereof

The invention discloses a master batch which is prepared from the following raw materials in percentage by weight: 8-12% of glycerinum, 12-18% of urea, 50-55% of zinc cyanurate and 20-25% of glycerinum zinc. The preparation method of the master batch comprises the following steps: stirring and mixing the glycerol, the urea, the zinc cyanurate and the zinc glyceroxide at a high speed according to the weight percentage, and then heating, extruding and granulating to prepare the master batch. The master batch provided by the invention is added into a PVB foamed product, so that the foaming temperature is reduced to 180-200 DEG C on the premise of ensuring high and stable foaming ratio.

Owner:济南金彩阳新材料科技有限公司

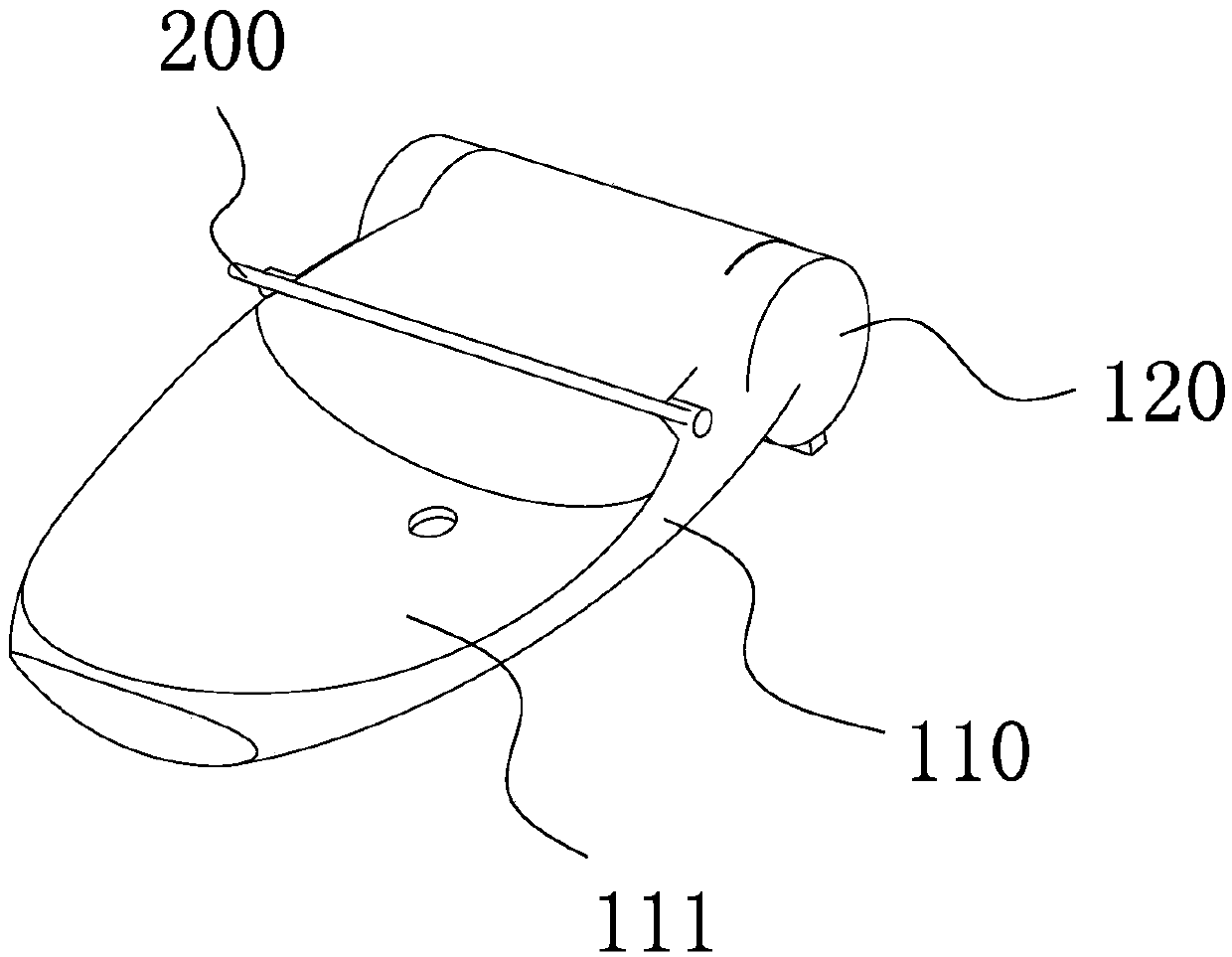

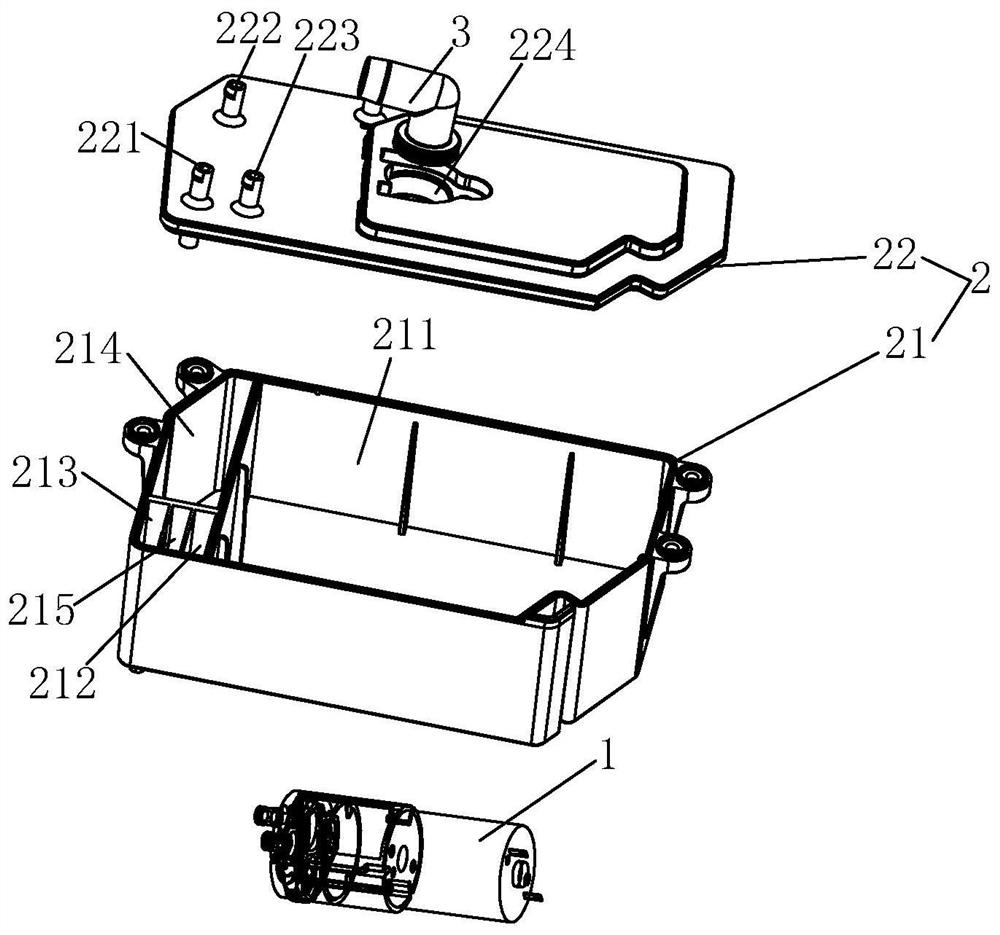

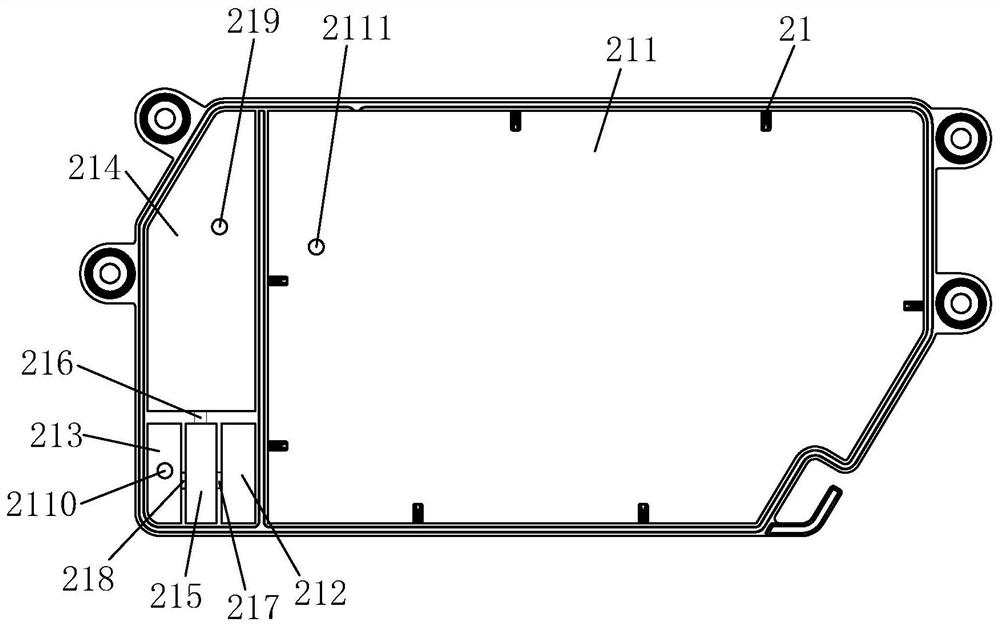

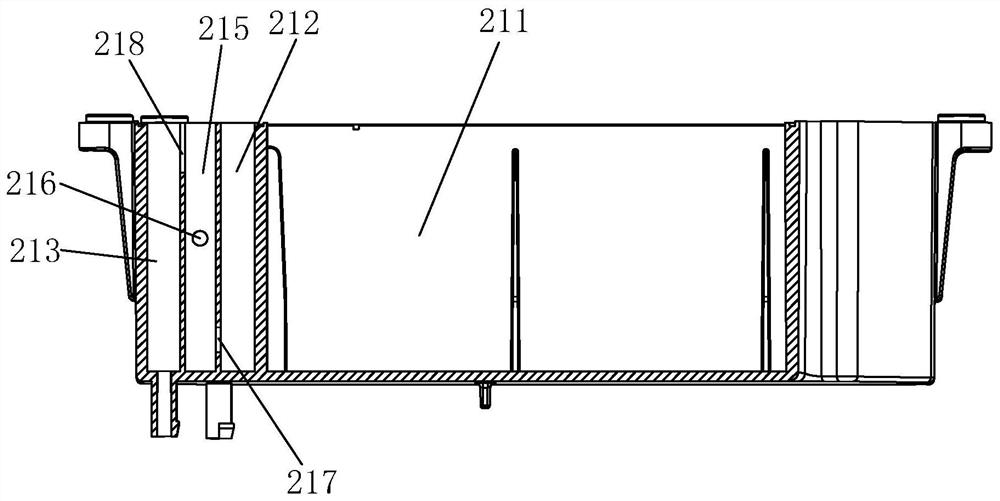

Mixing device of foaming liquid and method thereof, foaming system and closestool

PendingCN113605503AWell mixedSmall volumeMixing methodsLavatory sanitoryProcess engineeringEnvironmental geology

The invention discloses a foaming liquid mixing device and a method thereof, a foaming system and a closestool, the foaming liquid mixing device comprises a water inlet structure, a mixed liquid outlet, a mixing cavity, a foaming agent storage cavity and an infusion pump, and further comprises a plurality of dilution cavities which are communicated one by one to form a multi-stage dilution structure; the water inlet structure is communicated with a first-stage dilution cavity and a last-stage dilution cavity of the multi-stage dilution structure, an inlet of the infusion pump is communicated with a foaming agent outlet of the foaming agent storage cavity, and an outlet of the infusion pump is communicated with a foaming agent inlet of the first-stage dilution cavity; the final-stage dilution cavity is communicated with the mixing cavity, and the mixing cavity is communicated with the mixed liquid outlet. A foaming agent can be subjected to multi-stage dilution in the mixing process of the foaming agent and water, so that the foaming frequency can be increased and waste can be avoided under the condition of the same usage amount of the foaming agent, and meanwhile, the foaming agent and the water can be uniformly mixed, so that the foaming effect is ensured.

Owner:XIAMEN KEMU INTELLIGENT TECH

A method of making non-woven paper crepe foam wallpaper

ActiveCN105040523BGuaranteed foaming effectGuaranteed to meet the requirementsSpecial paperPaper/cardboardWrinkle skinPlasticizer

The invention discloses a method for making non-woven paper wrinkled and foamed wallpaper. In the invention, the base material of the non-woven paper wrinkled and foamed is more environmentally friendly non-woven paper, and the printing material is a wrinkled and foamed material with a changed melting point. , the melting point is 180 degrees, consistent with the melting point of PVC. In order to ensure the height of wrinkle foaming, two laser gravure printing PVC coatings are used to ensure that the height of the PVC printing layer meets the requirements, and finally another version of laser gravure wrinkling foaming material is printed on the PVC printing layer, using PVC melting point It has the same characteristics as the melting point of the crepe material, fully volatilizes the organic matter and plasticizer in the PVC, and foams the PVC and the crepe material together to ensure the foaming height and the foaming effect of the crepe material. Compared with the traditional PVC wrinkle foam, the non-woven paper wrinkle foam not only reduces the process, does not require a coating process, and can be printed and foamed directly on the gravure printing machine, and the wallpaper does not contain organic matter and plasticizers, which will be more environmentally friendly .

Owner:上海希尔彩印制版有限公司

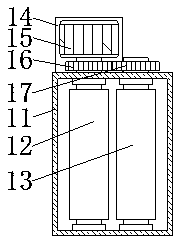

Novel water heater thin double-liner foaming mold and foaming method

The invention relates to the technical field of foaming molds, and discloses a novel water heater thin double-liner foaming mold and a foaming method.The novel water heater thin double-liner foaming mold comprises a machine body frame, a bottom table is fixedly installed at the bottom of the machine body frame, a micro air cylinder is fixedly installed at the top of the machine body frame, and a foam blocking rod frame is fixedly installed at the tail end of the micro air cylinder; and a main tray and an auxiliary tray are fixedly installed on the upper surface of the bottom table, and anti-abrasion devices are arranged at the bottom of the main tray and the bottom of the auxiliary tray correspondingly. In the foaming material injection process, a vertical frame is pushed by an air cylinder to move upwards, short connecting rods on the two sides of the vertical frame are opened at the same time, and under the action of a fixed frame plate, movable push plates at the left ends of the short connecting rods move leftwards to make contact with a water heater body and then continuously extrude a machine body frame till the short connecting rods are completely opened; therefore, deformation of the water heater body in the foaming process is avoided, and foaming forming stability is improved.

Owner:CHUZHOU KEXIN MECHANICAL TECH

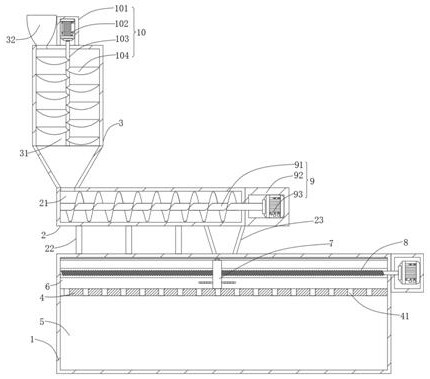

Rubber and plastic blending foaming agent filling device

PendingCN113414930AGuaranteed foaming effectImprove foaming qualityGrain treatmentsCakingReciprocating motion

The invention discloses a rubber and plastic blending foaming agent filling device which comprises a main shell. The top face of the main shell is fixedly connected with a material pushing pipe through a support; the top face of the material pushing pipe is fixedly connected with a crushing bin; a baffle is horizontally and fixedly connected into the main shell; a powder homogenizing cavity is formed in the position, above the baffle, in the main shell; a filling cavity is formed in the position, below the baffle, in the main shell; and two first sliding grooves are formed in the two sides of the interior of the powder homogenizing cavity. According to the rubber and plastic blending foaming agent filling device, the crushing bin is arranged, a crushing transmission assembly is arranged in the crushing bin, and the caking part and the adhesion part of a rubber and plastic blending foaming agent can be crushed under the action of a crushing cutter, so that the powder quality of the rubber and plastic blending foaming agent is guaranteed, and the foaming effect is guaranteed; meanwhile, a powder homogenizing plate is arranged and does reciprocating motion, so that the rubber and plastic blending foaming agent falls onto a shaking plate; and when the powder homogenizing plate does reciprocating motion, the shaking plate shakes, the rubber and plastic blending foaming agent falls down from a powder homogenizing opening in the shaking plate, so that the rubber and plastic blending foaming agent is more uniform during filling and discharging, and the foaming quality is improved.

Owner:滁州神州绝热科技有限公司

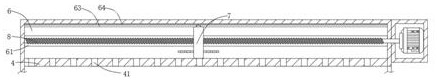

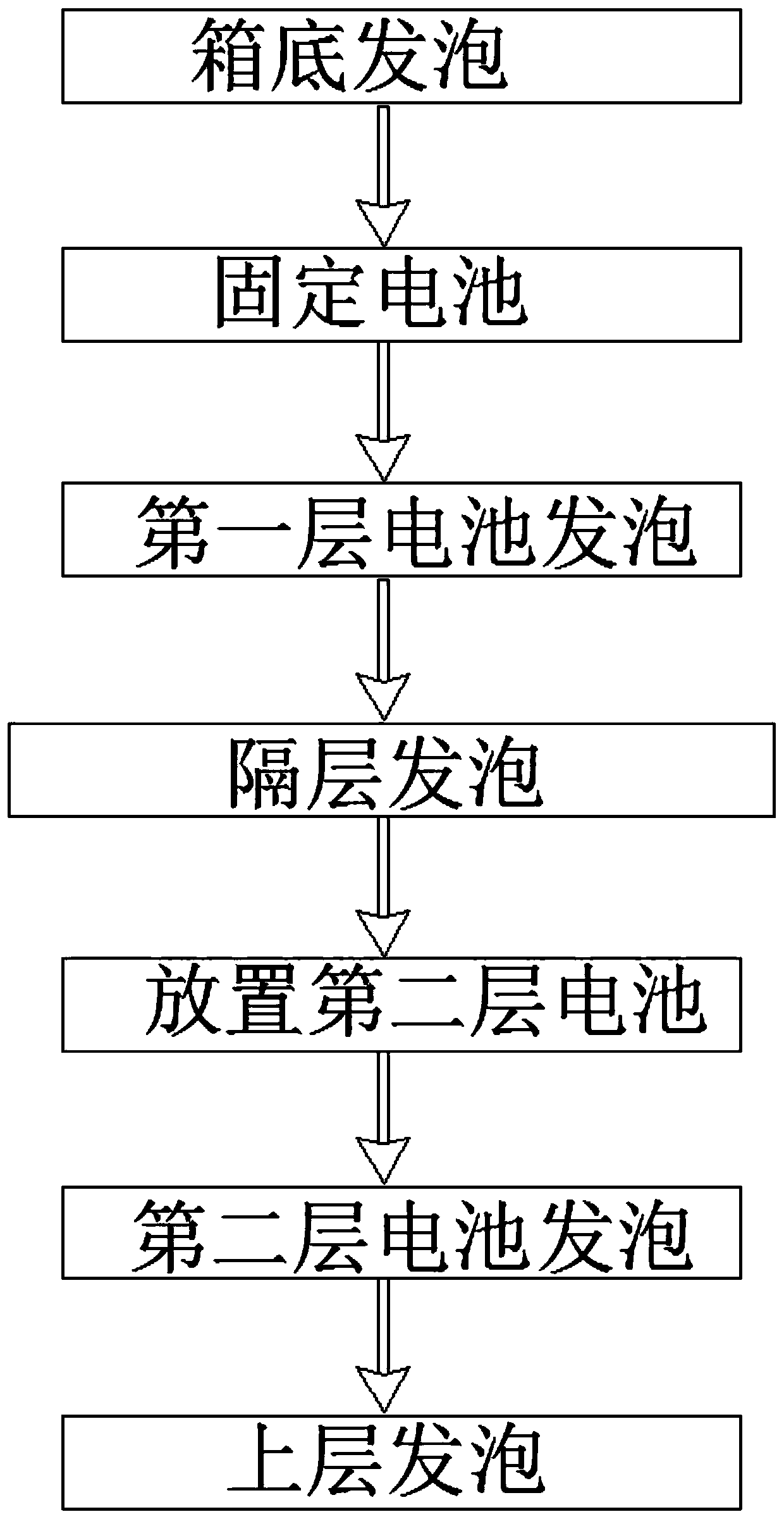

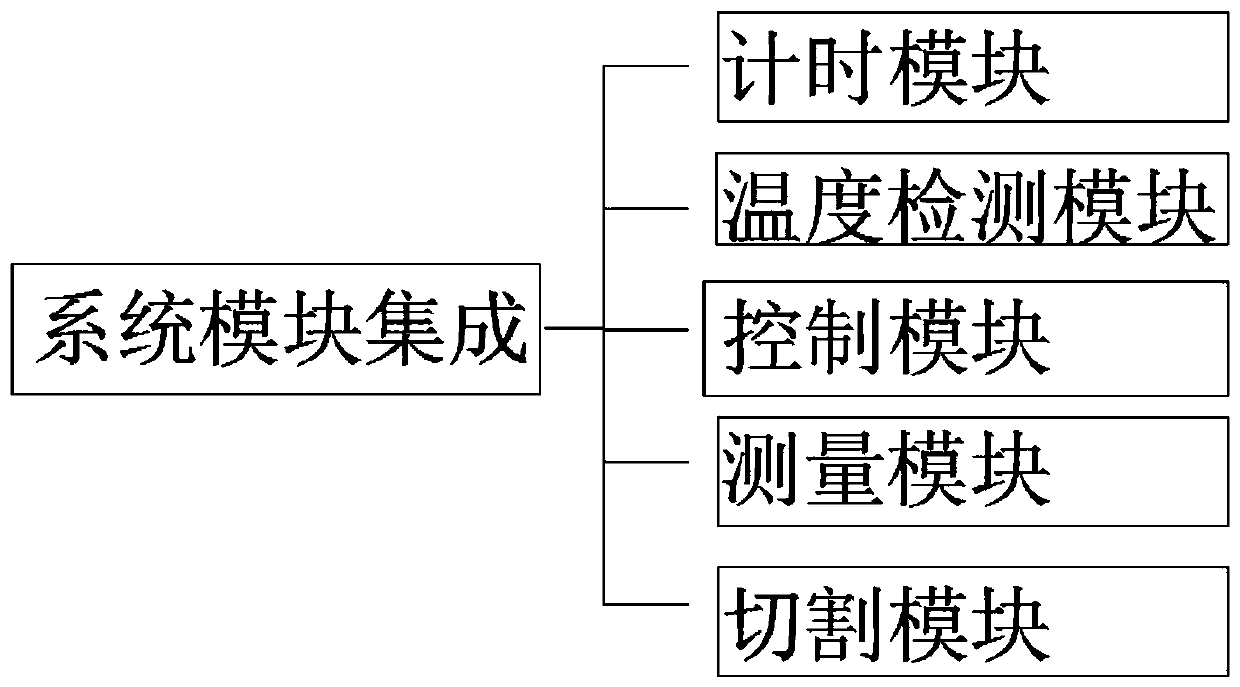

Foaming process of integrated battery pack

The invention discloses a foaming process of an integrated battery pack. The foaming process comprises the following steps of S1, foaming a box bottom, namely putting polyurethane at the bottom of a box body, and enabling the polyurethane to carry out foaming work; S2, fixing a battery, namely mounting and fixing a first layer of battery at the upper part of a first layer of foaming body; S3, foaming the first layer of battery, namely after mounting and fixing, carrying out foaming work on the first layer of battery under the action of the polyurethane; S4, foaming an interlayer, namely afterfoaming the first layer of battery, carrying out interlayer foaming, so as to enable the polyurethane to submerge the first layer of battery; and S5, placing a second layer of battery. According to the foaming process disclosed by the invention, the battery can be sufficiently protected and the resistance of the battery is improved; the battery can be used in high-cold and high-heat places, so that the use applicability of the battery is improved; enough intervals can be used for resisting heat conduction and preventing the battery from being damaged by overheating; enough polyurethane foaminglayer intervals also can be used for providing enough support; the foaming process has the advantages of better safety, excellent insulating property and good heat insulation property.

Owner:中北润良新能源汽车(徐州)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com