Novel bubble spraying machine and disinfecting method thereof

A new type of spray gun technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of low field applicability, increased material costs, pulling wires, etc., to ensure the lift and fan size, increase the attachment time, and avoid potential safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

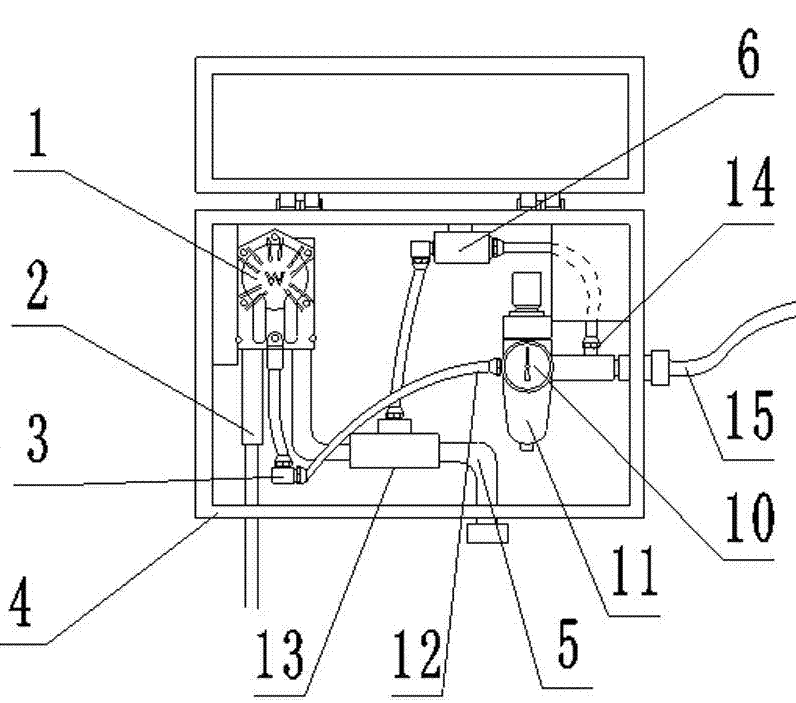

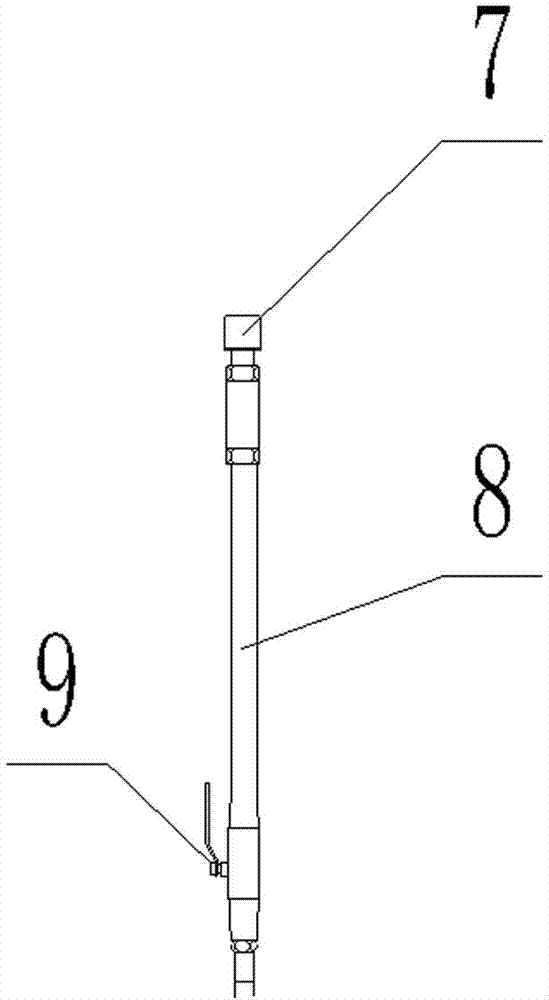

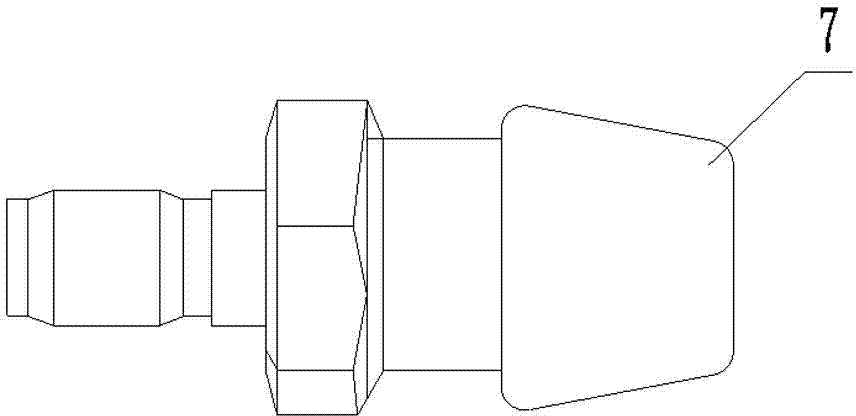

[0038] like figure 1 As shown, a new type of foam spraying machine is characterized in that, the air source 15 is connected with the pressure-stabilizing valve through the branch gas pipe 14, the branch gas pipe 14 is connected with the gas-liquid mixing pump 13 through the gas distribution regulating valve 6, and the pressure gauge filter 11 A pressure gauge 10 is installed on it, the pressure gauge filter 11 is connected to the pneumatic diaphragm pump connecting pipe 12, and the pneumatic diaphragm pump connecting pipe 12 is connected to the pneumatic diaphragm pump 1 through the air pipe buffer joint 3, and the two ends of the pneumatic diaphragm pump 1 are provided with inlets. The liquid pipe 2 is connected with the liquid outlet pipe 5, and the liquid outlet pipe 5 is connected with the spray gun. The spray gun includes a spray gun rod 8 and a spray head 7. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com