A hybrid plant-based polyurethane porous material impregnated with carbon nanotubes and graphene oxide and its preparation method

A technology of carbon nanotubes and mixed plants, which is applied in the field of automotive acoustic materials, can solve problems such as poor degradability and environmental pollution, and achieve the effects of easy degradation, reduced environmental pollution, and guaranteed drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

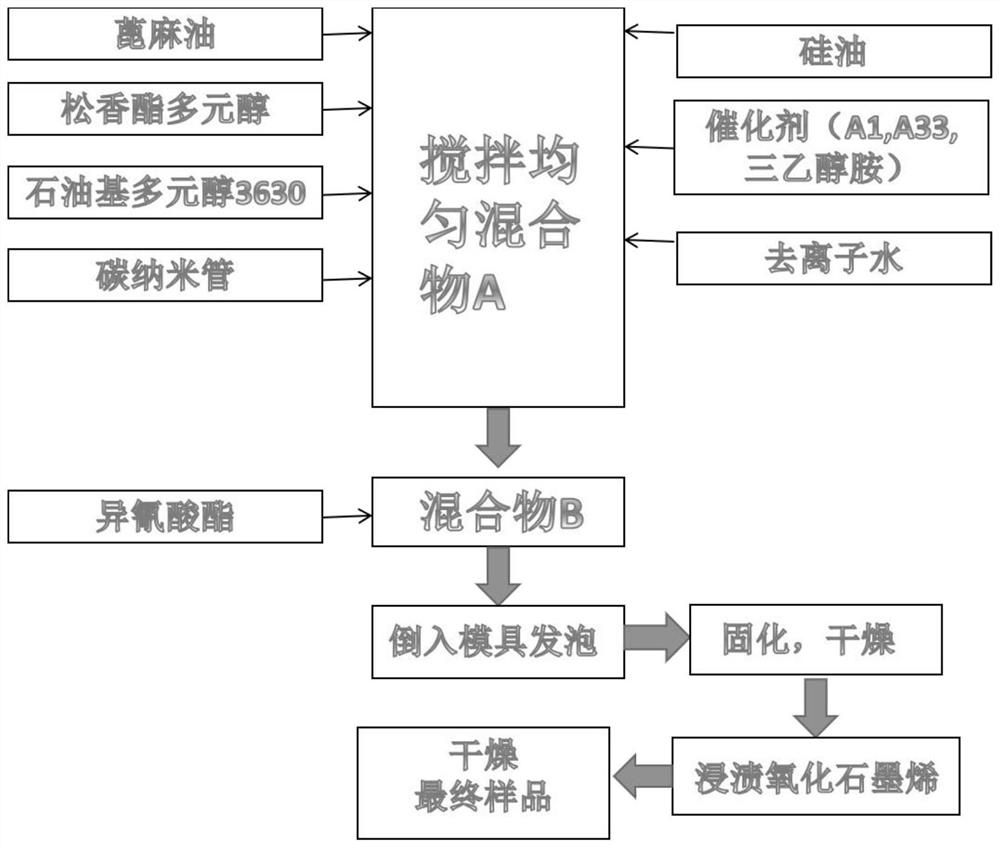

[0033] Such as figure 1 Shown, the preparation method step of the mixed plant-based polyurethane porous material based on carbon nanotube and graphene oxide impregnation is as follows:

[0034] Step 1, take the following raw materials according to the mass fraction:

[0035] Castor oil: 34-36 parts, rosin ester polyol 9-11 parts, polyether polyol: 68-72 parts, carbon nanotube: 3 parts, foam stabilizer: 0.6 parts, triethanolamine: 2.5 parts, catalyst A1: 0.08 parts, catalyst A33: 1.0 parts, deionized water: 2.5 parts;

[0036] Step 2. Add the raw materials into the stirring device, first stir at a very low speed n1=30rpm to prevent the carbon nanotubes from flying, and after the carbon nanotubes are fully mixed, stir at a speed n2=1200rpm to prepare a mixture A, and Stand for 1 to 2 minutes;

[0037] Step 3, adding 34 to 36 parts of polymerized MDI, and stirring at a speed of n3=1600rpm to obtain a mixture B;

[0038] Step 4. Pour the mixture B into the mold for free foamin...

Embodiment 1

[0044] Take the following raw materials by mass fraction:

[0045] Castor oil polyol: 35.124 parts, rosin ester polyol 10.607 parts, polyether polyol: 70.446 parts, foam stabilizer: 0.6 parts, triethanolamine: 2.5 parts, catalyst A1: 0.08 parts, catalyst A33: 1.0 parts, deionized Water: 2.5 parts; wherein, the hydroxyl value range of the castor oil polyol is 160~200mg KOH / g;

[0046] Step 2, adding the raw materials into a stirring device, stirring at a speed of n2=1200rpm to prepare a mixture A, and standing for 1 to 2 minutes;

[0047] Step 3, add 34 parts of polymerized MDI, and stir at the rotation speed n3=1600rpm to obtain the mixture B;

[0048] Step 4. Pour the mixture B into the mold for free foaming, put it into the incubator for curing for 12 hours, and the temperature is 50°C;

[0049] Step 5. After standing at room temperature, the surface crust is removed to obtain a mixed plant-based polyurethane porous material.

Embodiment 2

[0051] Take the following raw materials by mass fraction:

[0052] Castor oil polyol: 35.292 parts, rosin ester polyol 10.012 parts, polyether polyol: 69.921 parts, foam stabilizer: 0.6 parts, triethanolamine: 2.5 parts, catalyst A1: 0.08 parts, catalyst A33: 1.0 parts, deionized Water: 2.5 parts; wherein, the hydroxyl value range of the castor oil polyol is 160~200mg KOH / g;

[0053] Step 2, adding the raw materials into a stirring device, stirring at a speed of n2=1200rpm to prepare a mixture A, and standing for 1 to 2 minutes;

[0054] Step 3, add 34 parts of polymerized MDI, and stir at the rotation speed n3=1600rpm to obtain the mixture B;

[0055] Step 4. Pour the mixture B into the mold for free foaming, put it into the incubator for curing for 12 hours, and the temperature is 50°C;

[0056] Step 5. After placing at room temperature, remove the surface crust to obtain a mixed plant-based polyurethane porous material;

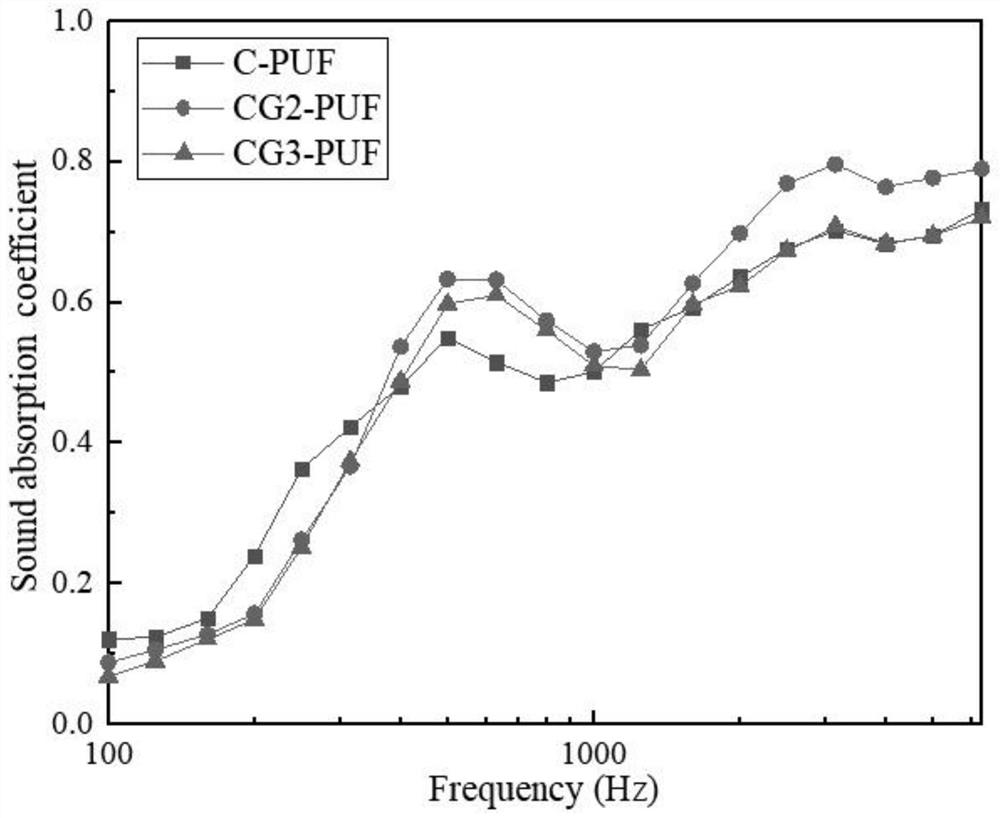

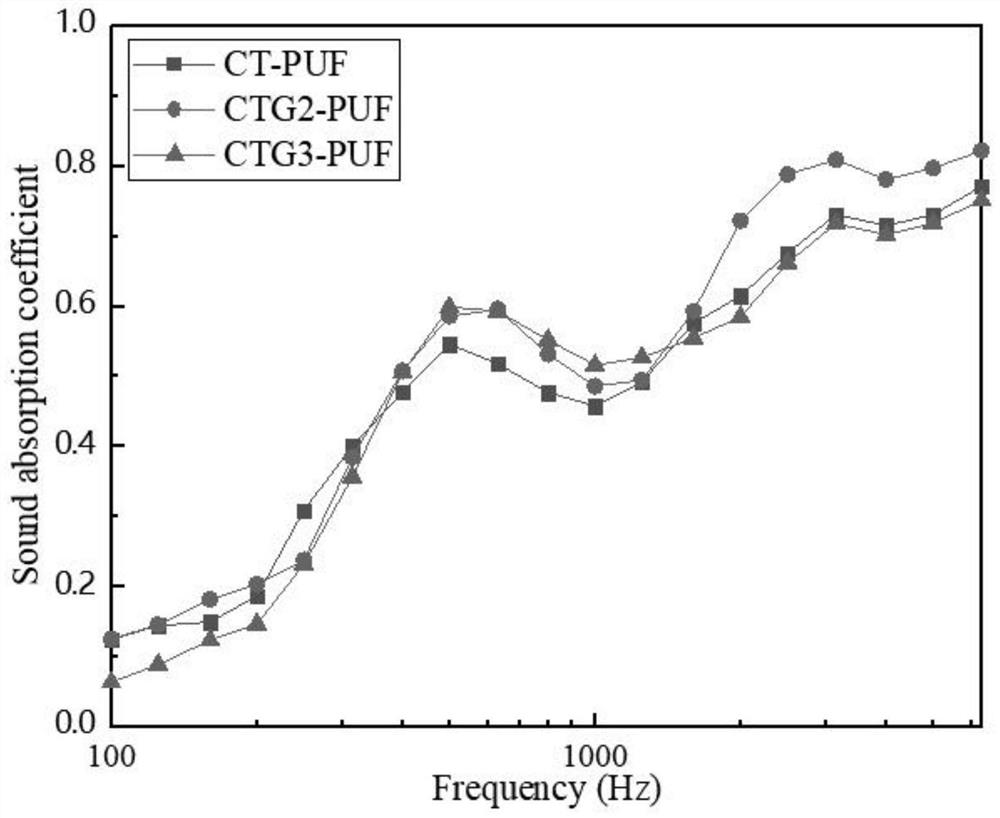

[0057] Step 6. Mix 2 parts of graphene oxide with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com