Polystyrene thermal-insulation plastic extrusion plate similar to EPS plate and preparation method thereof

A technology of polystyrene and polystyrene particles, which is applied in the field of extruded boards, can solve the problems of mixing and inability to identify the quality of materials from the appearance, and achieve the effects of reducing cell density, increasing hardness, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

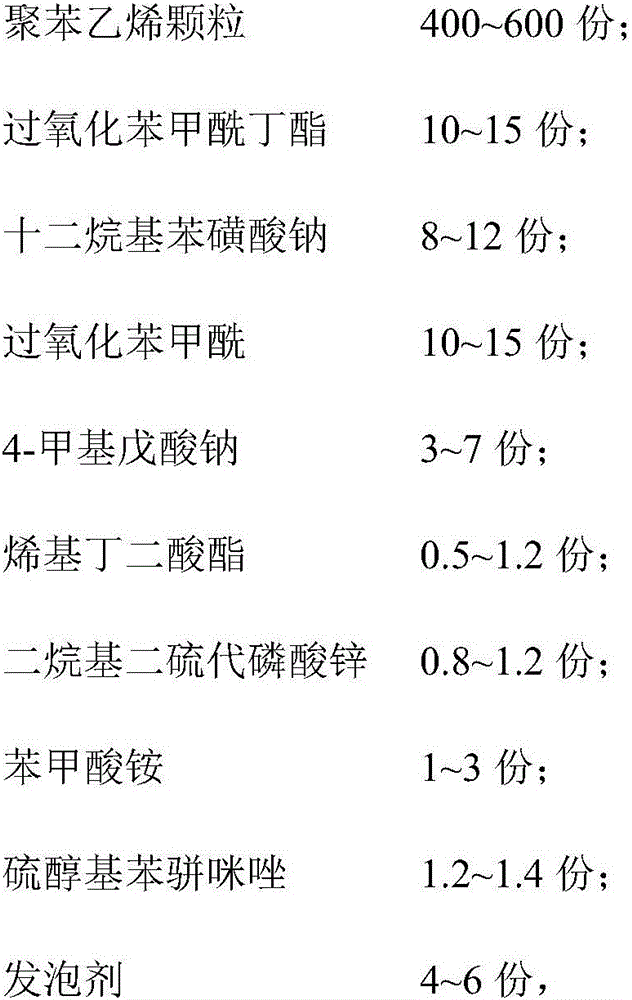

[0024] Embodiment 1: A polystyrene insulation extruded board similar to EPS board, including the following components:

[0025]

[0026] Each component is measured in parts by weight, wherein the polystyrene particles are composed of polystyrene virgin material, polystyrene recycled material and polystyrene waste, and the mixing ratio is 1.5:2:1.5.

[0027] The preparation method of the polystyrene insulation extruded board of the class EPS board of the present embodiment comprises the following steps:

[0028] (1) Mix and granulate polystyrene reclaimed material and polystyrene waste material after recovery, add in the mixer together with polystyrene new material, then add benzoyl peroxide, twelve Sodium alkylbenzene sulfonate and benzoyl peroxide, start the mixer to mix the materials, and heat the mixed materials to 150°C, keep stirring for 2 hours, then stop and cool;

[0029] (2) Add alkenyl succinate, zinc dialkyldithiophosphate and mercaptobenzoimidazole into the mix...

Embodiment 2

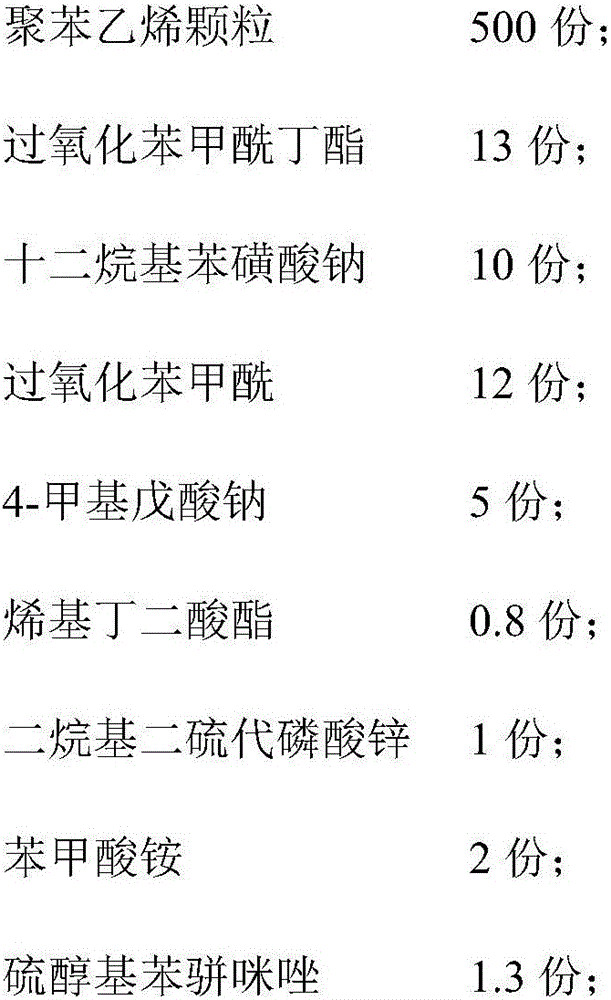

[0031] Embodiment 2: A polystyrene insulation extruded board like EPS board, including the following components:

[0032]

[0033] Each component is measured in parts by weight, wherein the polystyrene particles are composed of polystyrene virgin material, polystyrene recycled material and polystyrene waste, and the mixing ratio is 1.5:2:1.5.

[0034] The preparation method of the polystyrene insulation extruded board of the class EPS board of the present embodiment comprises the following steps:

[0035] (1) Mix and granulate polystyrene reclaimed material and polystyrene waste material after recovery, add in the mixer together with polystyrene new material, then add benzoyl peroxide, twelve Sodium alkylbenzene sulfonate and benzoyl peroxide, start the mixer to mix the materials, and heat the mixed materials to 200°C, keep stirring for 4 hours, then stop and cool;

[0036] (2) Add alkenyl succinate, zinc dialkyldithiophosphate and mercaptobenzimidazole into the mixer, sta...

Embodiment 3

[0038] Embodiment 3: A polystyrene insulation extruded board like EPS board, including the following components:

[0039]

[0040]

[0041] Each component is measured in parts by weight, wherein the polystyrene particles are composed of polystyrene virgin material, polystyrene recycled material and polystyrene waste, and the mixing ratio is 1.5:2:1.5.

[0042] The preparation method of the polystyrene insulation extruded board of the class EPS board of the present embodiment comprises the following steps:

[0043] (1) Mix and granulate polystyrene reclaimed material and polystyrene waste material after recovery, add in the mixer together with polystyrene new material, then add benzoyl peroxide, twelve Sodium alkylbenzene sulfonate and benzoyl peroxide, start the mixer to mix the materials, and heat the mixed materials to 180°C, keep stirring for 3 hours, then stop and cool;

[0044] (2) Add alkenyl succinate, zinc dialkyldithiophosphate and mercaptobenzoimidazole into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com