Economical polystyrene heat-preservation extruded board and preparation method thereof

A technology of polystyrene and polystyrene particles, which is applied in the field of extruded boards, can solve the problems of low product strength, broken molecular chains, and not easy to bend, so as to reduce production costs, reduce cell density, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

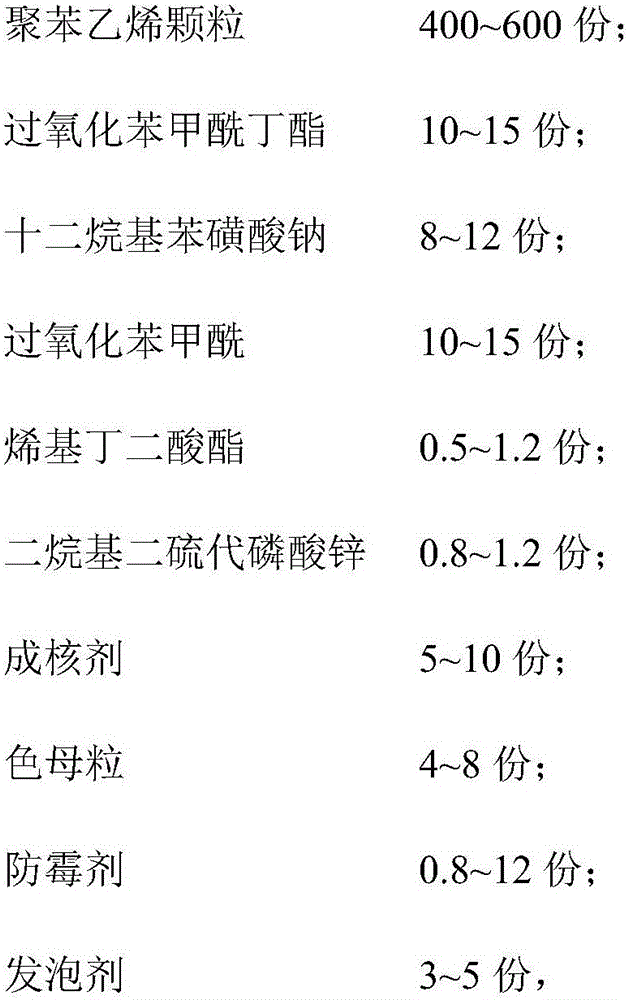

[0026] Embodiment 1: An economical polystyrene insulation extruded board, including the following components:

[0027]

[0028] Among them, polystyrene particles are composed of polystyrene virgin material, polystyrene recycled material and polystyrene waste, and the mixing ratio is 1:2:2. The antifungal agent is a mixture of 8-hydroxyquinoline copper and ammonium benzoate, and the mixing ratio is 1:1.2. The carrier of the color masterbatch is polyperfluoroethylene propylene.

[0029] The preparation method of economical polystyrene insulation extruded board described in this embodiment comprises the following steps:

[0030] (1) Mix and granulate polystyrene reclaimed material and polystyrene waste material after recovery, add in the mixer together with polystyrene new material, then add benzoyl peroxide, twelve Sodium alkylbenzene sulfonate and benzoyl peroxide, start the mixer to mix the materials, and heat the mixed materials to 150°C, keep stirring for 2 hours, then ...

Embodiment 2

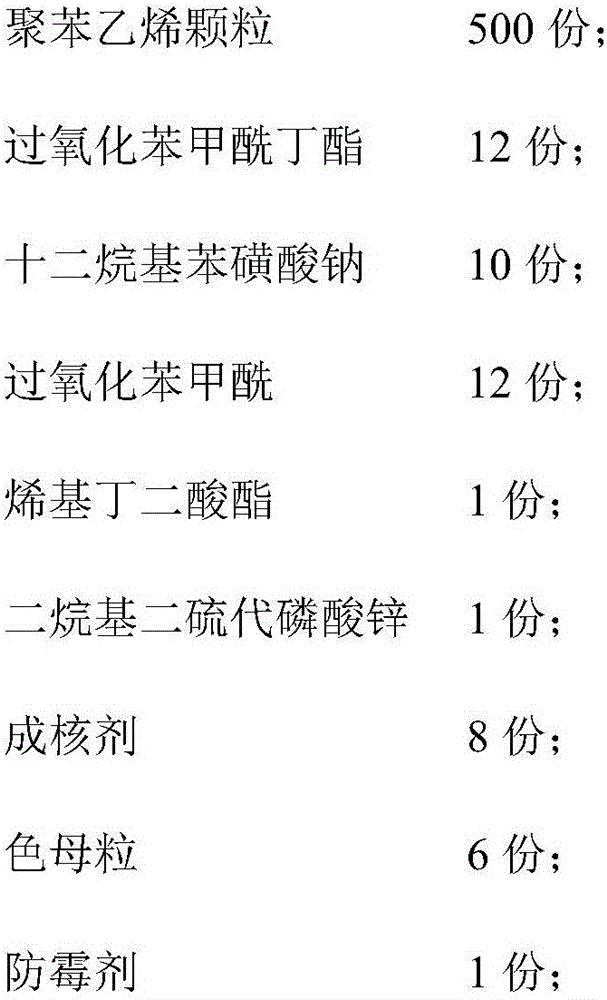

[0034] Embodiment 2: An economical polystyrene insulation extruded board, including the following components:

[0035]

[0036]

[0037] The polystyrene particles are composed of polystyrene virgin material, polystyrene recycled material and polystyrene waste, and the mixing ratio is 1:2:2. The antifungal agent is a mixture of 8-hydroxyquinoline copper and ammonium benzoate, and the mixing ratio is 1:1.2. The carrier of the color masterbatch is polyperfluoroethylene propylene.

[0038] The preparation method of economical polystyrene insulation extruded board described in this embodiment comprises the following steps:

[0039] (1) Mix and granulate polystyrene reclaimed material and polystyrene waste material after recovery, add in the mixer together with polystyrene new material, then add benzoyl peroxide, twelve Sodium alkylbenzene sulfonate and benzoyl peroxide, start the mixer to mix the materials, and heat the mixed materials to 200°C, keep stirring for 4 hours, t...

Embodiment 3

[0043] Embodiment 3: An economical polystyrene insulation extruded board, including the following components:

[0044]

[0045]

[0046] The polystyrene particles are composed of polystyrene virgin material, polystyrene recycled material and polystyrene waste, and the mixing ratio is 1:2:2. The antifungal agent is a mixture of 8-hydroxyquinoline copper and ammonium benzoate, and the mixing ratio is 1:1.2. The carrier of the color masterbatch is polyperfluoroethylene propylene.

[0047] The preparation method of economical polystyrene insulation extruded board described in this embodiment comprises the following steps:

[0048] (1) Mix and granulate polystyrene reclaimed material and polystyrene waste material after recovery, add in the mixer together with polystyrene new material, then add benzoyl peroxide, twelve Sodium alkylbenzenesulfonate and benzoyl peroxide, start the mixer to mix the materials, and heat the mixed materials to 180°C, keep stirring for 3 hours, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com