Nontransparent polymer resin and application thereof in serum separation gel

A technology for serum separation gel and polymer resin, which is applied in the field of serum separation gel and its preparation, can solve the problems of poor compatibility, easy phase separation, etc., and achieves the effects of moderate initiating activity, easy rate control, and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

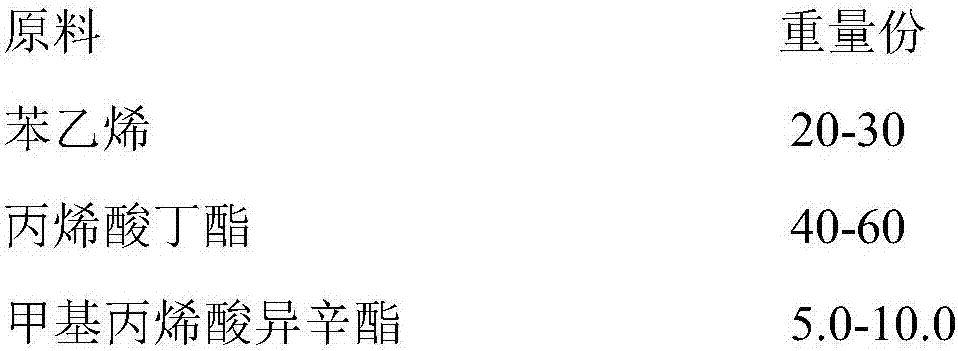

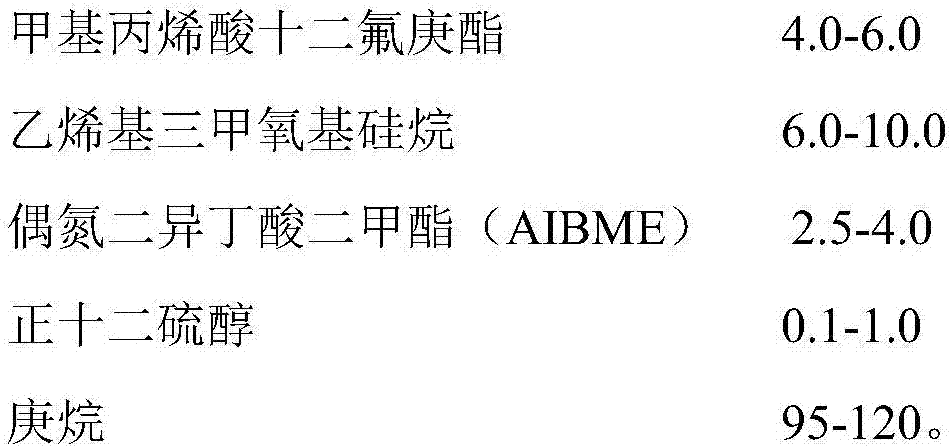

Method used

Image

Examples

Embodiment 2

[0036] Example 2: Preparation of Opaque Polymer Resin

[0037]Put 275g of heptane into the reactor and heat up to 65-70°C; add 6.0g of AIBME to 62.5g of styrene, 137.5g of butyl acrylate, 20.0g of isooctyl methacrylate and 1.25g of n-dodecanethiol In the mixed solution formed, stir and mix evenly and AIBME is completely dissolved to form a mixed solution A, drop the mixed solution A into the reaction kettle, control the drop rate of the mixed solution A, and complete the dropwise addition in 2.35 hours. During the dropping process, control The temperature of the reaction solution is 65-70°C; after the dropwise addition, start to heat up, control the temperature of the reaction solution between 70-75°C, and keep it warm for 0.5h; In the mixed solution composed of heptyl ester and 17.5g vinyltrimethoxysilane, stir and mix until the AIBME is completely dissolved to form a mixed solution B, and then add the mixed solution B dropwise into the above reaction kettle, and keep the rea...

Embodiment 3

[0038] Example 3: Preparation of Opaque Polymer Resin

[0039] Put 275g of heptane into the reaction kettle, heat up to 65-70°C; add 6.0g of AIBME to 62.5g of styrene, 137.5g of butyl acrylate, 25.0g of isooctyl methacrylate and 1.25g of n-dodecanethiol In the mixed solution formed, stir and mix evenly and AIBME is completely dissolved to form a mixed solution A, drop the mixed solution A into the reaction kettle, control the drop rate of the mixed solution A, and complete the dropwise addition in 2.4 hours. During the dropping process, control The temperature of the reaction solution is 65-70°C; after the dropwise addition, start to heat up, control the temperature of the reaction solution between 70-75°C, and keep it warm for 0.5h; In the mixed solution composed of heptyl ester and 17.5g vinyltrimethoxysilane, stir and mix until the AIBME is completely dissolved to form a mixed solution B, and then add the mixed solution B dropwise into the above reaction kettle, and keep th...

Embodiment 4

[0040] Example 4: Preparation of Opaque Polymer Resin

[0041] Put 275g of heptane into the reaction kettle, heat up to 65-70°C; add 6.0g of AIBME to 62.5g of styrene, 137.5g of butyl acrylate, 25.0g of isooctyl methacrylate and 1.25g of n-dodecanethiol In the mixed solution formed, stir and mix evenly and AIBME is completely dissolved to form a mixed solution A, drop the mixed solution A into the reaction kettle, control the drop rate of the mixed solution A, and complete the dropwise addition in 2.6 hours. The temperature of the reaction liquid is 65-70°C; after the dropwise addition is completed, the temperature is raised, and the temperature of the reaction liquid is controlled between 70-75°C, and kept for 0.5h; ester and 15.0g of vinyltrimethoxysilane, stir and mix until the AIBME is completely dissolved to form a mixed solution B, and then add the mixed solution B dropwise into the above reaction kettle, and keep the reaction solution during the dropwise addition The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com