A Processing Technology of Submerged Arc Welded Straight Seam Steel Pipe with Shock Absorbing Structure

A technology of shock absorption and processing technology, applied in the field of straight seam submerged arc welded steel pipes, it can solve the problems of comparable impact resistance of welds, and achieve the effects of avoiding pollution, reducing structural damage and stabilizing shock absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

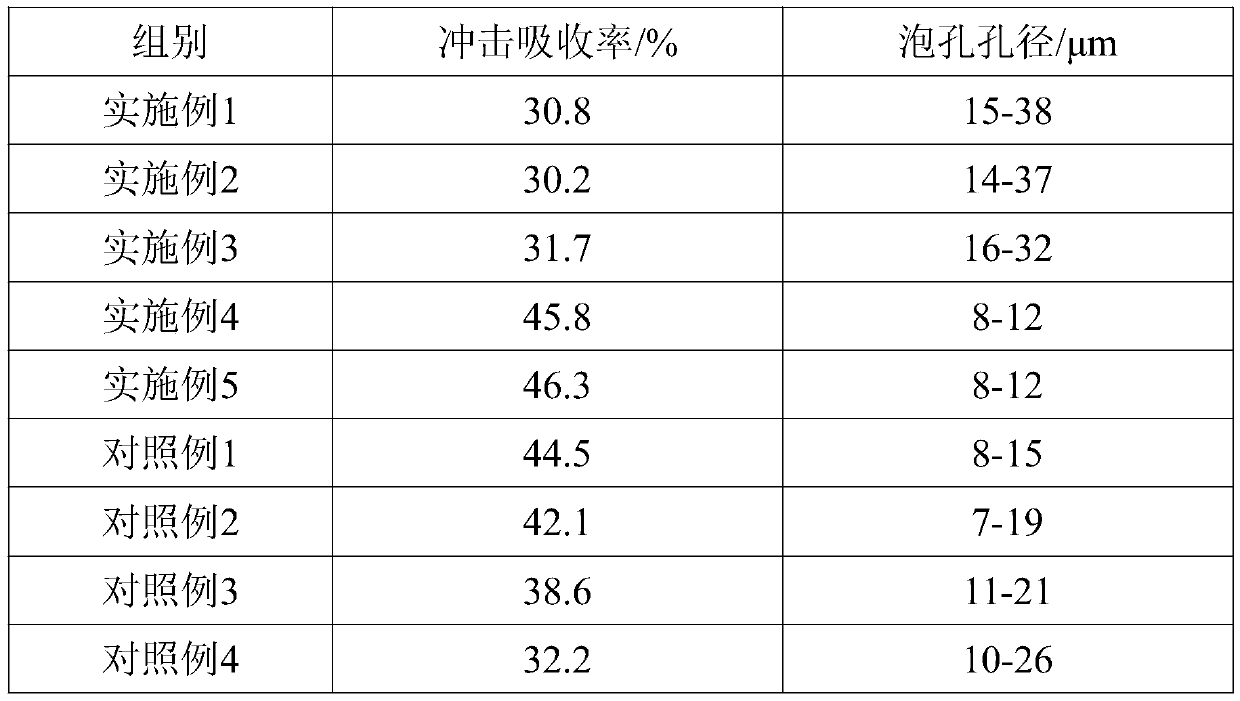

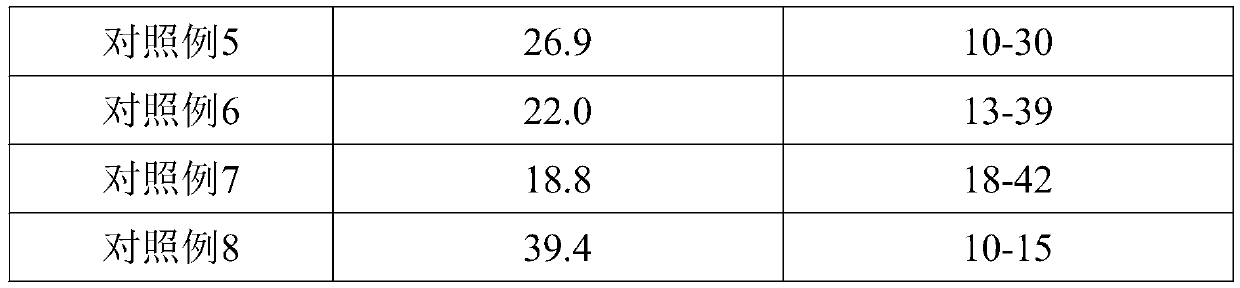

Examples

Embodiment 1

[0024] (1) Processing of submerged arc welded straight seam steel pipes: select carbon steel steel plate as the base layer and metal steel plate as the cladding layer. The bimetallic composite steel plate is made by hot rolling process, and is milled, pre-curved, JCO formed, and seamed Pre-welding, submerged arc internal welding base carbon steel steel plate, submerged arc external welding cladding metal steel plate, ultrasonic inspection, X-ray inspection, finishing treatment, namely submerged arc welding longitudinal seam steel pipe;

[0025] (2) Processing of impact absorbing material: heat 40kg magnesium ingot to 645-650℃ for heat preservation. When the magnesium melting rate reaches 50%, use permanent magnetic mixer to start stirring. After the magnesium ingot is completely melted, add 25kg aluminum ingot and continue heating to 660 -665℃ heat preservation and stirring, after the aluminum ingot is completely melted, add 5kg calcined kaolin, 5kg molecular sieve activation powd...

Embodiment 2

[0028] (1) Processing of submerged arc welded straight seam steel pipes: select carbon steel steel plate as the base layer and metal steel plate as the cladding layer. The bimetallic composite steel plate is made by hot rolling process, and is milled, pre-curved, JCO formed, and seamed Pre-welding, submerged arc internal welding base carbon steel steel plate, submerged arc external welding cladding metal steel plate, ultrasonic inspection, X-ray inspection, finishing treatment, namely submerged arc welding longitudinal seam steel pipe;

[0029] (2) Processing of impact absorbing material: heat 40kg magnesium ingot to 645-650℃ for heat preservation. When the magnesium melting rate reaches 50%, use permanent magnetic mixer to start stirring. After the magnesium ingot is completely melted, add 25kg aluminum ingot and continue heating to 660 -665℃ heat preservation and stirring, after the aluminum ingot is completely melted, add 5kg calcined kaolin, 5kg molecular sieve activation powd...

Embodiment 3

[0032] (1) Processing of submerged arc welded straight seam steel pipes: select carbon steel steel plate as the base layer and metal steel plate as the cladding layer. The bimetallic composite steel plate is made by hot rolling process, and is milled, pre-curved, JCO formed, and seamed Pre-welding, submerged arc internal welding base carbon steel steel plate, submerged arc external welding cladding metal steel plate, ultrasonic inspection, X-ray inspection, finishing treatment, namely submerged arc welding longitudinal seam steel pipe;

[0033] (2) Processing of impact absorbing material: heat 40kg magnesium ingot to 645-650℃ for heat preservation. When the magnesium melting rate reaches 50%, use permanent magnetic mixer to start stirring. After the magnesium ingot is completely melted, add 25kg aluminum ingot and continue heating to 660 -665℃ heat preservation and stirring, after the aluminum ingot is completely melted, add 5kg calcined kaolin, 5kg molecular sieve activation powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com