Auto pillow foaming experiment line

A technology for car seat cushions and experiments, applied in household components, household appliances, other household appliances, etc., can solve the problems of waste, long cycle, and large labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

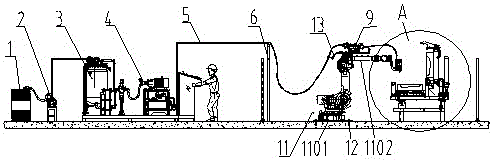

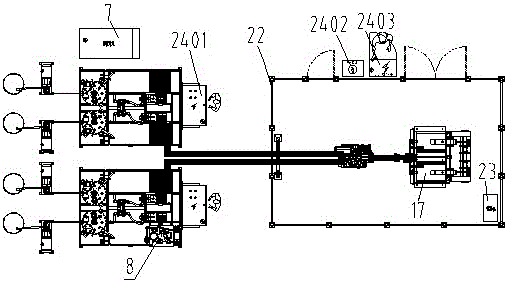

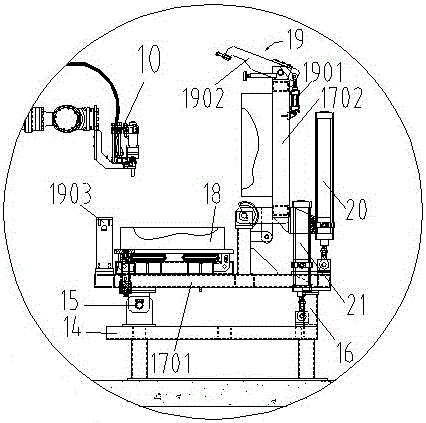

[0021] exist figure 1 with figure 2 In the embodiment of the present invention, the present invention includes an electronic control system 24 for controlling the operation of the experimental line, a two-component high-pressure foaming machine for foaming raw materials, a manipulator 11 for adjusting the pouring position of the raw materials, and a foaming machine for shaping the foaming raw materials. Formwork and safety devices for safety protection.

[0022] The electric control system 24 includes a foaming machine control cabinet 2401 for controlling the foaming of raw materials, a manipulator control cabinet 2402 for controlling the movement of the manipulator 11, and an experimental line for controlling the formwork 17 and communicating with the foaming machine and the manipulator 11 Control cabinet 2403.

[0023] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com