Mixing device of foaming liquid and method thereof, foaming system and closestool

A mixing device and foaming liquid technology, applied in mixing methods, mixers, water supply devices, etc., can solve problems such as waste, reduced use of a single bottle of foaming agent, and increased manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

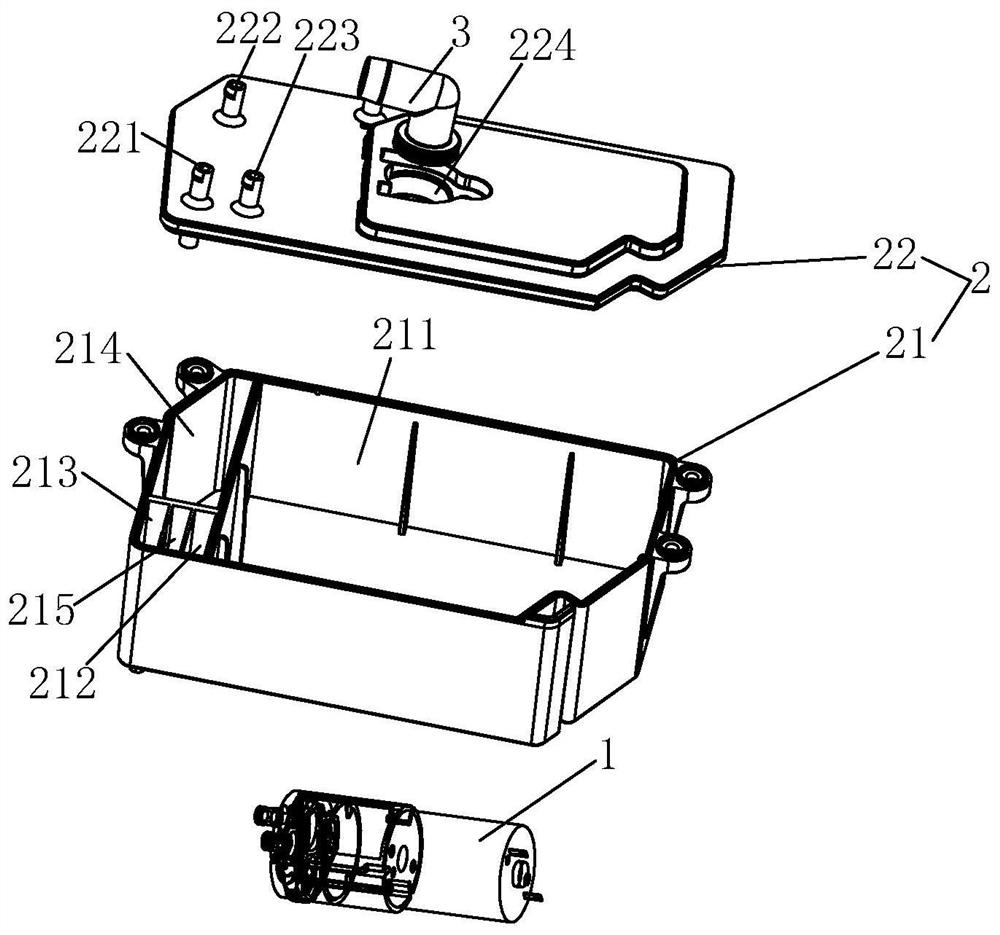

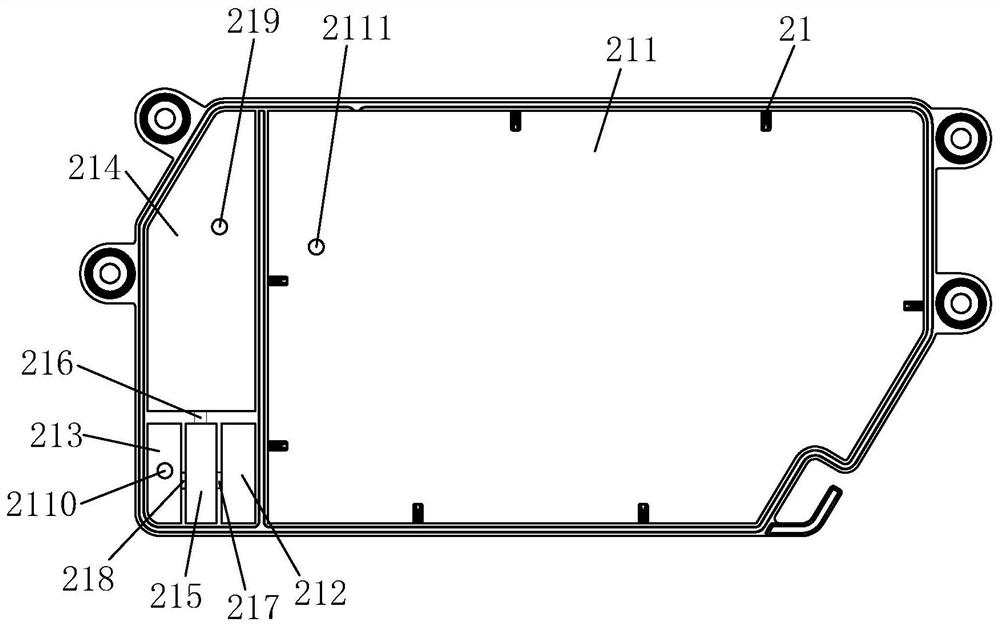

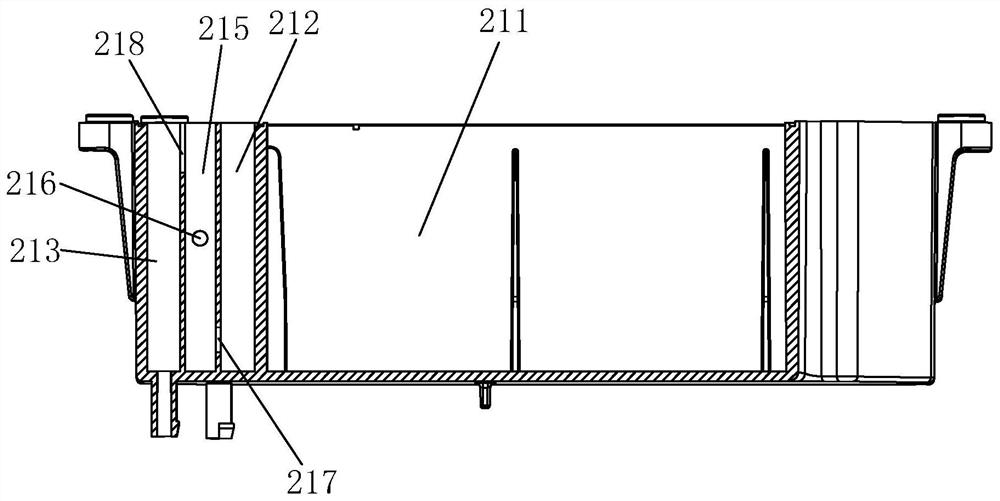

[0044] See Figure 1 - Figure 10 As shown, the mixing device of a foaming liquid of the present invention includes a structure, a mixing liquid outlet 223, a mixing chamber 212, a blowing agent storage chamber 211, and a pumping pump 2, further comprising several dilution cavities, the number of dilution cavities Connect one by one, constitute a multi-stage dilution structure, the water-based structure connects the first-stage dilution cavity 214 and the end-stage dilution cavity 215, the inlet of the extract of the pump 2, the foaming agent of the inlet of the pump 2 The outlet 2111, the outlet of the draw pump 2 communicates the foaming agent inlet 222 of the first stage dilution chamber 214; the mixing chamber 212 communicates the end-stage dilution cavity 215 in communication with the mixing chamber 212 in communication with the mixed liquid outlet 223. The first stage diluent cavity 214 refers to a dilution cavity of the first stage dilution in the multi-stage dilution structu...

Embodiment 2

[0062] See Figure 11 As shown, a mixture of a foaming liquid according to the present invention has a distinction with the above-described embodiment in that the fourth communication structure between the advanced water cavity 213 and the head dilution cavity 214 is a communication passage. Moreover, the communication channel is specifically provided in the built-in line 2112 in the mixing tank 2.

[0063] A mixing device of a foaming liquid according to the present invention has a working principle, such as above, and will not be described later.

Embodiment 3

[0065] See Figure 12 As shown, a mixture of a foaming liquid according to the present invention, which is different from the above-described embodiment in that the advanced water cavity 213, the first dilution cavity 214, the end-level dilution cavity 215, the layout of the mix cavity 212 is not Similarly, specifically, the in-water cavity 213 is located between the head-level dilution cavity 214 and the end-level dilution cavity 215, the in-water chamber 213, the end-level dilution chamber 215, and the layout of the mixing chamber 212 substantially constitute the L-shaped.

[0066] A mixing device of a foaming liquid according to the present invention has a working principle, such as above, and will not be described later.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com