Foaming process of integrated battery pack

A technology for integrating battery packs and batteries, which is applied in the field of battery pack foaming, can solve the problems that batteries cannot be used in cold regions in Northeast China or high-temperature regions in South China, affect the service life of battery packs, adaptability to use, and poor insulation, and achieve insulation Excellent performance, improved service life, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

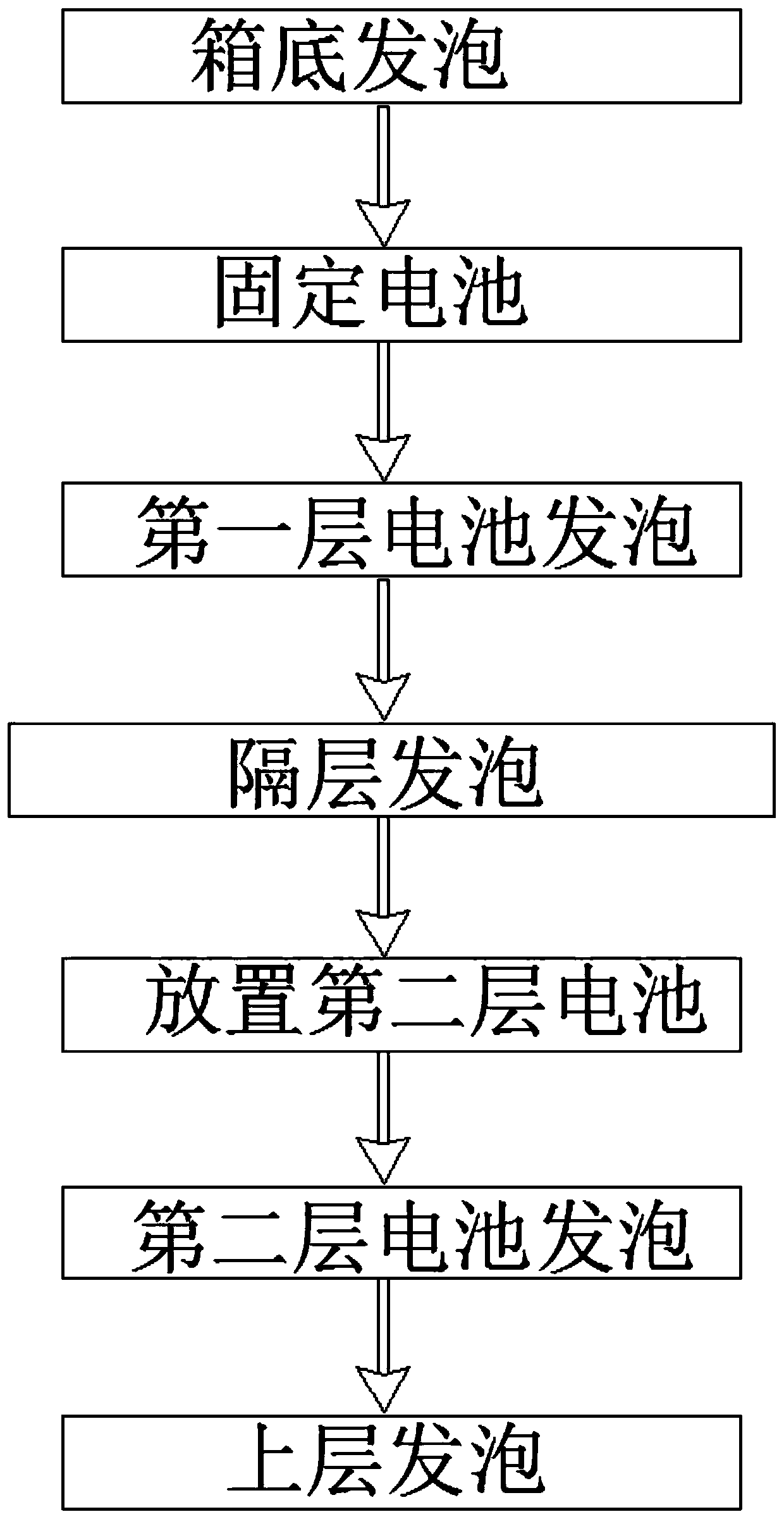

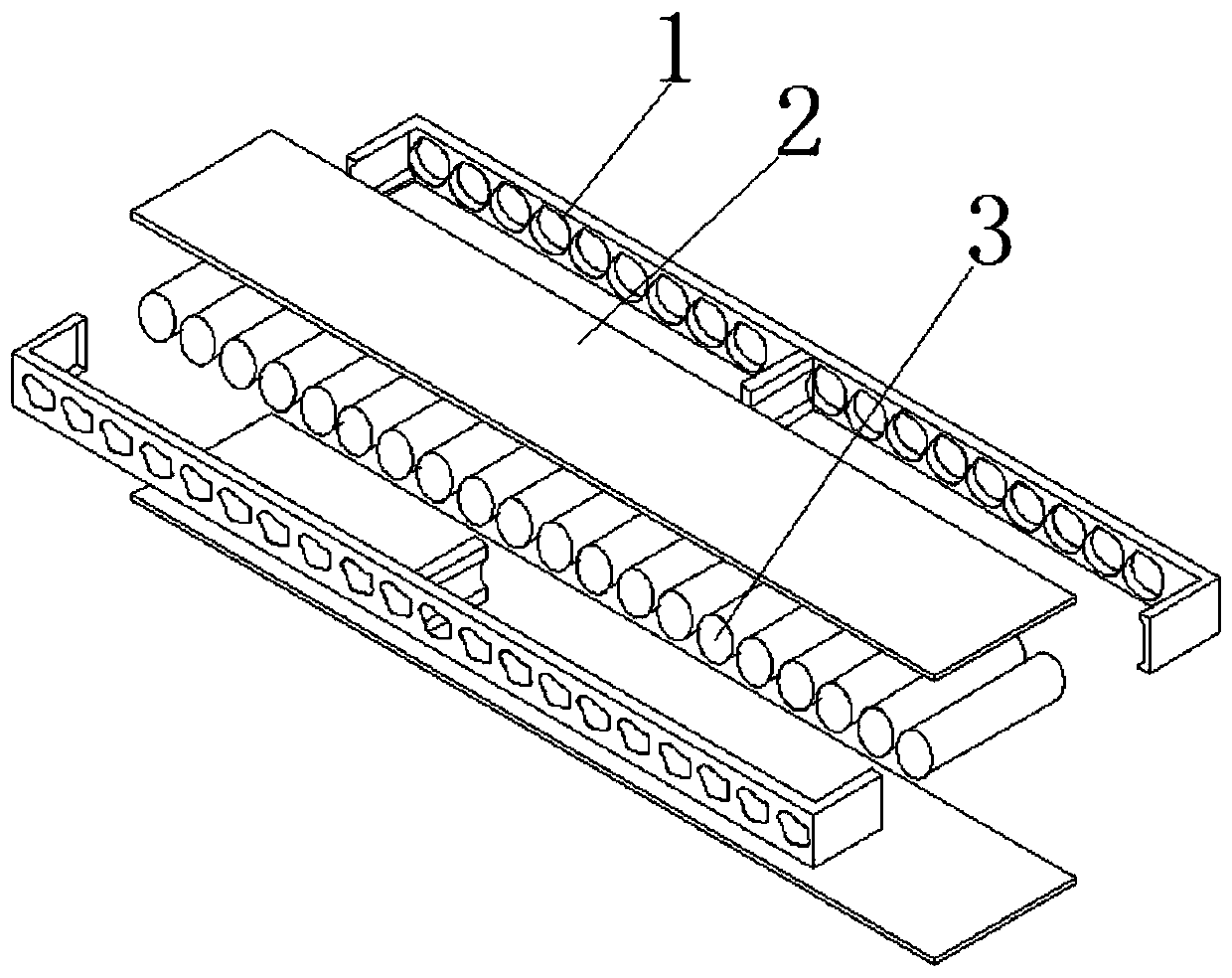

[0033] refer to Figure 1-3 , a foaming process for an integrated battery pack, comprising the steps of:

[0034] S1: Foaming at the bottom of the box, place polyurethane on the bottom of the box to make it foam;

[0035] S2: Fix the battery, install and fix the first layer of battery on the upper part of the first layer of foam;

[0036] S3: The first layer of battery is foamed. After installation and fixing, the first layer of battery is foamed under the action of polyurethane;

[0037] S4: Interlayer foaming, after the first layer of battery cells are foamed, interlayer foaming is performed, so that the polyurethane does not pass through the first layer of batteries;

[0038] S5: Place the second layer of batteries, place the second layer of batteries on the foamed polyurethane of the interlayer, and fix them;

[0039] S6: The second layer of battery is foamed, and the second layer of battery is foamed after fixing;

[0040] S7: The upper layer is foamed, so that the po...

Embodiment 2

[0044] refer to Figure 1-3 , a foaming process for an integrated battery pack, comprising the steps of:

[0045] S1: Foaming at the bottom of the box, place polyurethane on the bottom of the box to make it foam;

[0046] S2: Fix the battery, install and fix the first layer of battery on the upper part of the first layer of foam;

[0047]S3: The first layer of battery is foamed. After installation and fixing, the first layer of battery is foamed under the action of polyurethane;

[0048] S4: Interlayer foaming, after the first layer of battery cells are foamed, interlayer foaming is performed, so that the polyurethane does not pass through the first layer of batteries;

[0049] S5: Place the second layer of batteries, place the second layer of batteries on the foamed polyurethane of the interlayer, and fix them;

[0050] S6: The second layer of battery is foamed, and the second layer of battery is foamed after fixing;

[0051] S7: The upper layer is foamed, so that the pol...

Embodiment 3

[0055] refer to Figure 1-3 , a foaming process for an integrated battery pack, comprising the steps of:

[0056] S1: Foaming at the bottom of the box, place polyurethane on the bottom of the box to make it foam;

[0057] S2: Fix the battery, install and fix the first layer of battery on the upper part of the first layer of foam;

[0058] S3: The first layer of battery is foamed. After installation and fixing, the first layer of battery is foamed under the action of polyurethane;

[0059] S4: Interlayer foaming, after the first layer of battery cells are foamed, interlayer foaming is performed, so that the polyurethane does not pass through the first layer of batteries;

[0060] S5: Place the second layer of batteries, place the second layer of batteries on the foamed polyurethane of the interlayer, and fix them;

[0061] S6: The second layer of battery is foamed, and the second layer of battery is foamed after fixing;

[0062] S7: The upper layer is foamed, so that the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com