Master batch for reducing foaming temperature and application thereof

A technology of masterbatch and extrusion granulation, which is applied in the production of PVB foam products, can solve the problems of raw material volatilization, raw material consumption and waste, poor foaming effect, etc., achieve stable and stable foaming ratio, ensure foaming effect, reduce The effect of foaming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

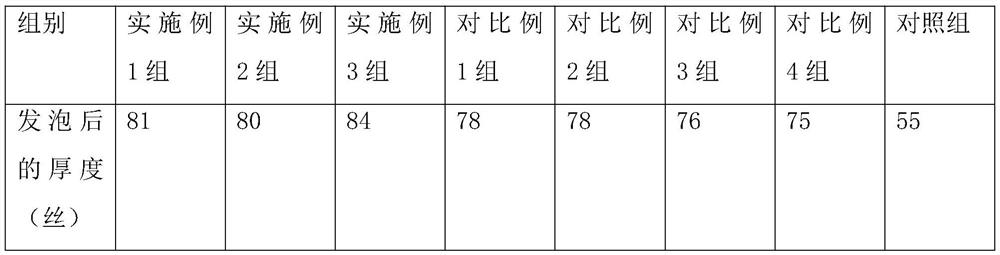

Examples

Embodiment 1

[0028] Embodiment 1: A masterbatch for reducing the foaming temperature, which is composed of the following raw materials in weight percentage: 8% glycerin, 12% urea, 55% zinc cyanurate, and 25% zinc glycerol.

[0029] Its preparation method comprises the following steps: Glycerin, urea, zinc cyanurate and zinc glycerol are stirred and mixed at a high speed in a high-speed blender according to the above-mentioned weight percentage, and the stirring speed of the high-speed blender is 5000r / min, and the stirring time is 25°C; then the temperature is raised to 125 °C, extrude and granulate to prepare a masterbatch with a particle size of 0.5 cm.

Embodiment 2

[0030] Embodiment 2: A masterbatch for reducing the foaming temperature, which is composed of the following raw materials in weight percentage: 12% glycerin, 18% urea, 50% zinc cyanurate, and 20% zinc glycerol.

[0031] Its preparation method comprises the following steps: Glycerin, urea, zinc cyanurate and zinc glycerol are stirred and mixed at a high speed in a high-speed blender according to the above-mentioned weight percentage, the stirring speed of the high-speed blender is 4000r / min, and the stirring time is 20; then the temperature is raised to 120 °C, extrude and granulate to prepare a masterbatch with a particle size of 0.5 cm.

Embodiment 3

[0032] Embodiment 3: A masterbatch for reducing the foaming temperature, which is composed of the following raw materials in weight percentage: 10% glycerin, 15% urea, 52% zinc cyanurate, and 23% zinc glycerol.

[0033] Its preparation method comprises the following steps: Glycerin, urea, zinc cyanurate and zinc glycerol are stirred and mixed at a high speed in a high-speed blender according to the above-mentioned percentage by weight, the stirring speed of the high-speed blender is 4500r / min, and the stirring time is 20°C; then the temperature is raised to 122 °C, extrude and granulate to prepare a masterbatch with a particle size of 0.5 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com