Measured medium flowing type anti-freezing liquidometer device

A flow type, antifreeze technology, applied in the field of metering, can solve the problems of steam or electric energy consumption, clutter, etc., and achieve the effect of clean site, convenient installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

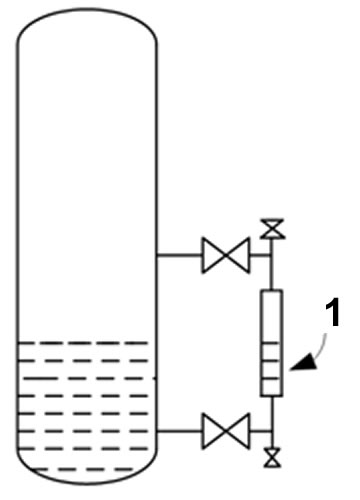

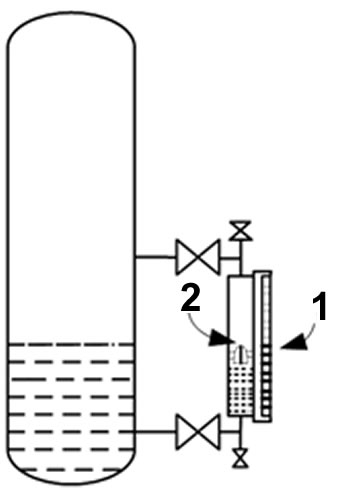

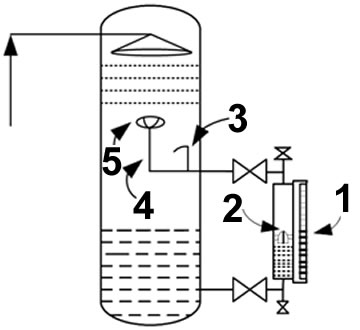

[0022] The specific implementation of the liquid level gauge of the present invention will be described below by taking the water level gauge at the bottom of the air cooling tower of the air separation plant as an example. The function of the air cooling tower is to cool the high temperature air under pressure (such as 80°C) to the air at a lower temperature (such as 15°C); the hot air enters the air cooling tower from the middle and lower part of the air cooling tower, and the cooling water enters the air cooling tower from the middle and upper part The tower is sprayed downward through the water distributor, and the hot air is cooled and discharged from the top of the air-cooling tower to enter the subsequent process. The cooling water exchanges heat with the hot air and then enters the water cooling system. image 3 As shown, the air guide pipe 3, the restrictor pipe 4 and the receiving plate 5 are connected to the negative pressure guide pipe of the glass tube liquid level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com