Low-temperature leakage detecting liquid used for air tightness detection of liquid propellant storage and transportation device

A technology of air tightness inspection and liquid propellant, which is applied in the direction of using liquid/vacuum to measure liquid tightness and detecting the appearance of fluid at the leak point, and can solve the problems affecting the reliability of air tightness inspection and liquid propellant Potential safety hazards, no patents or literature reports, etc., to avoid icing, improve safety factor and work efficiency, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

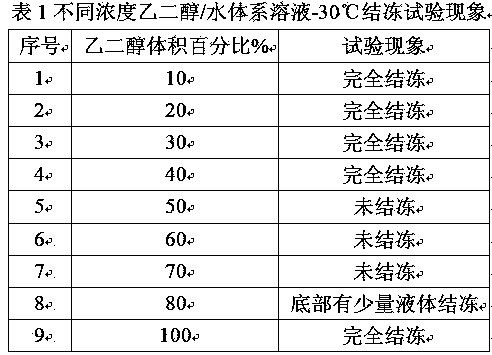

[0055] Measure or weigh: 500ml of water, 500ml of ethylene glycol, 60ml of octylphenol polyoxyethylene ether, 11g of sodium dodecylsulfonate and 6g of disodium hydrogen phosphate;

[0056] Add ethylene glycol, octanylphenol polyoxyethylene ether, sodium dodecylsulfonate, water, and disodium hydrogen phosphate in turn into the container, and stir until uniform while adding to prepare a low-temperature leak detection liquid;

[0057] When in use, stir with a brush, and after foaming, apply the foam to the parts that need leak detection; the low-temperature leak detection solution prepared in this example can be used in an environment of -30°C to -21°C, with strong foaming ability and no freezing .

Embodiment 2

[0059] Measure or weigh: 500 milliliters of water, 500 milliliters of ethylene glycol, 50 milliliters of octylphenol polyoxyethylene ether, 15 grams of sodium dodecylsulfonate and 10 grams of disodium hydrogen phosphate; the rest are the same as in Example 1.

Embodiment 3

[0061] Measure or weigh: 300ml of water, 700ml of ethanol, 70ml of phenylethylphenol polyoxyethylene ether, 8.6g of sodium dodecylsulfonate and 4.3g of disodium hydrogen phosphate;

[0062] Add ethanol, octylphenol polyoxyethylene ether, sodium dodecylsulfonate, water, and disodium hydrogen phosphate sequentially into the container, and stir until uniform while adding to prepare a low-temperature leak detection liquid; Low temperature leak detection fluid can be used in the environment of -40℃~-31℃, with strong foaming ability and no freezing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com