Differential-pressure type anti-freezing liquid level meter

An antifreeze, differential pressure technology, applied in the direction of displaying the liquid level indicator through pressure measurement, can solve the problems of consumption of steam or electric energy, clutter, etc., and achieve the effect of solving freezing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

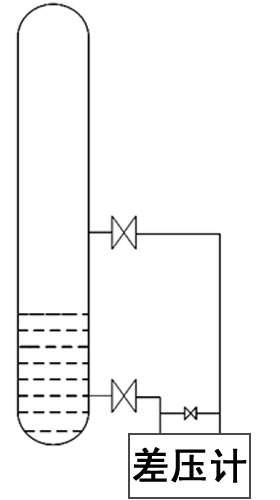

Image

Examples

Embodiment Construction

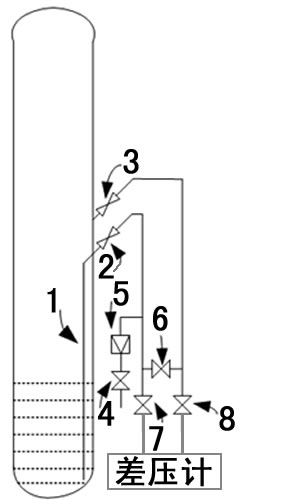

[0014] The present invention will be further described below in conjunction with accompanying drawing.

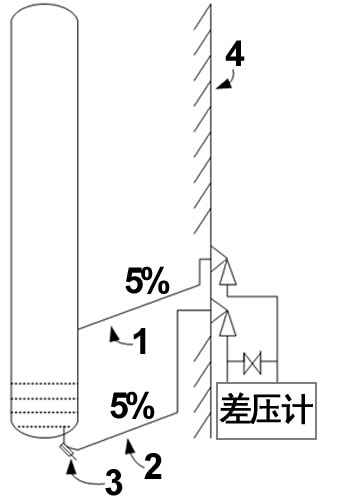

[0015] see image 3 . image 3 Shown in is to take the water level gauge at the bottom of the air cooling tower of the air separation plant as an example to illustrate the specific implementation of the differential pressure antifreeze level gauge of the present invention. According to the requirements of the liquid level process index L at the bottom of the air cooling tower (the liquid level process index L refers to the specific liquid level index, such as: 1 meter, 2500mm), the positive and negative phase pressure pipes are selected to be drawn out on the air cooling tower at a height of 1.5L , the positive and negative phase pressure pipelines are inclined upward to form an angle of 75 degrees with the tower wall of the air cooling tower, and a cut-off valve 2 is set at the place where the positive phase pressure pipeline just exits the air cooling tower, and the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com