Whole-glass heat pipe vacuum solar collector

An all-glass, heat collector technology, applied in the direction of solar heat collectors, solar heat collectors using working fluids, fluid circuit connections of solar heat collectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

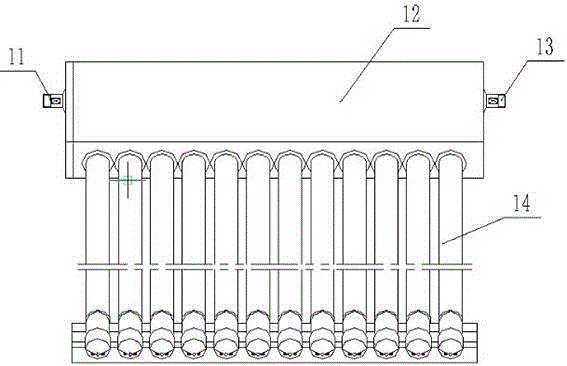

[0033] Embodiment 1: as figure 1 Shown is a schematic structural view of Embodiment 1 of the all-glass heat pipe vacuum solar collector of the present invention, which includes two parts: a header 12 and an all-glass heat pipe vacuum solar collector tube 14. The mouth of the all-glass heat pipe vacuum solar collector tube 14 is directly inserted into the header 12, and the sunlight is absorbed by the all-glass heat pipe vacuum solar collector tube 14 and converted into heat, which is transmitted to the water in the header 12, and installed on both sides of the header 12 There is a water inlet 11 and a water outlet 13, water enters the header 12 from the water inlet 11, and flows out from the water outlet 13 after being heated.

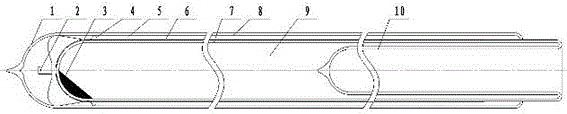

[0034] figure 2 It is a structural schematic view of the all-glass heat pipe vacuum solar collector tube 14 in Embodiment 1 of the present invention. figure 2 Among them, the cover glass tube 8 and the inner glass tube 7 are both closed at one end,...

Embodiment 2

[0040] Embodiment 2: as Figure 4 , Figure 5 and Image 6 Shown, embodiment 2 is identical with embodiment 1 basic structure, and its difference is:

[0041] Figure 4 It is a schematic structural view of an all-glass heat pipe vacuum solar collector tube in Embodiment 2 of the present invention, which has the same basic structure as Embodiment 1, and its difference lies in Embodiment 1, see figure 2 , the solar selective absorbing coating 6 is only attached to the outer surface of the inner glass tube 7; in embodiment 2, as Figure 4 As shown, the solar selective absorbing coating 6 is attached to the outer surface of the inner glass tube 7 and part of the outer surface of the evaporation section 10 .

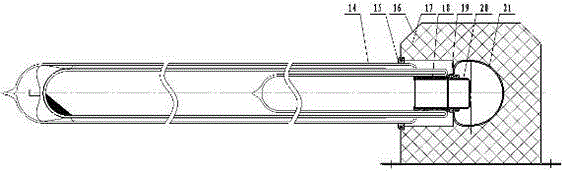

[0042] Figure 5 It is a schematic cross-sectional structure diagram of the all-glass heat pipe vacuum solar collector of Embodiment 2 of the present invention, which is the same as Embodiment 1 in basic structure, and its difference lies in Embodiment 1, see image 3 , ...

Embodiment 3

[0044] Embodiment 3: as Figure 7 , Figure 8 and Figure 9 Shown, embodiment 3 is identical with embodiment 1 and embodiment 2 basic structures, and its difference is:

[0045] Figure 7 It is a structural schematic diagram of an all-glass heat pipe vacuum solar heat collecting tube in Embodiment 3 of the present invention. The basic structure is the same as the schematic diagram of the structure of the all-glass heat pipe vacuum solar collector tube in embodiment 1 and implementation 2, and its difference is that: the cover glass tube 8, the inner glass tube 7, and the condenser tube 10 are directly annularly fused together, and the condenser tube Glass tube 25 in water is arranged in 10, can reduce the water content in condensation pipe 10.

[0046] Figure 8 It is a schematic cross-sectional structure diagram of the all-glass heat pipe vacuum solar collector of embodiment 3, which is basically the same as the cross-sectional structural schematic diagram of the header in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com