Pre-washing technology and device used for cryogenic separation of synthesis gas

A cryogenic separation and pre-washing technology, which is applied in separation methods, dispersed particle separation, gas fuel, etc., can solve the problems of blocking the cold box and affecting the long-term stable and safe operation of the cold box, so as to improve the online rate and avoid abnormal Simple effect of parking, craft technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

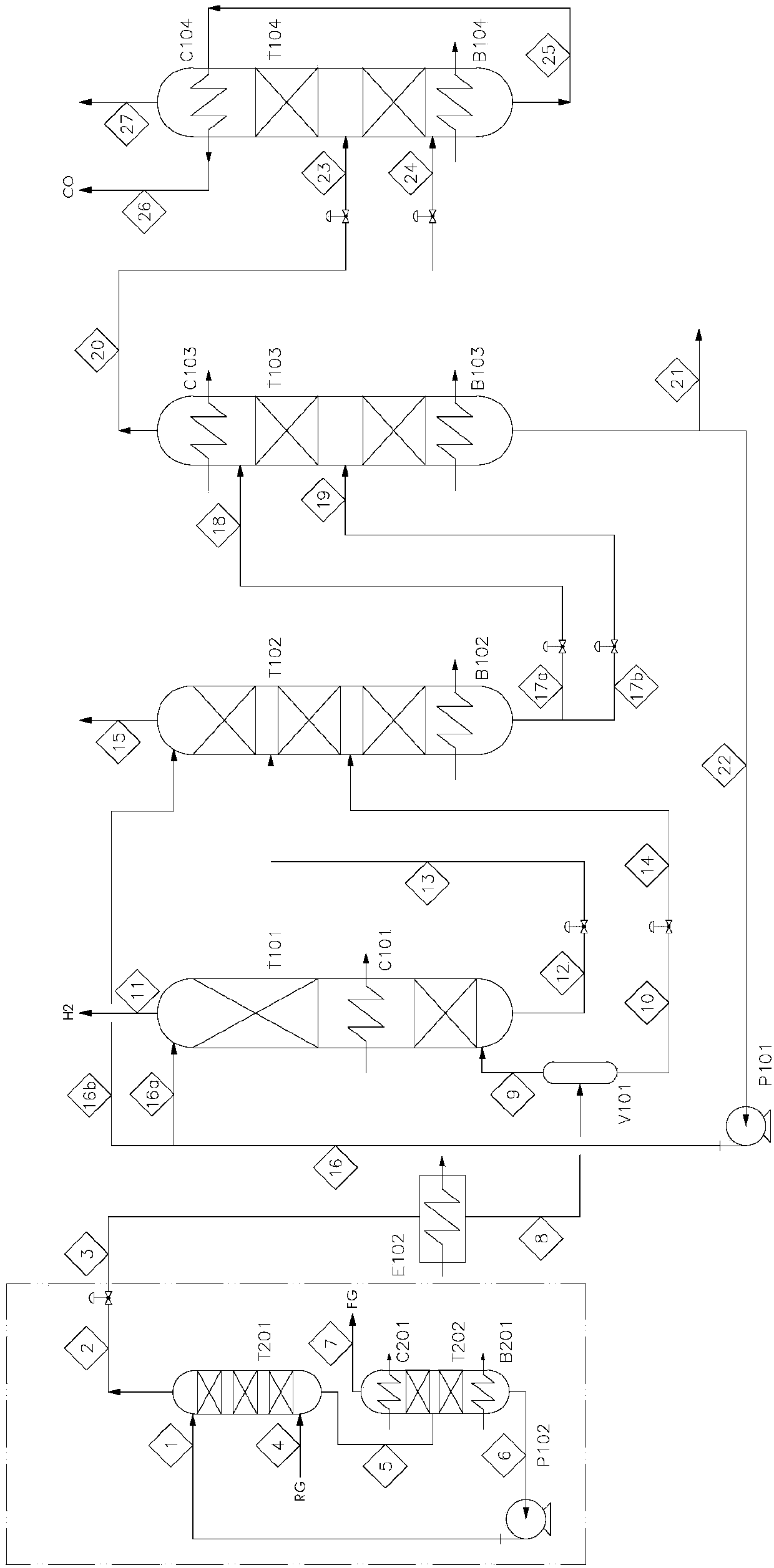

[0049] like figure 1 Shown, the pre-washing cold box (attached) of the low-carbon hydrocarbon washing process of the present invention figure 1 inside the dotted frame) is located in the synthesis gas cryogenic separation main cold box (attached figure 1 Out of the middle dotted frame) upstream, before the raw syngas enters the main cold box, it enters the pre-washing cold box, and the pre-washing agent 1 in the pre-washing cold box converts unsaturated hydrocarbons and Macromolecular saturated hydrocarbons are absorbed, and the purified raw material synthesis gas 2 is sent from the top of the pre-washing absorption to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com