Upper connection type antifreeze integrated service station

A service station and box technology, applied in the field of hose service stations, can solve the problems of aging of hose tapes and corrosion of service stations, and achieve the effects of solving contamination and corrosion, saving maintenance costs and improving operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, and the specific embodiments do not limit the scope of protection claimed by the present invention.

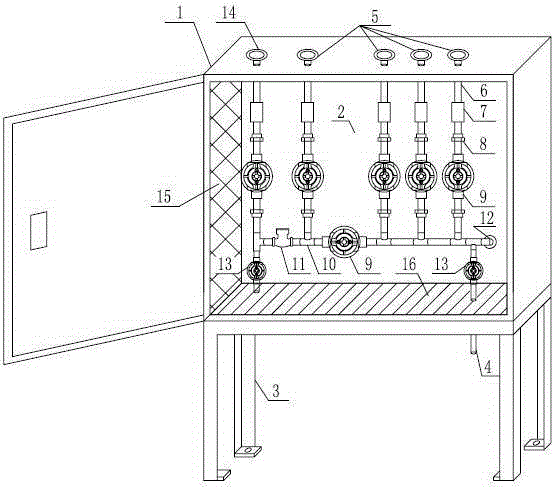

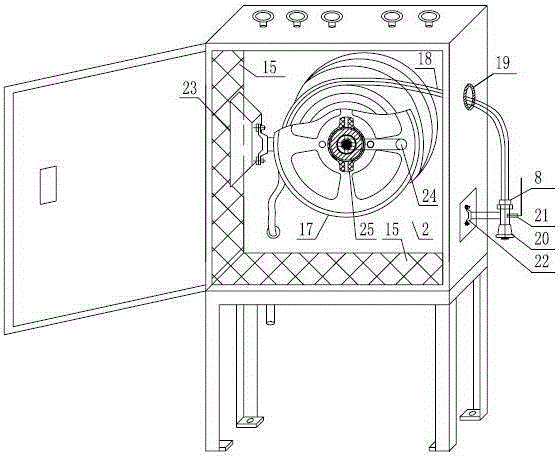

[0022] The utility model relates to an integrated anti-freeze service station with an upward connection type, which is used in the case where the medium inlet pipeline of public works is higher than the service station. as attached figure 1 And attached figure 2 As shown, it is composed of a box body 1, a partition plate 2, and a leg 3. The partition plate is installed vertically in the box body and divides the box body into two relatively independent parts, the front part of the box body and the rear part of the box body. The partition plate is It is detachable and connected with the box body in the form of bolts. A medium inlet 5 and a condensate outlet 14 are set on the top plate of the front of the box, and a liquid collecting pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com