Plug-in anti-frozen-blocking casing gas recovery device

A recovery device and casing gas technology, applied in the direction of wellbore/well valve device, production fluid, wellbore/well parts, etc., can solve the problem of valve core freezing and blocking, and achieve the solution of freezing blocking and complete recovery of casing gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

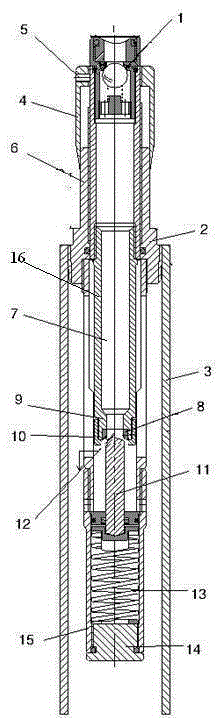

[0019] In order to overcome the problem of easy clogging of existing devices, the present invention provides such as figure 1 Shown is a plug-in anti-freeze blocking casing gas recovery device. The device solves the problem of freezing blocking of the valve core and achieves the purpose of completely recovering casing gas. The constant pressure air release valve opens the exhaust and discharges the condensed water at the same time. So as to completely solve the problem of heat absorption and freezing blocking in winter when the gas is released; at the same time, the one-way valve can prevent the crude oil from flowing into the casing.

[0020] A plug-in antifreeze blocking casing gas recovery device, comprising an oil pipe 3, a constant pressure air release valve 2 and a pressure conductor 15, the lower end of the constant pressure air release valve 2 is inserted into the oil pipe 3, and the upper end of the constant pressure air release valve 2 is provided with There is a pre...

Embodiment 2

[0027] On the basis of Embodiment 1, in this embodiment, the pressure regulating cap 4 and the pressure conductor 15 are fixedly connected by bolts 5 .

[0028] The pressure regulating cap 4 of the constant pressure vent valve 2 of the device is fixed on the pressure conductor 15 by the bolts 5, which ensures that the pressure change value sensed by the pressure conductor 15 is adjusted and the constant pressure vent valve 2 is adjusted to provide the required pressure. value.

[0029] The lower end of the intake chamber 7 is sleeved on the valve holder 9 through a gasket 8 .

[0030] The valve holder 9 is sealedly connected with the lower end of the intake chamber 7 through the sealing gasket 8 to ensure that the interior of the intake chamber 7 is sealed.

[0031] The valve holder 9 is connected with the valve seat 10 through a screw thread. The screw connection ensures that the valve holder 9 will not slip off and is connected with the valve seat 10 as a whole.

[0032] ...

Embodiment 3

[0037] On the basis of Embodiment 1, in this embodiment, a scale sleeve 6 is provided at the outer upper end of the air inlet chamber 7 .

[0038] A scale sleeve 6 is arranged outside the air inlet chamber 7, so that the adjustment changes can be clearly and intuitively seen, and the scale sleeve 6 can accurately display the read data.

[0039] The scale sleeve 6 is sleeved outside the air inlet cavity 7 through an O-ring seal.

[0040] The O-ring seal prevents the scale sleeve 6 fitted outside the air inlet chamber 7 from falling off due to temperature changes, and ensures that the scale sleeve 6 is tightly connected with the air inlet chamber 7 .

[0041] The pressure regulating cap 4 of the constant pressure air release valve 2 of the device is fixed on the pressure conductor 15 through bolts 5, the scale sleeve 6 is sleeved outside the air inlet chamber 7 through an O-ring seal, and the upper end of the air inlet chamber 7 is connected by a screw thread. To the valve 1; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com