Aluminum alloy product suitable for structure and function integration, and preparation method thereof

A technology of aluminum alloy and products, applied in the field of aluminum alloy materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

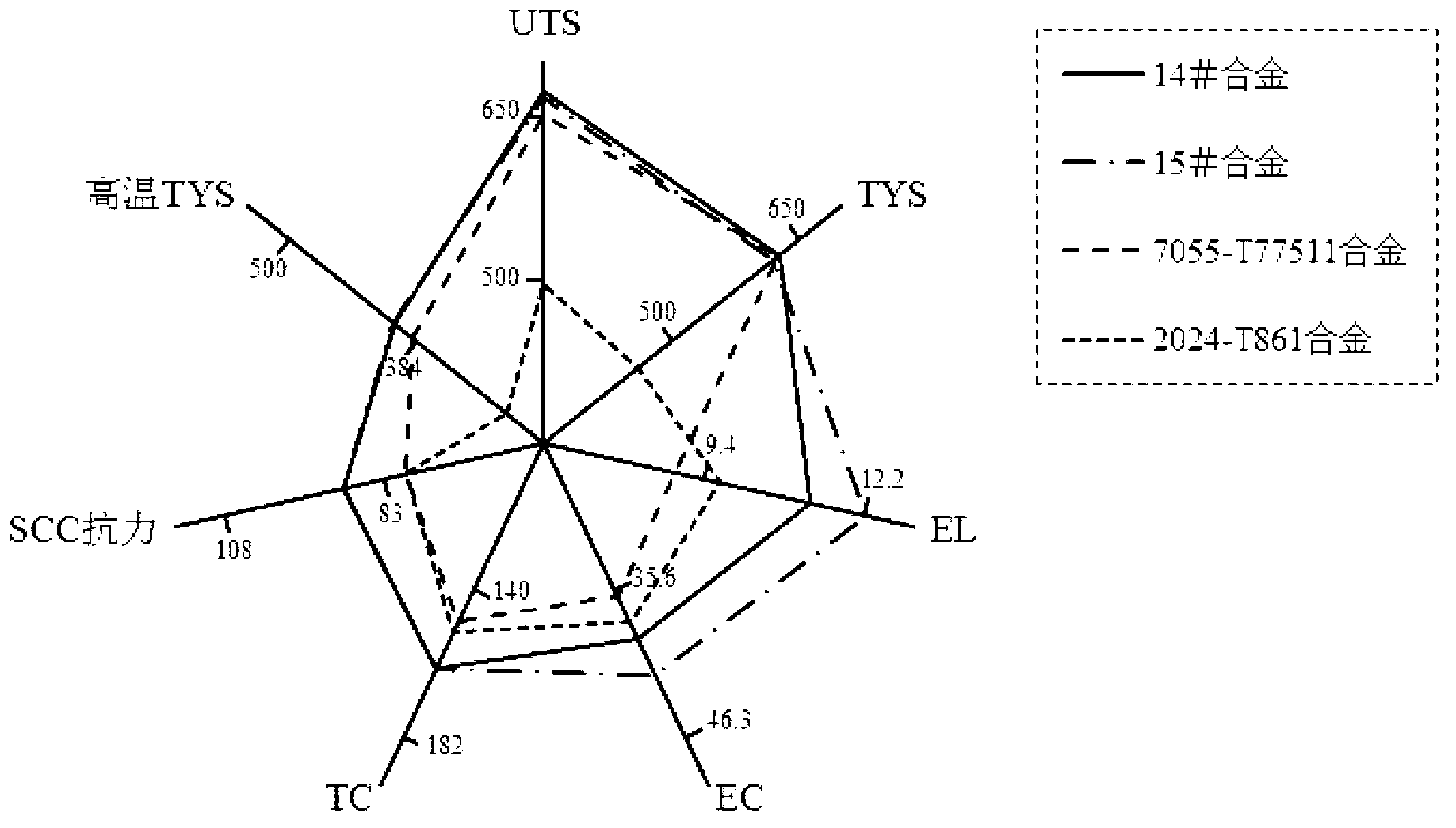

Examples

preparation example Construction

[0071] The present invention also relates to a preparation method for producing the aluminum alloy product, wherein the aluminum alloy product includes a deformed aluminum alloy product and an aluminum alloy cast product. The process of deforming and processing aluminum alloy products can be described as "alloy preparation and melting-ingot preparation by semi-continuous casting-ingot homogenization heat treatment-deformation processing (extrusion, rolling, forging, drawing) to obtain deformed products- Solution treatment and stress relief treatment - aging treatment - finished product". The manufacturing process of the aluminum alloy casting product can be described as "alloy preparation and smelting-die casting forming-solution treatment-aging treatment-finished product". It includes the following steps:

[0072] (1) making semi-continuous casting ingots or mold castings as described in the present invention;

[0073] (2) Carry out homogenization heat treatment to gained i...

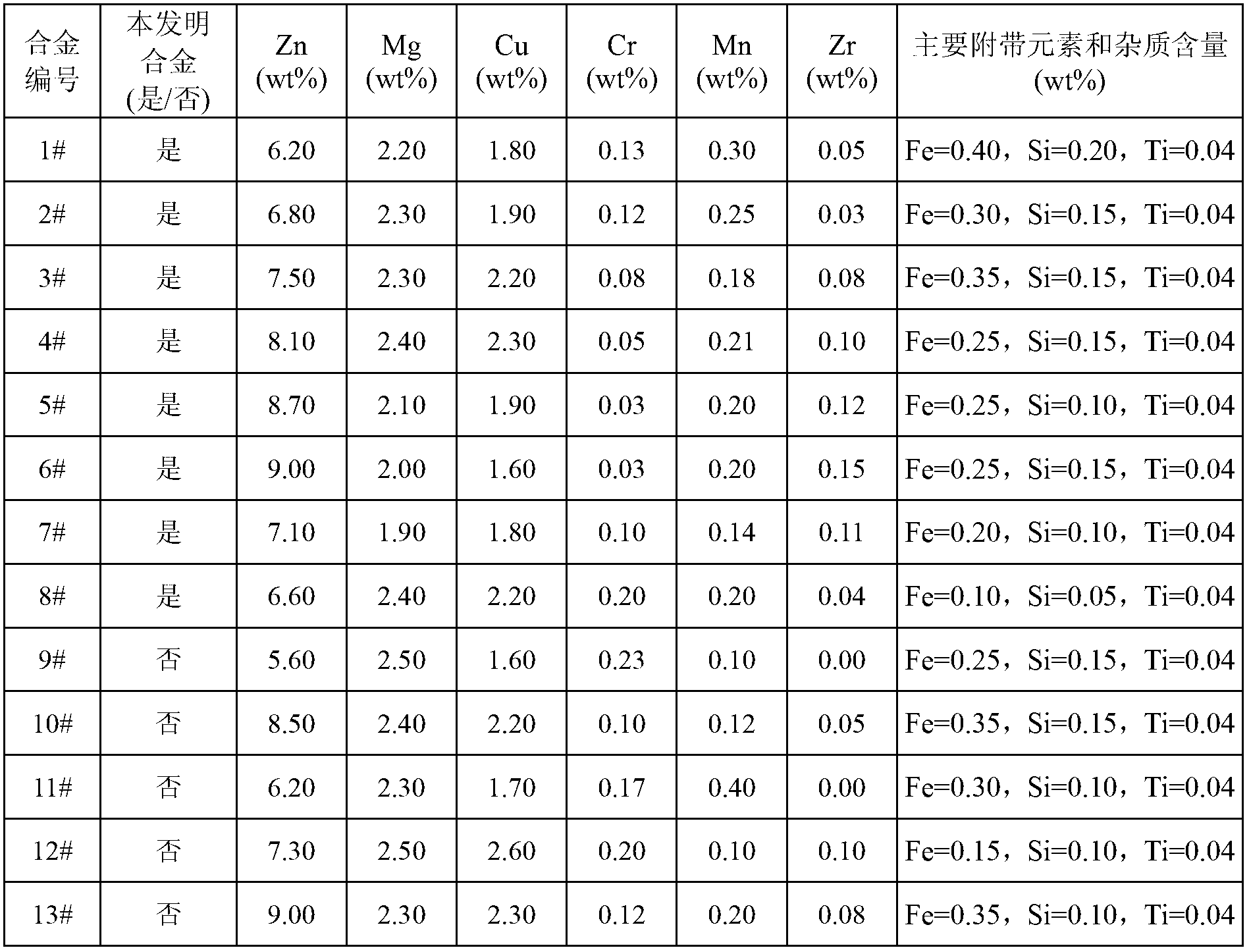

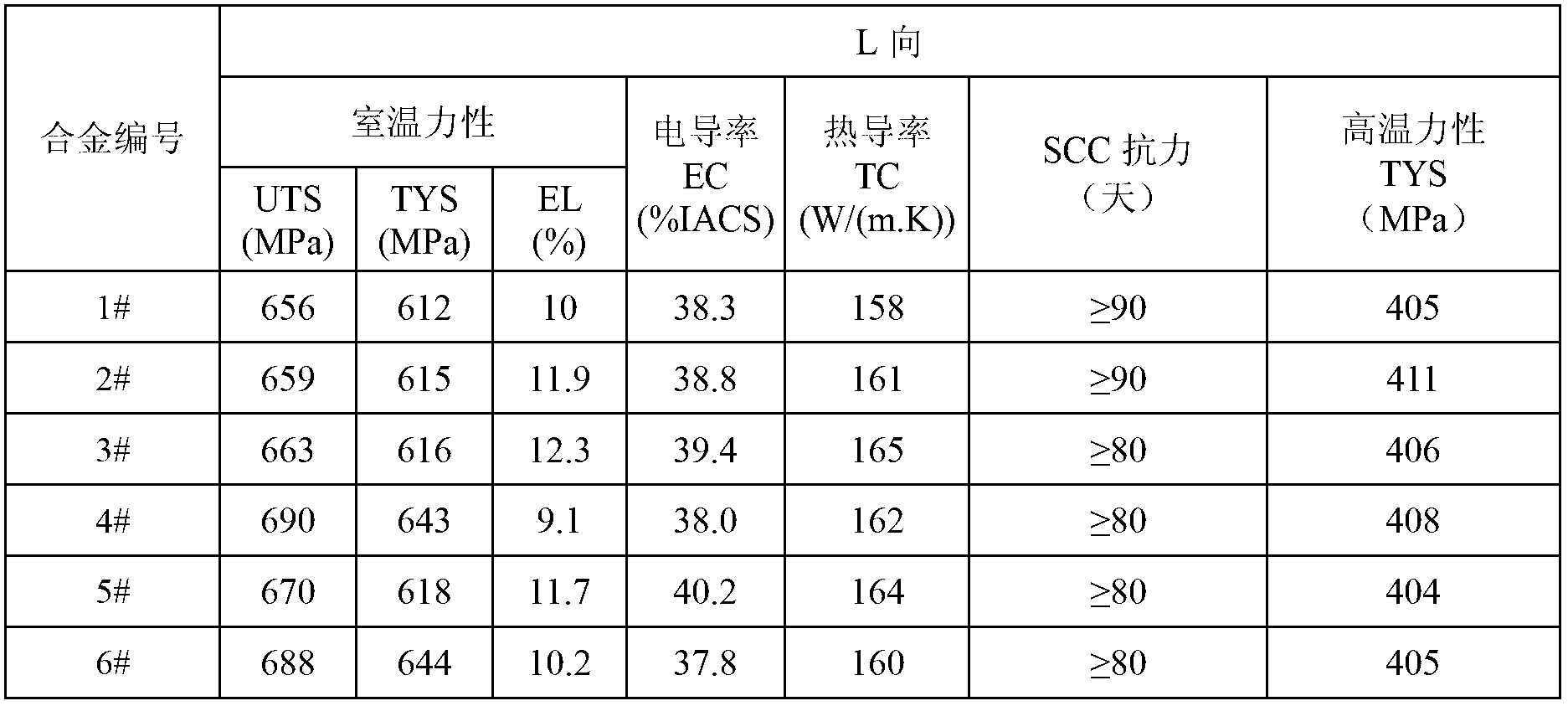

Embodiment 1

[0088] Alloys were prepared on a laboratory scale to demonstrate the principles of the invention. The composition of the alloy is shown in Table 1. The round ingot of Ф210mm is prepared by the well-known methods of alloy melting, degassing, inclusion removal, and semi-continuous casting. The homogenization annealing system of the ingot is selected as (440±5°C / 12h)+(472±3 °C / 24h), followed by slow cooling in air. After peeling and sawing, an extruded billet of Ф190×400mm is obtained. The extruded billet was preheated at 420±10°C for 4 hours, and then extruded on an 800-ton extruder to finally obtain extruded rod products with a size of Ф20mm, and the extrusion ratio was 16.7. In order to better and accurately control the surface quality and dimensional tolerance of the deformed parts, combined with the optimized design of the extrusion tool and mold, and the precise control of the extrusion speed. After sawing these alloy extruded rods to length, solution heat treatment is c...

Embodiment 2

[0097] A batch of round ingots with a diameter of Ф380 mm were prepared by industrial tests through the well-known methods of alloy melting, degassing, inclusion removal, and semi-continuous casting. The composition of the ingots is shown in Table 3. The homogenization annealing system of the ingot is selected as (440±5°C / 12h)+(472±3°C / 24h), followed by slow cooling in air. After peeling and sawing, an extruded billet of Ф360×600mm is obtained.

[0098] Table 3 Alloy composition of industrial test

[0099]

[0100] Preheat the extruded billet at 420±10°C for 4 hours, and then extrude it on a 1600-ton extruder according to different extrusion models designed to obtain rod products with a specification of Ф30mm and an outer diameter of Ф36mm×wall thickness of 2.5mm Pipe products, T-shaped products with a width of 200mm × height 40mm × wall thickness 5mm. In order to better and accurately control the surface quality and dimensional tolerance of deformed parts, combined with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com