Method and device for producing concentrated sulfuric acid by recycling waste acid from sulfate process titanium dioxide production

A technology of titanium dioxide waste acid and concentrated sulfuric acid, which is applied in sulfur trioxide/sulfuric acid, chemical instruments and methods, sulfur compounds, etc. The effect of low operating energy consumption and large usable amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

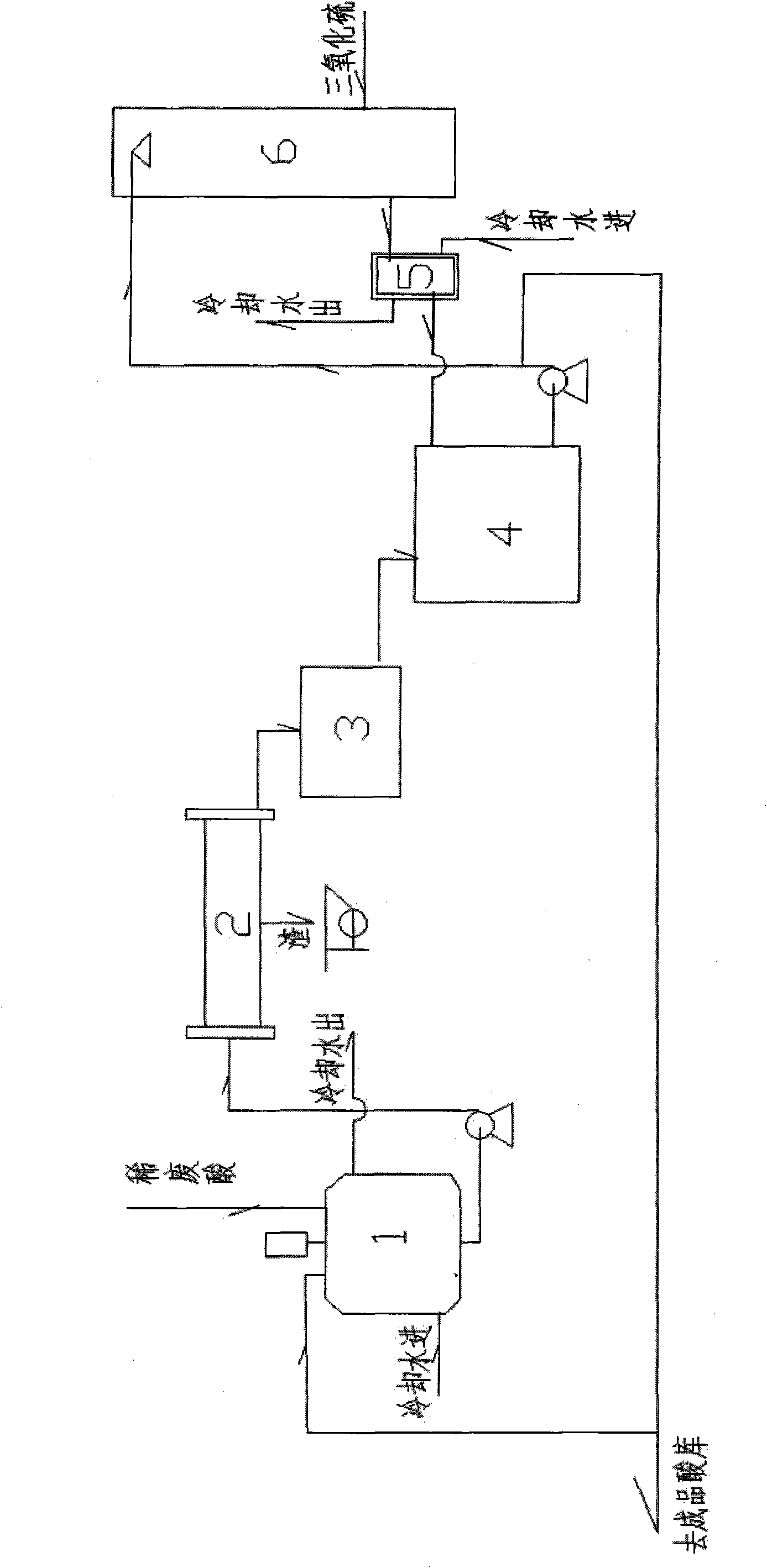

Embodiment 1

[0028] A set of sulfuric acid plant that produces 20 tons of 98% sulfuric acid per hour used to add 3 tons of fresh water to the sulfuric acid circulation tank 4 per hour. Now, 6 tons of 49% pre-extracted concentrated sulfuric acid from the pre-extracted concentrated acid tank 3 is used instead of supplementary water, and gradually added to the sulfuric acid circulation tank 4 of the sulfuric acid absorption system, and 98% sulfuric acid in the sulfuric acid circulation tank is continuously injected into the sulfuric acid absorption tower 6 to absorb SO 3 , absorbing SO per hour 3 16 tons (equivalent to 20 tons of 98% sulfuric acid), after the acid concentration increases, after being cooled to 65°C by the heat exchanger 5, it returns to the sulfuric acid circulation tank 4 and is diluted by the pre-extracted concentrated sulfuric acid added. Consumption is about 70% when not adding concentrated sulfuric acid in advance, and the adding speed of concentrated sulfuric acid in a...

Embodiment 2

[0031] The same set of sulfuric acid plant producing 20 tons of 98% sulfuric acid per hour as in Example 1 needed to replenish 3 tons of fresh water to the sulfuric acid circulation tank 4 per hour in the past. According to the present invention, 6 tons of 49% concentrated waste acid (this concentrated waste acid can be made by methods such as spray tower concentration, steam concentration, reverse osmosis concentration, etc.) Supplementary water is gradually added to the sulfuric acid circulation tank 4 of the sulfuric acid absorption system. The 98% sulfuric acid in the sulfuric acid circulation tank 4 is continuously pumped into the sulfuric acid absorption tower 6 to absorb SO 3 After the concentrated increase of acid, it is cooled by heat exchanger 5, and gets back to sulfuric acid circulation tank 4, and the concentrated waste acid added is diluted, and the adding speed of concentrated waste acid is as the criterion with the concentration of sulfuric acid in the tank 4 b...

Embodiment 3

[0033] Replace the 3 tons / hour of water that needs to be supplemented with the original 3 tons / hour of water that has been concentrated by the steam concentration system to 73.5% concentration of sulfuric acid titanium dioxide waste acid or the mixed solution of the same concentration obtained by the compounding method, at a rate of 12 tons per hour. Gradually add in the sulfuric acid circulation tank 4 of the sulfuric acid absorption system in the sulfuric acid plant identical with embodiment 1, 98% sulfuric acid in the sulfuric acid circulation tank 4 constantly pushes into the sulfuric acid absorption tower 6 to absorb SO 3 , after the acid concentration increases, it is cooled to about 68°C through the heat exchanger 5 (the amount of cooling water at this time is equivalent to about half of that when the concentrated sulfuric acid is not added in advance), and returns to the sulfuric acid circulation tank 4, and the concentrated waste acid added is Dilution, the adding spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com