Atom transition free radical polymerization initiation system and application of the same for preparing macromolecular compound

A high molecular compound, polymerization initiation technology, applied in the application of the preparation of high molecular compounds, AGETATRP atom transfer radical polymerization initiation system field, can solve the problems of amine ligand toxicity, affect active polymerization, large amount of catalyst, etc., to avoid The effect of toxicity, overcoming high temperature polymerization, and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

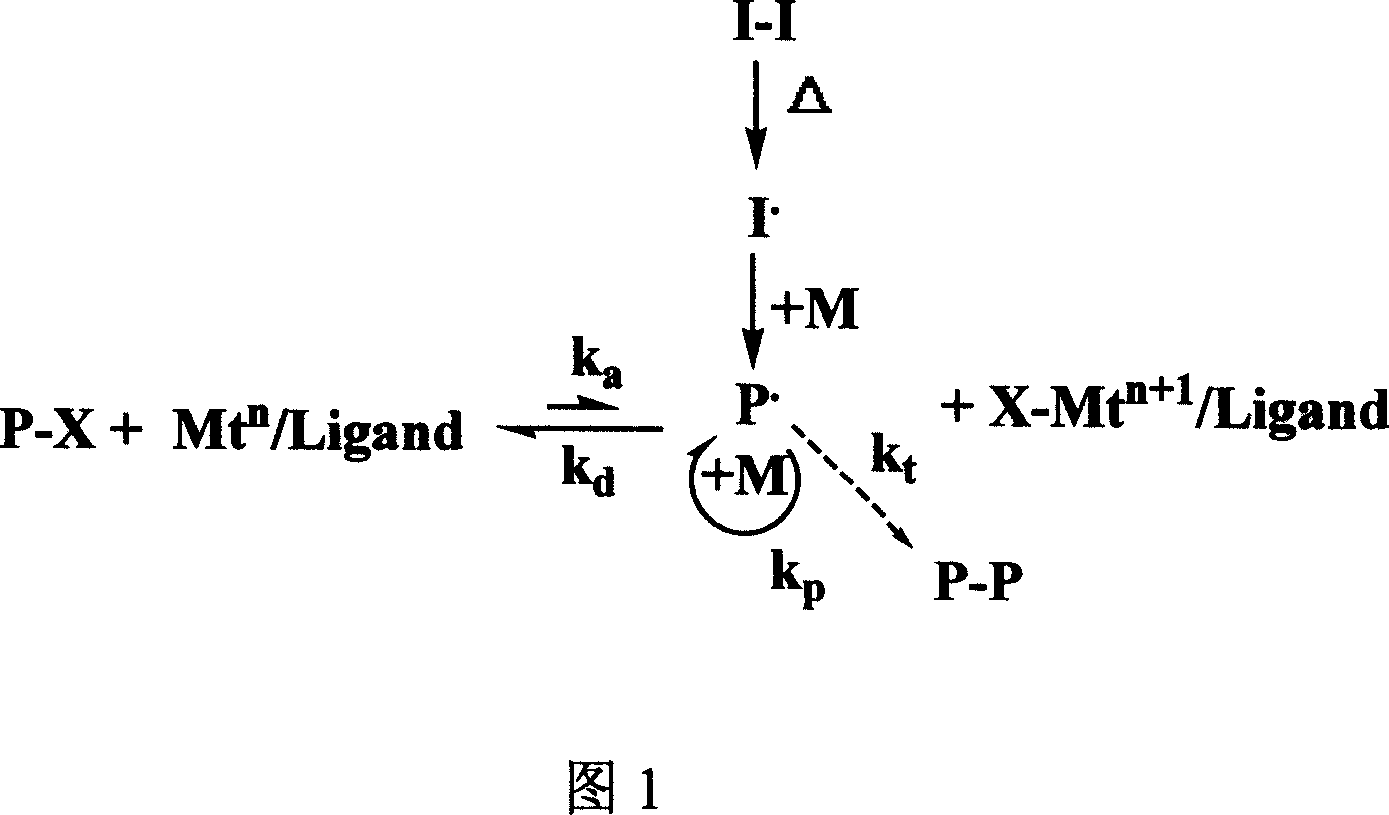

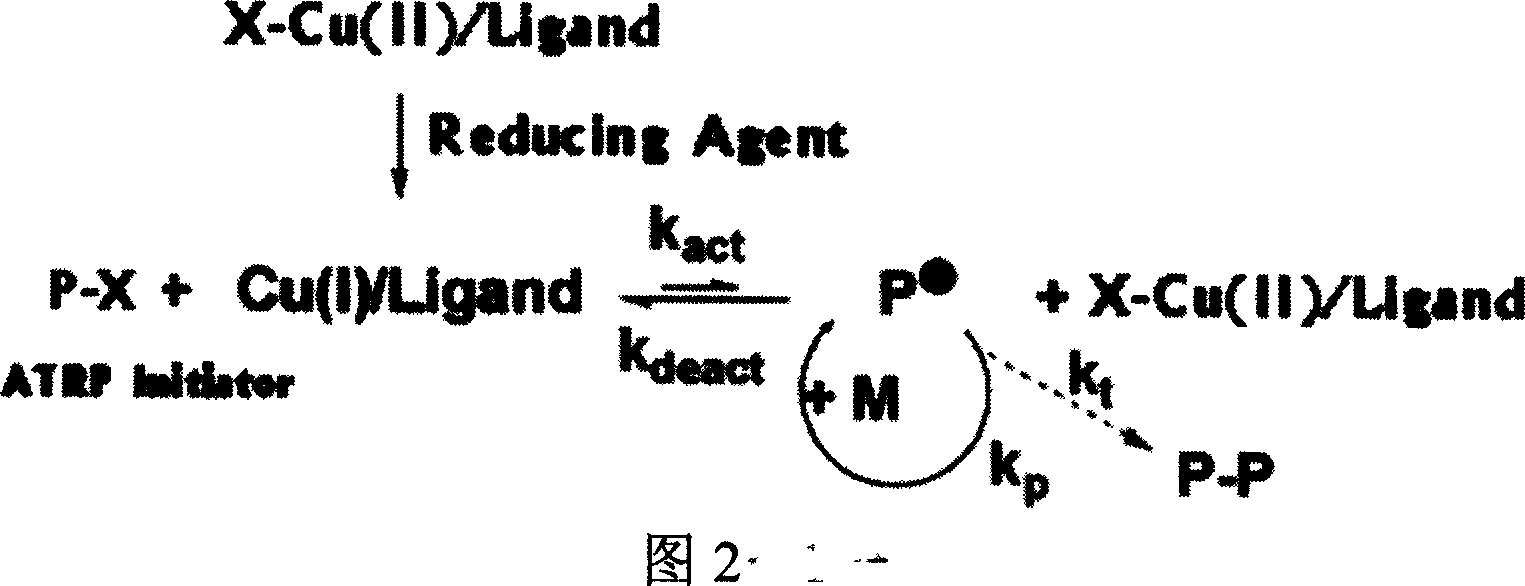

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Methylimidazole acetate ionic liquid ([Hmim][CH 3 AGET Atom Transfer Radical Polymerization of Methyl Methacrylate (MMA) in COO])

[0035] Weigh the catalyst CuBr 2 (copper bromide) 1 part, 0.5 part of reducing agent hydroquinone in 600 parts of [Hmim][CH 3 COO] (methylimidazolium formate) dissolved in the ionic liquid, nitrogen in addition to oxygen. Weigh 600 parts of MMA (methyl methacrylate) monomer, pass nitrogen to remove oxygen, add to ionic liquid, continue to pass nitrogen to remove oxygen, seal, keep the temperature at 60°C for 20 minutes, inject 1 part of 2-bromo Ethyl isobutyrate initiator, constant temperature reaction at 60°C. After three hours, the polymerization liquid was treated with methanol to obtain PMMA (polymethyl methacrylate), Mn=36700, PDI=1.30.

Embodiment 2

[0036] Embodiment 2: Methylimidazole acetate ([Hmim][CH 3 AGET Atom Transfer Radical Polymerization of Methyl Methacrylate (MMA) in COO]) Ionic Liquid

[0037] Weigh the catalyst CuBr 2 1 part, reducing agent hydroquinone 0.5 part in 100 parts of [Hmim][CH 3 COO] dissolved in the ionic liquid, nitrogen in addition to oxygen. Take by weighing 100 parts of MMA monomer, after passing nitrogen to remove oxygen, add in the ionic liquid, continue to pass nitrogen to remove oxygen, seal, keep the temperature at 60 ℃ for 20 minutes, inject 3 parts of initiator 2-bromoisobutyrate ethyl ( (CH 3 ) 2 CBrCOOC 2 h 5 ), react at a constant temperature of 60°C. Two hours later, the reaction conversion rate was 92%. The polymerization solution was treated with aqueous methanol to obtain PMMA with Mn=7200 and PDI=1.17.

Embodiment 3

[0038] Embodiment 3: Methylimidazole acetate ([Hmim][CH 3 COO]) AGET Atom Transfer Radical Polymerization of Methyl Methacrylate (MMA) in Ionic Liquid

[0039] Weigh 1 part of catalyst CuBr 2 , 0.5 parts of reducing agent hydroquinone in 100 parts of [Hmim][CH 3 Dissolve in COO] ionic liquid, take by weighing 100 parts of MMA monomer, add in the ionic liquid, keep the temperature at 60 ℃ for 20 minutes, inject 3 parts of initiator 2-bromoisobutyric acid ethyl ester ((CH 3 ) 2 CBrCOOC 2 h 5 ), constant temperature reaction at 60°C. Two hours later, the reaction conversion rate was 87.4%, and the polymerization solution was treated with aqueous methanol, resulting in PMMA with Mn=7500 and PDI=1.16, and oxygen had no effect on the polymerization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com