Patents

Literature

77results about How to "The processing position is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

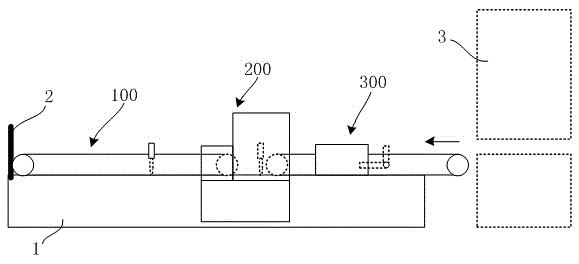

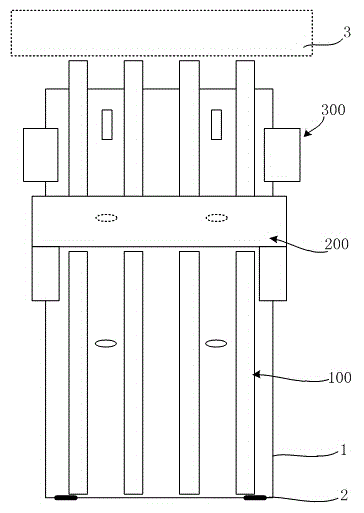

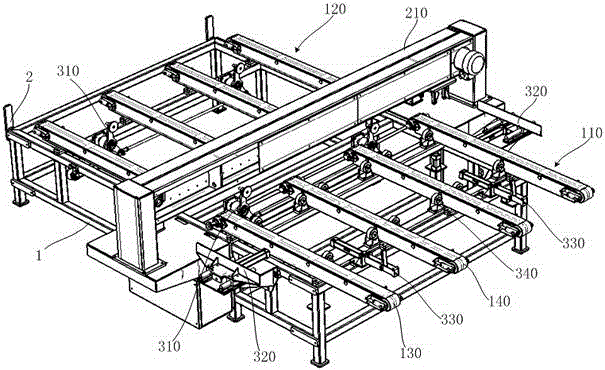

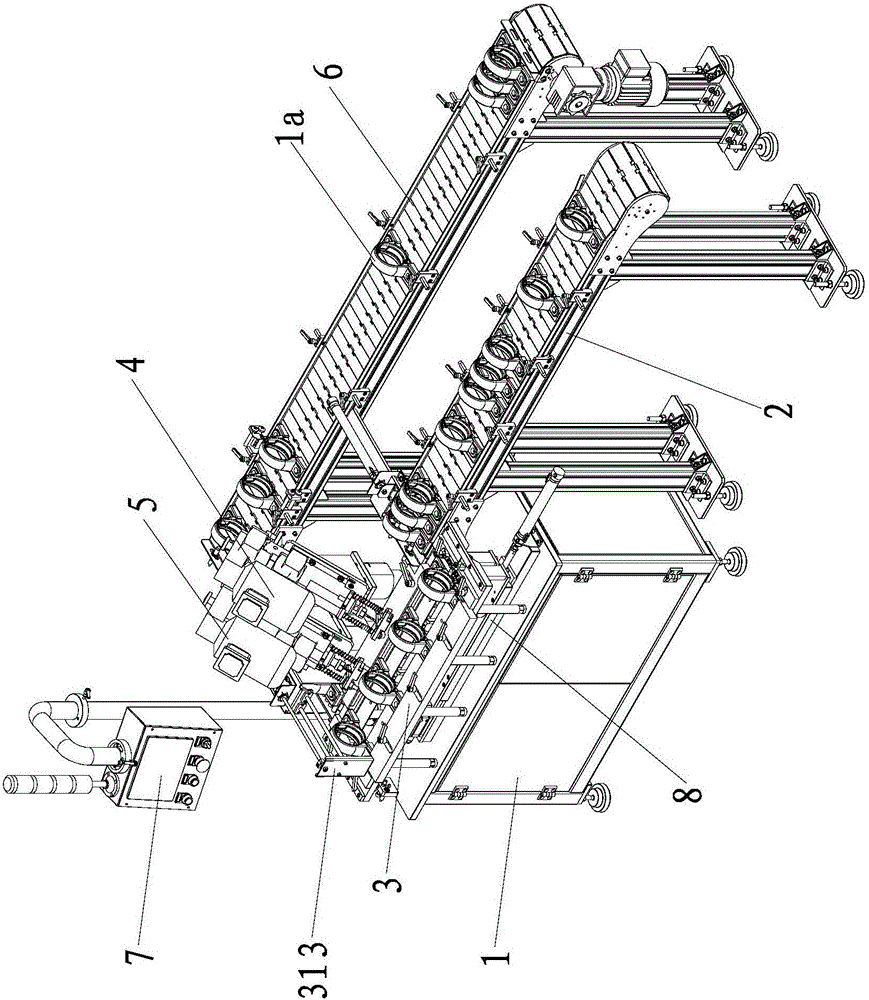

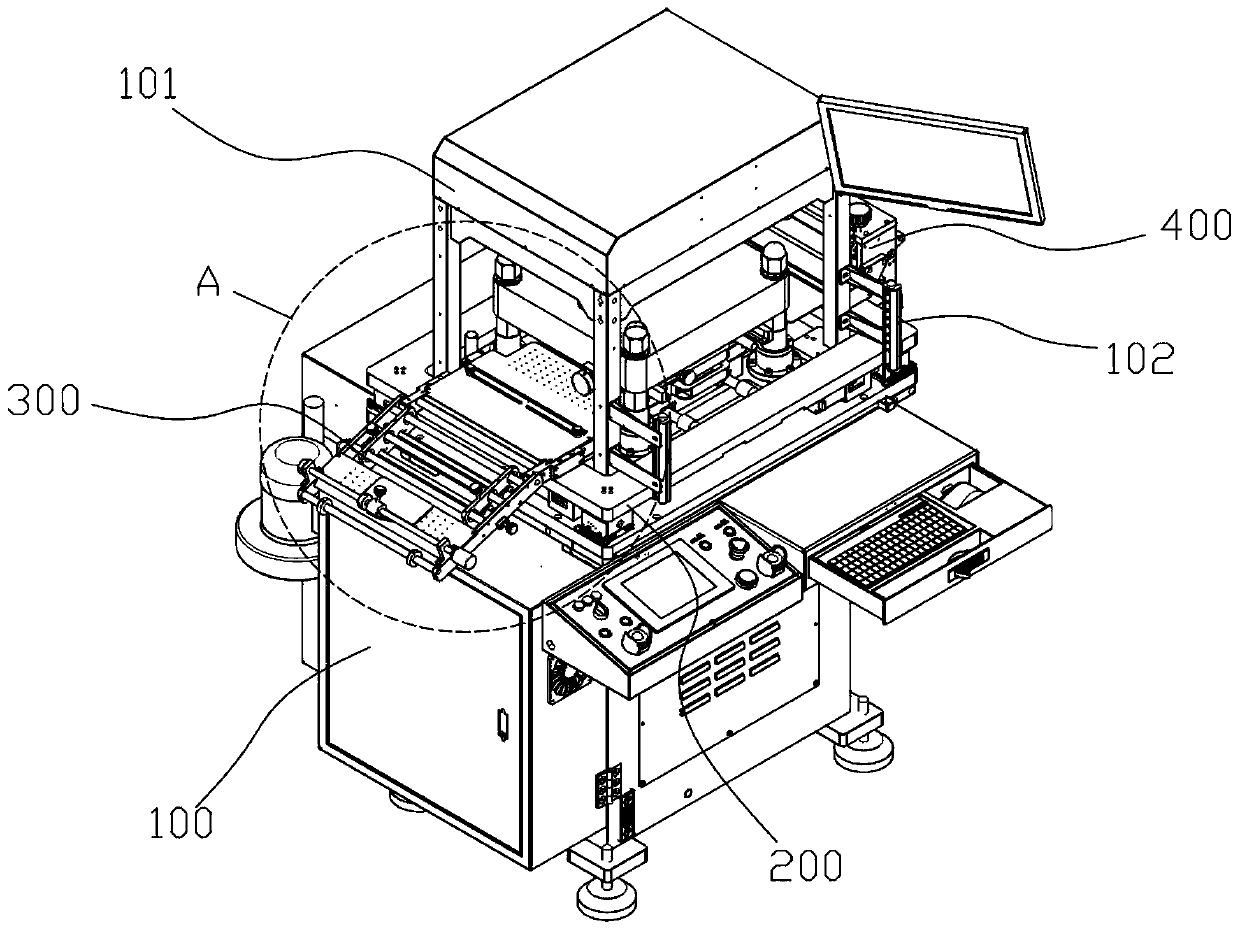

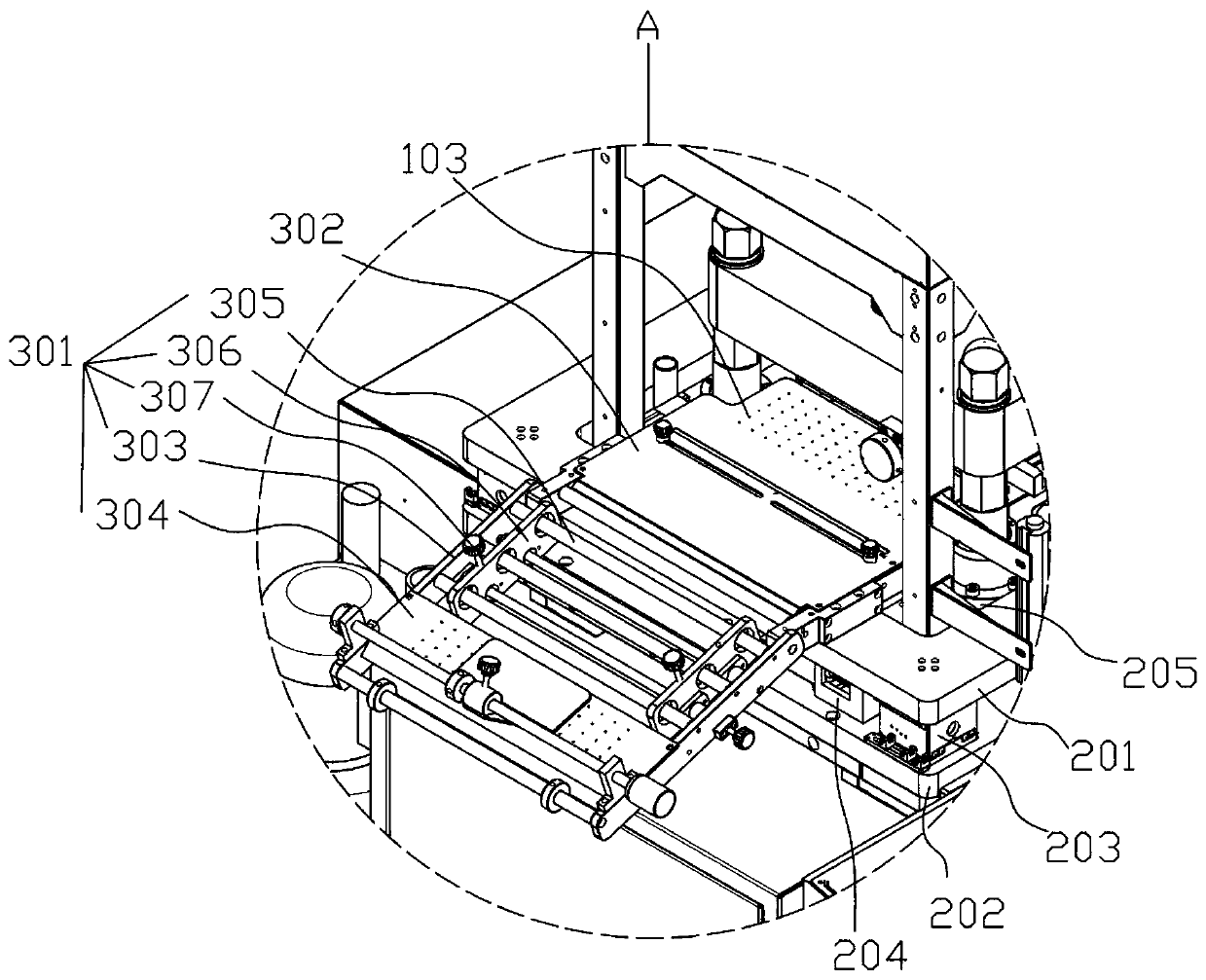

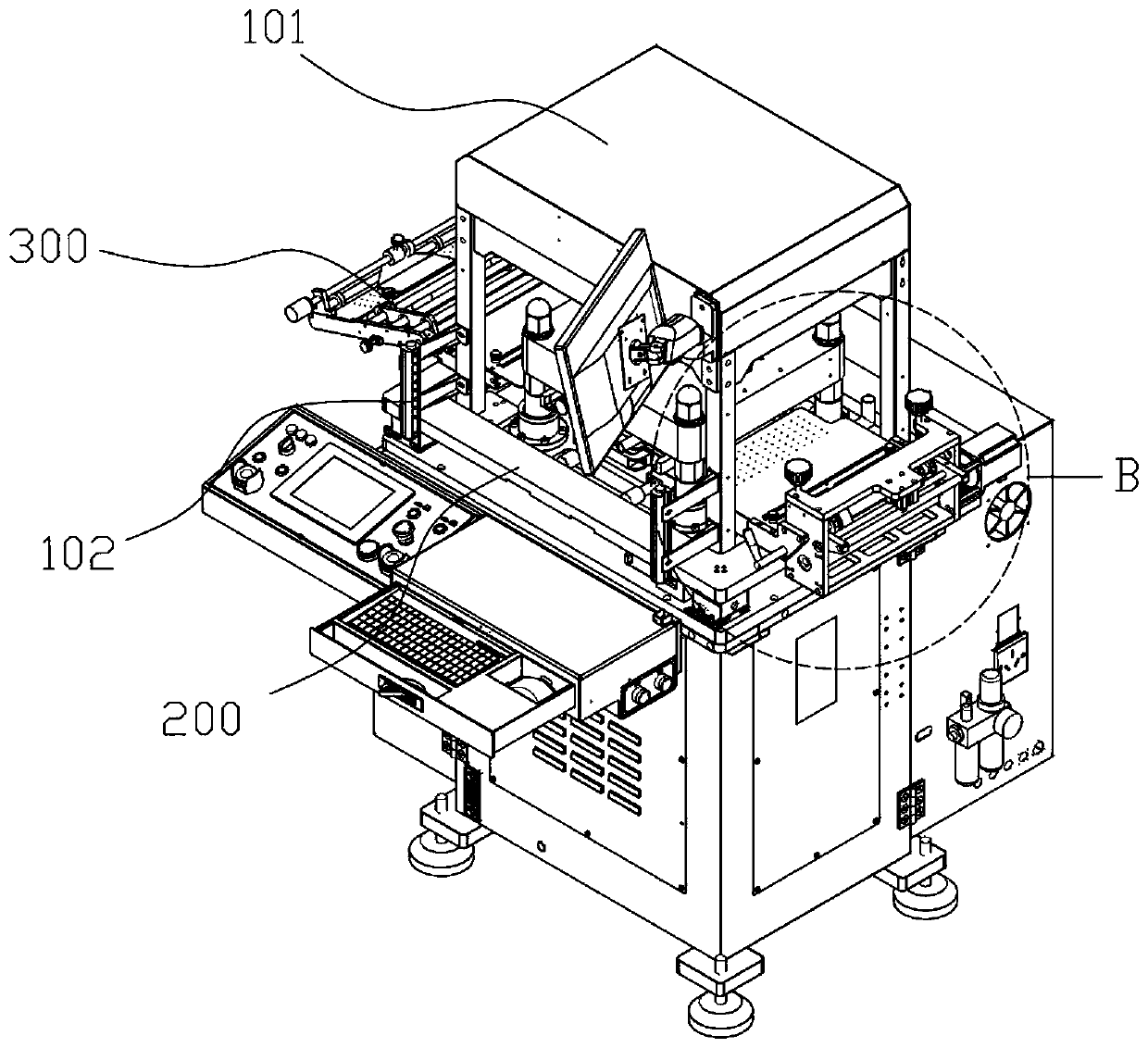

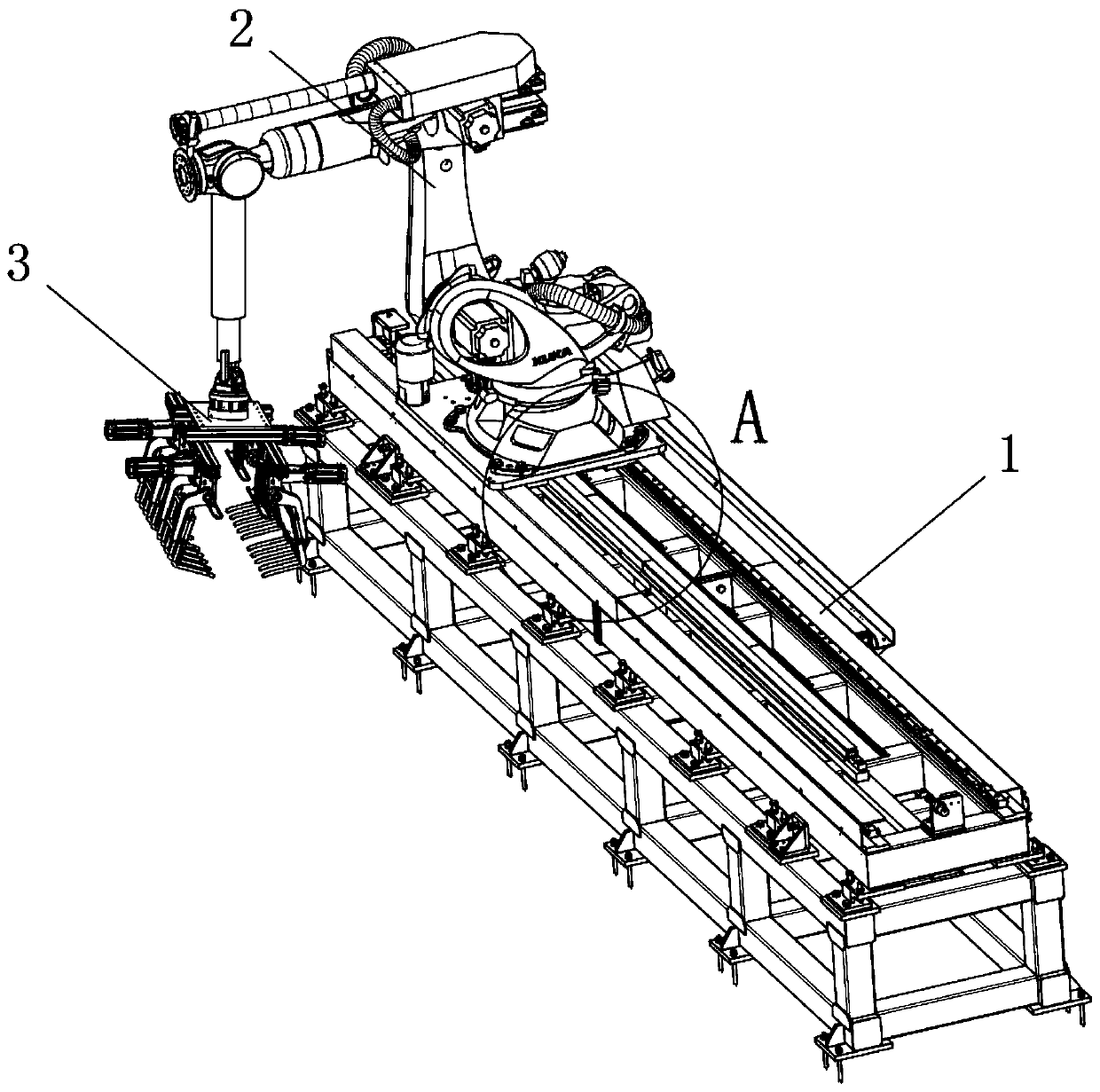

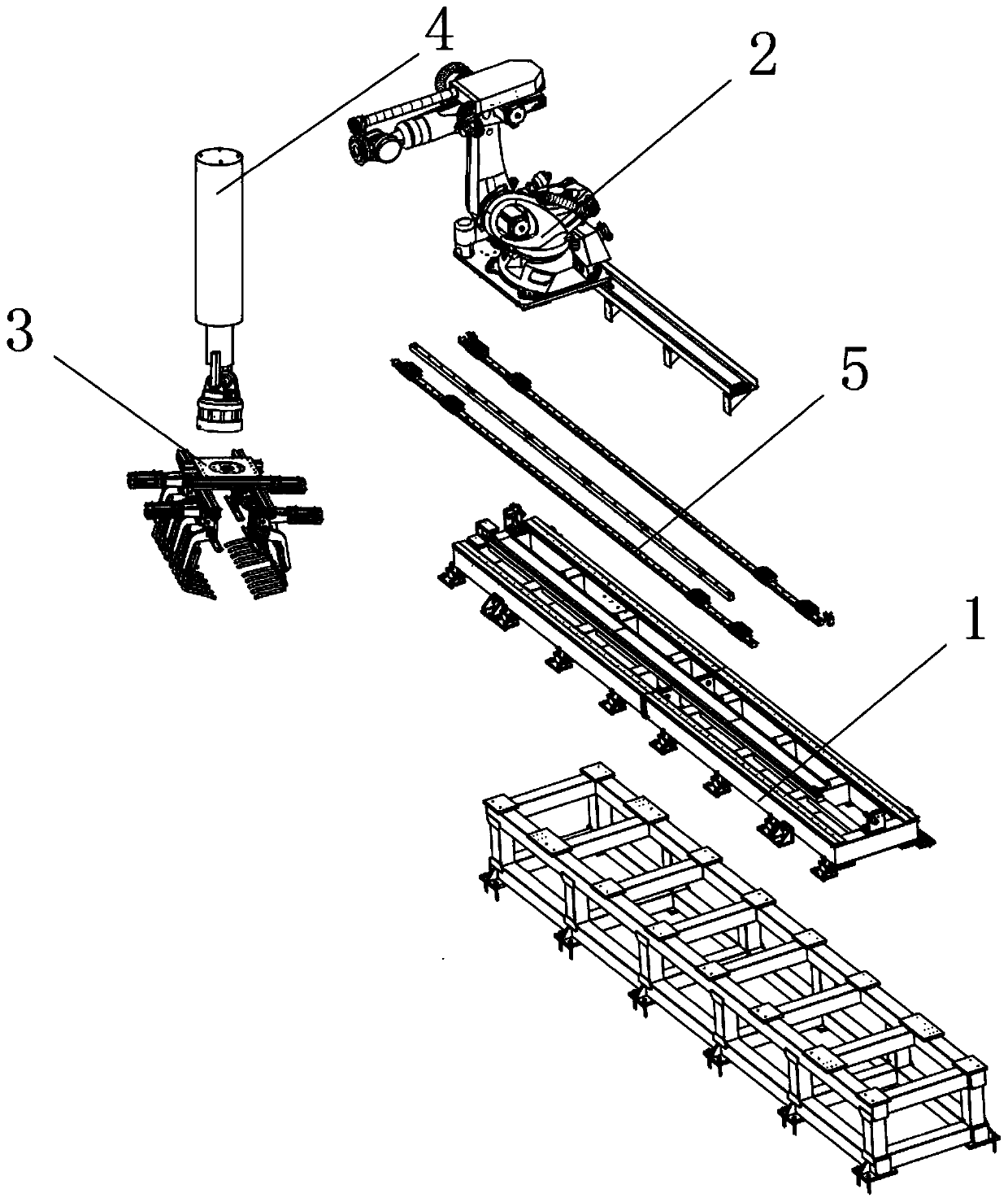

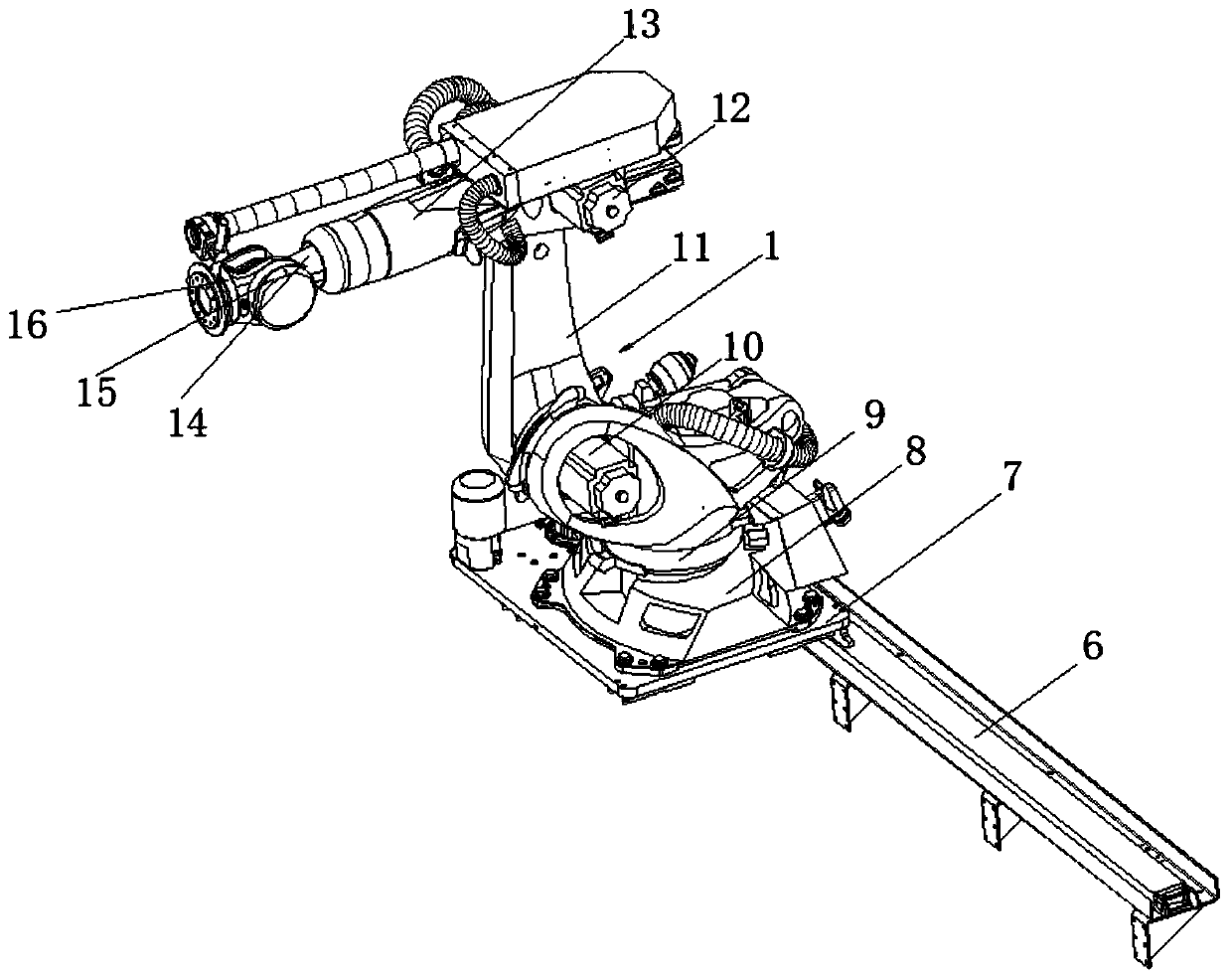

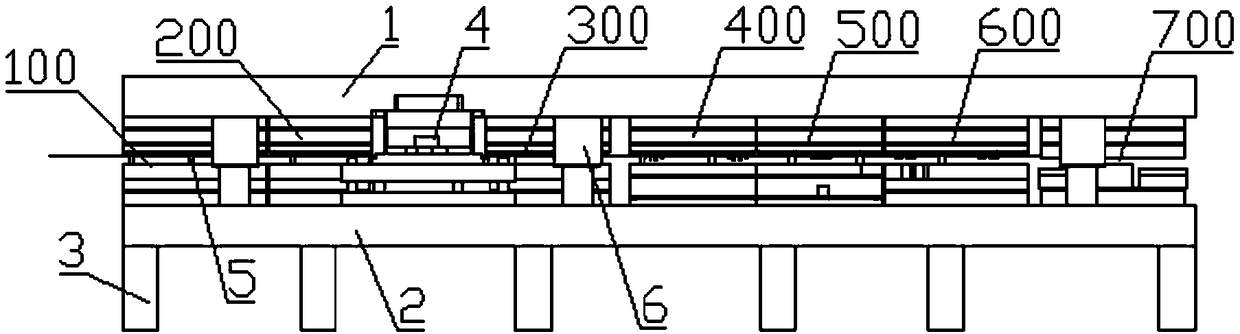

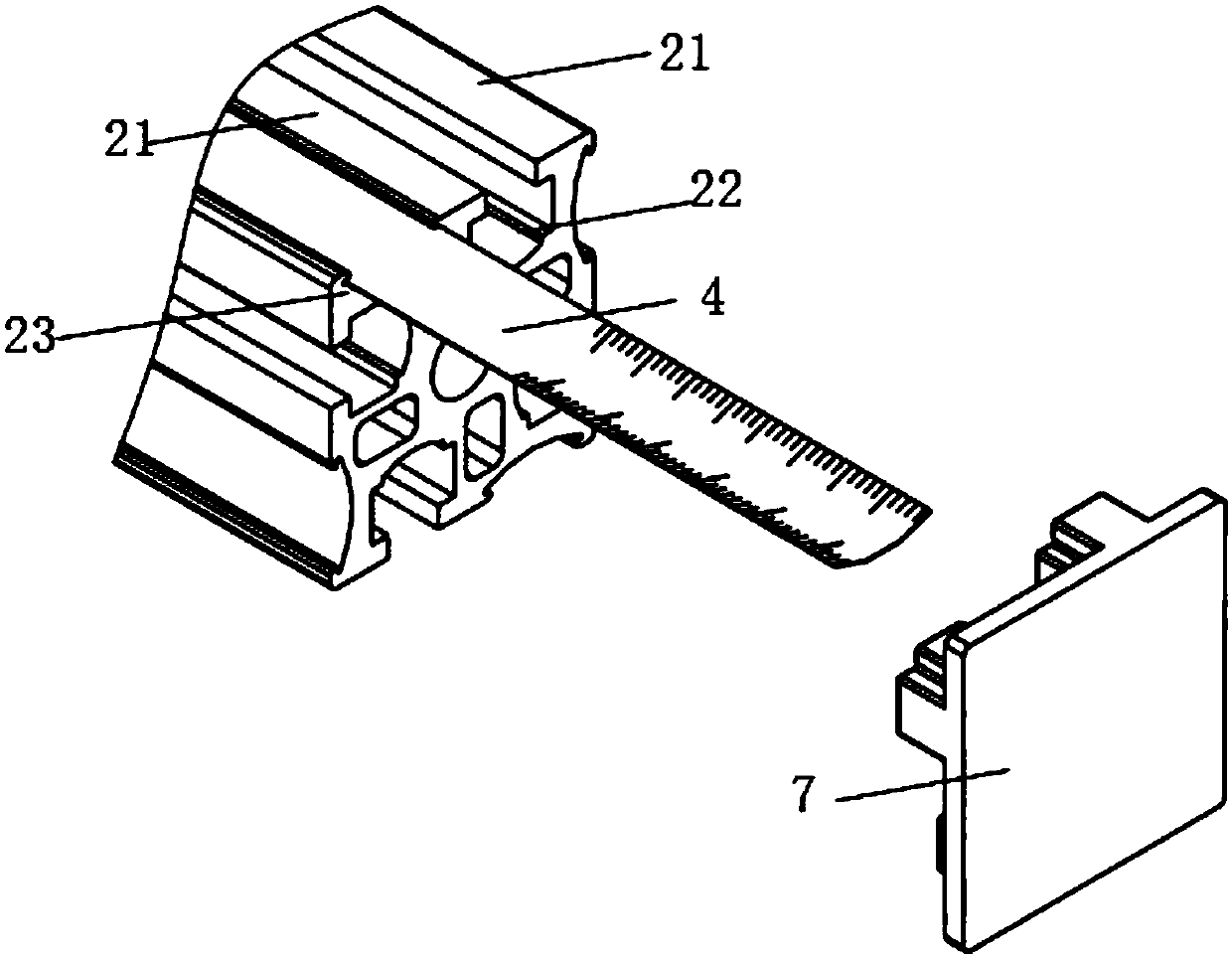

Conveying and trimming assembly used for melamine board, trimming and board discharging assembly and achieving method of conveying and trimming assembly and trimming and board discharging assembly

InactiveCN104444480AReduce labor intensityHigh precisionOther plywood/veneer working apparatusRegistering devicesHeat pressEngineering

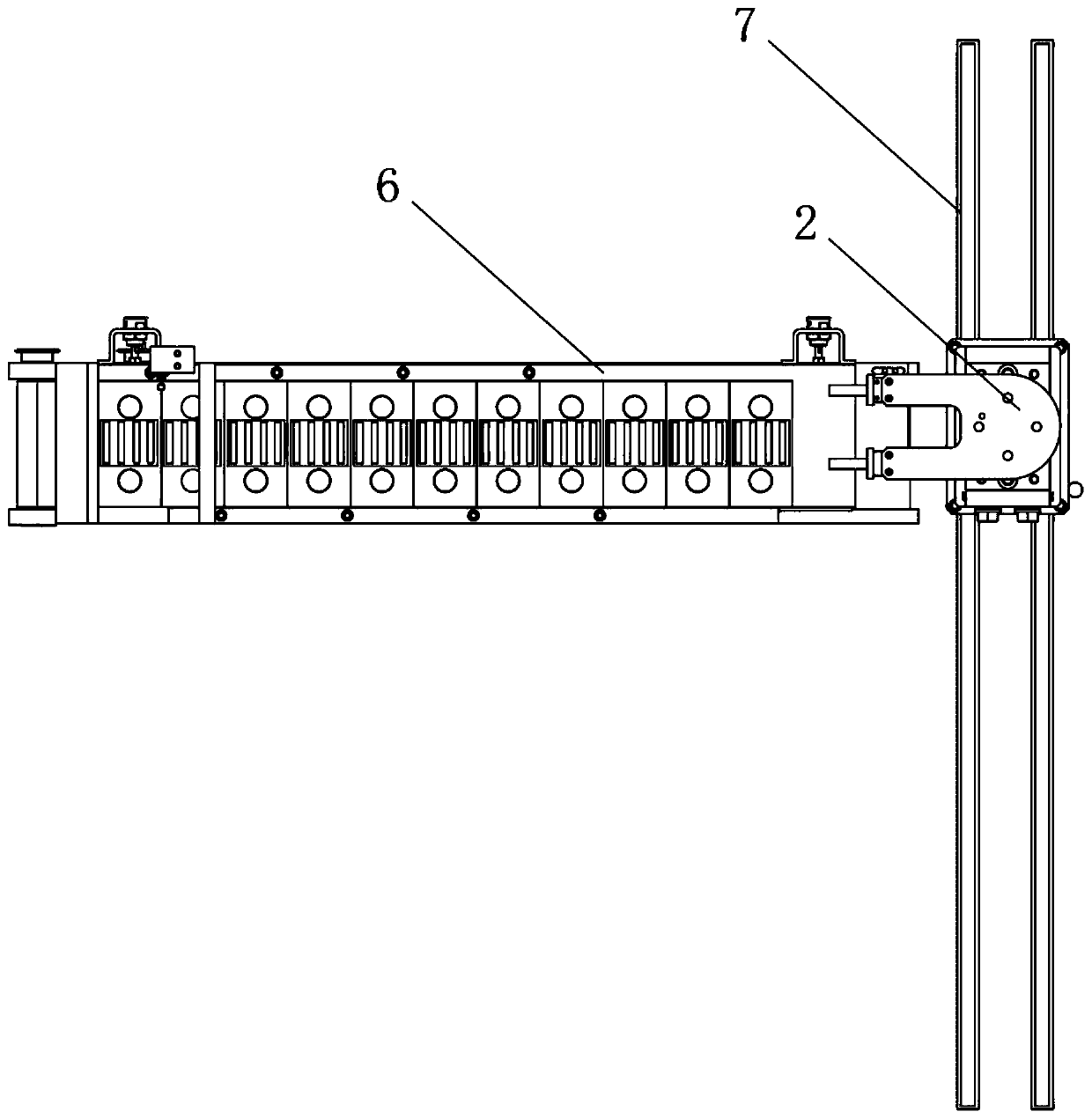

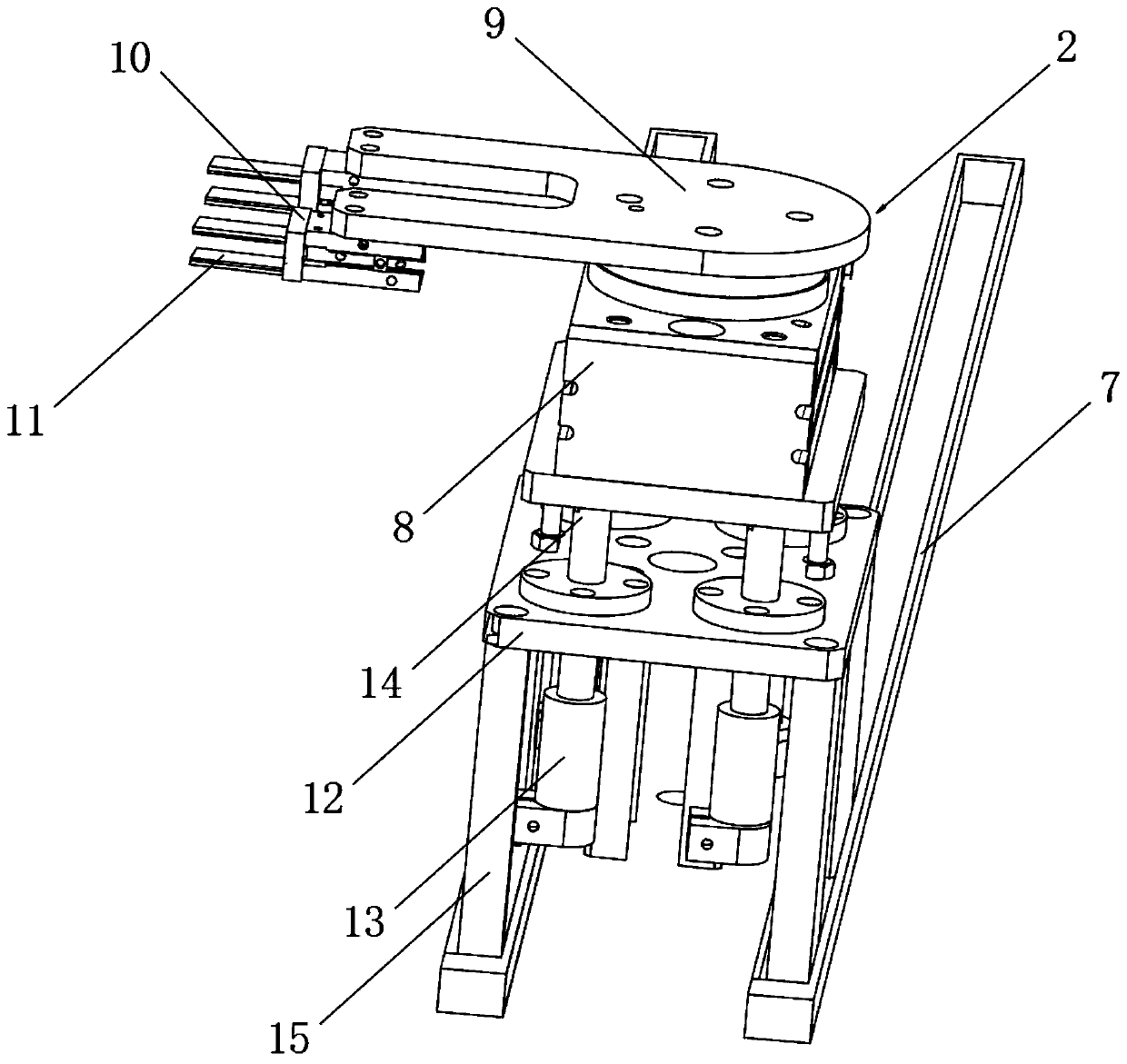

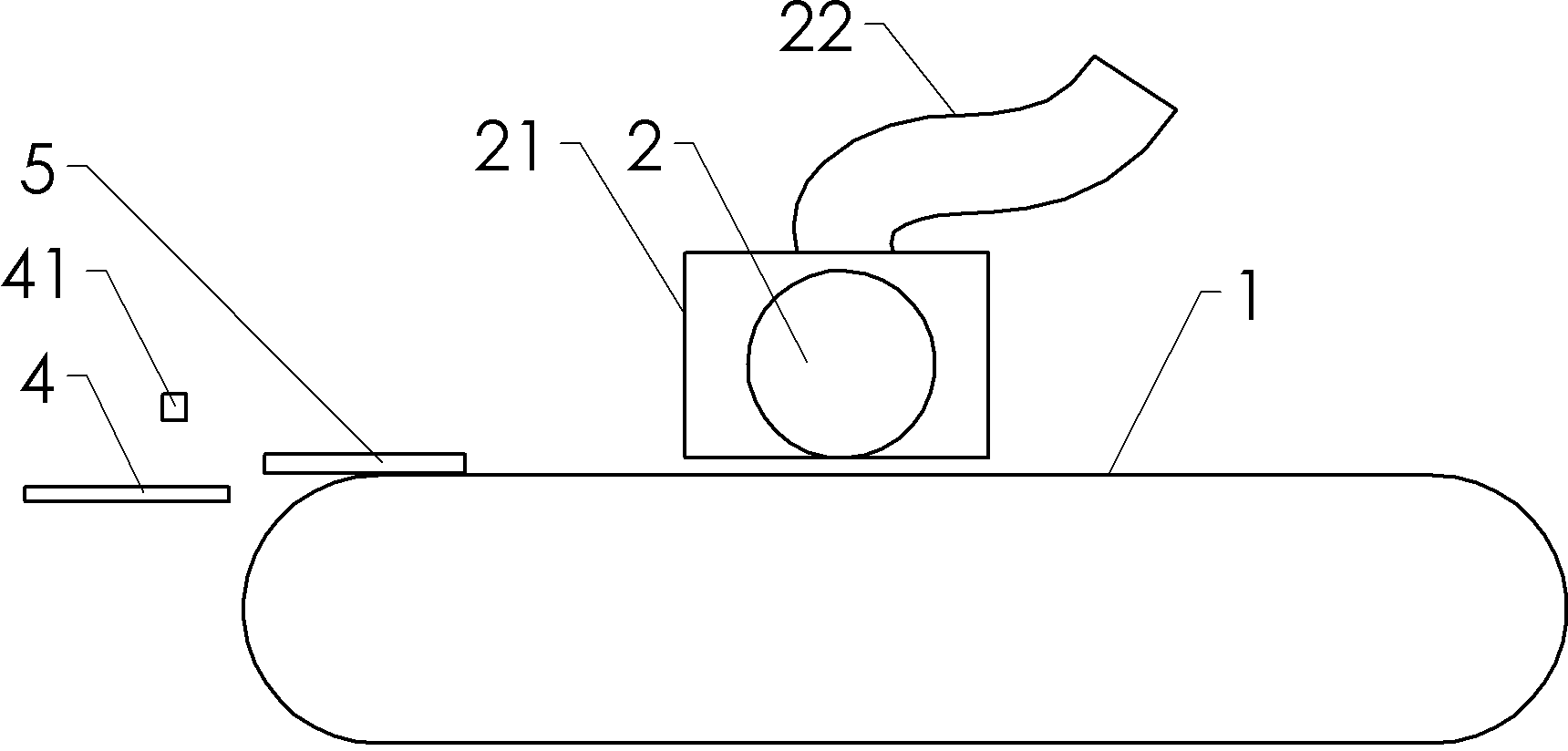

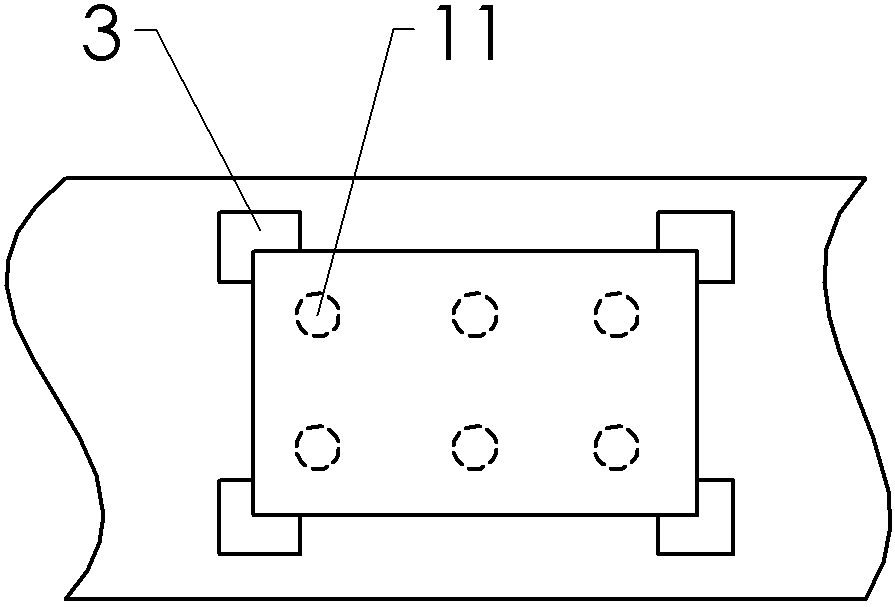

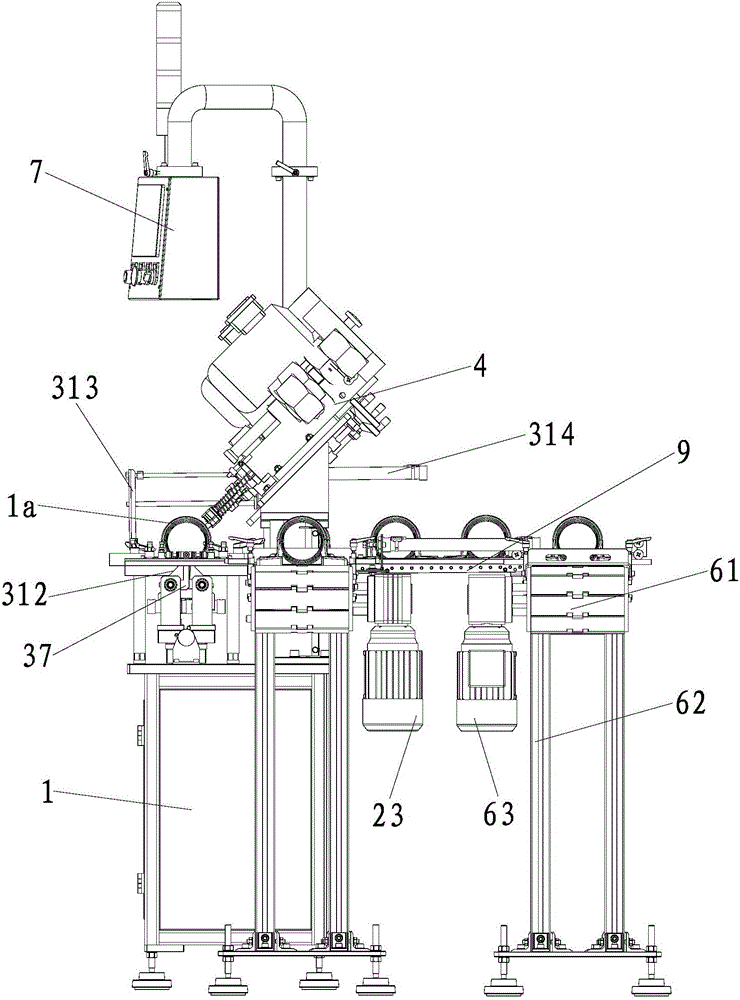

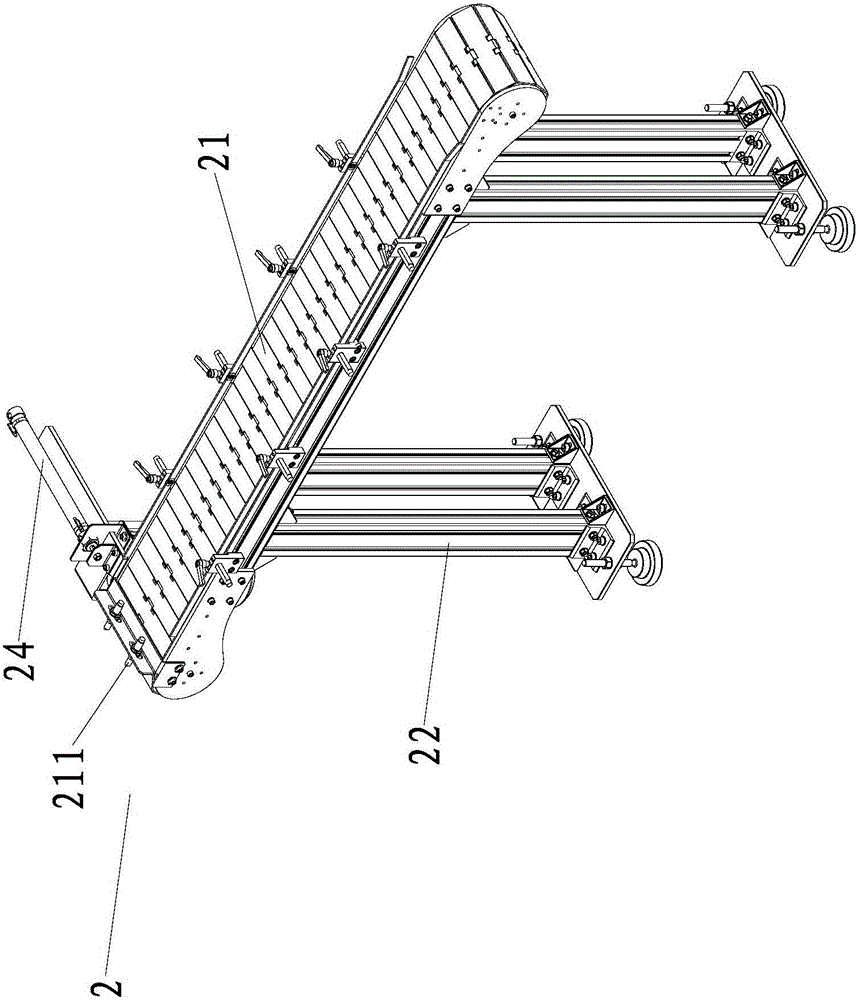

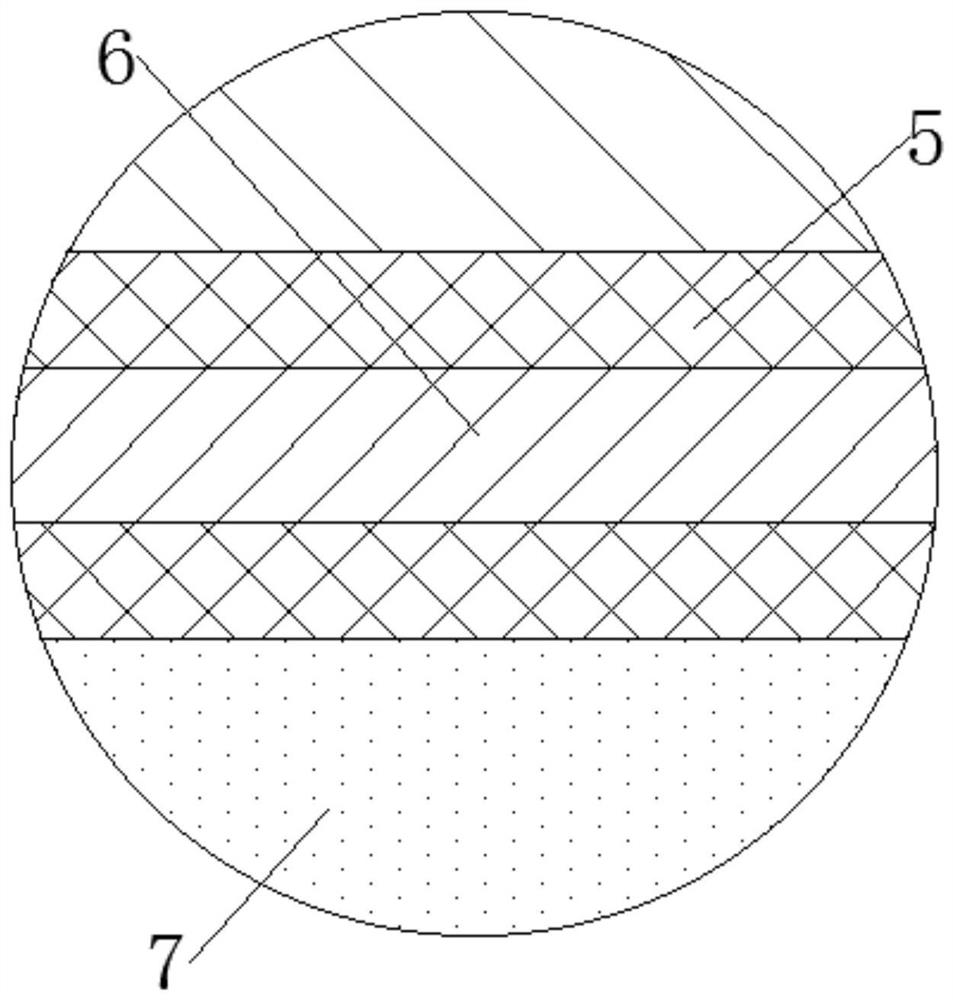

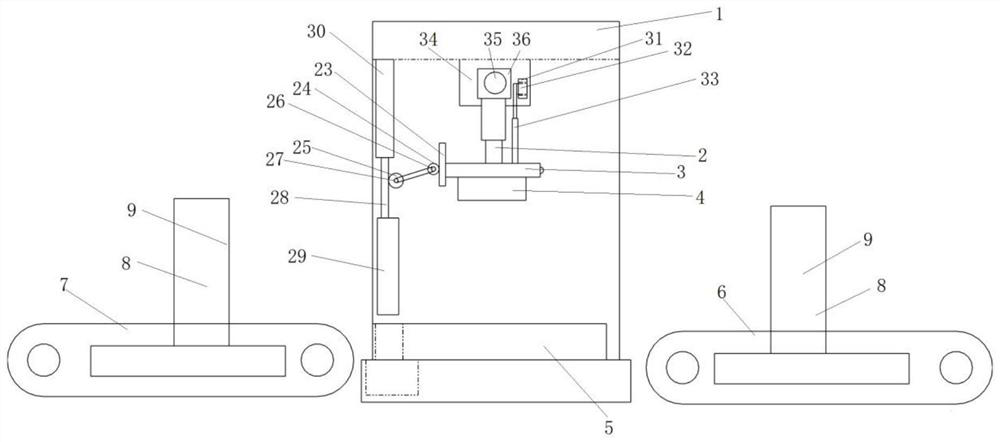

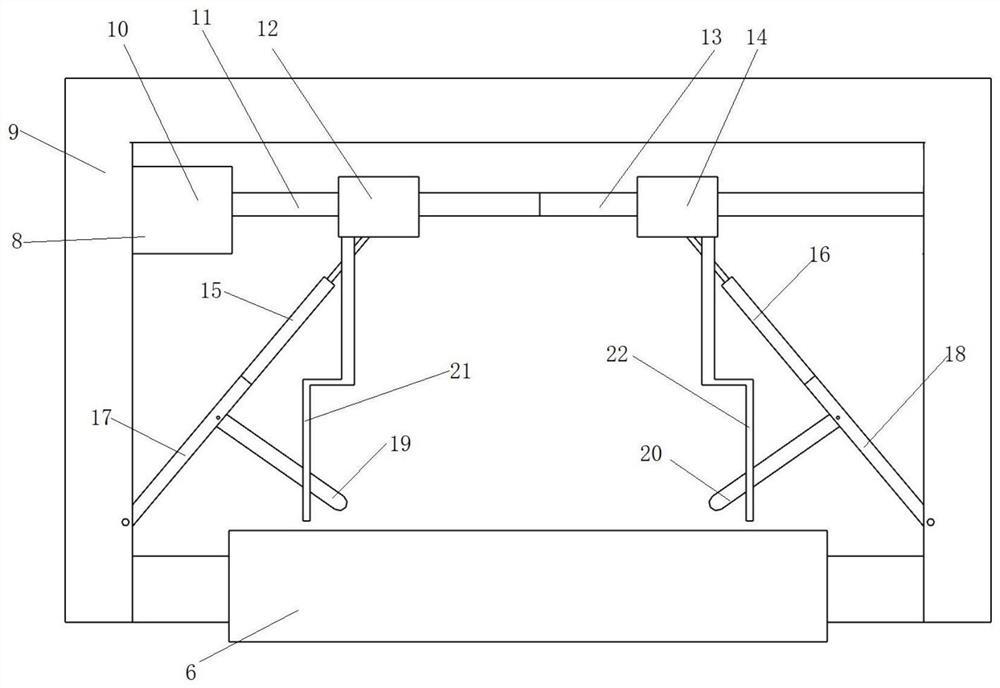

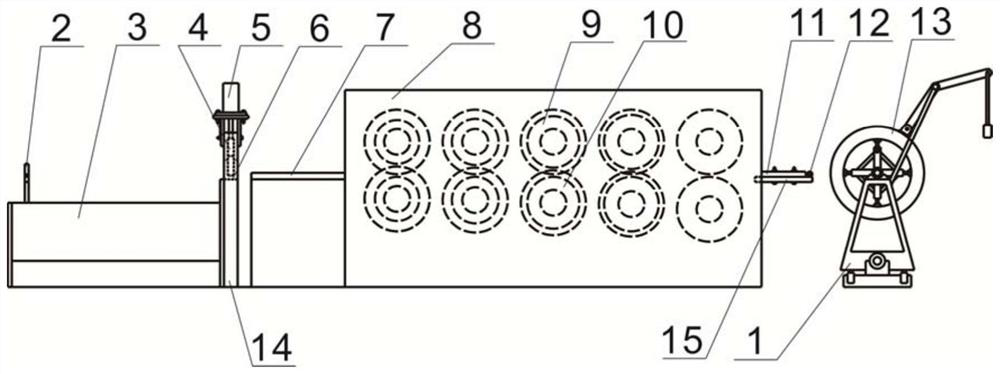

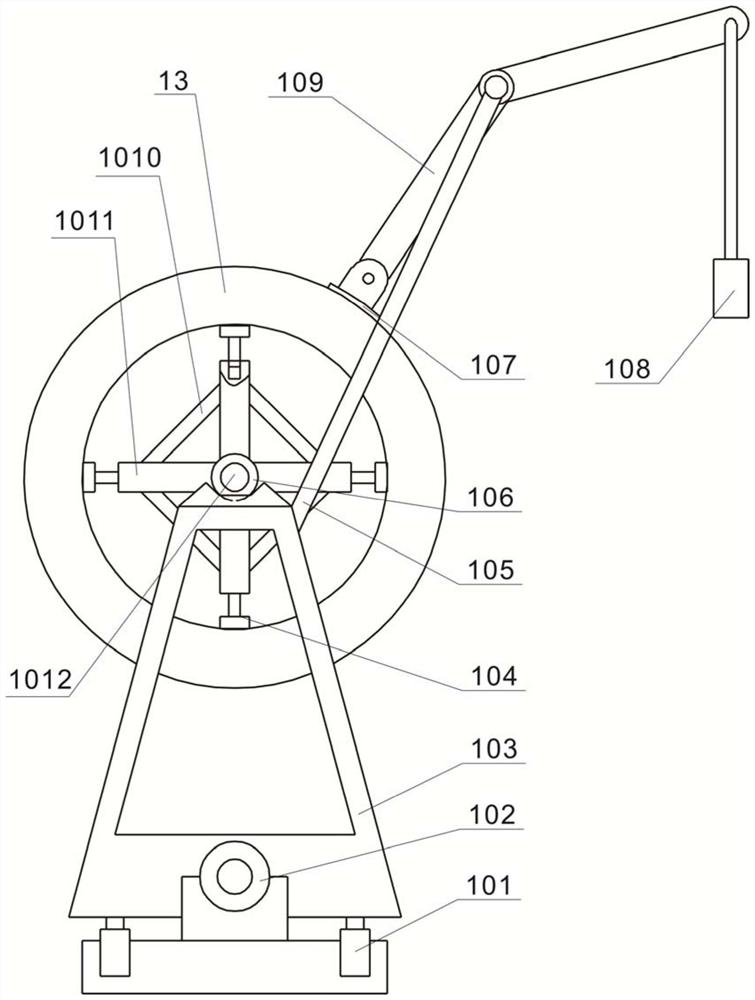

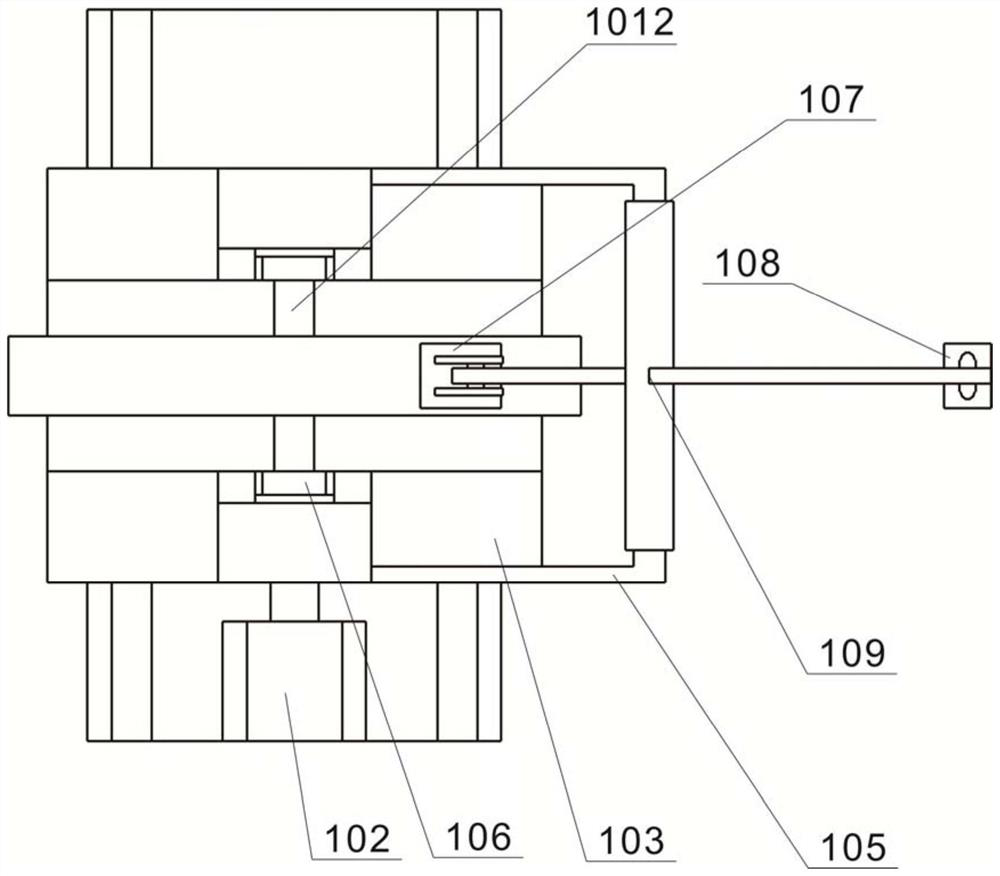

The invention discloses a conveying and trimming assembly for a melamine board. The conveying and trimming assembly comprises a bottom frame arranged outside a discharging port of a hot press, a two-section type conveying mechanism arranged on the bottom frame in the discharging direction, a positioning and position adjusting mechanism installed on the bottom frame and used for adjusting the position of a board on the two-section type conveying mechanism to as to conveniently conduct trimming, a trimming mechanism arranged at the sectioned position of the two-section type conveying mechanism in a crossing mode, and a tail-end baffle located at the tail end of the two-section type conveying mechanism. The invention further discloses a trimming and board discharging assembly which comprises the conveying and trimming assembly and a board discharging and carrying mechanism connected with the conveying and trimming assembly. Under the cooperation action of the conveying mechanism and the positioning and position adjusting mechanism, the board obtained after hot pressing is conveyed to a designated position, trimming is conducted on the board through the trimming mechanism, the board is well placed through the board discharging and carrying mechanism, an automatic mechanical device can fully replaced labor force, the labor intensity of workers is greatly lowered, the labor cost is reduced, and the production efficiency is effectively improved.

Owner:李茂华

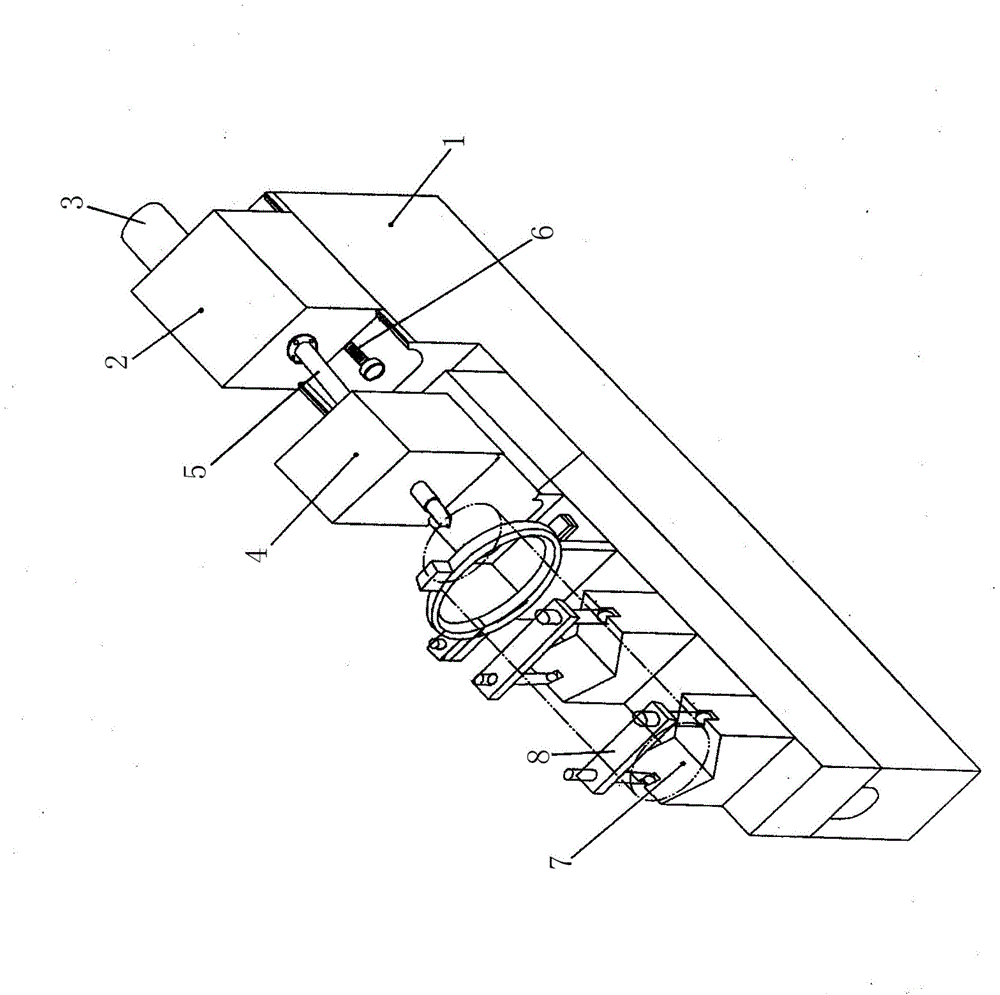

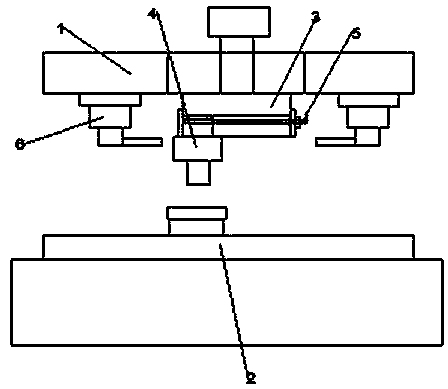

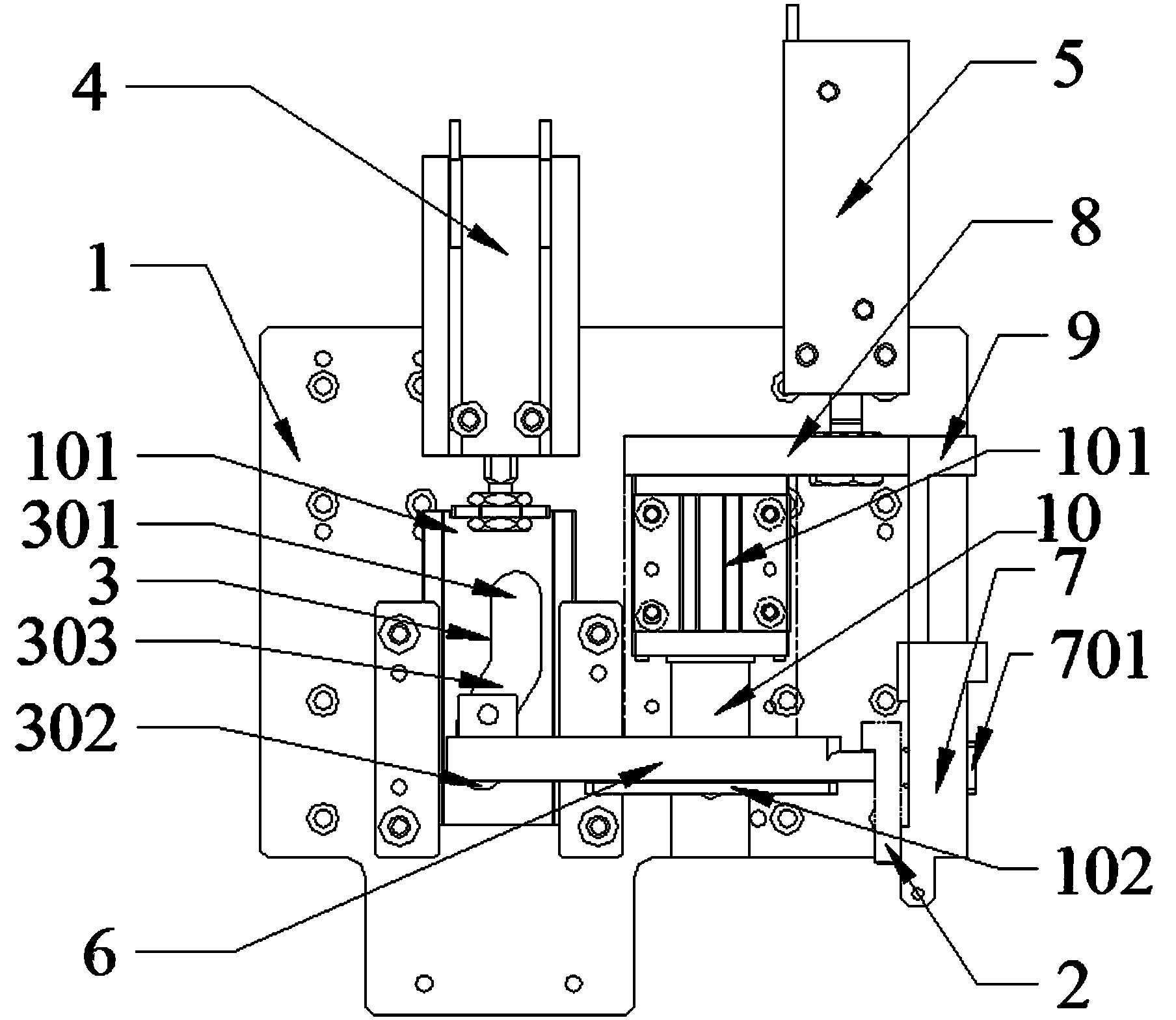

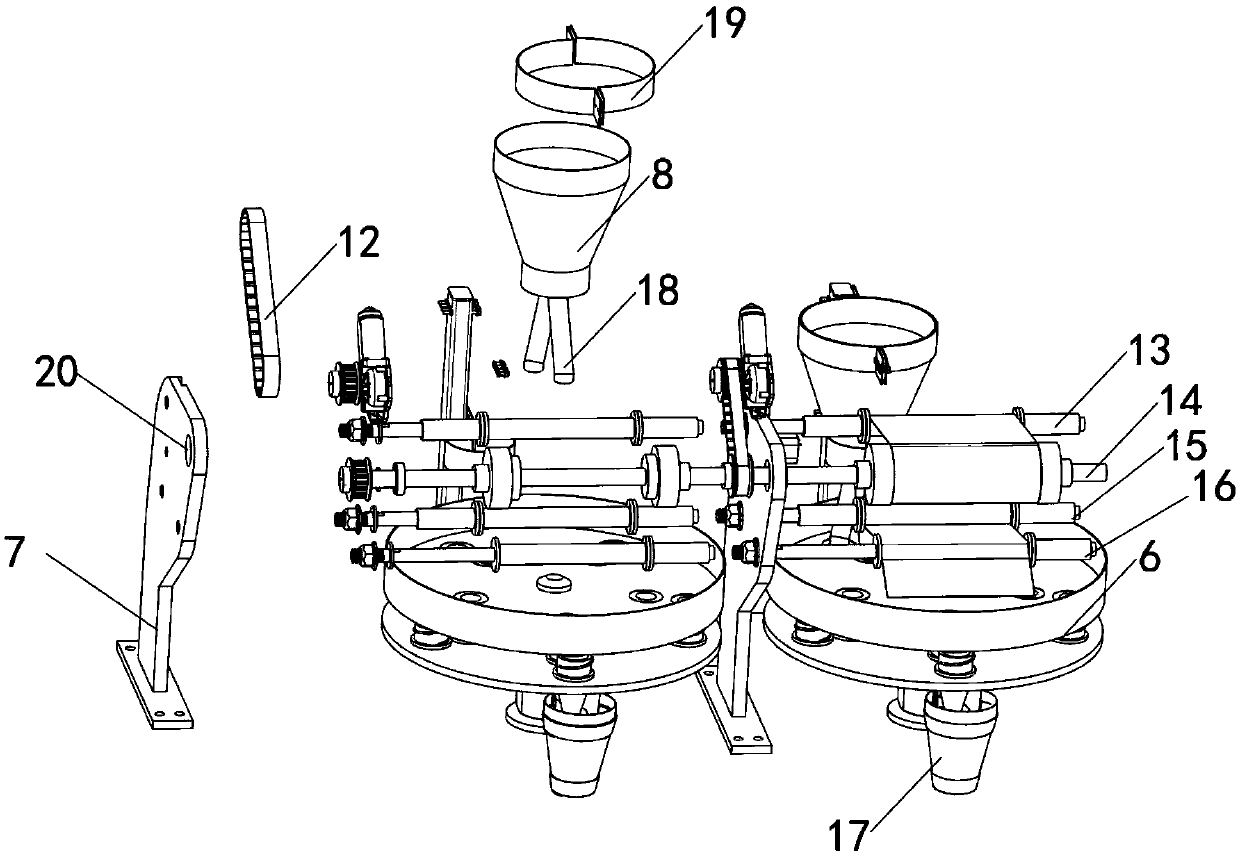

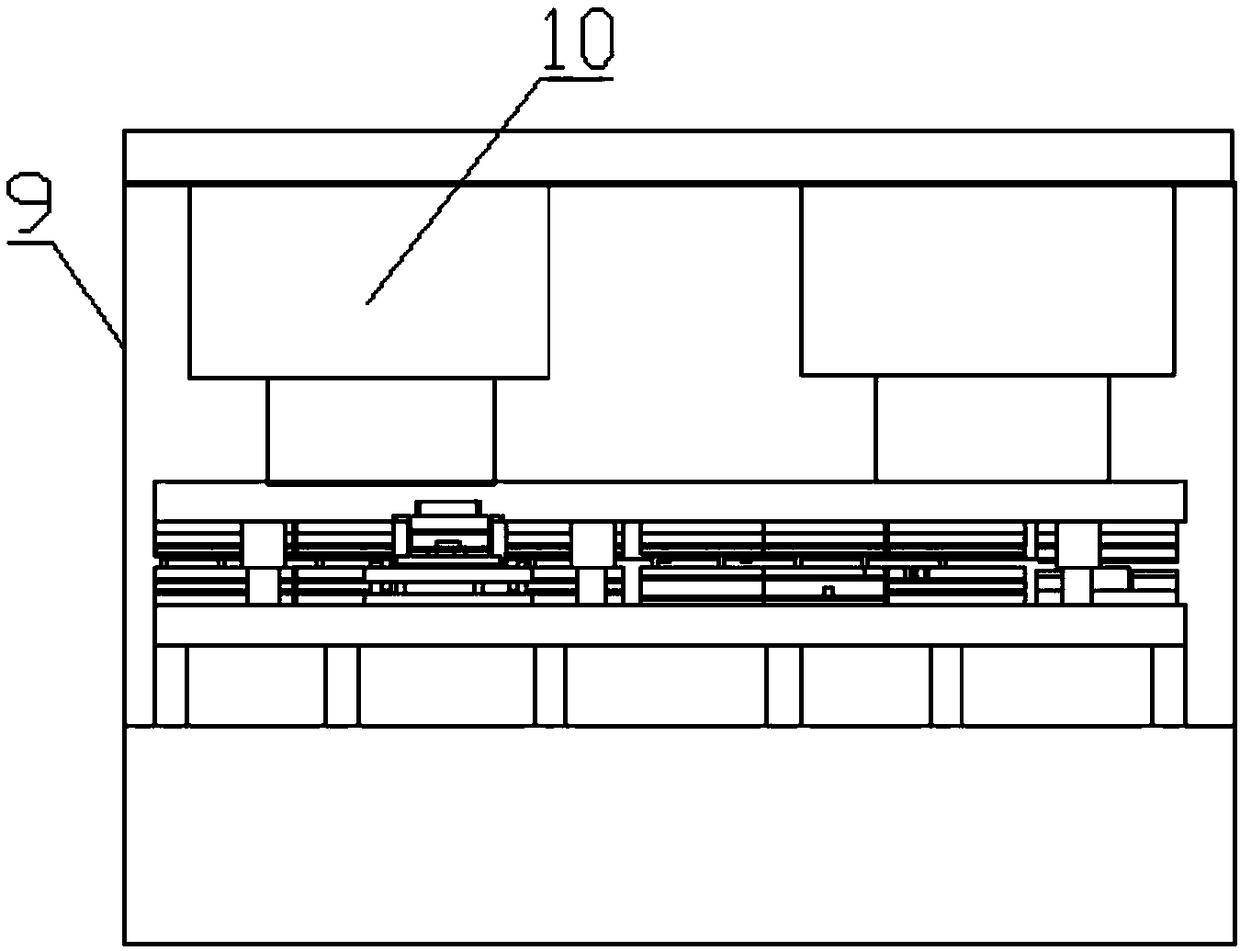

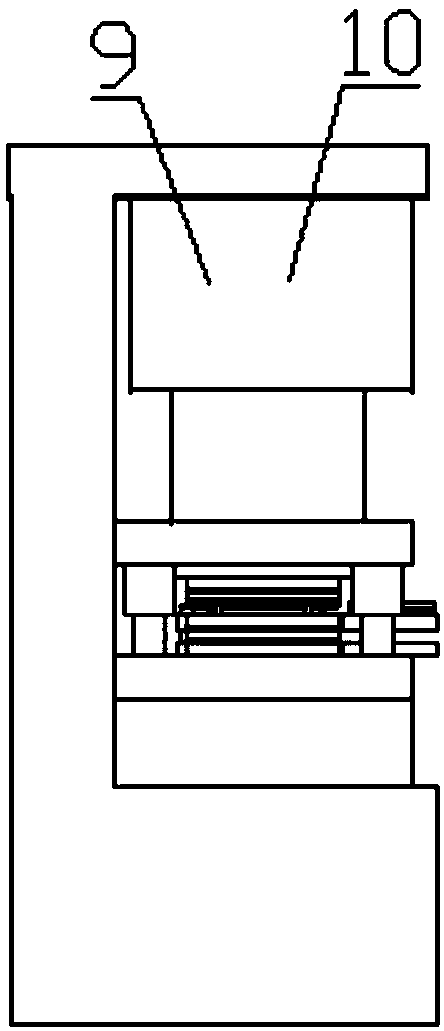

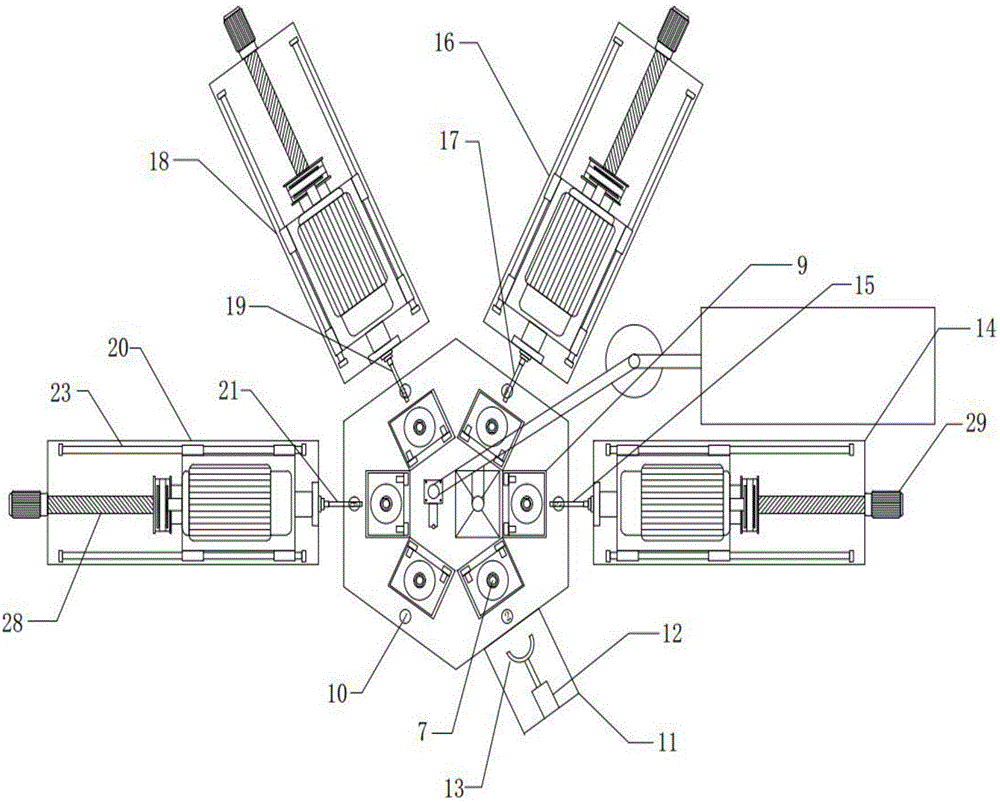

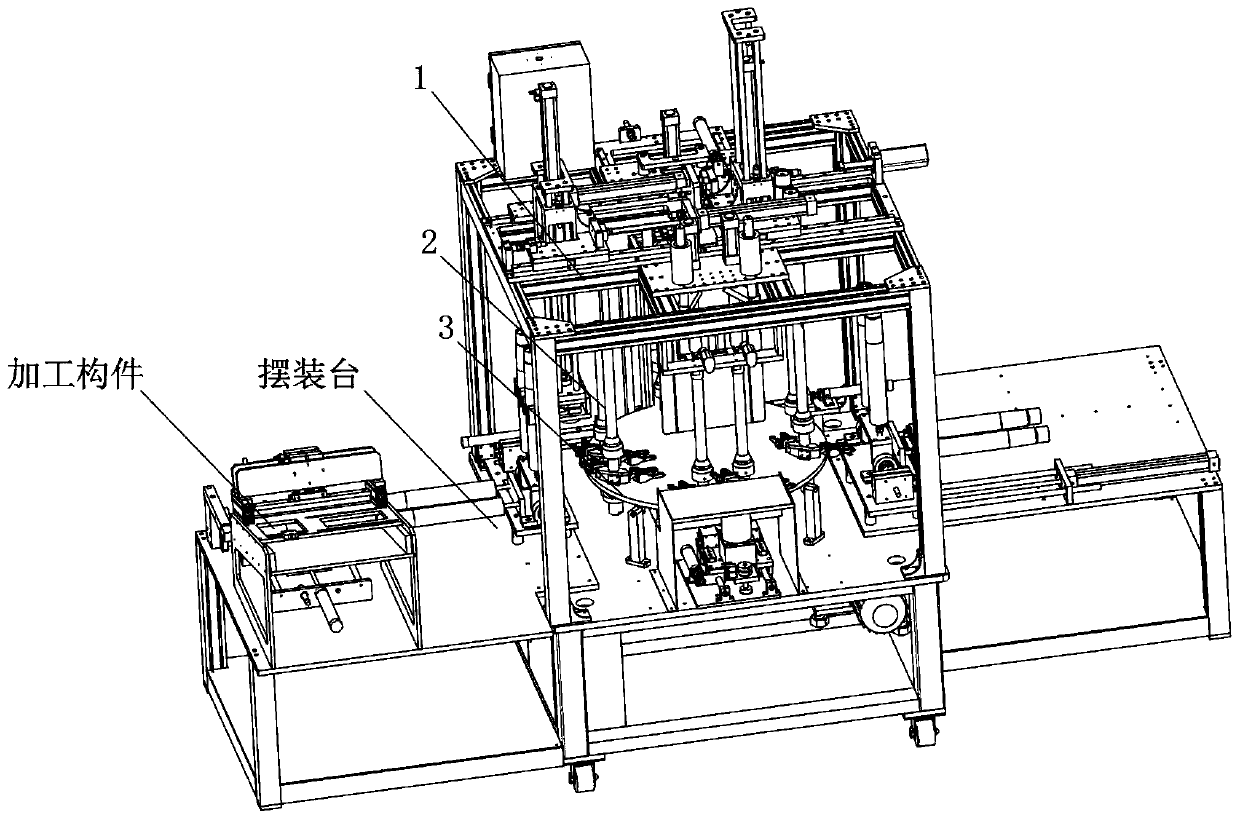

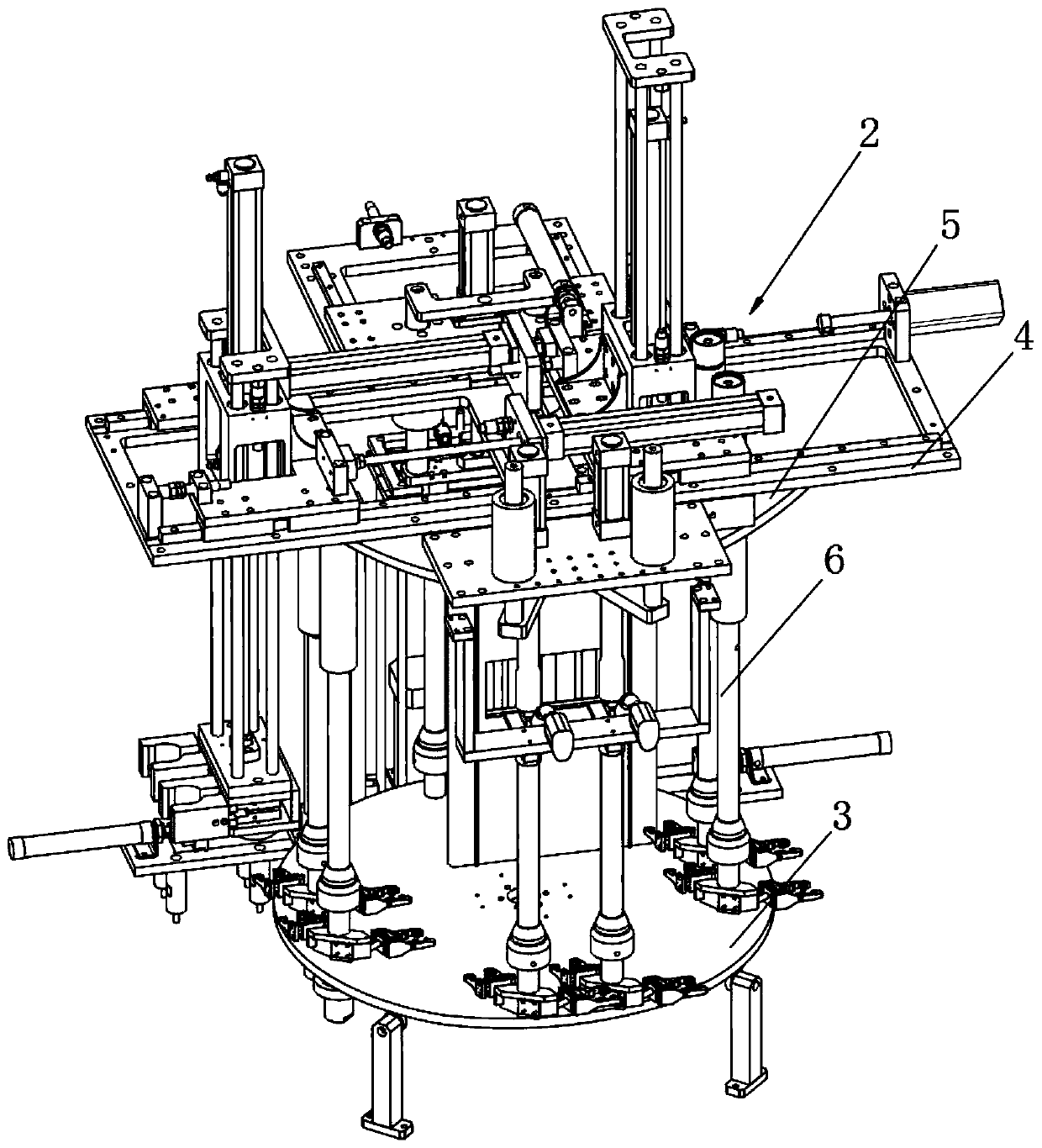

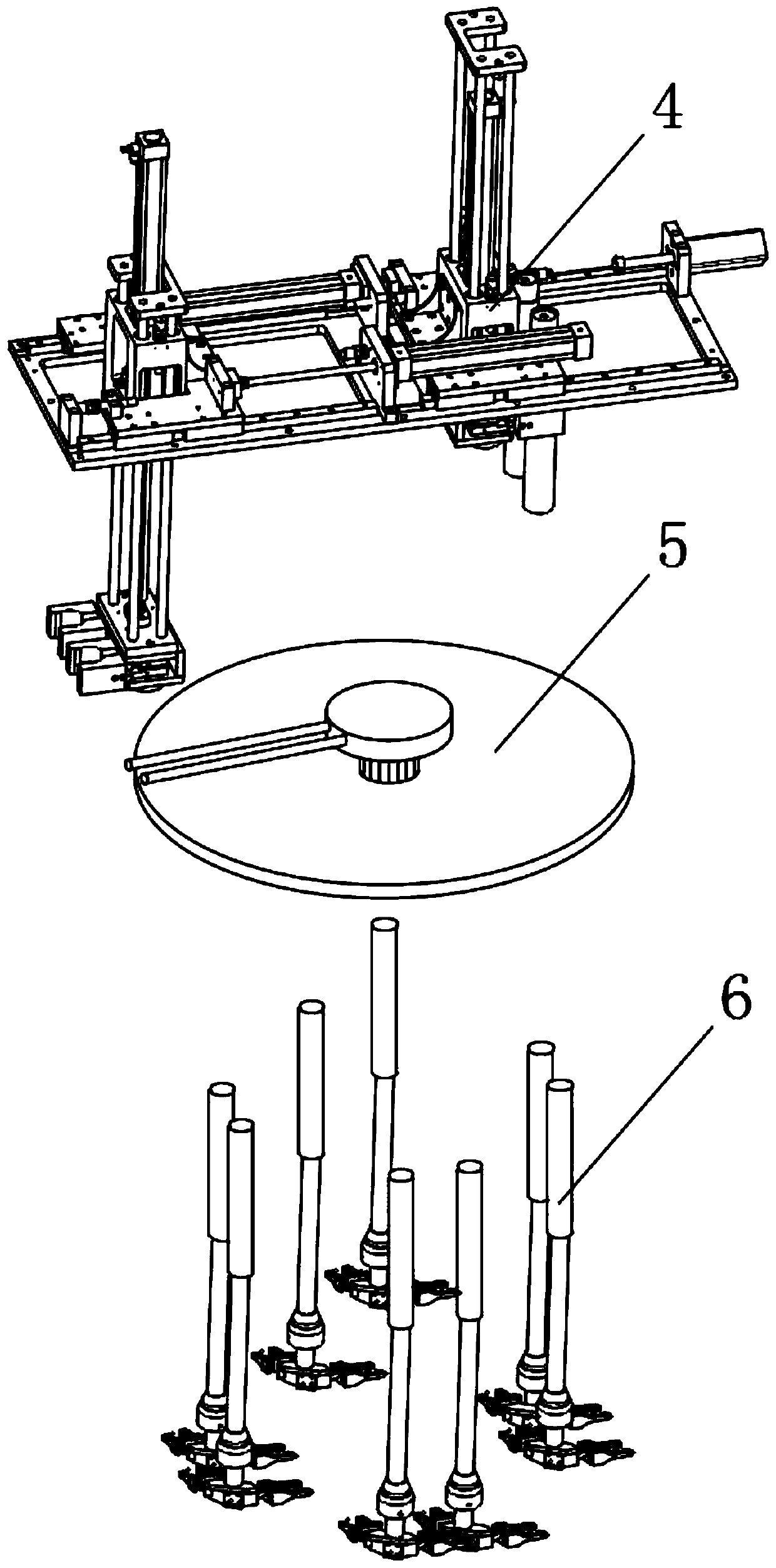

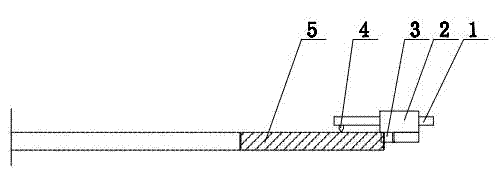

Rotary robot welding fixture and working method thereof

ActiveCN110000503APrevent fallingPrecise positioning of welding workWelding/cutting auxillary devicesAuxillary welding devicesMotor driveEngineering

The invention discloses a rotary robot welding fixture comprising an arranging and installing table, a front clamping seat, a rear chuck and side pressure seats. The front clamping seat is arranged above the arranging and installing table, one side of the front clamping seat is provided with the circular rear chuck, and the multiple side pressure seats are arranged at the edge of the rear chuck inan equal-radian manner. A first motor is arranged above the front clamping seat. The rotary robot welding fixture has the beneficial effects that when a welding mechanism performs welding work, a fourth motor drives robot components on a clamping and connecting seat to rotate to achieve fine adjustment of the positions, and it is ensured that the welding work of the welding structure on the robotcomponents is more precise in position and higher in efficiency; and the automatic degree of rotary clamping fixing work by the welding fixture on the robot components is higher, and much time and labor are saved in the using process. Four second motors drive the front clamping seat to move in two mounting frames, a plurality of first hob gears cooperate with a gear to rotate to ensure that the front clamping seat and the robot components are adjusted and moved more smoothly and securely, and collision and abrasion between all parts of the front clamping seat are reduced.

Owner:昆山高科创志机器人自动化有限公司

Conveyor belt for metal workpieces

InactiveCN103057900AThe processing position is accurateConveyorsGrinding machinesEngineeringConveyor belt

The invention provides a conveyor belt for metal workpieces and solves the problem that metal workpieces on the conveyor belt are instable under the effect of external force in the prior art. The conveyor belt for metal workpieces comprises a movable belt body and is characterized in that magnets, which can be permanent magnets or electromagnetism generators, are arranged on the belt body. The magnets operate to generate magnetic field firmly adsorbing the metal workpieces on the conveyor belt so as to guarantee positional stability of the metal workpieces.

Owner:黄维明

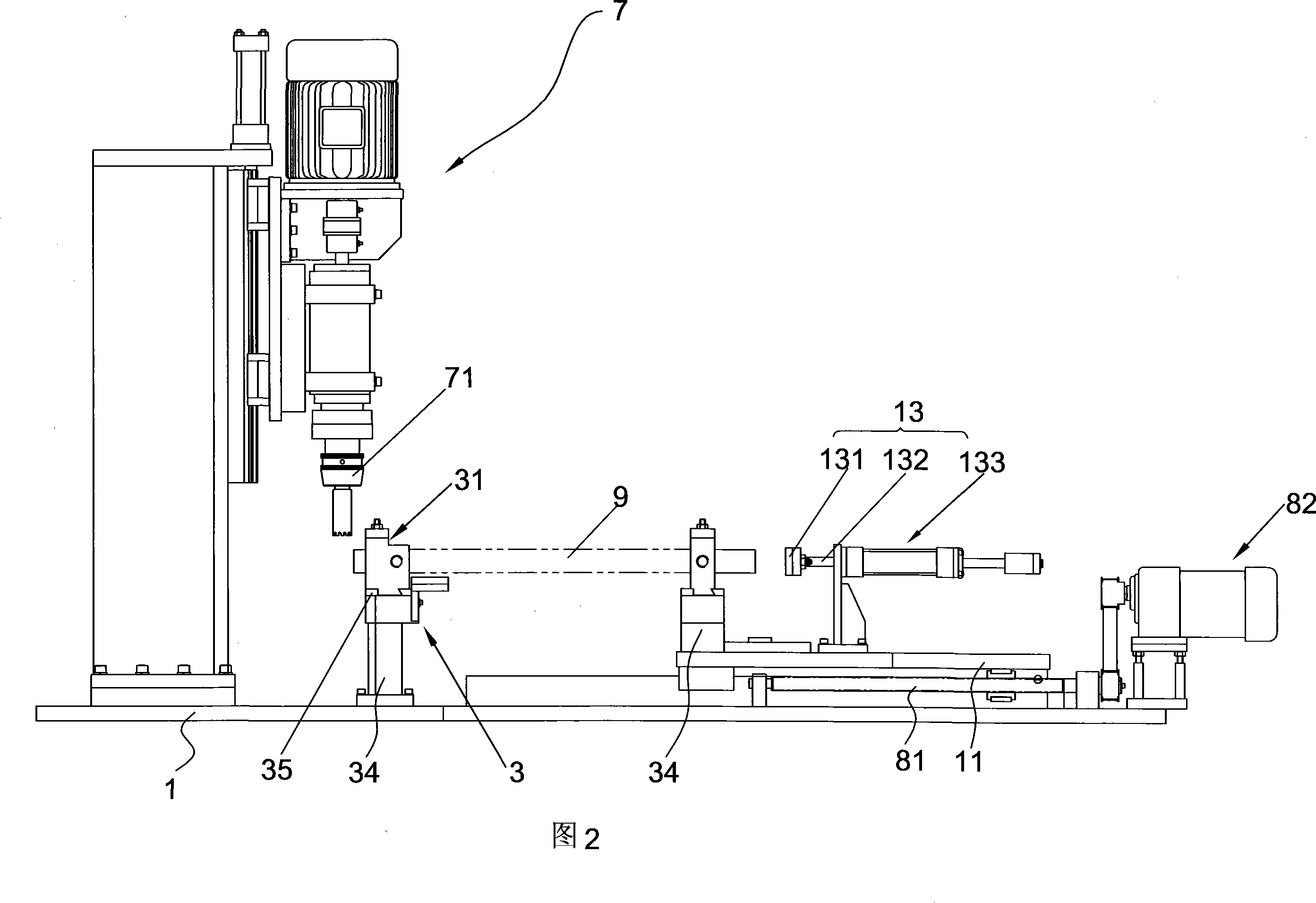

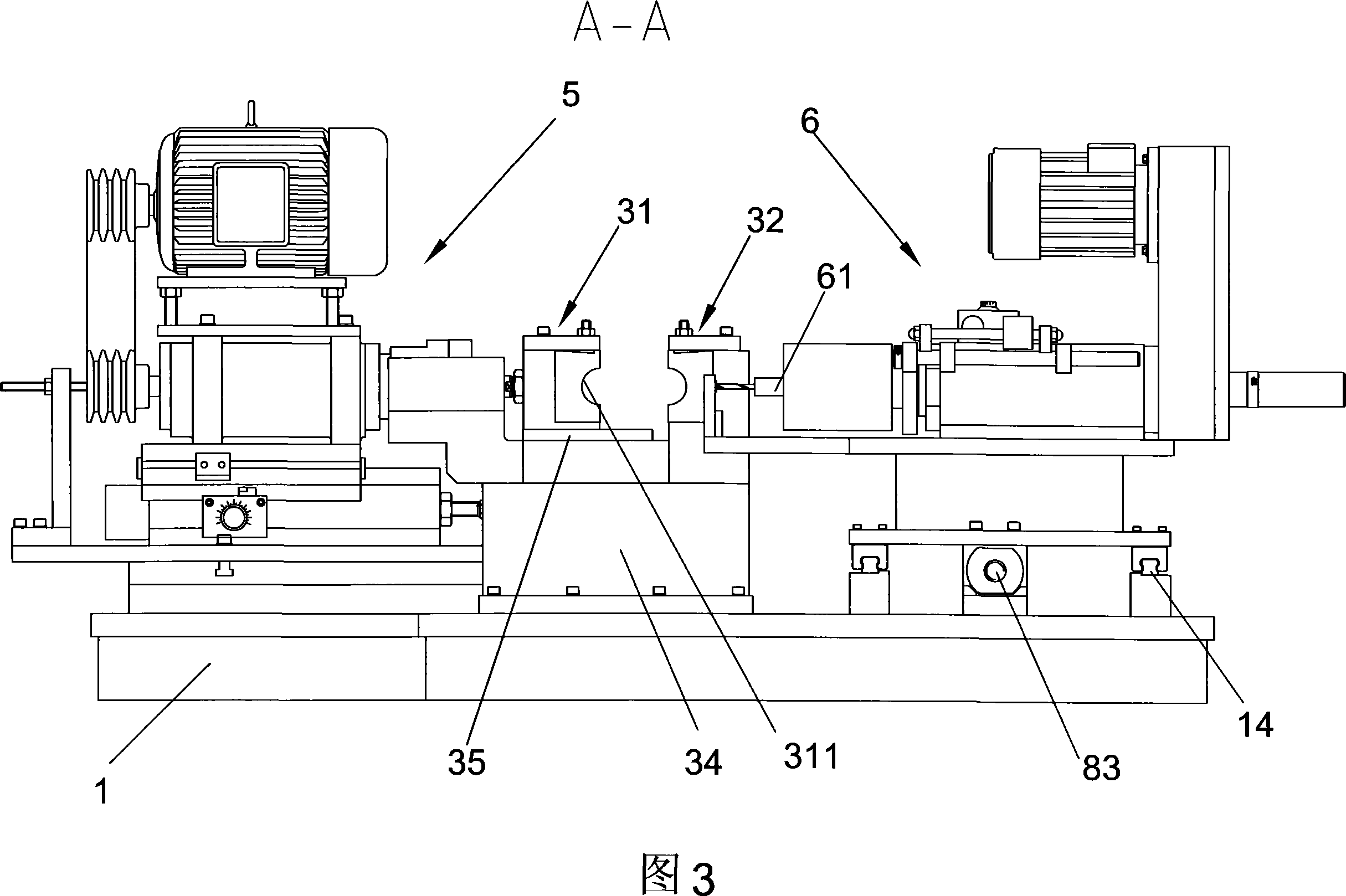

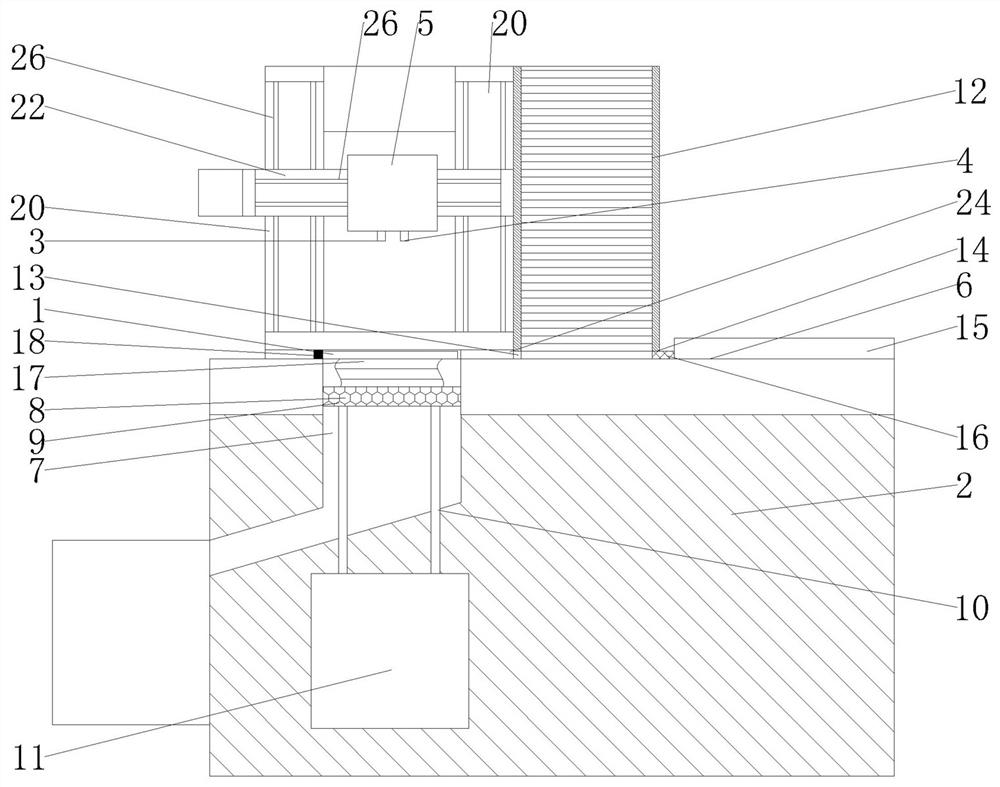

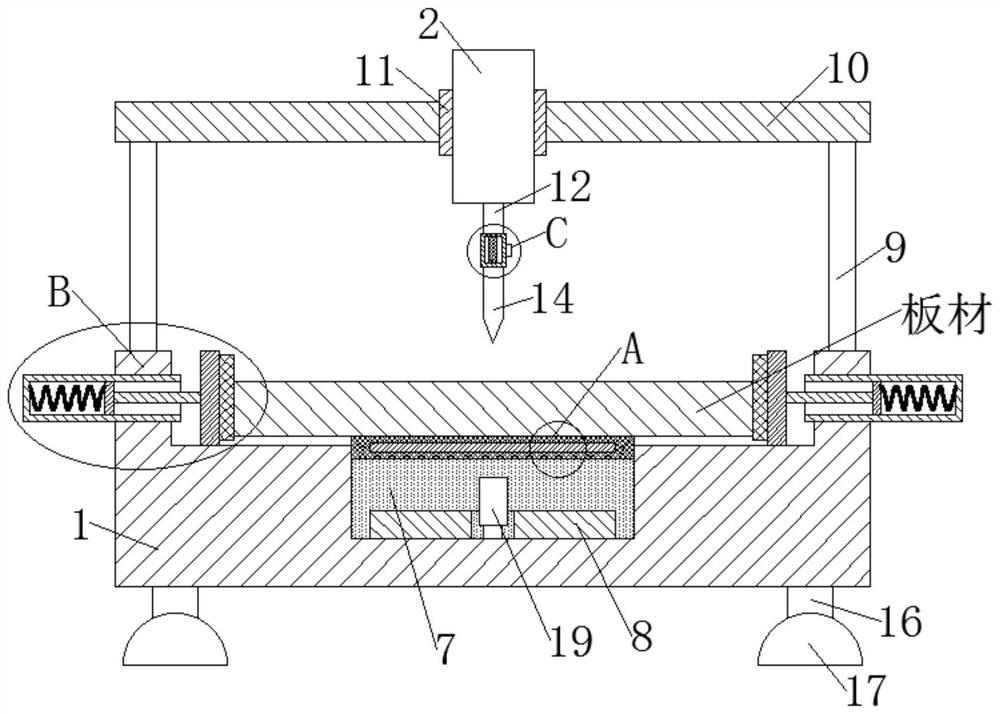

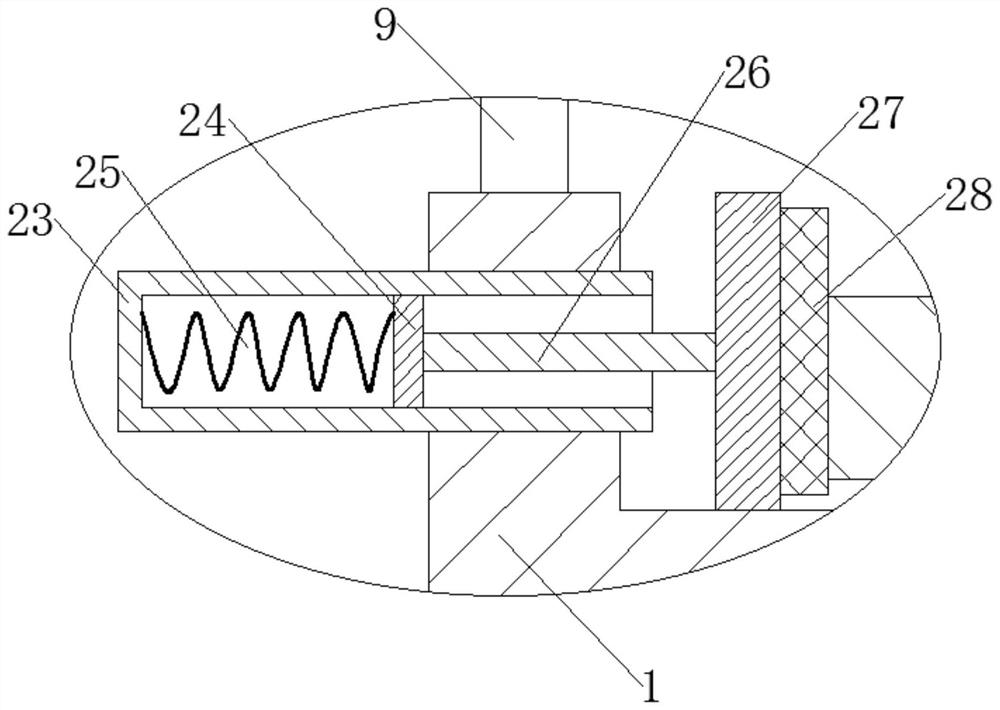

Drilling machine tool for round timber tip

InactiveCN104626280AFastenedThe processing position is accurateStationary drilling machinesFixed frameElectric machinery

The invention discloses a drilling machine tool for a round timber tip. The drilling machine tool for the round timber tip is characterized in that a main machine head is supported at one end of a machine tool body by a guide rail, a driving motor is arranged at the upper part of one side of the main machine head, a drilling rod supporting block is arranged at the inner side of the main machine head, a drilling rod connected with the main machine head is supported by the drilling rod supporting block, a propelling screw is arranged at the lower part of the main machine head, multiple clamp bases are arranged at the other side of the machine tool body, the center of a workpiece fixing frame on each clamp base and the center of the drilling rod are positioned on the same horizontal line; the drilling machine tool can be used for deeply processing the tip of a round timber due to the arrangement, the clamping effect is firm, and the processing position is accurate; and the drilling machine tool is economic and practical, can be operated conveniently and has high production efficiency.

Owner:陈红

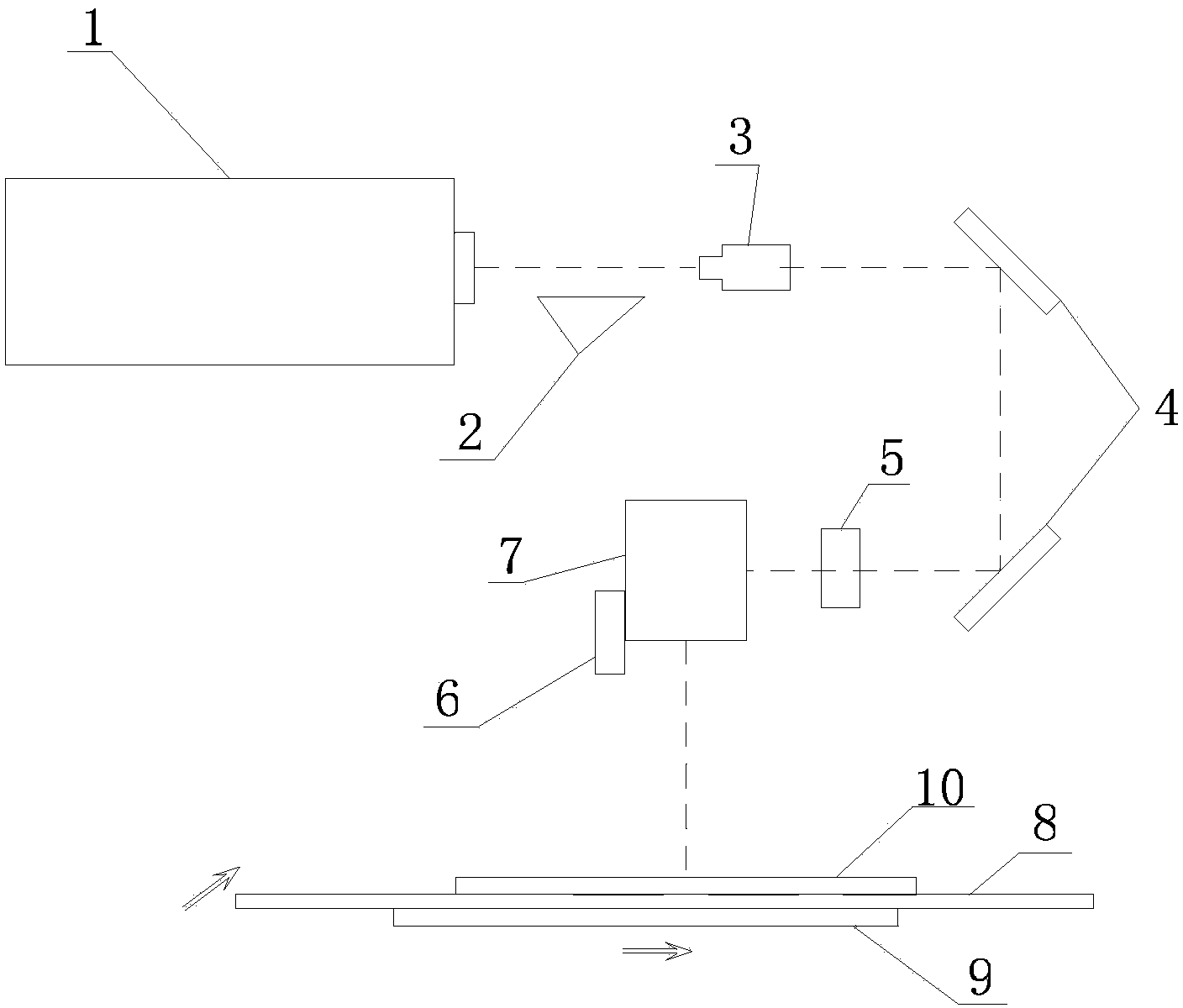

Device and method for carrying out laser machining on light guide board inside glass

InactiveCN104237997AImprove divergence angleSmall spotGlass shaping apparatusOptical light guidesCamera lensThree dimensional microstructure

The invention relates to a device and method for carrying out laser machining on a light guide board inside glass. A beam expander, a 45-degree total reflection mirror set, a beam shaping unit and a scanning galvanometer are arranged on a light path of the output end of a laser in sequence. The beam output end of the scanning galvanometer right faces a carrier platform. A CCD system is installed on the scanning galvanometer. A lens of the CCD system right faces the carrier platform. Laser beams emitted by the laser are coaxially expanded through the beam expander, the beam transmission divergence angle is improved, the light path is made to be aligned, and the light spot is smaller after focusing is carried out by coaxially expanding the laser beams; the expanded beams reach the 45-degree total reflection mirror set and enter the beam shaping unit, the shaped focusing light spot can be of a three-dimensional microstructure inside the glass, the shaped beams reach the scanning galvanometer, laser beams emitted by the scanning galvanometer are focused inside the glass serving as a workpiece to be machined, and marks are etched inside the glass. The device is high in light transmittance, wide in application range, long in service life, not prone to abrasion and accurate in machining position.

Owner:SUZHOU DELPHI LASER

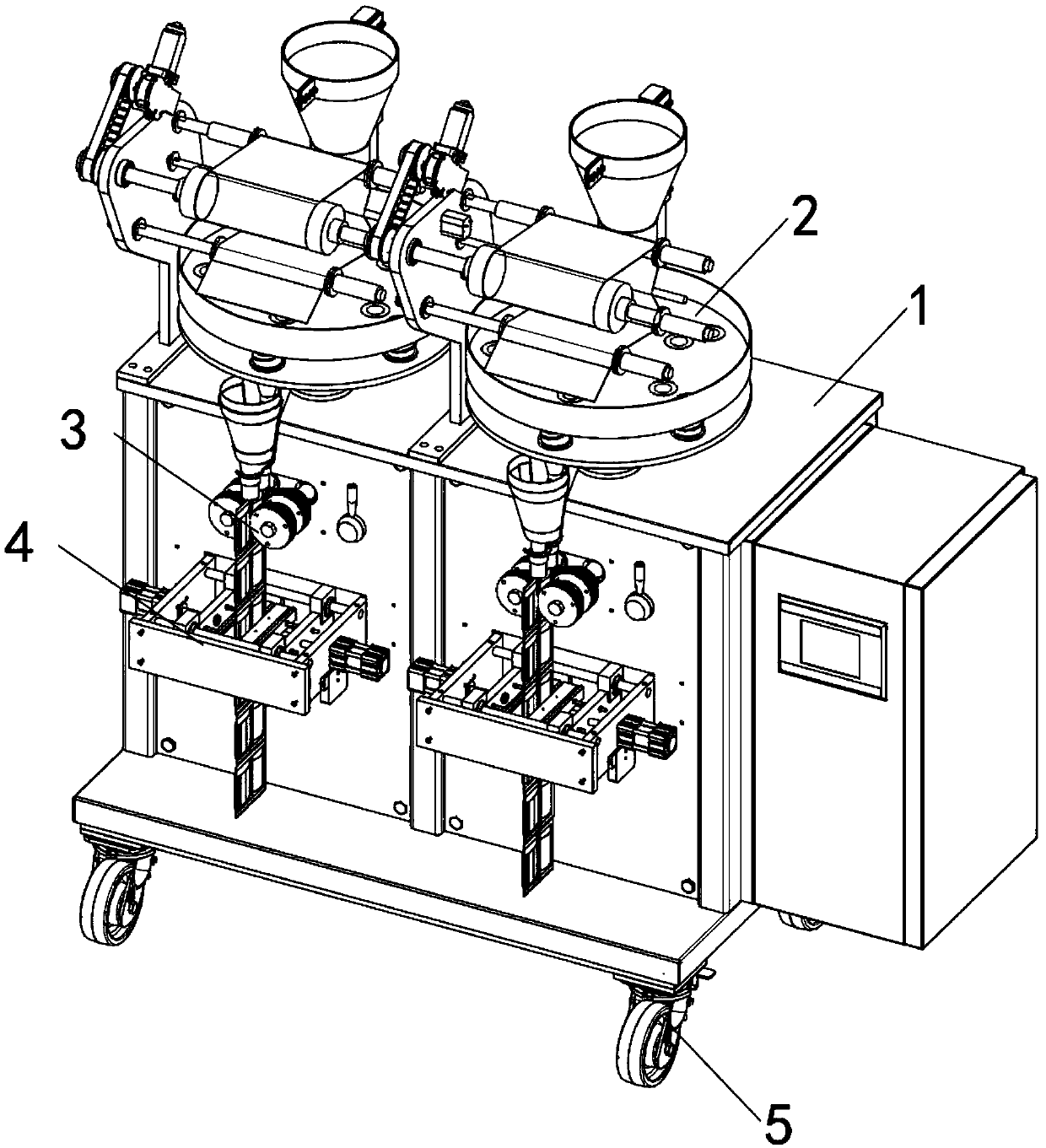

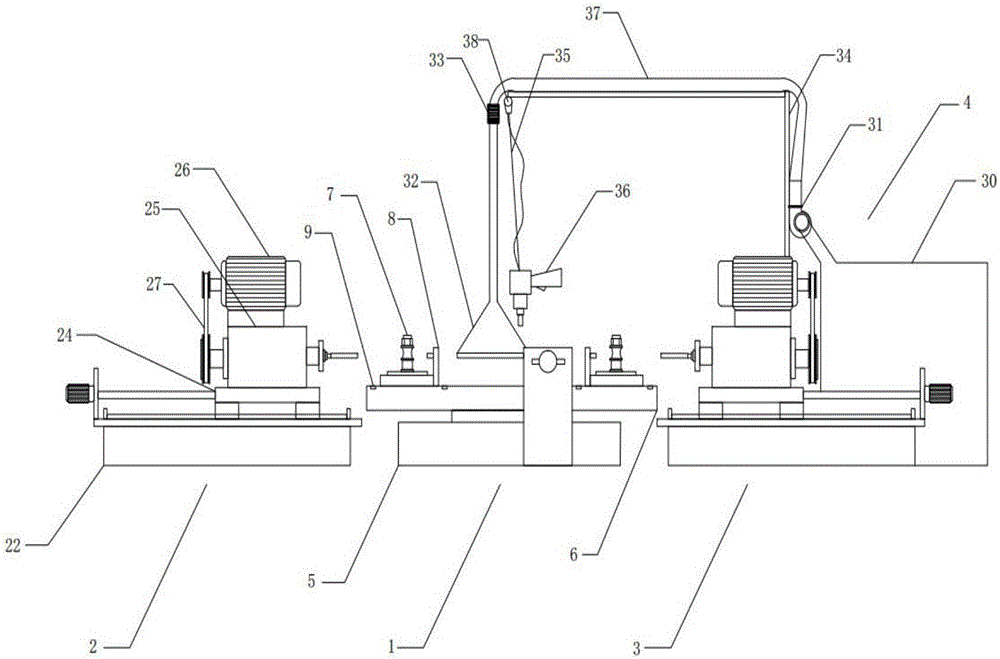

Full-automatic drilling and tapping machine for fuel nozzle hole of vertical bearing block

InactiveCN105855886AAvoid easy cloggingHigh degree of automationWork clamping meansOther manufacturing equipments/toolsControl systemScrap

The invention discloses a full-automatic drilling and tapping machine for a fuel nozzle hole of a vertical bearing block. The drilling and tapping machine comprises a workbench, a charging mechanism, a clamping mechanism, a drilling mechanism, a tapping mechanism, a discharging mechanism and a control system, wherein the clamping mechanism comprises a work passage and a clamping device positioned under the work passage; the clamping device comprises a front clamping assembly and a rear clamping assembly which are matched with each other; the front clamping assembly comprises a front supporting plate, a front oscillating bar arranged on the front supporting plate and a plurality of front claws coating the front oscillating bar; the rear clamping assembly comprises a rear supporting plate, a rear oscillating bar arranged on the rear supporting plate and a plurality of rear claws coating the rear oscillating bar. The full-automatic drilling and tapping machine has the advantage that the bearing block clamping mechanism cannot be easily blocked by scrap iron, and has the advantages of high automatic degree, high production efficiency and low labor cost.

Owner:FK BEARING GRP

Punching clamp for high-temperature nozzle

ActiveCN111618627AProtect playAvoid swingingDrilling/boring measurement devicesPositioning apparatusPunchingStructural engineering

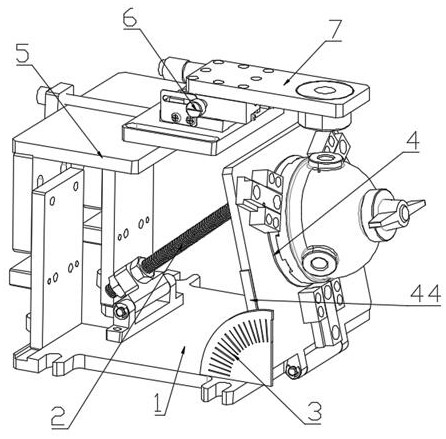

The invention discloses a punching clamp for a high-temperature nozzle. The punching clamp for the high-temperature nozzle comprises a supporting base, an angle adjusting mechanism, an angle measuringassembly, a clamping mechanism, a fixed adjusting mechanism, a movable adjusting mechanism and a drill bit protection assembly, wherein the supporting base is fixed on a drilling machine operating platform, the angle adjusting mechanism is hinged to the supporting base and the clamping mechanism, the bottom of the clamping mechanism is movably connected with the right end of the supporting base,the angle measuring assembly is fixed to the right front side of the supporting base, the fixed adjusting mechanism is vertically fixed to the left end of the supporting base, the movable adjusting mechanism is arranged on the fixed adjusting mechanism, and the drill bit protection assembly is arranged on the movable adjusting mechanism and extends to the position over the clamping mechanism. Thepunching clamp can effectively guarantee a precise punching position, is stable in clamping, reduces the reject ratio, is good in machining effect, and has good market application value.

Owner:深圳市阿尓法智慧科技有限公司

CCD die cutting machine

PendingCN110919766AThe processing position is accurateReduce wasteMetal working apparatusEngineeringMaterial supply

The invention discloses a CCD die cutting machine comprising a workbench, a frame and a computer. The CCD die cutting machine further comprises an alignment platform, a material supplying mechanism, afeeding mechanism, a die cutting mechanism and a CCD visual assembly. The material supplying mechanism and the feeding mechanism are arranged on the alignment platform and used for traction of a machined material. The die cutting mechanism is arranged between the material supplying mechanism and the feeding mechanism and used for machining the machined material which reaches the die cutting mechanism through traction by the material supplying mechanism and the feeding mechanism. The CCD visual assembly comprises a CCD visual camera electrically connected with the computer. The visual direction of the CCD visual camera is directed at the die cutting mechanism, and the CCD visual camera collects images of the machined material and sends the information to the computer for analysis. When themarked center point of the machined material coincides with a center point set by the computer, the computer sends an instruction to the die cutting mechanism to conduct die cutting. Compared with anexisting die cutting machine, the CCD die cutting machine has the advantages of automatic die cutting, accurate machining position and less production waste.

Owner:宏文科技(广东)有限公司

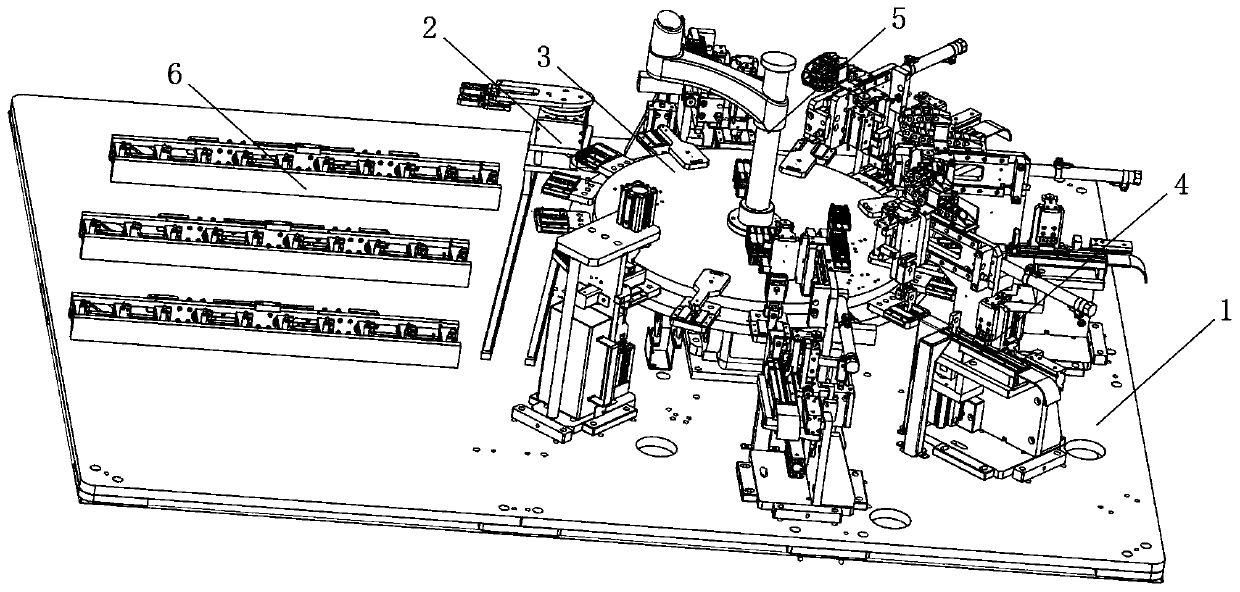

Robot part processing clamp with multi-angle fixing function

InactiveCN110065048AEasy to processThe processing position is accurateProgramme-controlled manipulatorGripping headsMotor driveIndustrial engineering

The invention discloses a robot part processing clamp with a multi-angle fixing function. The robot part processing clamp comprises an installing platform, a movable disc and a clamping seat, the movable disc is arranged above the installing platform, the clamping seat is arranged below one end of the movable disc, and a bottom support plate is horizontally arranged below the movable disc. The robot part processing clamp has the beneficial effects that robot parts are clamped and fixed through a plurality of equally-spaced clamping jaws, it is ensured that the robot parts can be processed by aprocessing instrument more conveniently, efficiently and stably; a transferring and connecting seat drives the clamping seat to move front and back on the installing platform to adjust the position,on one hand, the position of processing of the robot parts by the processing instrument is more precise and adjustable, on the other hand, it is ensured that after the robot parts are processed, and the robot parts can be quickly and conveniently transferred and put to the specific position to be arranged; and a first motor drives the clamping seat to rotate by 360 degrees to ensure that the moving, transferring and putting efficiency of the robot parts is high and the scope is wider.

Owner:XUZHOU COLLEGE OF INDAL TECH

Plate bending machine with adjustable upper pressure plates

InactiveCN108127027AThe processing position is accurateShorten processing timeShaping toolsEngineeringPress brake

The invention discloses a plate bending machine with adjustable upper pressure plates. The plate bending machine with the adjustable upper pressure plates comprises a rack, wherein a working table isarranged on the rack; an upper mounting seat which is provided with a plurality of movable upper pressure plates is arranged on the rack and positioned at the upper end of the working table; the uppermounting seat is driven by a hydraulic cylinder to move vertically; a plurality of chutes are formed in the upper mounting seat; fixing blocks on the movable upper pressure plates are assembled in the chutes; sealing plates for sealing the chutes are arranged on the front side and the rear side of the upper mounting seat; a locking piece is arranged on each sealing plate; a locking hole which cooperates with the corresponding locking piece is formed in the fixing block of each movable upper pressure plate; and adjusting mechanisms capable of moving in a left-right direction are arranged on the rack and positioned on the front side and the rear side of the upper mounting seat. The plate bending machine with the adjustable upper pressure plates is simple in structure and reasonable in design; different numbers of upper pressure plates in different models can be mounted as needed; and processing of different grooves in plates can be implemented.

Owner:江苏久日数控机床有限公司

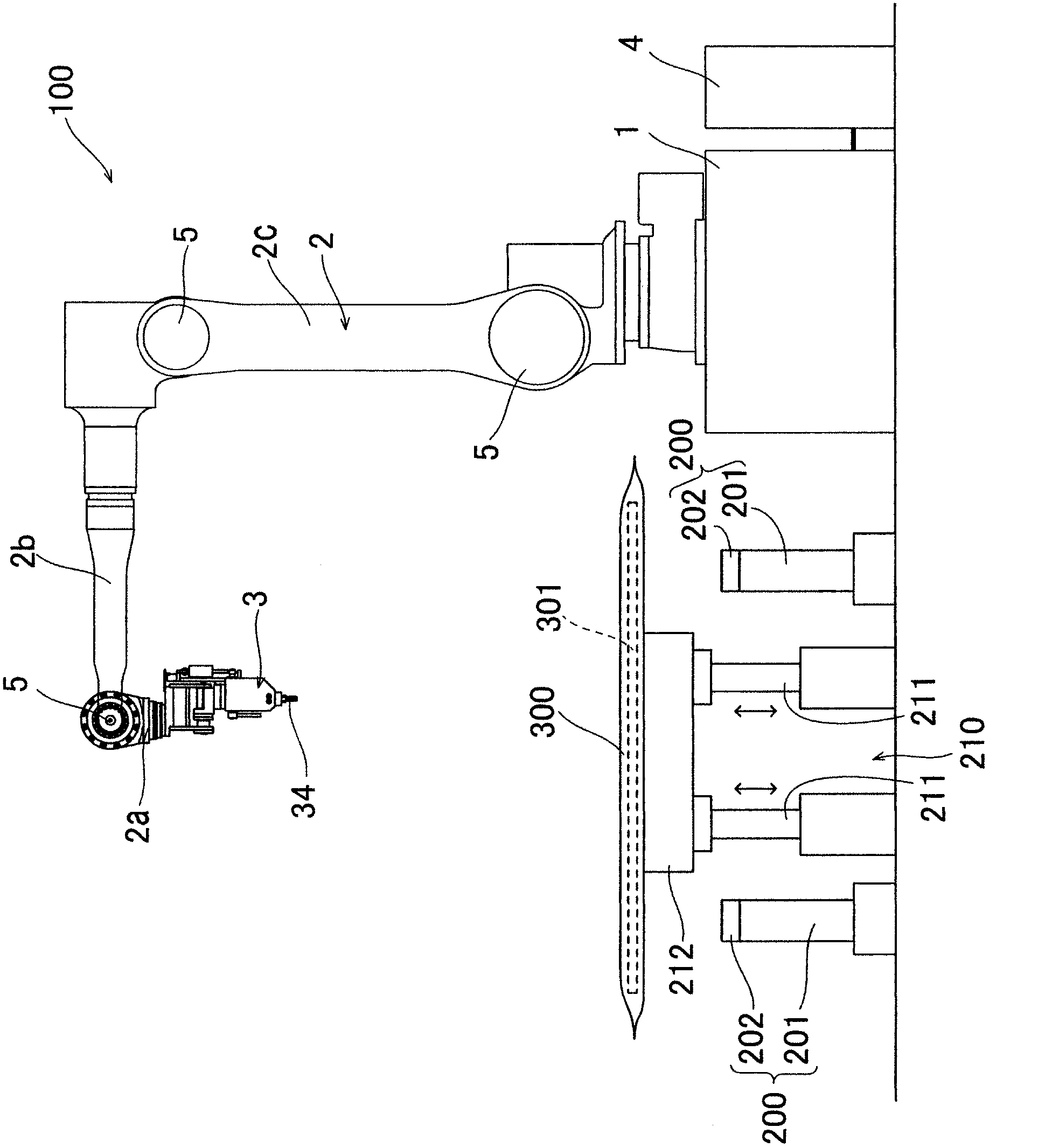

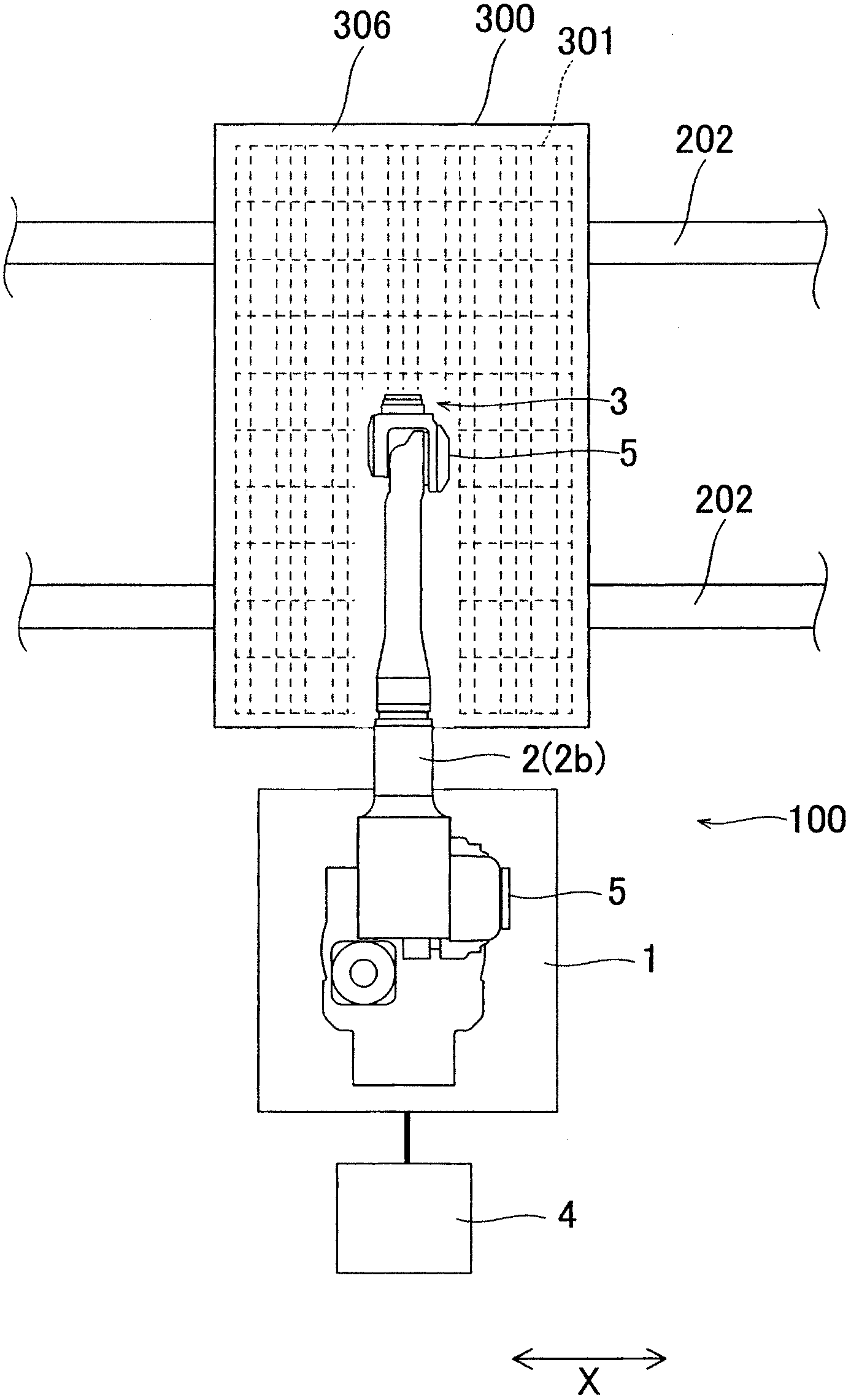

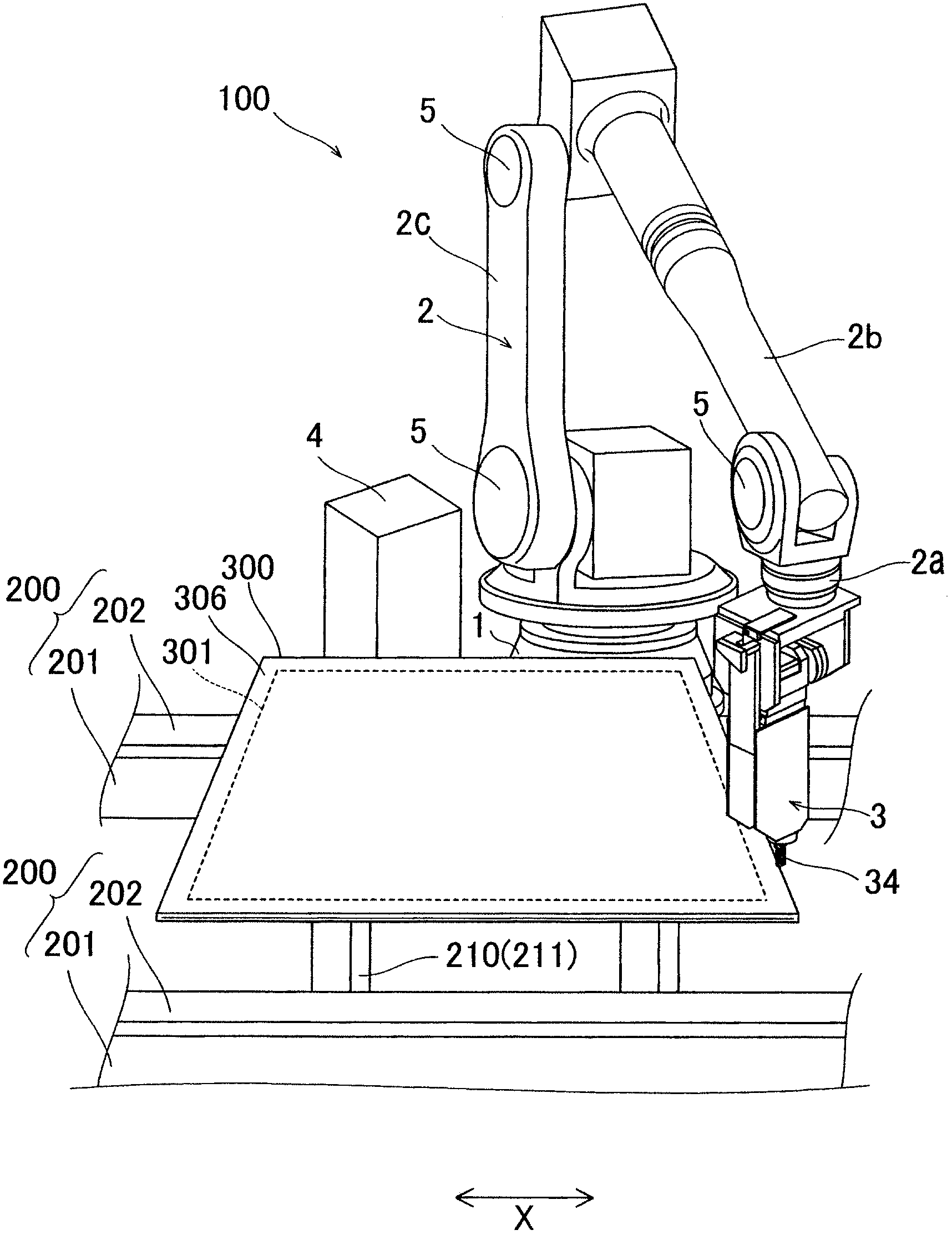

Processing apparatus, tool, processing method, and method for setting processing position

InactiveCN103203775AThe processing position is accurateAccurately obtainedProgramme controlProgramme-controlled manipulatorComputer science

The present invention relates to a processing apparatus, a tool, a processing method, and a method for setting a processing position. The processing apparatus includes a tool processing a protruding portion of a sheet member covering a base substrate protruding from the base substrate and a control portion mechanically or electrically detecting a position where the tool comes into contact with the base substrate and acquiring a processing position based on the position where the tool comes into contact with the base substrate.

Owner:YASKAWA DENKI KK

Press mounting machine for workpiece

ActiveCN103350338AThe assembly position is accurateThe processing position is accurateMetal working apparatusDevice formEngineering

The invention discloses a press mounting machine for a workpiece, which comprises a fixing plate, and as well as a clamping device for clamping the workpiece, a sliding part sliding in an accommodating groove and providing a slide rail for the clamping device, a push device for pushing the workpiece to an assigned position, and a driving device for providing power for the clamping device and the push device, wherein the accommodating groove is fixed on the fixing plate; the driving device is composed of a first motive power piece placed at the upper part of the sliding part and providing power for the clamping device, and a second motive power piece providing power for the push device; the clamping device forms a compressing piece with one end slidably connected with the slide rail and the other end used for compressing the workpiece, and a guiding piece used for limiting the sliding range of the workpiece; the push device forms a connecting rod fixedly connected with the second motive power piece, a compression rod for pushing the workpiece to move, and a slide rod fixed with the lower part of the connecting rod. Aiming at the L-shaped workpiece, the invention provides the press mounting machine with simple structure, low cost and excellent press mounting effect.

Owner:江苏烽禾升智能科技有限公司

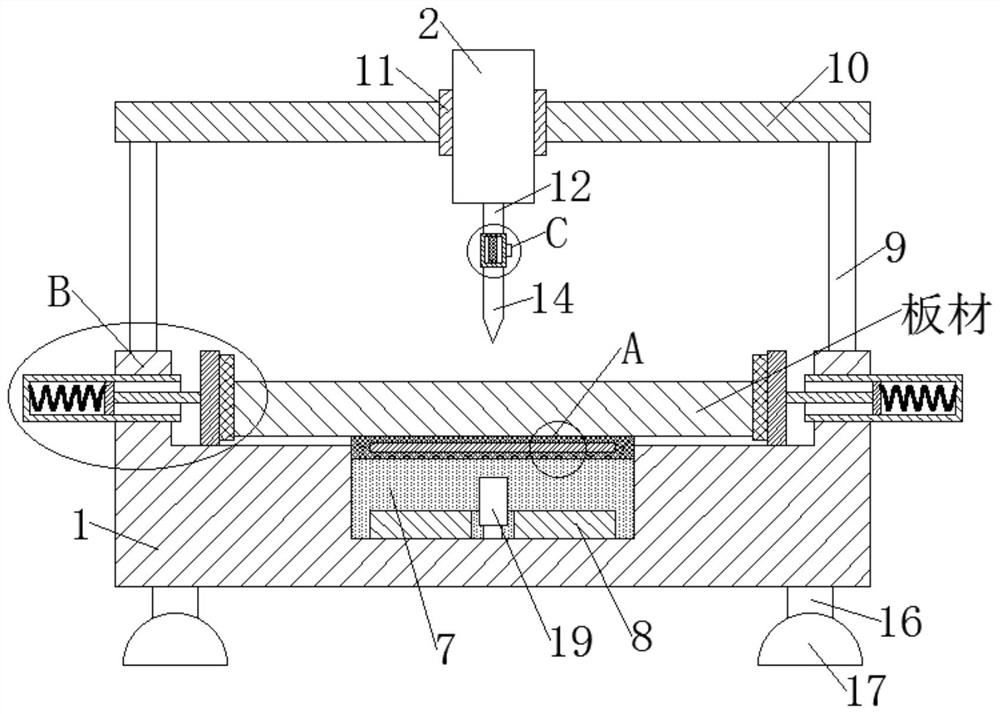

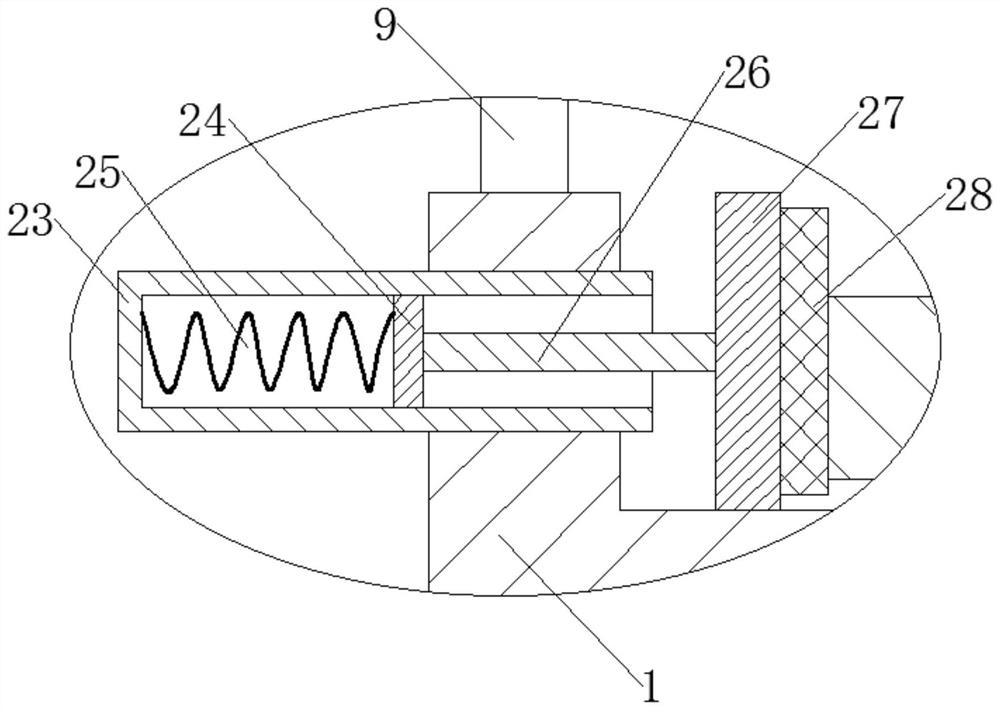

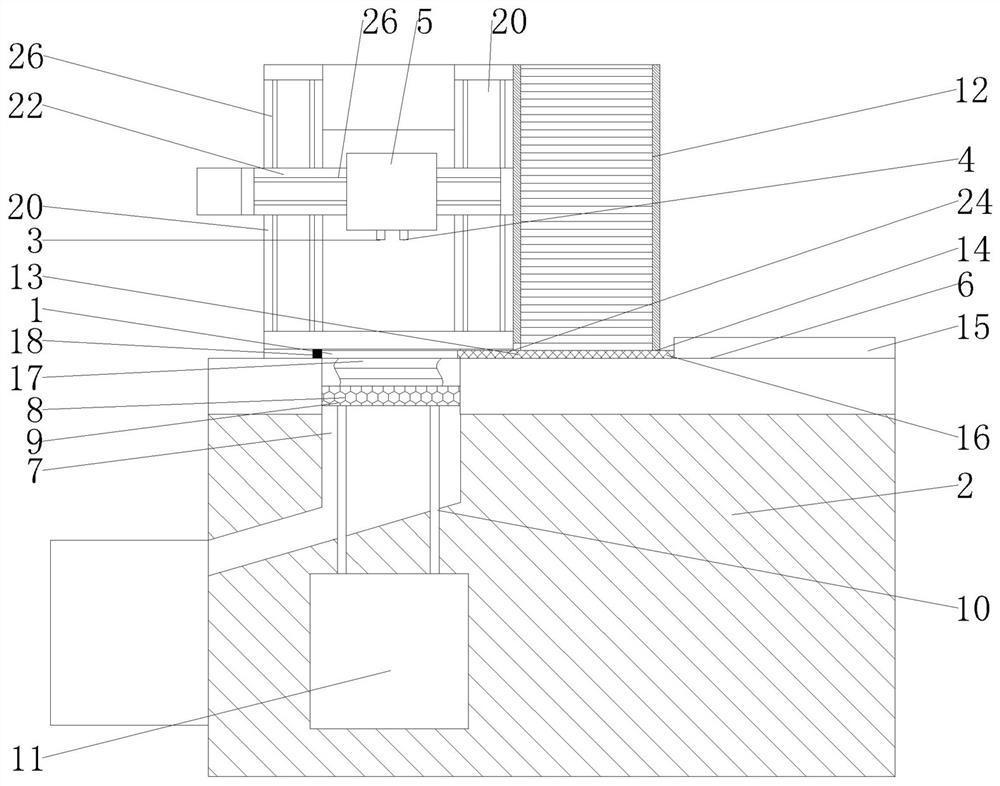

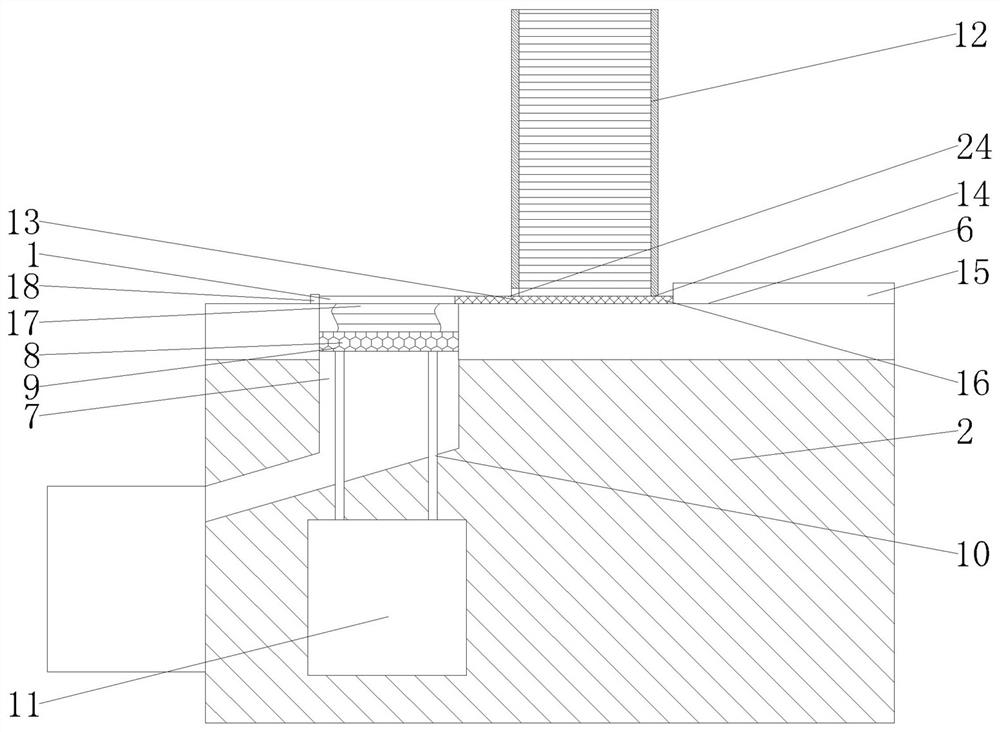

High molecular plate punching device for automobile rear axle housing production

ActiveCN112775277AAvoid deformationAvoid moving phenomenonMetal-working feeding devicesPositioning devicesStructural engineeringElectrostatic generator

The invention discloses a high molecular plate punching device for automobile rear axle housing production. The high molecular plate punching device comprises a base and a punching air cylinder, a containing groove is formed in the base, a liquid storage groove is formed in the center of the containing groove, the liquid storage groove is sealed through an elastic film, a conductive plate is fixedly connected to the bottom of the liquid storage groove, a conductive net is arranged in the elastic film, and a mounting barrel is fixedly connected to the punching air cylinder; the bottom of the mounting barrel is fixedly connected with a punching rod, and the outer wall of the mounting barrel is fixedly connected with an electrostatic generator; the conductive plate and the conductive net are powered on to enable electrorheological fluid to be hardened to support a plate, and the punching air cylinder drives the punching rod to descend for punching; when the punching rod descends, negative charges gathered at the tip of the punching rod enable negative charges on the conductive net to be discharged, therefore, the electrorheological fluid at the punching position is softened, and punching operation is facilitated; and meanwhile, the electrorheological fluid on the periphery of the punched position is in a hardened state, the plate is supported, and deformation of the punched position is avoided.

Owner:武汉方鼎汽车部件制造有限公司

Bicycle below tube arc mill

InactiveCN101125375AEasy clampingImprove processing efficiencyOther manufacturing equipments/toolsLarge fixed membersVehicle frameMilling cutter

The invention discloses a radian milling machine of the lower pipe for a bicycle. The machine comprises a machine frame, a clamping mechanism, a first knife milling seat, a second knife milling seat and a third knife milling seat; wherein, the first knife milling seat, the second knife milling seat and the third knife milling seat are respectively provided with a first mobile knife milling fixed seat, a second mobile knife milling fixed seat and a third mobile knife milling fixed seat, three of which are respectively arranged onto the machine frame corresponding to the position relation of a bicycle head pipe, a five way pipe and an upright pipe of the bicycle. The three mobile knife milling fixed seats are able to rotate around the axial line of the seats. In this way, the bicycle head pipe and the five way pipe as well as the upright pipe are respectively proceeded with radian milling operation at the front end and back end parts of the lower pipe to be processed, and also are drilled with holes at the lateral part of the lower pipe by the drill seat. Through simulating the assembling relationship of the bicycle frame, the invention complete the processing of the lower pipe under the first time and also has the advantages of convenient assembling and clamping operation, high efficiency of processing and accurate processing position.

Owner:庄添财

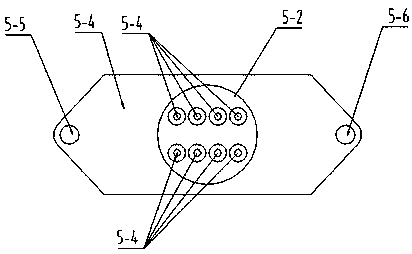

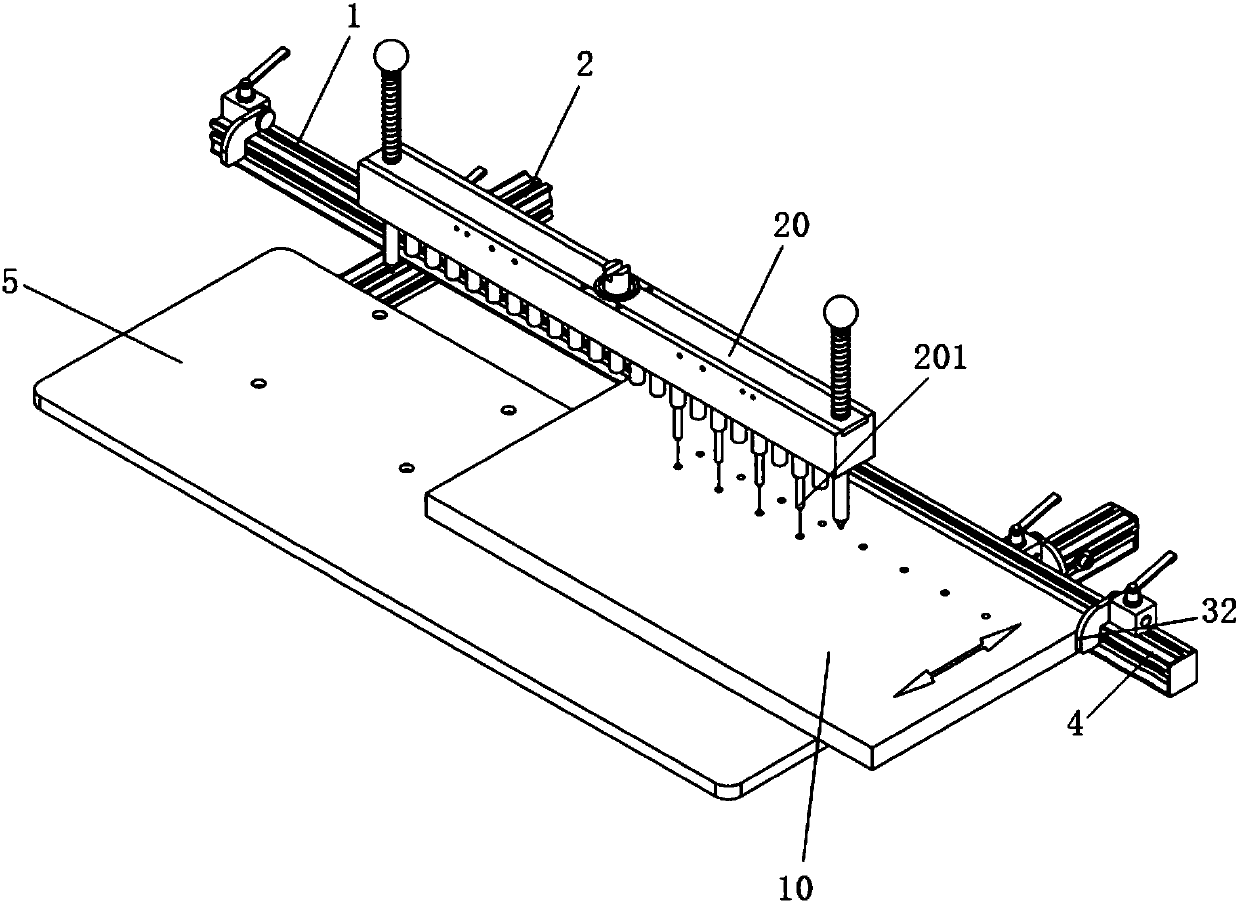

Hydraulic multi-spindle tapping machine

InactiveCN108213614AImprove work efficiencyThe processing position is accurateThread cutting machinesEngineeringFlange

The invention relates to a tapping machine, in particular to a hydraulic multi-spindle tapping machine, and belongs to the technical field of machine manufacturing. The hydraulic multi-spindle tappingmachine comprises a pedestal, a working table, a connection arm, a top plate, a tapping mechanism and a driving device, wherein the working table is arranged at the middle position of the top of thepedestal, and is used for clamping a workpiece to be tapped; the connection arm comprises a left connection arm and a right connection arm; the top plate is connected with the pedestal through the left connection arm and the right connection arm; the driving device is arranged at a position, which corresponds to the working table, of the top plate; a main shaft is connected below the driving device; the main shaft is connected to the tapping mechanism; the tapping mechanism comprises a pressing plate, a flange arranged below the pressing plate and tapping tools uniformly distributed along a circumference on the flange; and the tapping tools can correspond to the workpieces to be subjected to tapping machining on the working table.

Owner:镇江亚昆机械有限公司

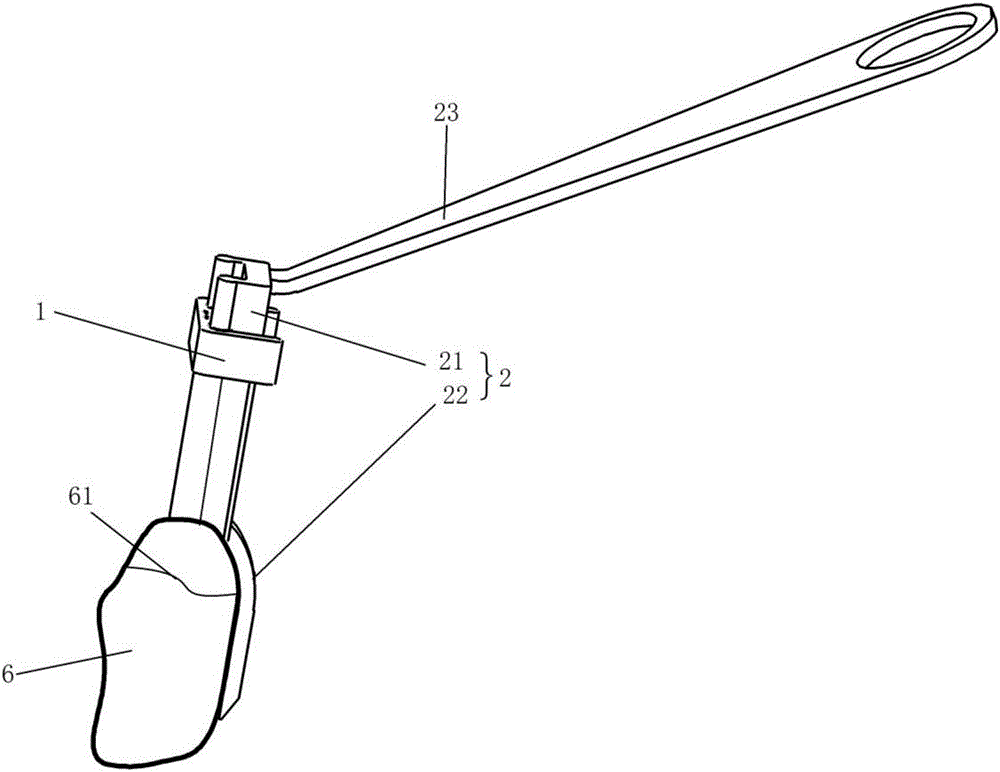

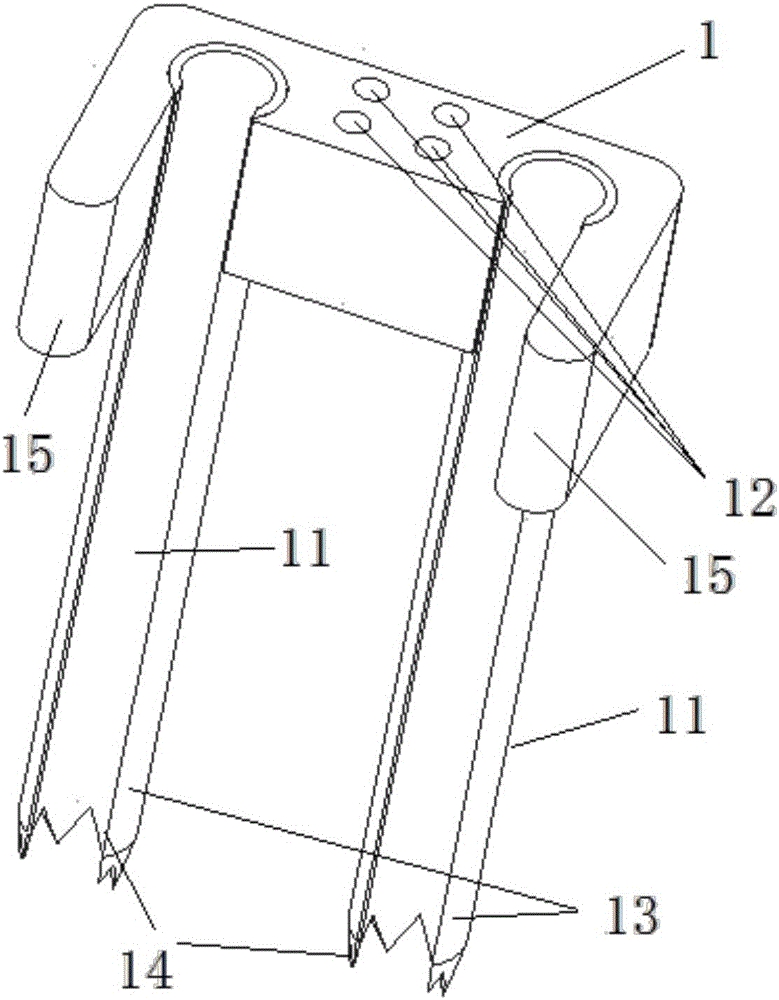

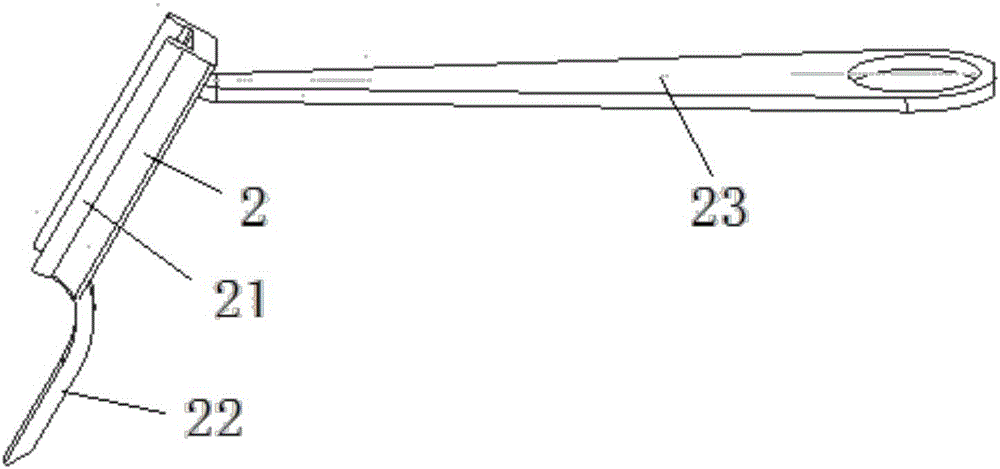

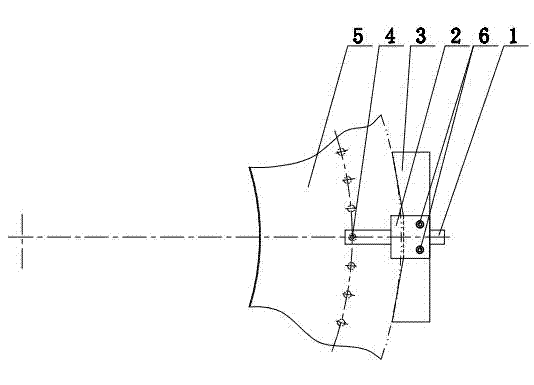

Bone fixator guide instrument

PendingCN106580422AAchieve orientationInsert smoothlyOsteosynthesis devicesBone drill guidesEnthesisDrill hole

The invention provides a bone fixator guide instrument which comprises a guide apparatus main body, a locating device and a guide sleeve, wherein the guide apparatus main body comprises two guide straight slots; the guide straight slots can be in sliding fit with two fixation jaws; a plurality of kirschner wire holes formed along the extension direction of the guide straight slots are formed in the guide apparatus main body; the locating device comprises a first slide binding part and an extension part; the first slide binding part comprises two raised lines in sliding fit with the two guide straight slots; the extension part has an arc-shaped structure matched with the bone outer side face; when the extension part is contacted with the bones, the guide apparatus main body can slide along the first slide binding part so as to be contacted with the bones; after the guide apparatus main body is located, kirschner wires are punched into the kirschner wire holes so as to fix the guide apparatus main body; the guide sleeve can be inserted into the guide straight slots so as to guide a bit to the bones for drilling; the guide straight slots can be used for guiding the fixation jaws into the drill holes.

Owner:付中国 +1

Automobile part stamping positioning device

ActiveCN113198935AEasy stamping handlingEasy accessMetal-working feeding devicesMetal working apparatusHydraulic cylinderMotor vehicle part

The invention discloses an automobile part stamping positioning device which comprises a supporting frame. A machining table is arranged on the supporting frame, a moving motor fixedly connected with the supporting frame is arranged above the machining table, and a lead screw is connected to the output end of the moving motor. A ball is connected to the lead screw, a hydraulic cylinder is connected to the lower end of the ball, a stamping part is connected to the telescopic end of the hydraulic cylinder through a clamping plate, and the lead screw rotates to control the ball to move front and back. A distance sensor is arranged on the clamping plate, a controller is connected to the distance sensor, a first rack is fixedly arranged on the left side of the clamping plate, and a first gear is in engaged transmission connection with the left side of the first rack. A second gear in transmission connection with the first gear is arranged on the left side of the first gear, a second rack is in engaged transmission connection with the left side of the second gear, an impact detection rod is arranged at the lower end of the second rack, and a material circulation opening formed in the supporting frame is formed below the impact detection rod. By means of the method, better positioning is facilitated, the machining position of the automobile part is further accurately determined, the probability of local deformation of the automobile part is reduced, and the product quality is improved.

Owner:WUHU CHANGRUI AUTO PARTS

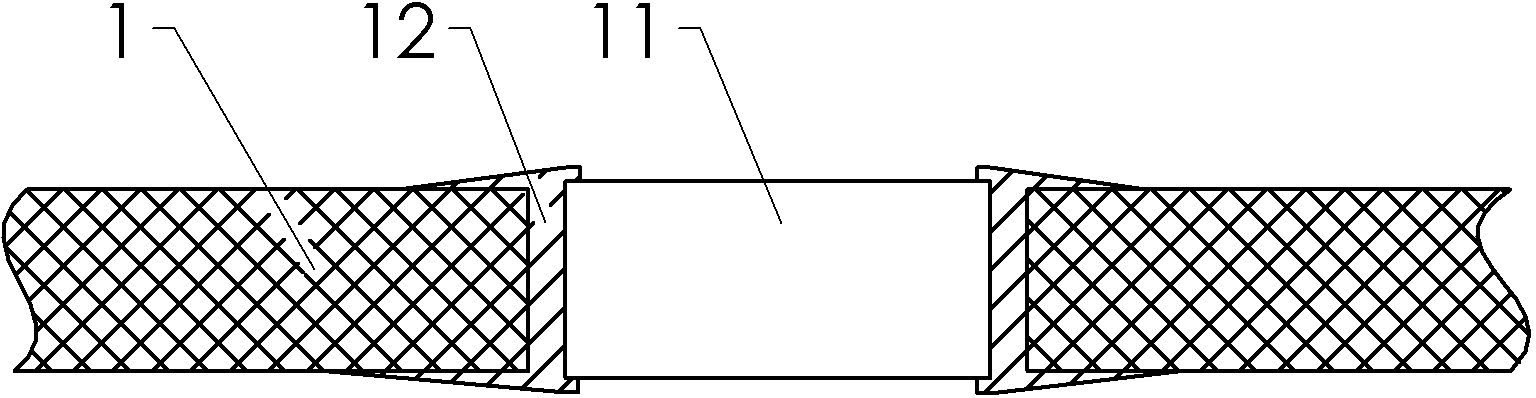

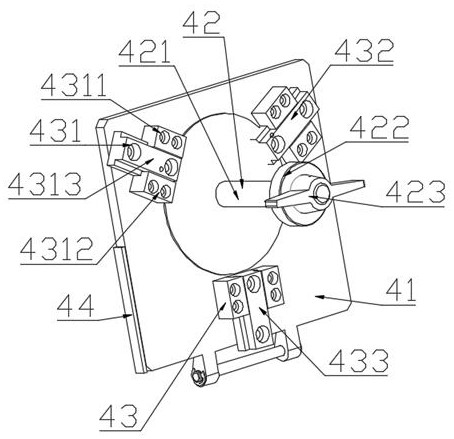

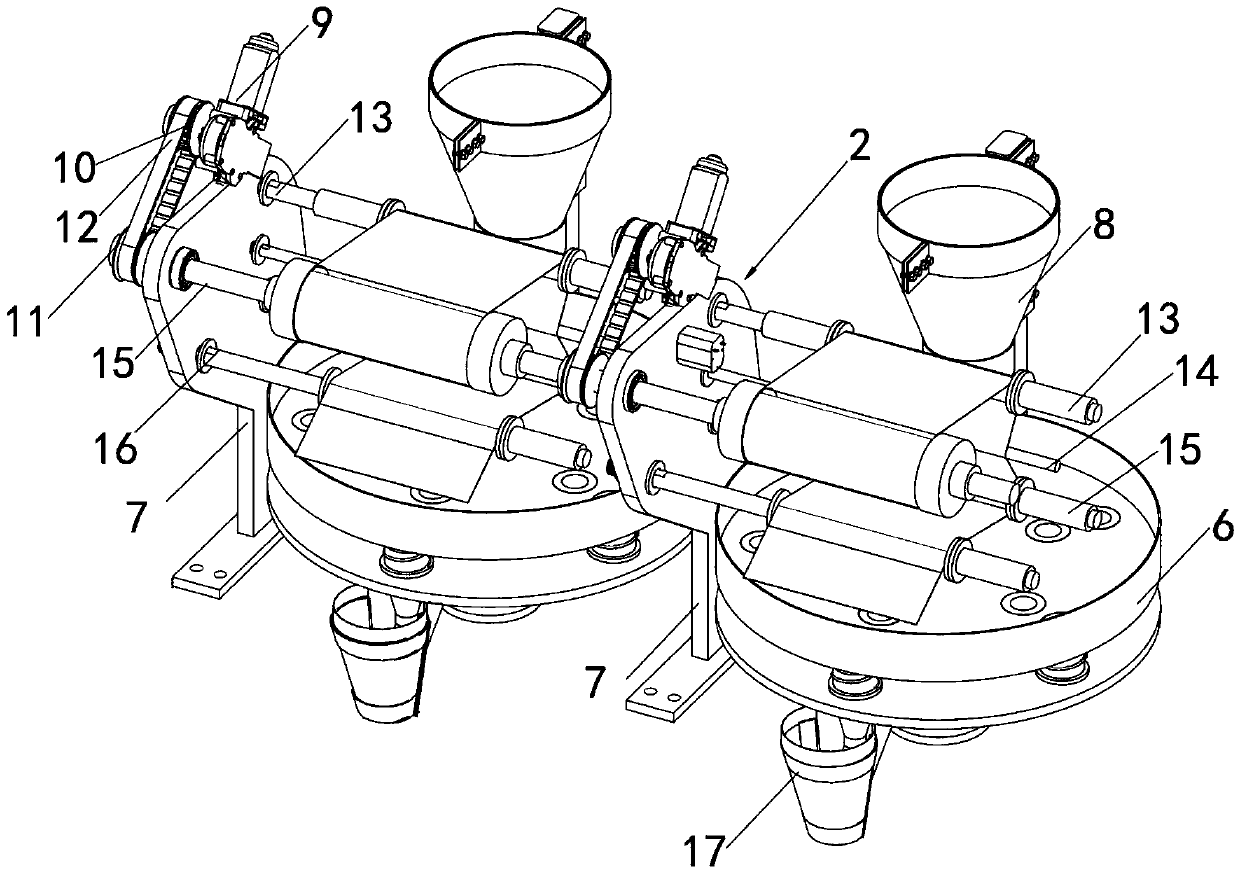

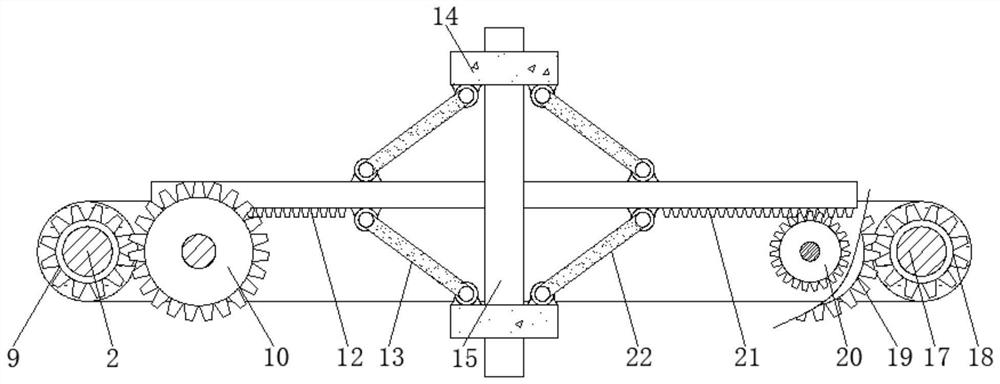

Rolling conveying mechanism for electronic device PVC sealing bag, and working method of rolling conveying mechanism

The invention discloses a rolling conveying mechanism for electronic device PVC sealing bags. The rolling conveying mechanism for electronic device PVC sealing bags comprises a distribution box, a roll-up conveying platform, rolling clamping bases and repressing bases. The roll-up conveying platform is arranged above the distribution box. The rolling clamping bases are horizontally arranged at thetwo ends of the distribution box respectively. The repressing bases are horizontally arranged below the two rolling clamping bases respectively. Cover plates are horizontally arranged on the two sides of the roll-up conveying platform respectively. A supporting base is arranged at one end of each of the two cover plates. The rolling conveying mechanism for electronic device PVC sealing bags has the beneficial effects that four roll-up conveying rollers are used in cooperation to carry out roll-up conveying on sealing bags, rolling teeth which are arranged on a rolling belt at equal intervalsare used in cooperation with tooth clamping grooves to synchronously drive the roll-up conveying rollers to convey the sealing bags, the speed of transferring and conveying the sealing bags is more uniform and constant, it is guaranteed that rolled parts of the sealing bags are embossed more uniform by the rolling clamping bases, tooth strips pressed by a pressing clamping plate through pressing teeth on the sealing bags are more uniform and constant in distribution interval; and the rolling conveying mechanism for electronic device PVC sealing bags is convenient to operate, solid, durable, good in social benefit and economical benefit, and applicable to promotion for use.

Owner:滁州市云米工业设计有限公司

Wiring hidden box machining tool

PendingCN109304621AAccurate shapePrecise hole positionOther manufacturing equipments/toolsPunchingEngineering

The invention discloses a wiring hidden box machining tool, and belongs to the field of wiring hidden box manufacturing. The wiring hidden box machining tool comprises an upper mounting seat and a lower mounting seat which are mounted on a rack. A punching and tapping mold set, a stamping mold set and a forming mold set are sequentially mounted in the upper mounting seat and the lower mounting seat in the feeding direction. The punching and tapping mold set is used for machining mounting holes, lug seats, connecting holes and knock-off holes on plates. The stamping die set is used for machining buckles and clamp grooves on the plates, and gaps used for subsequent forming and splicing are punched on the two sides, in the width direction, of each plate. The forming die set is used for bending the plates after the plates are shorn off to form finished hidden boxes. By means of the wiring hidden box machining tool, one-time machining of wiring hidden boxes can be continuously completed, the machined wiring hidden boxes are precise in shape and accurate in hole position, and the machining efficiency is extremely high.

Owner:安徽省华夏机床制造有限公司

Numerical control six-station drilling and reaming integrated machine

InactiveCN106799593AThe processing position is accurateImprove pass rateOther manufacturing equipments/toolsMaintainance and safety accessoriesNumerical controlElectrical and Electronics engineering

The invention relates to a numerical control six-station drilling and reaming integrated machine. The numerical control six-station drilling and reaming integrated machine is characterized in that six part fixtures are uniformly distributed on the circumference adopting the axis of a rotary disc as the circle center; each part fixture corresponds to one station label; limiting devices are arranged on the part fixtures; grooves are formed in the peripheries of the part fixtures; a locating device is arranged at a station of one station label; a cylinder is connected on the locating device; the end part of the cylinder is connected with a locating piece; a rough drilling mechanism, a fine drilling mechanism, a rough reaming mechanism and a fine reaming mechanism are anticlockwire arranged at a station of the station label on the right side of the locating device sequentially; a chip removal mechanism comprises a bracket; the tail end of the bracket is arranged right above the axis of the rotary disc; an air pipe is fixed to the bracket; one end of the air pipe is connected with a chip removal hood; the other end of the air pipe is connected with a chip collection tank through an induced draft fan; a collecting and releasing part is arranged at the tail end of the bracket; and the collecting and releasing part is connected with a clamping gun through a hanging rope. According to the numerical control six-station drilling and reaming integrated machine, the drilling and reaming processing positions are guaranteed accurate, the processing effect is good, and a chip removal protection function is achieved.

Owner:TIANJIN LONGZHI VALVE

Locating and clamping device for side plate glass of computer case

InactiveCN111975681AThe processing position is accuratePrecise positioningWork holdersGear wheelComputer aid

The invention relates to the technical field of computer aided equipment, and discloses a locating and clamping device for side plate glass of a computer case. The locating and clamping device comprises an input roller, and a rotating shaft I is arranged in the input roller; the surface of the rotating shaft I is provided with fluted disks, and the surface of each fluted disk is provided with a transmission gear; the surface of each transmission gear is provided with a first gear, and a screw rod is arranged in each first gear; and the surface of each screw rod is provided with a push plate,and a sliding rod is arranged in each push plate. According to the locating and clamping device for the side plate glass of the computer case, through cooperative application of the fluted disks and the transmission gears, the first gears and the screw rods, and the push plates and the sliding rods, as well as cooperation between the push plates, the position of the side plate glass can be regulated, and it is ensured that the machining position of the side plate glass is accurate; the locating effect of the side plate glass is improved, and the production efficiency of a glass side plate is improved effectively; and the product cost is reduced.

Owner:广州安华网络科技有限公司

Mounting and mobilizing mechanism for machining of lithium battery frame inside new energy automobile

ActiveCN109366212AImprove installation capacityEasy to installAutomatic control devicesFeeding apparatusEngineeringSlide plate

Owner:东台海滨科技创业园管理有限公司

Auxiliary fixing equipment for processing superconducting magnet

InactiveCN110539181APrevent shaking or slidingQuality improvementPositioning apparatusMetal working apparatusSuperconducting CoilsMotor drive

The invention discloses an auxiliary fixing equipment for processing a superconducting magnet. The auxiliary fixing equipment comprises a sleeve supporting table, an auxiliary fixing table and placingmounting tables. The auxiliary fixing table is arranged above the middle of the sleeve supporting table in a sleeved mode. The placing mounting tables are arranged on the two sides of the sleeve supporting table. A top adjusting plate is arranged at the top of the auxiliary fixing table. The auxiliary fixing equipment has the beneficial effects that a fourth motor drives a second swing rod and aclamping claw to overturn through a second rotating shaft to enable the superconducting magnet to be buckled into a buckling groove for auxiliary fixation, so that processing mechanisms on the two sides of the equipment can be used for processing the superconducting magnet conveniently, and it is guaranteed that the superconducting magnet is more stable when being processed; different superconducting magnets can be clamped by the two ends of a fixed clamping seat at the bottom of a mounting frame, and it is ensured that the capacity of superconducting magnet auxiliary fixing of the equipment is higher; and the fourth motor drives the second swing rod to overturn through the second rotating shaft to adjust the superconducting magnet fixing and clamping distance between the two clamping claws, so that the equipment can carry out auxiliary fixation on the superconducting magnets with different volumes and sizes, and the adaptation universality is ensured.

Owner:HENAN UNIV OF URBAN CONSTR

Marking tool

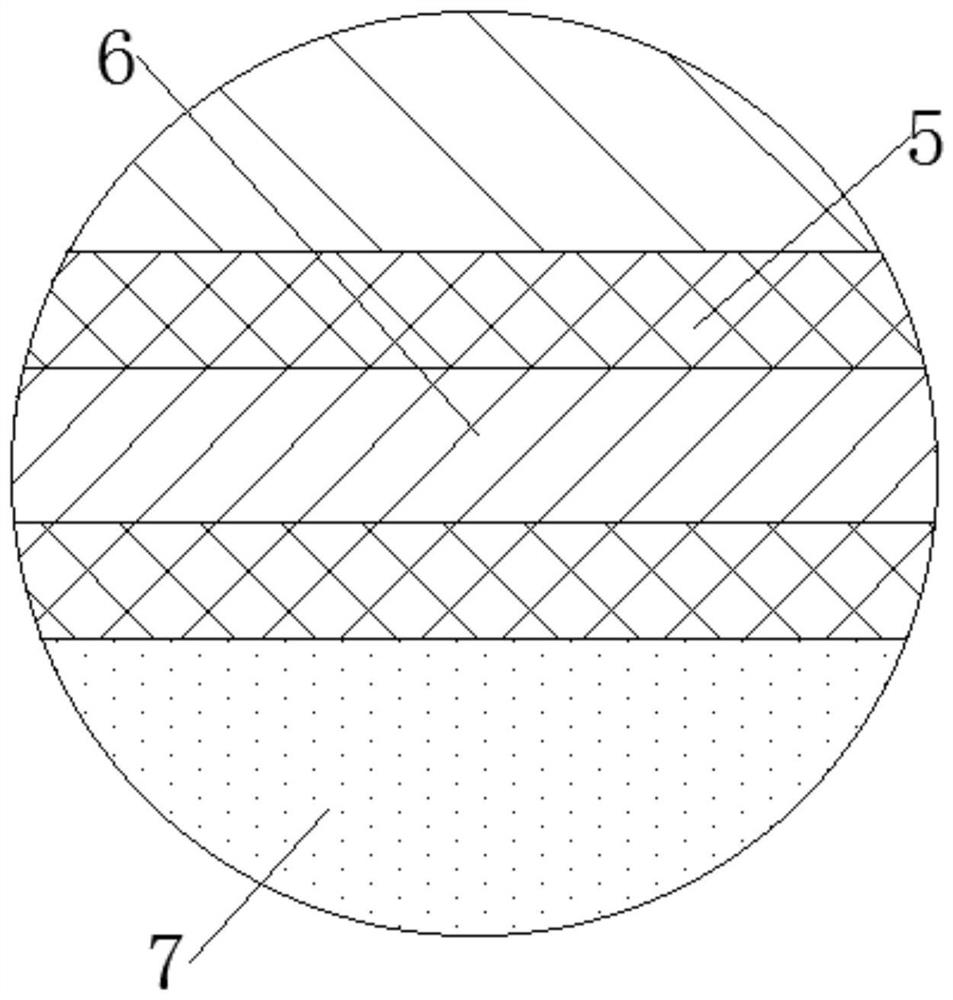

InactiveCN102848372AEasy to processSimple structureOther workshop equipmentIndustrial engineeringFastener

The invention relates to a marking tool. The marking tool comprises a workpiece, wherein the outer round edge of the workpiece is provided with a locating plate; one end of the locating plate is provided with a V-shaped surface which is matched with and propped against the outer round edge of the workpiece; the upper part of the locating plate is provided with a clamp body; a marking plate penetrates through the middle part of the clamp body; the marking plate on the clamp body is locked on the locating plate through a fastener; and one end of the marking plate is provided with a marking needle. The marking tool disclosed by the invention is simple in structure, low in manufacturing cost, and convenient to install and operate; the locating plate is matched with the clamp body, so that the marking tool can mark accurately without aligning a centre point, thus overcoming the defect of the prior art that the centre point is difficult to be aligned for marking large workpieces; and the marking tool can mark a required centre circle based on the outer circle of the workpiece, so that the part of the workpiece to be machined can be conveniently determined, the workpiece can be accurately machined to form a finished product, the machining precision of the product can be ensured, the production efficiency can be improved, and cost can be lowered.

Owner:中国船舶重工集团公司第七〇二研究所

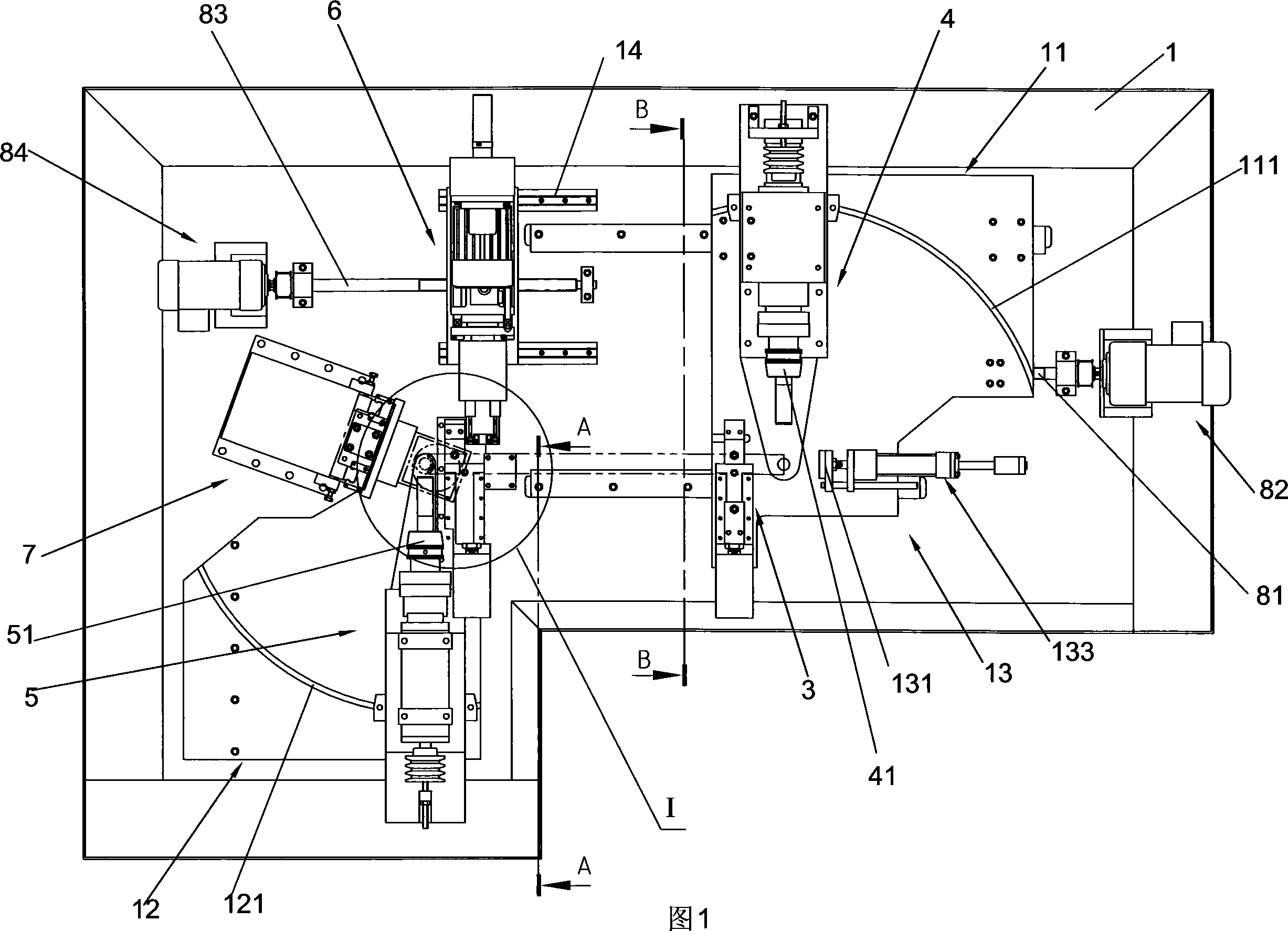

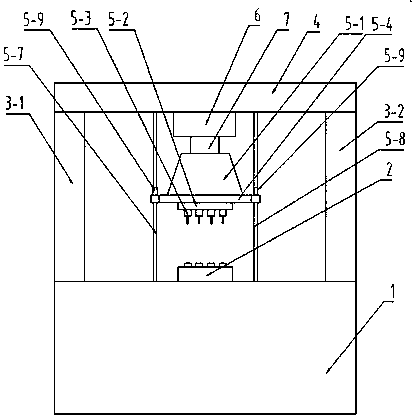

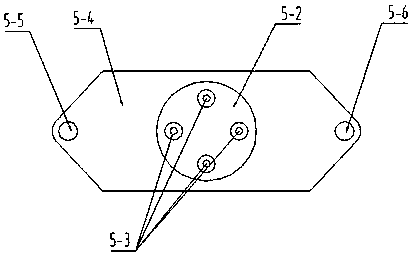

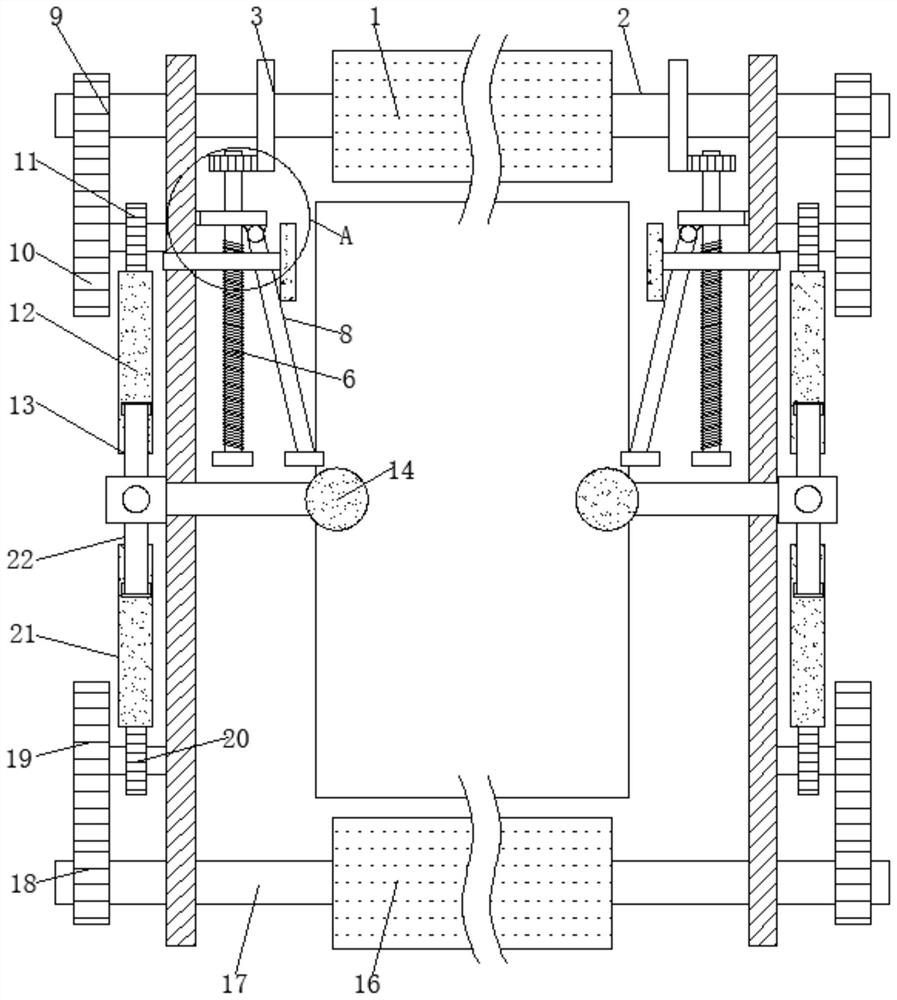

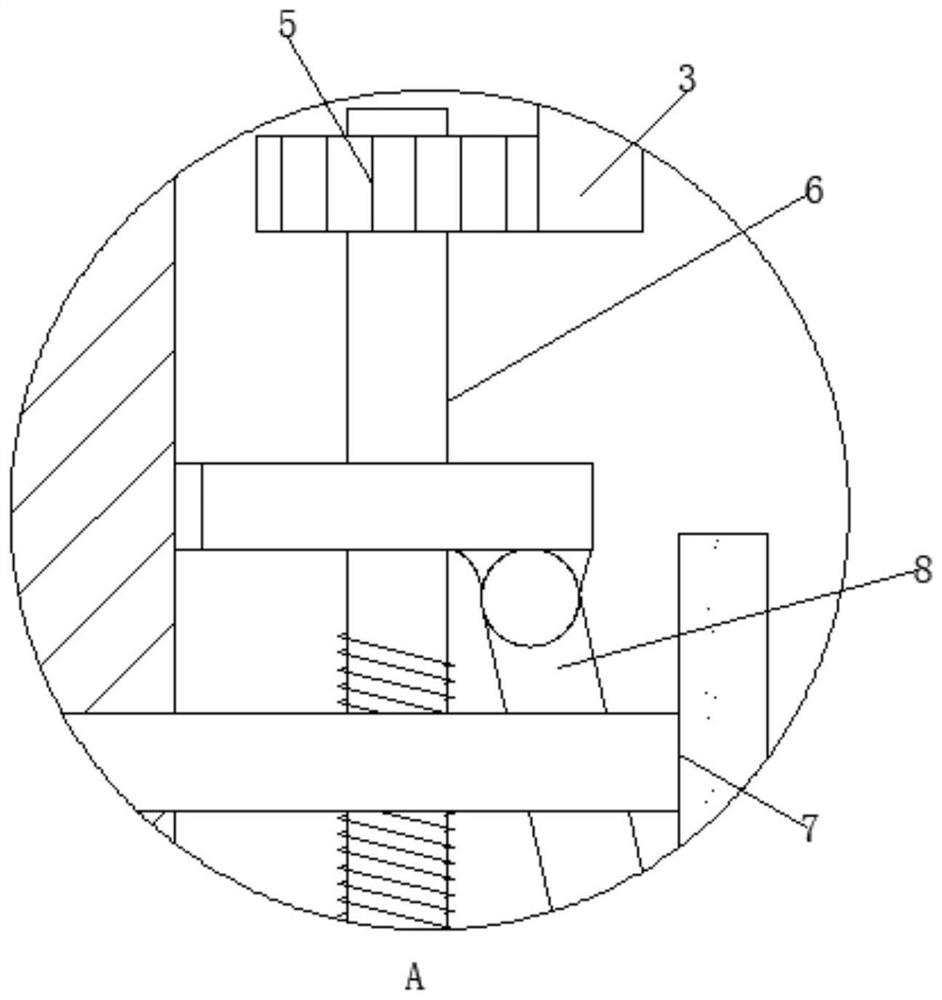

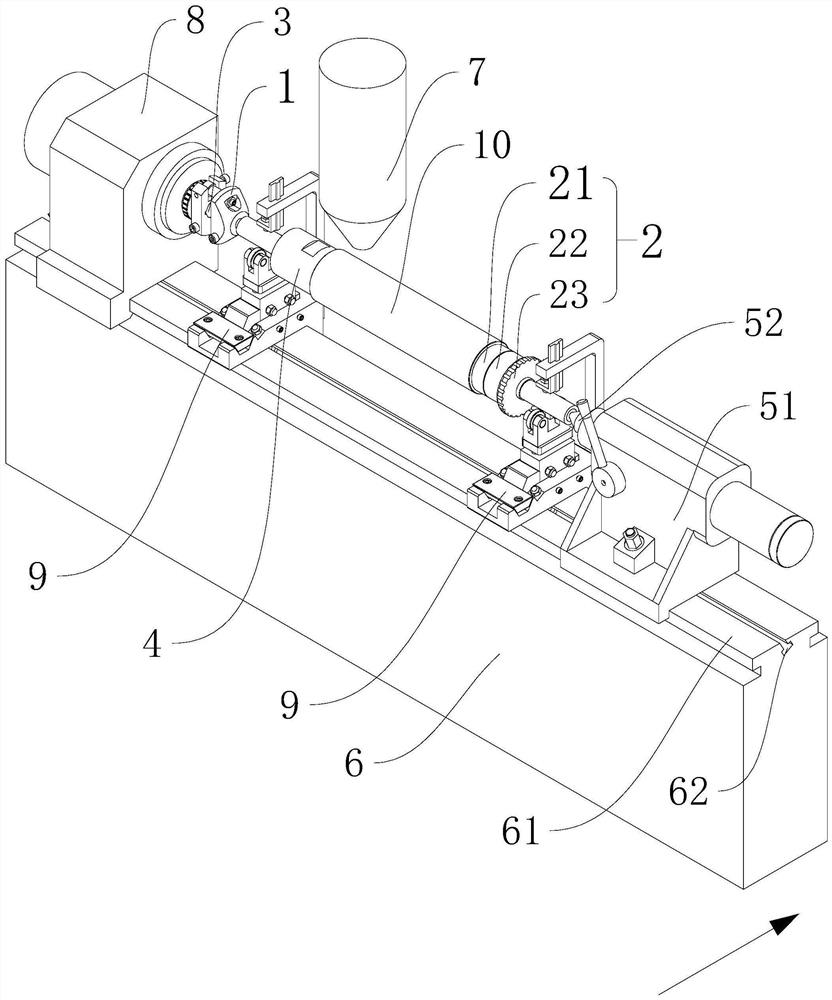

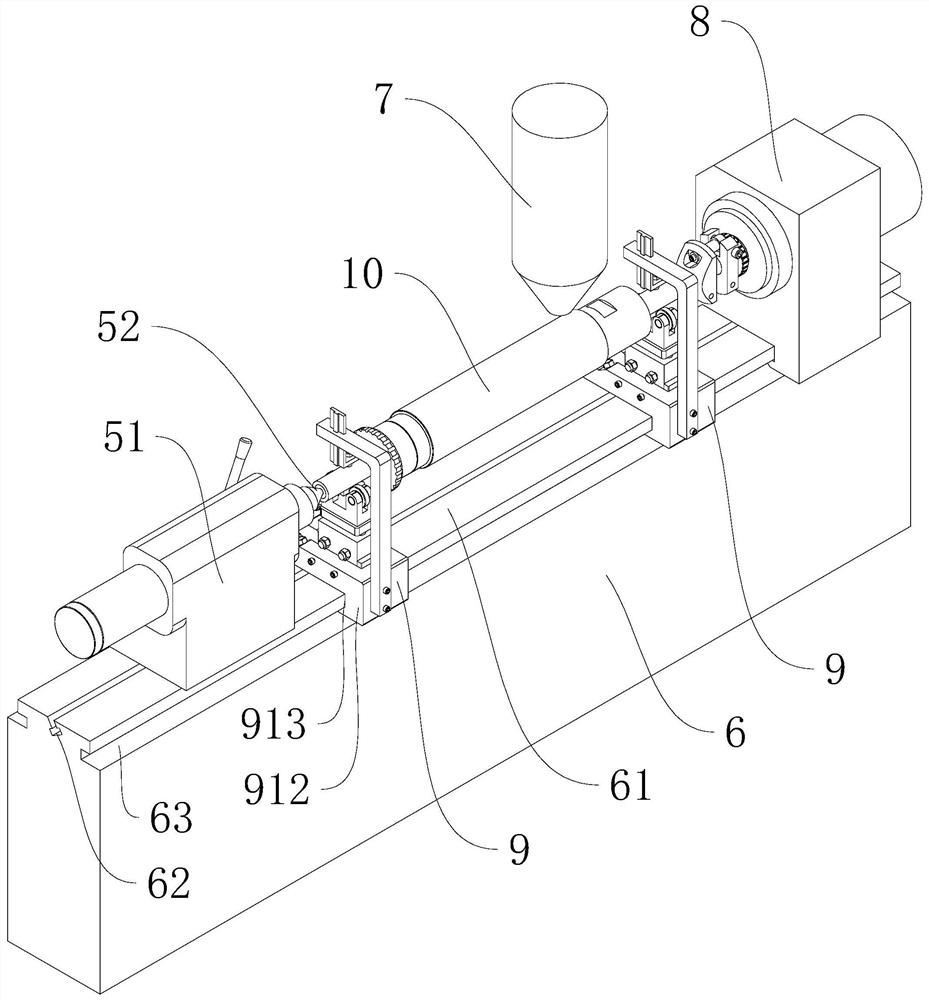

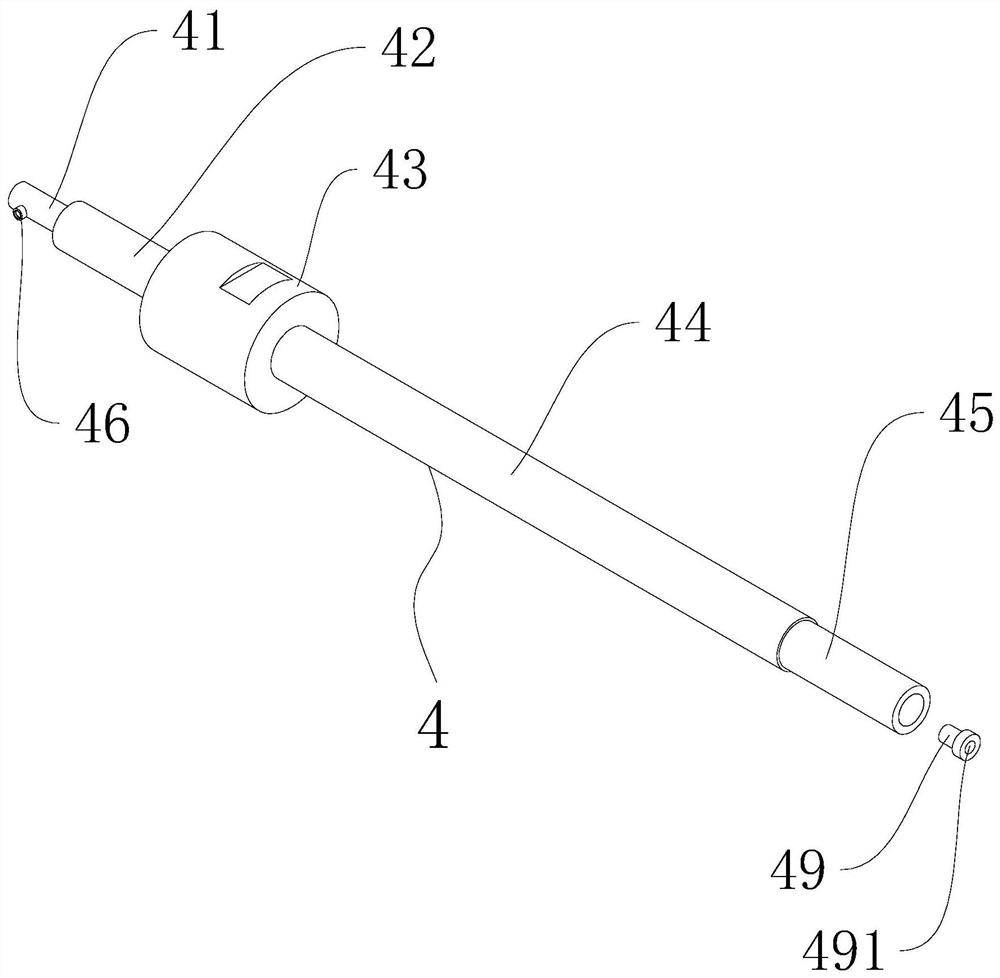

Indexing machining system for long-barrel-shaped workpiece

ActiveCN113385835AEliminates the effects of axial positioningReduce positioning offsetLaser beam welding apparatusEngineeringErbium lasers

The invention discloses an indexing machining system for a long-barrel-shaped workpiece. The indexing machining system comprises a lathe bed, a chuck mechanism, a positioning assembly, a horizontally-arranged indexing center, a mandrel and a tail center; an indexing driving device capable of moving transversely, a tailstock and a supporting device are arranged on the lathe bed, the indexing driving device is in driving connection with the indexing center, the tail center is fixedly arranged on the tailstock, and the indexing center is in transmission connection with the mandrel through the chuck mechanism. According to the indexing machining system for the long-barrel-shaped workpiece, radial positioning of the mandrel is completed through cooperation of the supporting device, the influence of the gravity of the mandrel and the long-barrel-shaped workpiece on indexing positioning is eliminated under the supporting effect of the supporting device, the indexing center and the tail center abut against one end of the mandrel correspondingly under cooperation of the indexing center and the tail center, the positioning deviation of the mandrel is greatly reduced, the mandrel, the indexing center and the tail center are located at the same coaxiality, axial positioning of the mandrel and the workpiece is achieved more accurately, and it is guaranteed that the machining position of a laser is accurate.

Owner:GUANGDONG ORIGINAL POINT INTELLIGENT TECH CO LTD

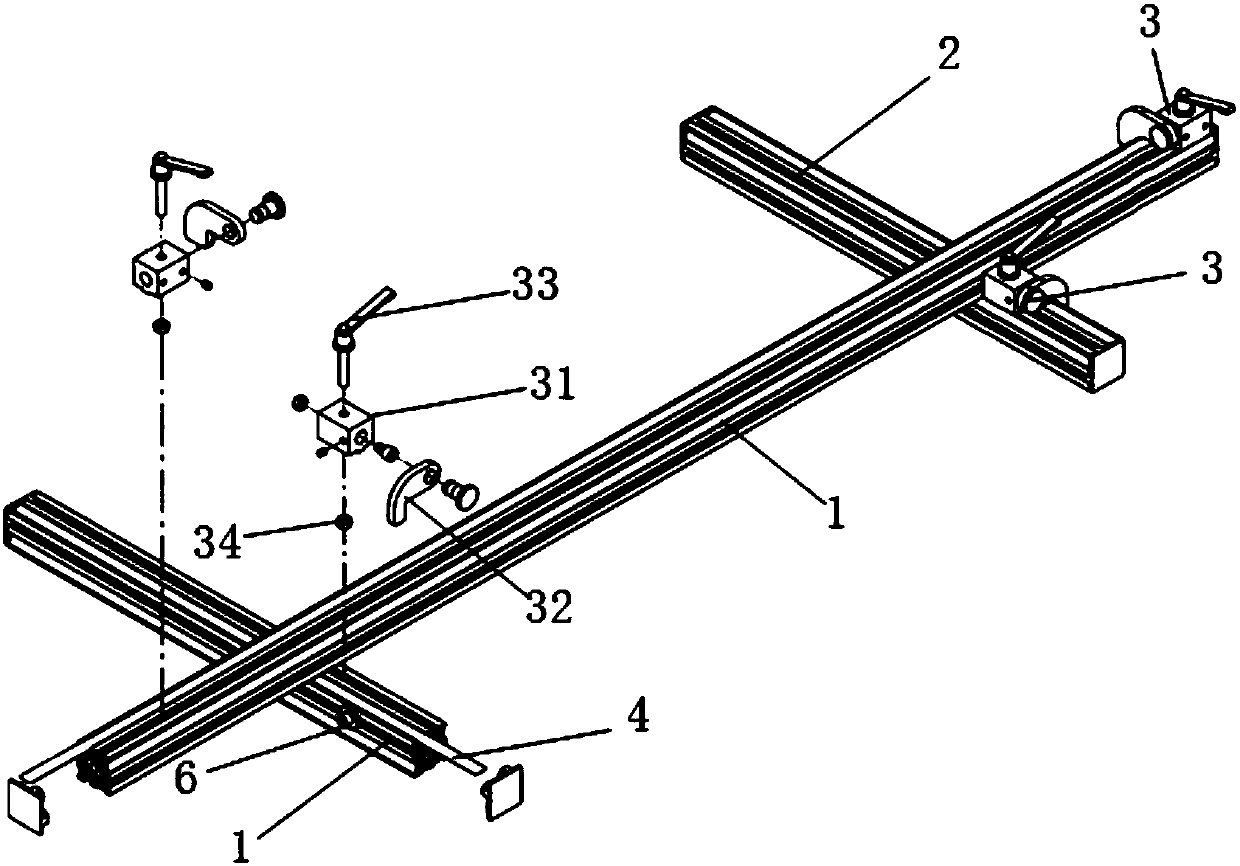

Drilling positioning device for steel plate

InactiveCN107891302AThe processing position is accurateEasy to replace the rulerPositioning apparatusMetal-working holdersSteel platesSheet steel

The invention relates to a steel plate drilling positioning device, comprising a first track, a second track, a sliding device, a ruler bar and a support plate, the second track is arranged at intervals, the first track is straddled above the second track, and the support plate is set on the On the second track, the sliding device is arranged on the first track and the second track, the first track and the second track are tracks with the same structure, and the track includes a sliding surface, a sliding groove and a mounting groove, and the distance between the sliding groove and the mounting groove is Setting, the sliding surface is set on the surface of the track and located on both sides of the sliding groove, the sliding device includes a sliding seat, a baffle, a fixed rod and a nut, the sliding seat is set on the sliding surface, the baffle is set on the side of the sliding seat, and the nut is set on In the slide groove, the fixed rod passes through the slide seat and is threadedly connected with the nut, the ruler bar is inserted in the installation groove, and the baffle plate is arranged above the installation groove. The invention can directly adjust and locate the position of the steel plate according to the value of the ruler bar, so that the processing position of the steel plate is more accurate.

Owner:天津曹氏传动机械制造有限公司

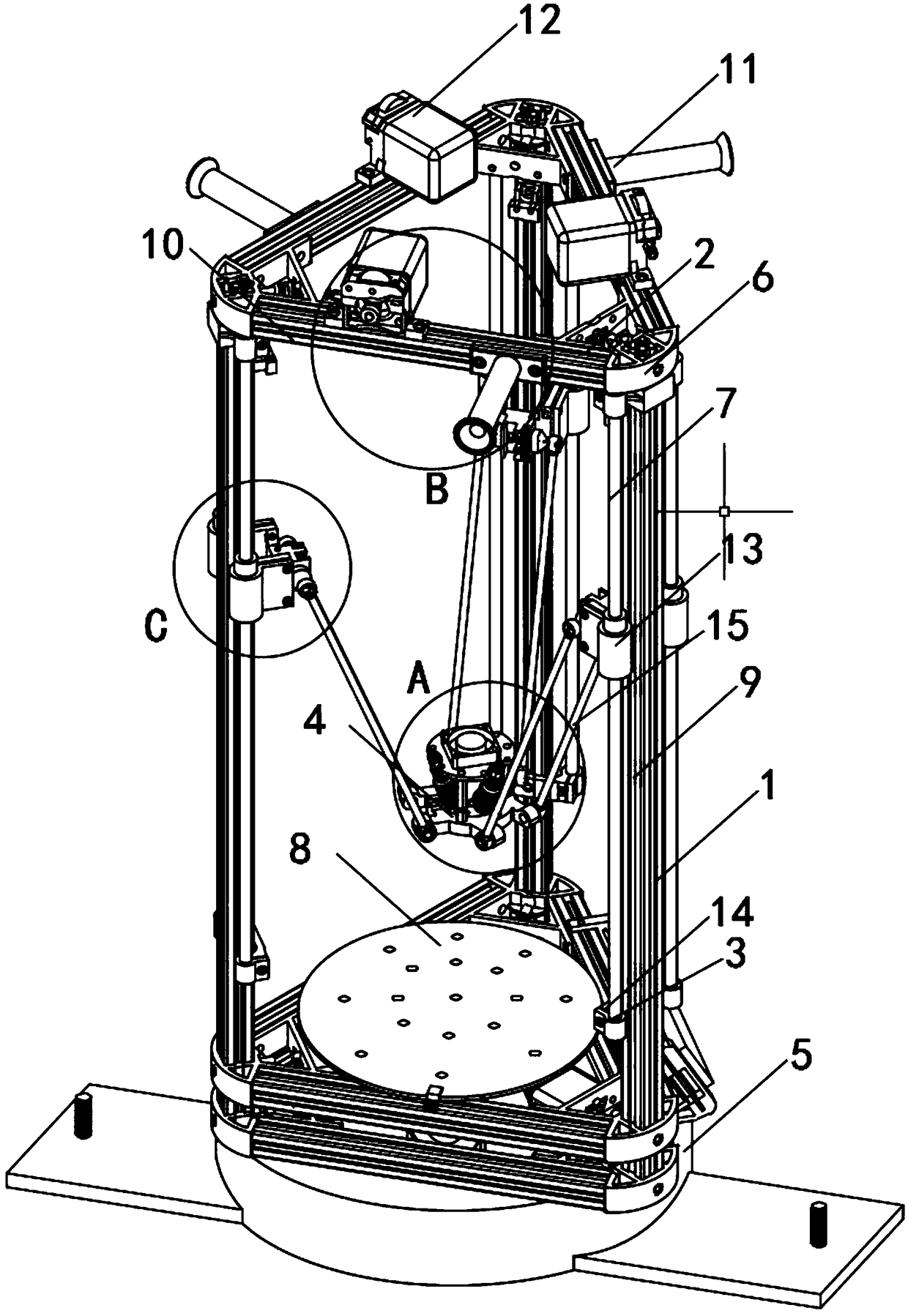

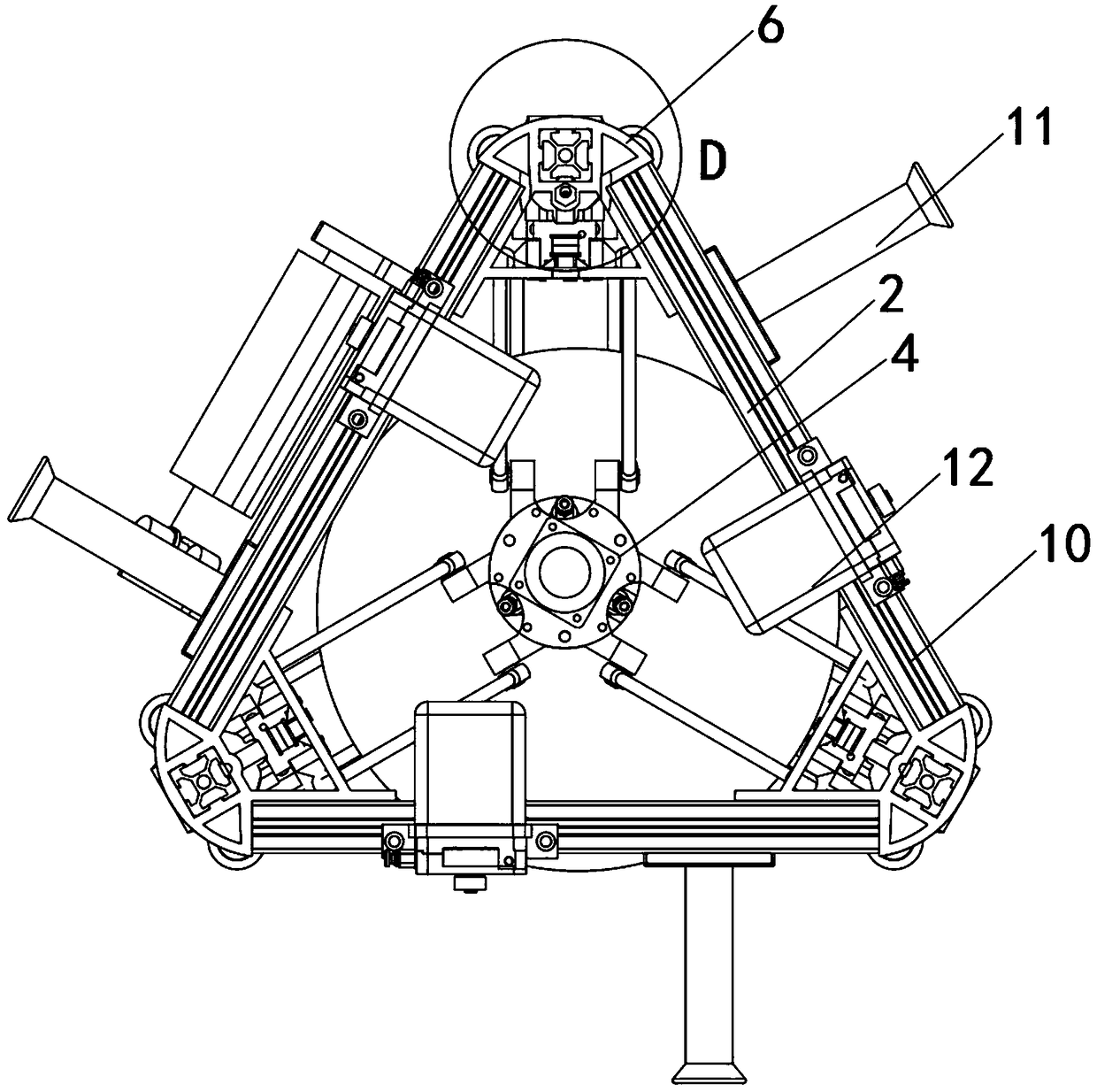

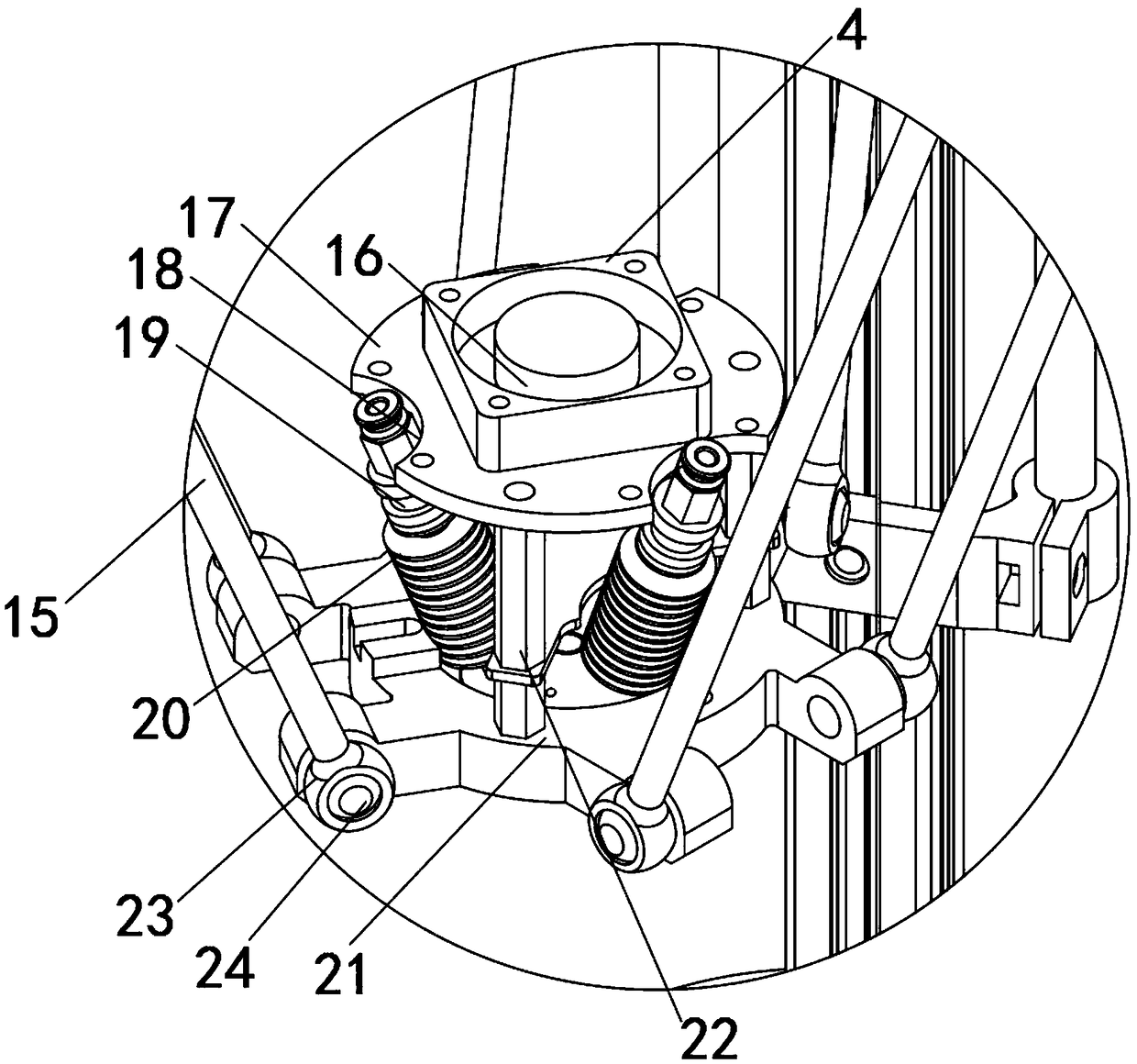

Laser engraving thermal fusion forming 3D printing method and 3D printing equipment

ActiveCN113059800AThe processing position is accurateAdditive manufacturing apparatusIncreasing energy efficiencyLaser engravingEngineering

The invention discloses a laser engraving thermal fusion forming 3D printing method. The method comprises the steps that firstly, a computer is adopted for modeling a 3D article to be printed, and a computer processor analyzes the pattern and shape of each unit thickness layer based on a three-dimensional data model of the 3D article; 2, a laser engraving and cutting mechanism is adopted for emitting laser to cut and engrave blank pieces according to the pattern and shape of a unit layer, the thickness of the blank pieces is the same as the unit thickness, the blank pieces are stacked layer by layer, and the 3D article is formed through heating or laser irradiation bonding; and 3, the formed 3D article is modified in a mode of grinding or laser engraving. The invention further relates to 3D printing equipment used in the laser engraving thermal fusion forming 3D printing method. According to the method and equipment, the blank pieces are adopted for machining, rapid forming can be achieved, and the speed is higher.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

A polymer sheet punching device for the production of automobile rear axle housing

ActiveCN112775277BAvoid deformationAvoid moving phenomenonMetal-working feeding devicesPositioning devicesPunchingLiquid storage tank

The invention discloses a polymer plate punching device for the production of automobile rear axle housing, comprising a base and a punching cylinder, a placing groove is arranged on the base, a liquid storage groove is arranged in the center of the placing groove, and the liquid storage groove is sealed by an elastic film , The bottom of the liquid storage tank is fixed with a conductive plate, the elastic film is provided with a conductive net, the punching cylinder is fixed with a mounting cylinder, the bottom of the mounting cylinder is fixed with a punching rod, and the outer wall of the mounting cylinder is fixed with static electricity. The electrorheological fluid hardens to support the plate, the punching cylinder drives the punching rod to descend to punch the hole, when the punching rod descends, the negative charge accumulated at the tip of the punching rod makes the negative charge on the conductive net discharge. Open, so that the electrorheological fluid at the punching position is softened, which is convenient for the punching operation. At the same time, the electrorheological fluid around the punching position is in a hardened state, supporting the plate and avoiding the deformation of the punching position.

Owner:武汉方鼎汽车部件制造有限公司

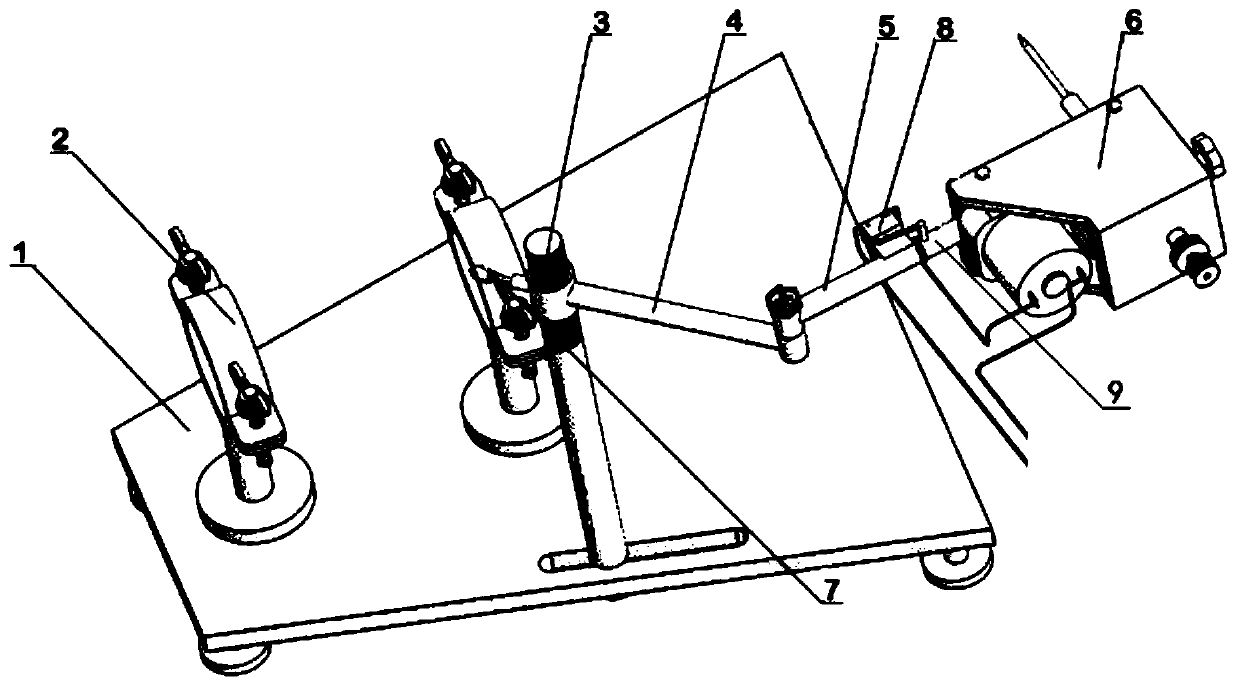

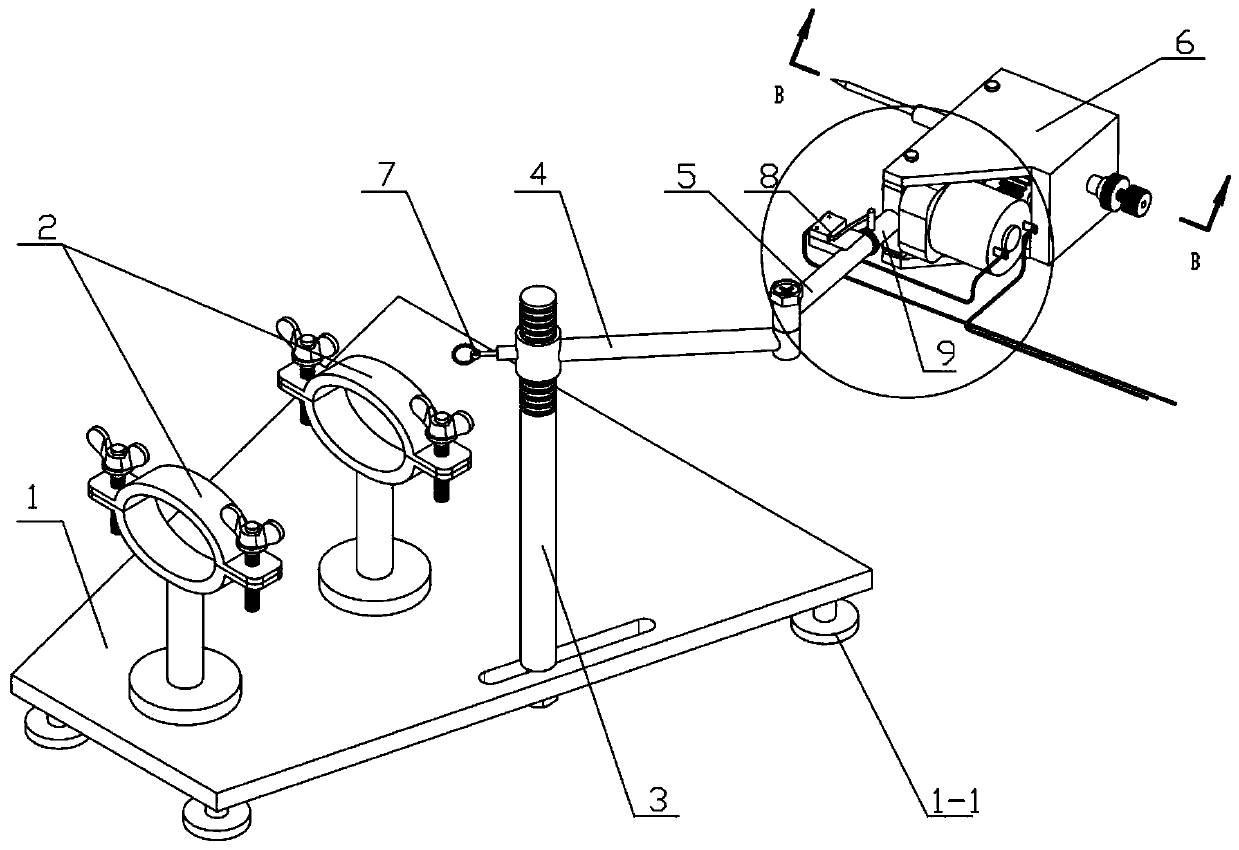

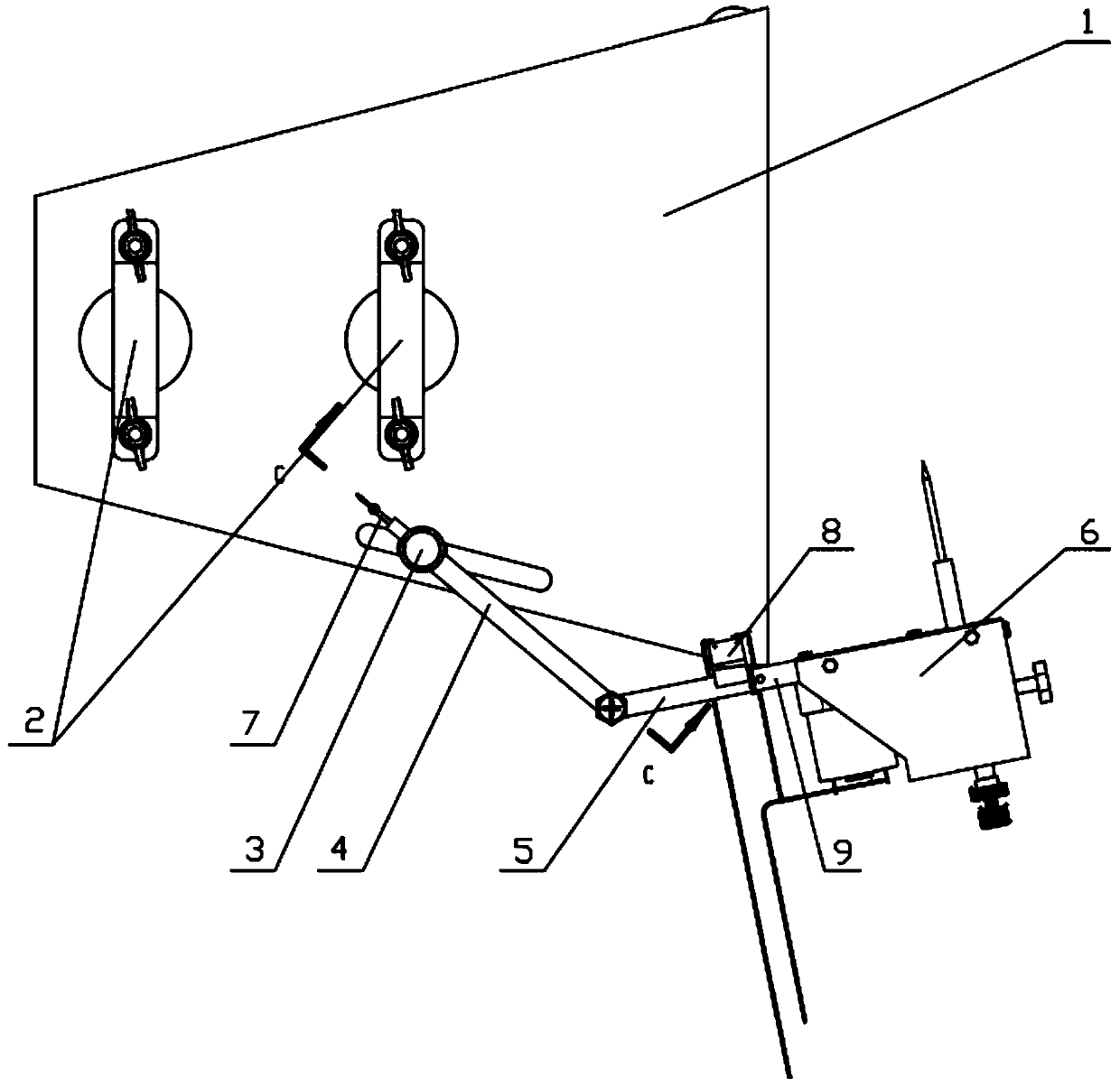

Automatic tungsten electrode polishing tool used in coordination with angle grinder

PendingCN111558879AEasy to adjustAvoid separate purchasesGrinding drivesGrinding feed controlAngle grinderEngineering

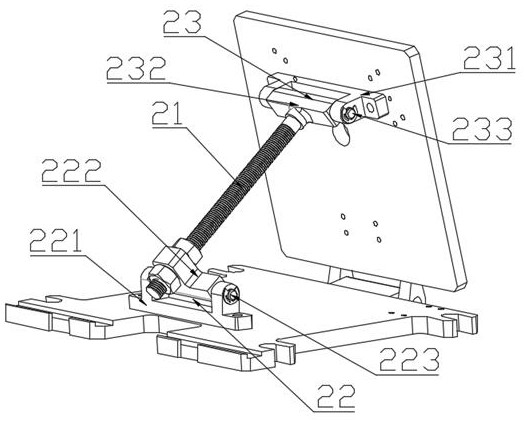

The invention provides an automatic tungsten electrode polishing tool used in coordination with an angle grinder, and belongs to the field of mechanical devices. The automatic tungsten electrode polishing tool comprises a base, an angle grinder fixing frame, a stand column, a main connecting rod, an auxiliary connecting rod and a tungsten electrode clamping and rotating device; the angle grinder fixing frame is fixedly installed on the base; a kidney-shaped through hole is formed in the base; the stand column is detachably installed in the kidney-shaped through hole of the base; one end of themain connecting rod is installed on the stand column in a sliding manner, and the other end of the main connecting rod is hinged to one end of the auxiliary connecting rod; and the other end of the auxiliary connecting rod is hinged to the tungsten electrode clamping and rotating device. The automatic tungsten electrode polishing tool aims to solve the problems that the existing special tungstenelectrode polishing tools need to be purchased separately, the adjustment of the polishing taper is inconvenient, the cost is high, and the applicability is low. The automatic tungsten electrode polishing tool is simple in structure, ingenious in design, convenient in disassembly and assembly, firm in assembly, low in cost and suitable for popularization.

Owner:SHANGHAI AUTOMATION INSTRAION CO LTD

Automatic processing device for right angle of strip steel

PendingCN114101322AEasy to controlGuaranteed alignment detection effectGuiding/positioning/aligning arrangementsMeasuring devicesVertical planeStrip steel

The automatic strip steel right-angle machining device comprises an uncoiler, a right-angle rolling mill, a discharging rail, a shearing machine and a material collecting groove are sequentially arranged at one end of the uncoiler in the first direction, and the uncoiler is arranged on the ground in a rolling mode in the second direction; the uncoiling machine comprises a first base, a mounting assembly used for mounting a strip steel coil is rotationally arranged on the first base, and a pre-tightening assembly is arranged on the first base; a limiting assembly is arranged between the uncoiler and the right-angle rolling mill and comprises a second base fixed to the right-angle rolling mill, and a first limiting block and a second limiting block are arranged on the second base in a sliding mode. According to the device, the positions of the uncoiler, the first limiting block and the second limiting block in the second direction can be adjusted, the center line of the strip steel and the rolling center line are located on the same vertical plane by adjusting the positions of the uncoiler, the first limiting block and the second limiting block in the second direction, and therefore it is guaranteed that the machining position of the strip steel is accurate; therefore, the strip steel right-angle processing quality is ensured.

Owner:SICHUAN RUIZHI ELECTRICAL STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com