Conveying and trimming assembly used for melamine board, trimming and board discharging assembly and achieving method of conveying and trimming assembly and trimming and board discharging assembly

A technology of hot-pressing machine and cyanide board, which is applied to other plywood/plywood appliances, sending objects, transportation and packaging, etc., can solve the problems of poor working environment, many hidden dangers, and low labor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

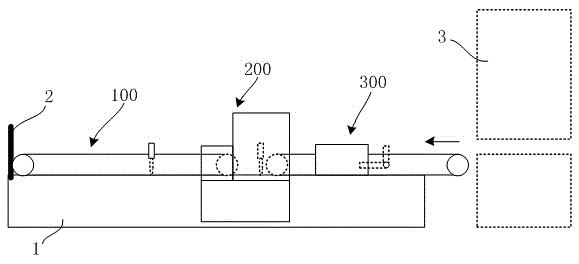

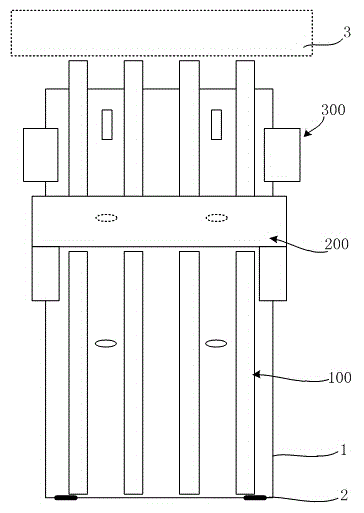

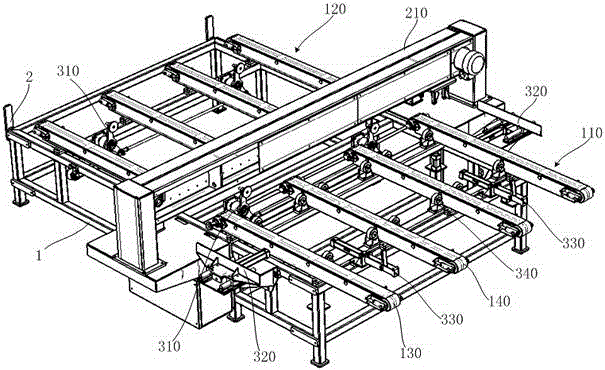

[0079] like Figure 1 to Figure 4 As shown, the conveying and trimming assembly for the melamine board hot press includes a chassis 1 arranged outside the discharge port of the hot press 3, and a two-stage conveying mechanism 100 arranged on the chassis along the discharge direction. , the positioning and adjusting mechanism 300 installed on the chassis for adjusting the position of the sheet on the two-stage conveying mechanism to facilitate trimming, the trimming mechanism 200 across the segment of the two-stage conveying mechanism, and the The end baffle 2 at the end of the two-stage conveying mechanism, wherein the control system is omitted and not shown. The bottom frame is used as a support, and its setting position makes the two-stage conveying mechanism just able to catch the discharge of the hot press. The structure of each institution is described in detail below:

[0080] The two-stage conveying mechanism 100 includes a front-end conveying assembly 110 located nea...

Embodiment 2

[0091] like Figure 5As shown, the difference in structure between this embodiment and Embodiment 1 is mainly that a platen mechanism 400 is added above the two-stage conveying mechanism, and a plate rear end correction mechanism must be used in the positioning and adjusting mechanism, and a plate rear end correction mechanism must be used in the trimming mechanism. Adaptive trimming head assembly is adopted, which increases the function of processing two sheets. Specifically, the platen pressing mechanism includes an upper support frame 5 connected to the bottom frame and located above the two-stage conveying mechanism, and a front platen platen mechanism 410 arranged on the upper support frame and located above the front end conveying assembly and matched with it or / and located at The matching rear platen mechanism 420 above the rear conveying assembly. In this embodiment, both the front-end platen mechanism and the rear-end platen mechanism are provided, and they all inclu...

Embodiment 3

[0096] like Image 6 and Figure 7 As shown, the difference between this embodiment and Embodiments 1 and 2 is that this embodiment is based on the trimming lower plate assembly of the aforementioned conveying and trimming assembly, and in terms of structure, it is based on the structure of the aforementioned conveying and trimming assembly Add a subsequent mechanism for moving the trimmed sheets from the end of the conveying mechanism to the stacked rear of the conveying mechanism. Specifically, the additional structure includes an upper support extension frame 6 connected with the bottom frame, a four-way transfer mechanism 500 arranged on the upper support extension frame along the discharge direction and vertical direction, and a four-way transfer mechanism connected with the four-way transfer mechanism. Suction cup mechanism 600 for grabbing sheet. In actual design, the upper support frame and the upper support extension frame can be integrated to reduce volume and mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com