Automatic tungsten electrode polishing tool used in coordination with angle grinder

A technology for grinding tools and angle grinders, which is applied to the parts of grinding machine tools, manufacturing tools, grinding drive devices, etc., can solve the problems of poor applicability, high cost, and inconvenient adjustment of grinding taper, and achieve convenient adjustment, The effect of high processing precision and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

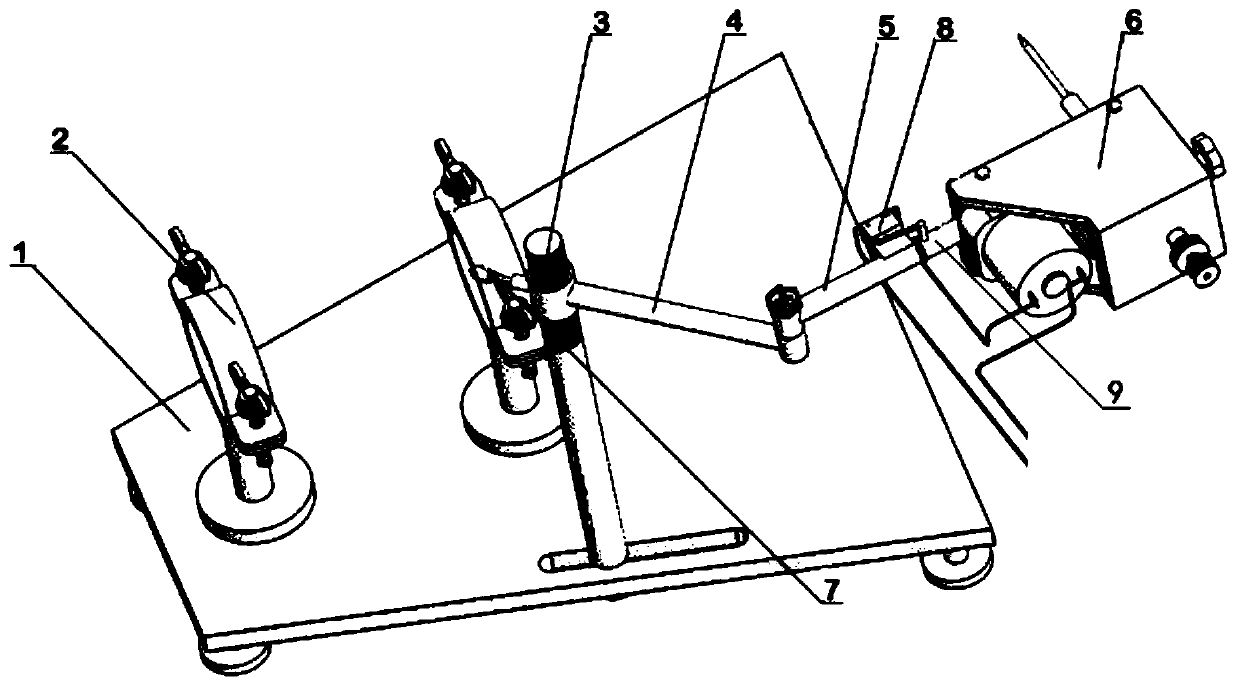

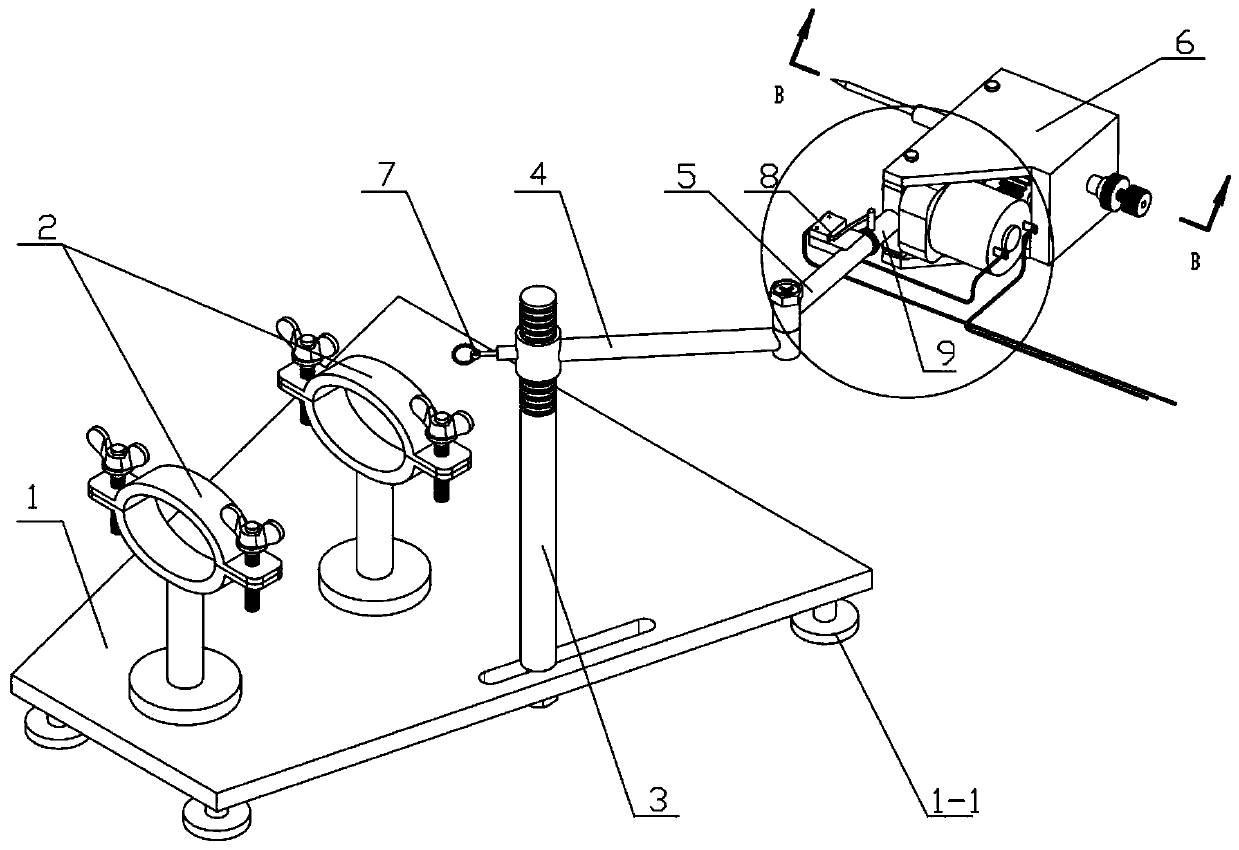

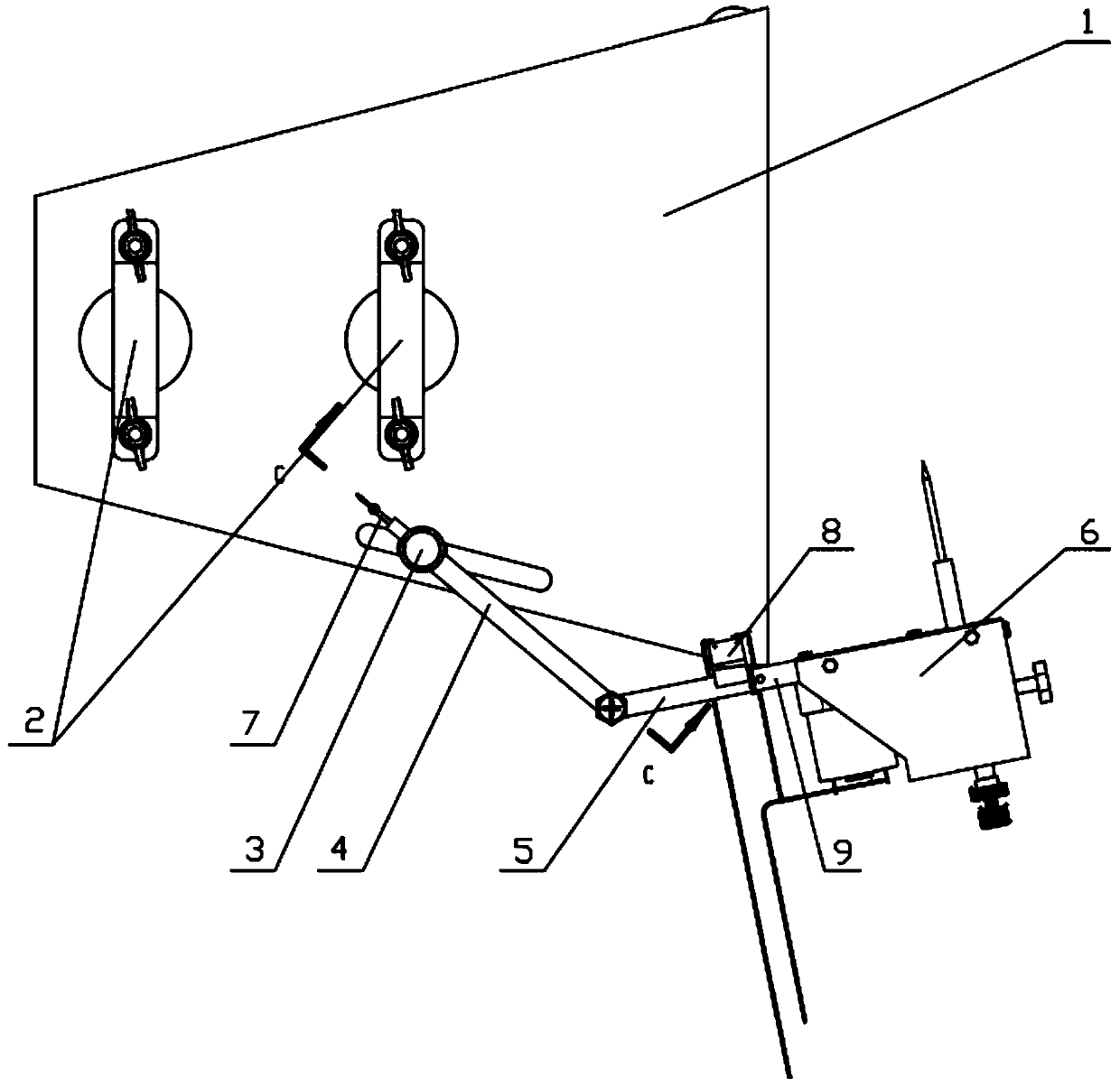

[0035] Specific implementation mode one: combine Figure 1-Figure 5Describe this embodiment, a tungsten automatic grinding tool used with an angle grinder in this embodiment, including a base 1, two angle grinder fixing frames 2, a column 3, a main connecting rod 4, a secondary connecting rod 5, a tungsten The pole clamps the rotating device 6 and the indexing pin 7, and the two angle grinder fixing rings 2 are fixed and installed on the base 1 in parallel, and a waist-shaped through hole is processed on the base 1 on the right side of the two angle grinder fixing brackets 2, A threaded hole is processed at the bottom of the column 3, and the column 3 is fixedly installed in the waist-shaped through hole of the base 1 through the screw fit of the bolt and the threaded hole at the bottom. , one end of the main link 4 is slidingly installed in the groove at the upper end of the column 3 through the indexing pin 7, the height of the main link 4 can be adjusted through the indexin...

specific Embodiment approach 2

[0036] Specific implementation mode two: combination Figure 1-Figure 5 Description of this embodiment, an automatic tungsten electrode grinding tool used with an angle grinder, also includes a micro switch 8, the micro switch 8 is installed on the auxiliary connecting rod 5, and the switch of the micro switch 8 is protruding from the left end of the switch shaft 9. Protrusion 91 contact installation, micro switch 8 is electrically connected with tungsten pole clamping and rotating device 6, vertically rotates tungsten pole clamping and rotating device 6, and when adjusted to a suitable angle, protrusion 91 and micro switch 8 mutually Squeeze, trigger the micro switch 8, and close the loop, so that the 12V motor unit 614 inside the tungsten pole clamping and rotating device 6 starts to drive the tungsten pole to rotate. Then start the angle grinder again to grind the tungsten electrode.

specific Embodiment approach 3

[0037] Specific implementation mode three: combination Figure 1-Figure 5 Describe this embodiment, an automatic tungsten electrode grinding tool used with an angle grinder in this embodiment, the angle grinder fixing frame 2 includes a fixing bracket 2-1, an upper fixing ring 2-2 and a lower fixing ring 2- 3. The lower fixing ring 2-3 is fixedly installed on the fixing bracket 2-1, the left and right ends of the upper fixing ring 2-2 and the lower fixing ring 2-3 are fixedly connected by adjusting nuts, and the angle grinder is installed on the upper fixing ring 2- 2 and the lower fixing ring 2-3, tighten the upper fixing ring 2-2 and the lower fixing ring 2-3 through the adjusting nut to realize the fixing of the angle grinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com