Punching clamp for high-temperature nozzle

A punching fixture, high temperature technology, applied in the direction of clamping, manufacturing tools, drilling/drilling equipment, etc., can solve the problems that the drilling position cannot be guaranteed, the drilling slope is unstable, and the drilling position is offset. Achieve good market application value, good processing effect and stable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

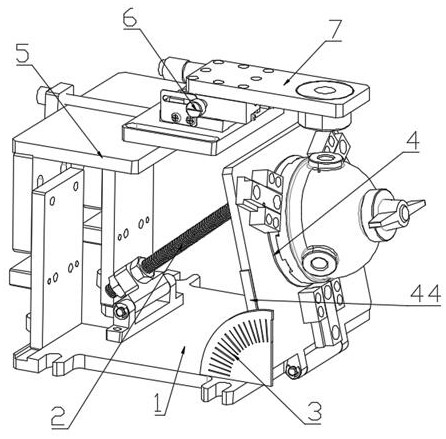

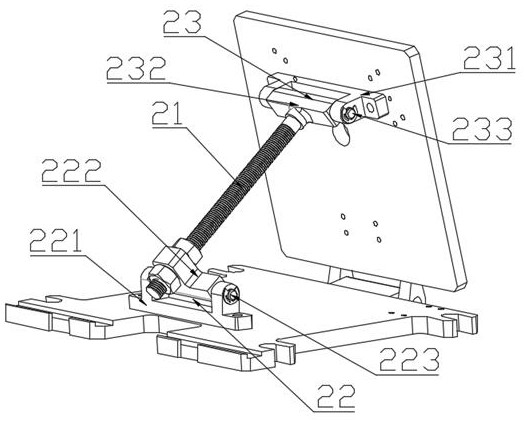

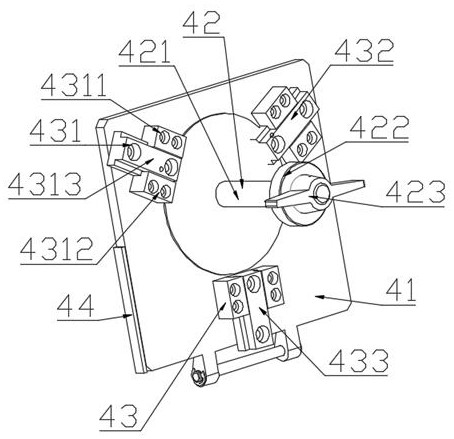

[0032] Such as figure 1 As shown, Embodiment 1 of the present invention: a punching jig for high temperature nozzles, the punching jig for high temperature nozzles is fixed on the drilling machine console, the punching jig for high temperature nozzles includes a support base 1 , an angle adjustment mechanism 2, an angle measurement assembly 3, a clamping mechanism 4, a fixed adjustment mechanism 5, a movable adjustment mechanism 6 and a drill protection assembly 7, the support base 1 is fixed on the drilling machine console, and the angle adjustment mechanism 2 One end is hinged with the left side of the support base 1, the other end of the angle adjustment mechanism 2 is hinged with the upper back side of the clamping mechanism 4, and the bottom of the clamping mechanism 4 is hinged with the right end of the support base 1 The angle measurement assembly 3 is fixed on the right front side of the support base 1, and the inner side of the angle measurement assembly 3 is in conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com