Bicycle below tube arc mill

A bicycle and milling cutter technology, which is applied to milling machine equipment, milling machine equipment details, metal processing machinery parts, etc., can solve the problems of down tube deviation, inconvenience, and low processing efficiency, and achieve accurate processing positions, flexible applications, and The effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

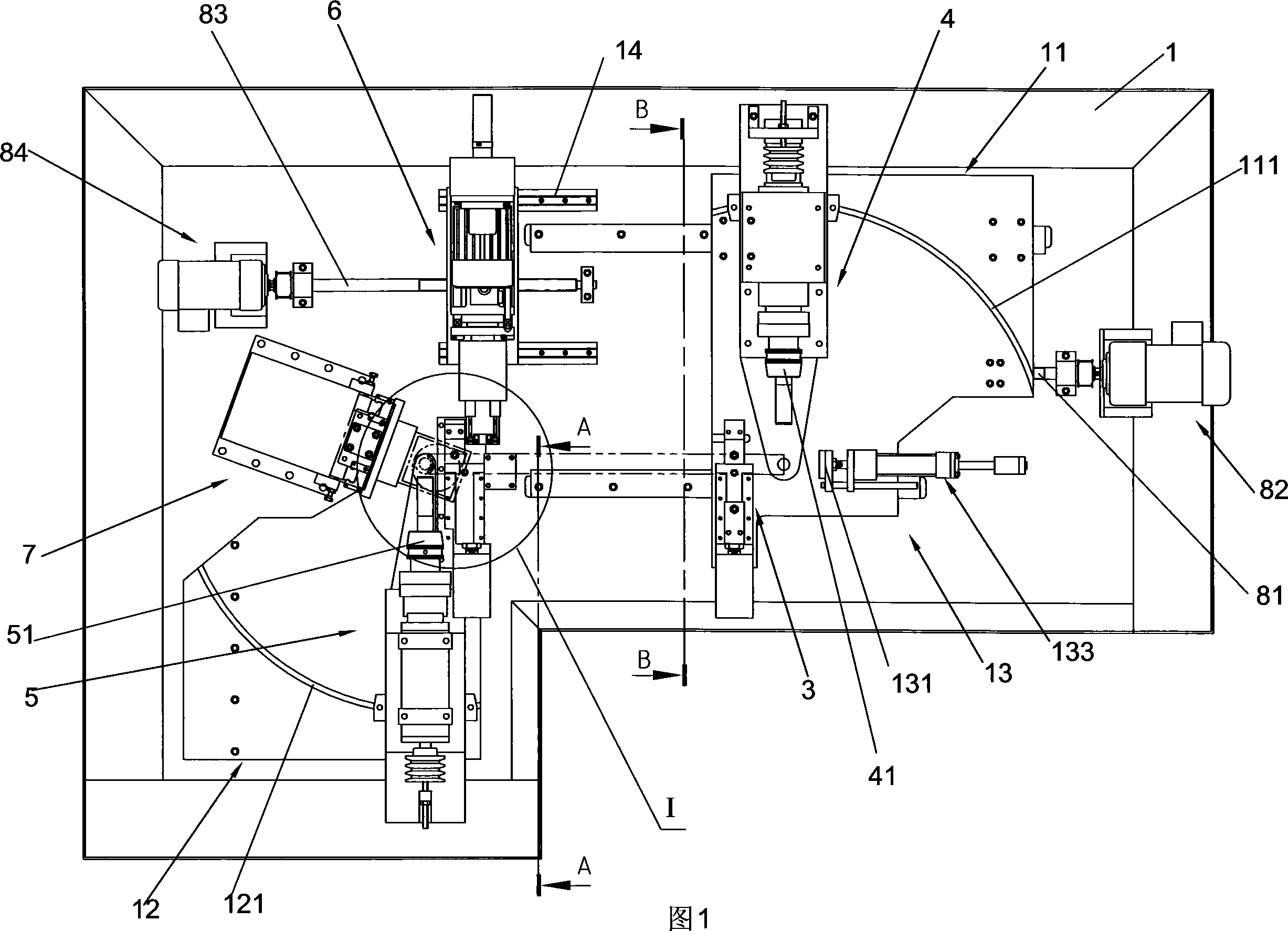

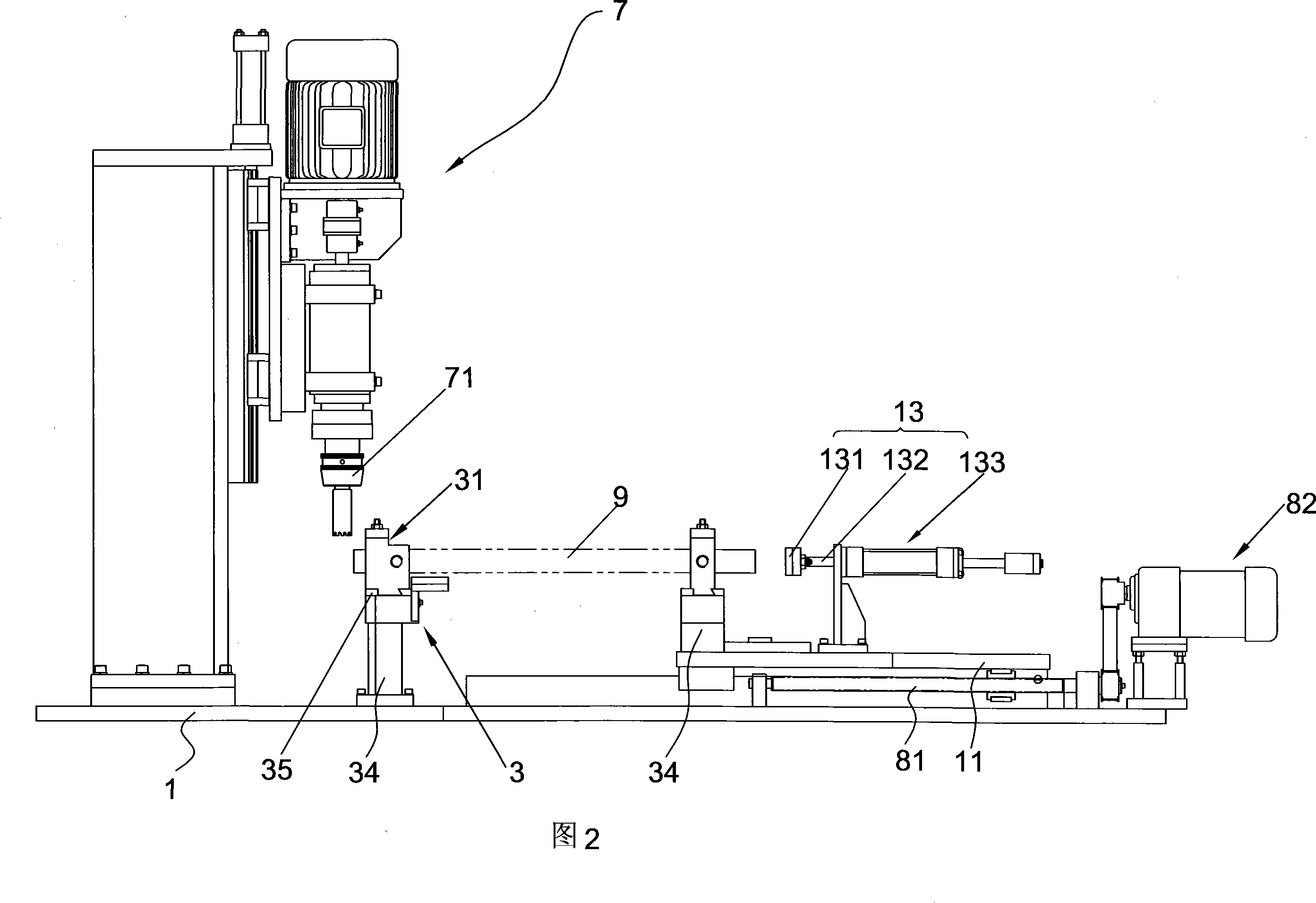

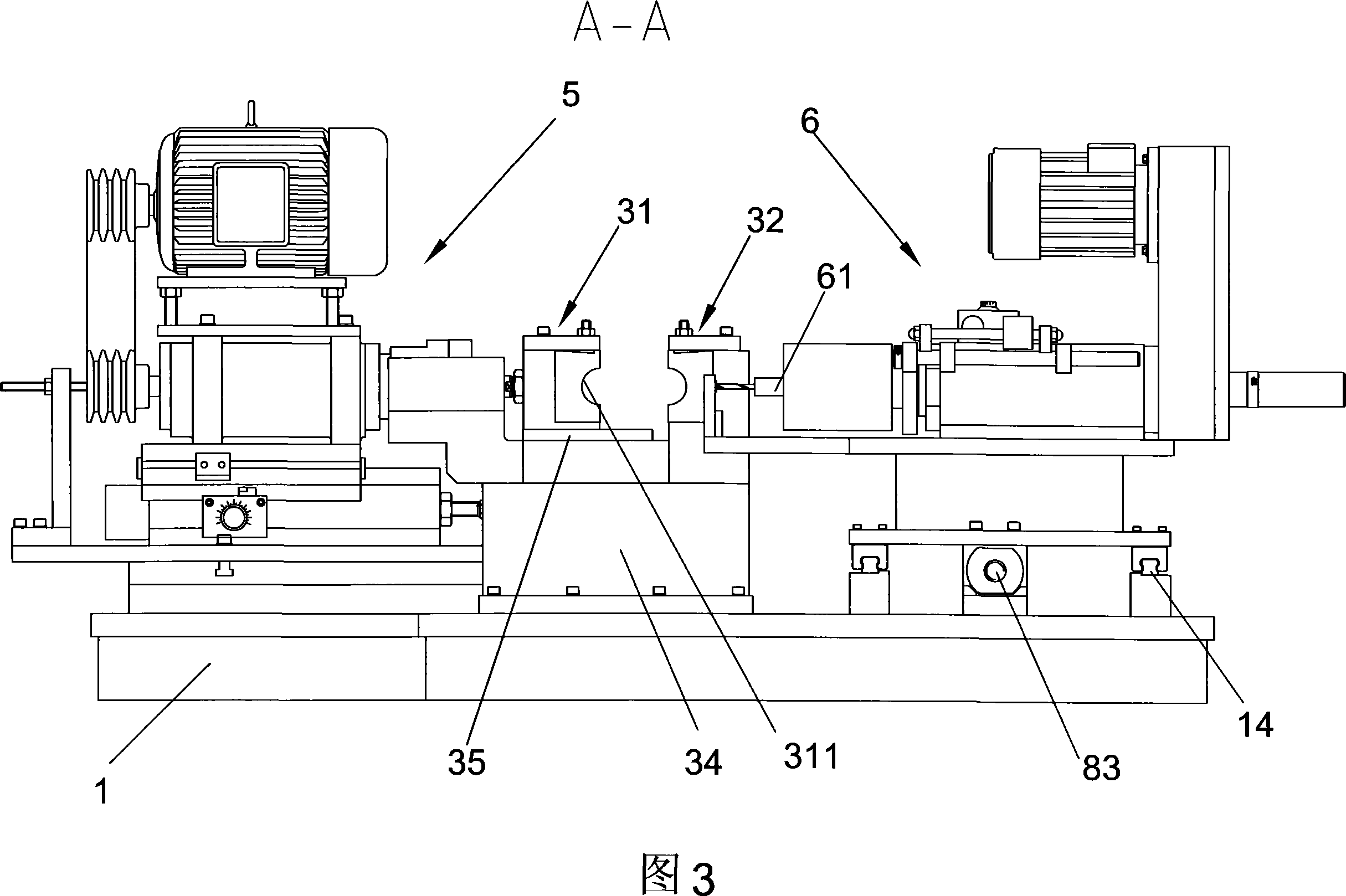

[0027] Referring to Figures 1 to 5, a bicycle down tube arc milling machine includes a frame 1, a clamping mechanism arranged on the frame 1 and used to fix the down tube 9, a first Milling tool seat 4 , second milling tool seat 5 and third milling tool seat 7 .

[0028] The clamping mechanism includes a pair of clamping units 3, the clamping unit 3 includes a clamping base 34, a first clamping block 31 movably arranged on the clamping base 34, and a second clamping block 32 fixedly arranged on the clamping base 34, The opposite sides of the first clamping block 31 and the second clamping block 32 are respectively provided with a circular arc-shaped notch 311, so that the down tube 9 to be processed is firmly clamped between the first clamping block 31 and the second clamping block 32. between.

[0029] The first milling cutter seat 4, the second milling cutter seat 5, and the third milling cutter seat 7 are respectively provided with a first milling cutter fixing seat 41, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com