Processing apparatus, tool, processing method, and method for setting processing position

A processing device and processing position technology, applied in the direction of manufacturing tools, metal processing, glass cutting devices, etc., can solve the problems of difficult semiconductor wafer shooting, difficult to accurately obtain the processing position, etc., and achieve the effect of accurate processing position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

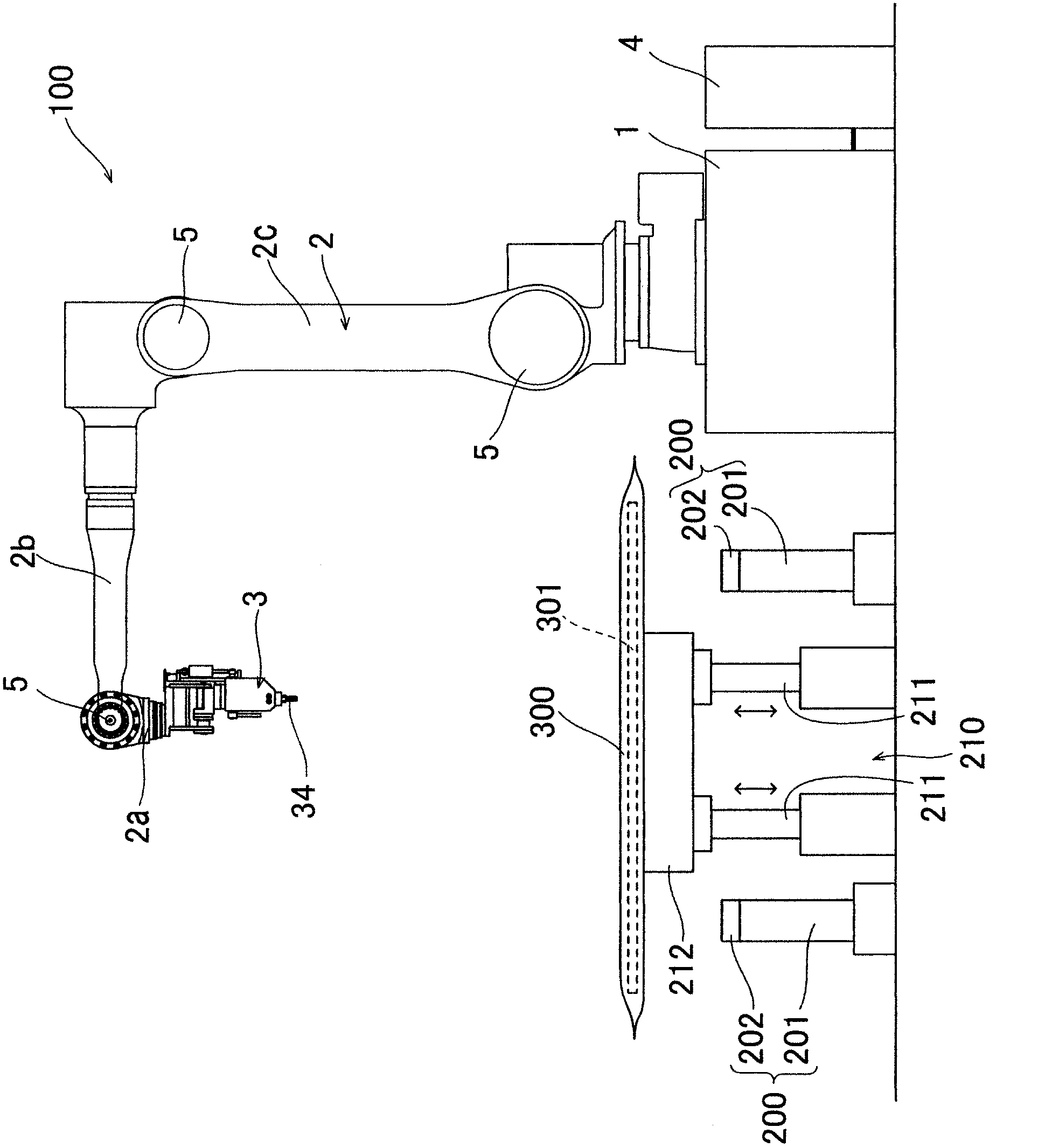

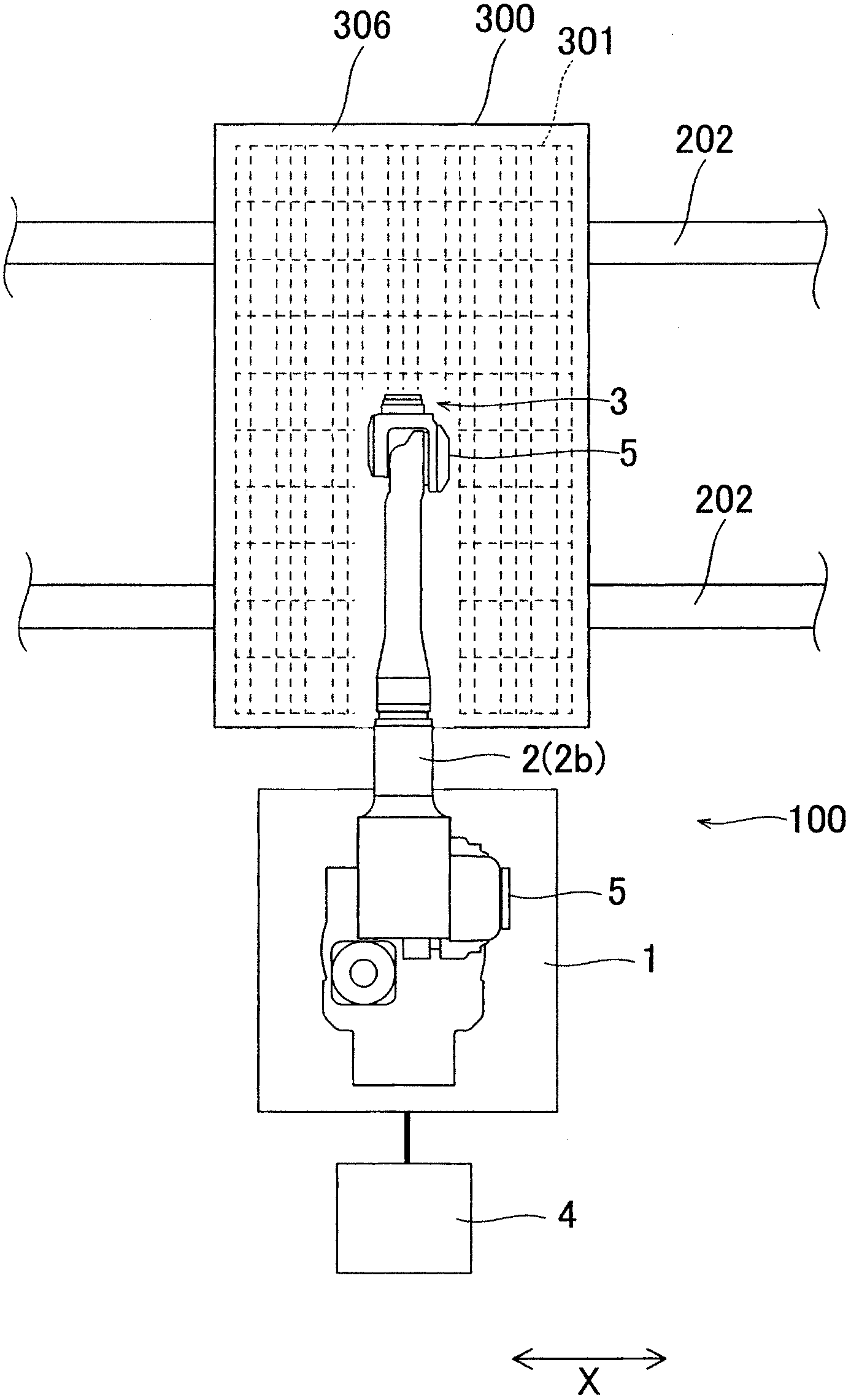

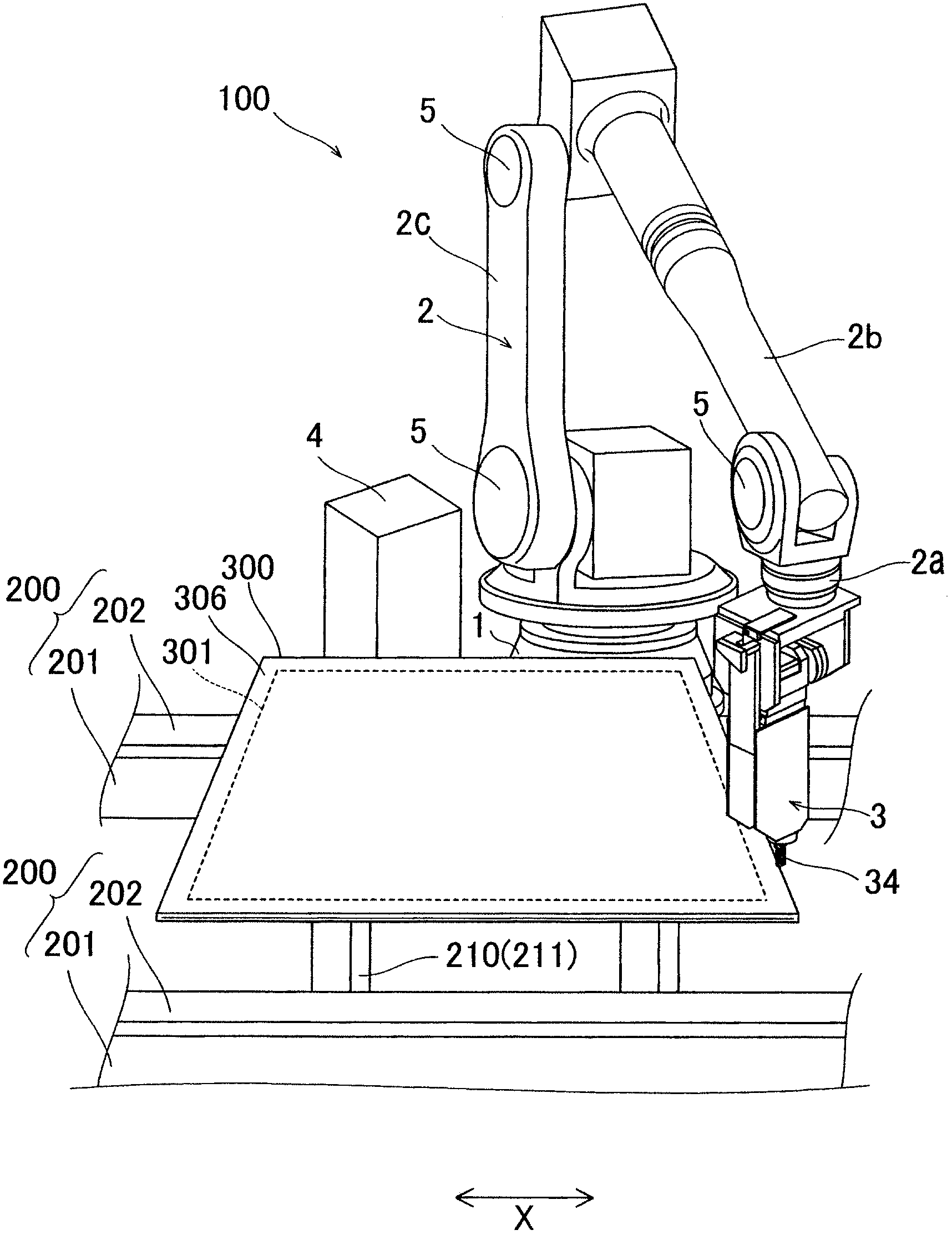

[0039] First, refer to Figures 1 to 9 The structure of the robot 100 according to the first embodiment will be described. The robot 100 is an example of a "processing device". In other words, robots can include not only figure 1 The articulated robot shown can also include SCARA-type robots and Cartesian-type (Cartesian) robots. In addition, processing tools can be arranged on a gantry with at least three axes perpendicular to each other.

[0040] Such as Figure 1 to Figure 3 As shown, the robot 100 includes a base 1 , a robot arm 2 installed on the base 1 , an end effector 3 installed at the front end of the robot arm 2 , and a robot controller 4 for controlling the overall movement of the robot 100 . A conveyor 200 that transfers the substrate 300 and a mount portion 210 that mounts the substrate 300 when trimming is performed are provided near the robot 100 .

[0041] The conveyor 200 includes a table part 201 and a roller part 202 set on the table part 201 to move th...

no. 2 approach )

[0079] Next, refer to Figure 17 and Figure 18 The end effector 6 according to the second embodiment will be described. In this second embodiment, unlike the above-described first embodiment in which a substantially U-shaped thermal cutter 34 is contained in the end effector 3 , a thermal cutter 64 in the form of a cutter is contained in the end effector 6 . The thermal cutter 64 is an example of a "knife".

[0080] Such as Figure 17As shown, the end effector 6 according to the second embodiment includes an arm mounting part 61 , an air slide 62 , a thermal cutter body 63 and a thermal cutter 64 . The arm mounting portion 61 is fixedly mounted on the arm portion 2 a and located above the air slide 62 . The heat cutter main body 63 is arranged below the air slide table 62 . The thermal cutter blade 64 is attached to the front end of the thermal cutter main body 63 along a direction intersecting the vertical direction (Z direction) at a predetermined angle θ2.

[0081] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com