Conveyor belt for metal workpieces

A technology for metal workpieces and conveyor belts, which is applied in the field of conveyor belts and can solve problems such as instability of metal workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

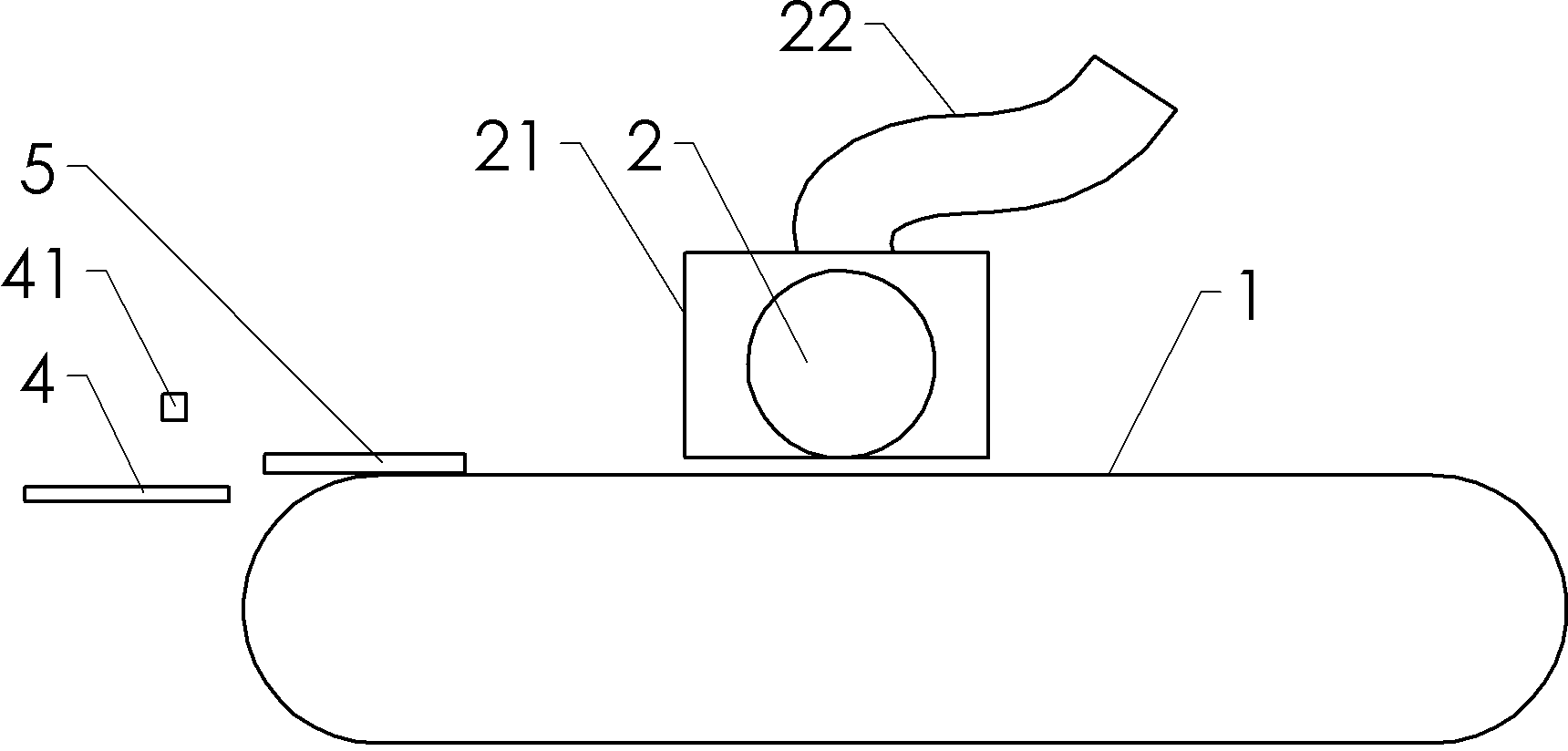

[0022] Take the blade grinding treatment of kitchen knives as an example, such as figure 1 As shown: it includes a conveyor belt body 1 including a frame and a magnetic body, a grinding wheel 2 arranged above the belt body, a dust cover 21 is arranged around the grinding wheel, and a negative pressure dust suction pipe 22 is connected to the dust cover. The negative pressure suction pipe is connected with an exhaust fan.

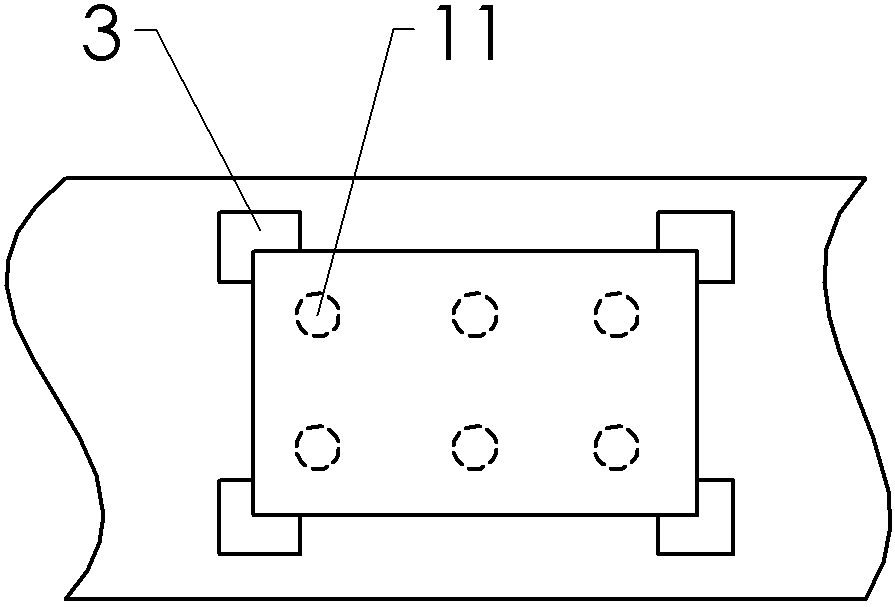

[0023] Such as figure 2 Shown: the belt body is provided with four L-shaped positioning blocks 3 to prepare for the position of the fixed blade, and each blade position on the belt body is provided with six strong magnets 11.

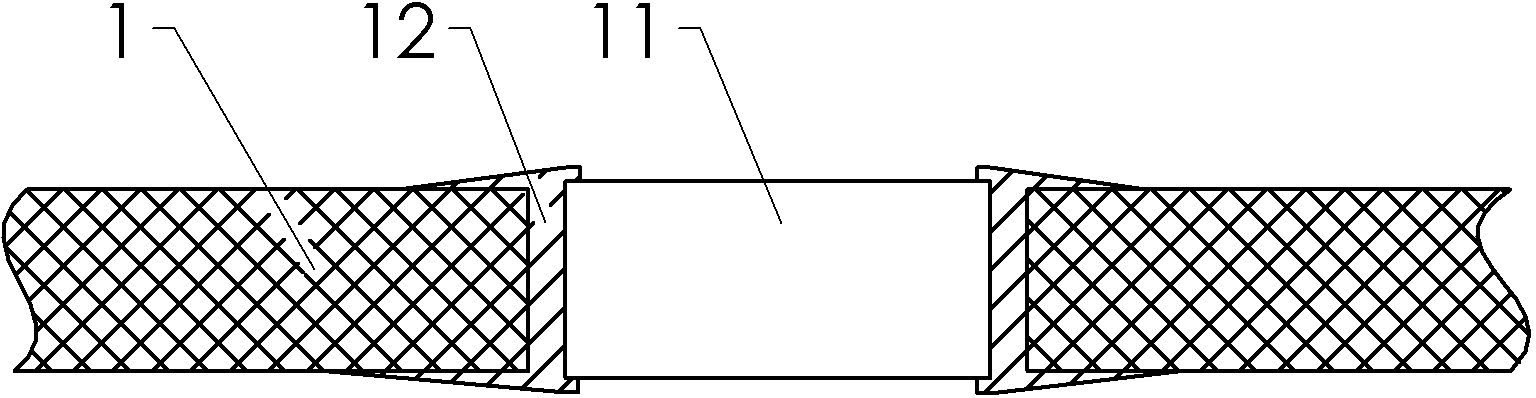

[0024] Such as image 3 As shown: the belt body is provided with a fixing hole, the ring-shaped magnet fixing part 12 is riveted in the fixing hole, and the columnar strong magnet 11 is clamped in the magnet fixing part.

[0025] Such as figure 1 As shown: the discharge end of the belt body is provided with a discharge pallet 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com