Press mounting machine for workpiece

A technology for press-fitting machines and workpieces, applied in the field of "L"-shaped workpiece press-fitting machines, which can solve the problems of increasing the number of parts, high requirements for control parts, and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

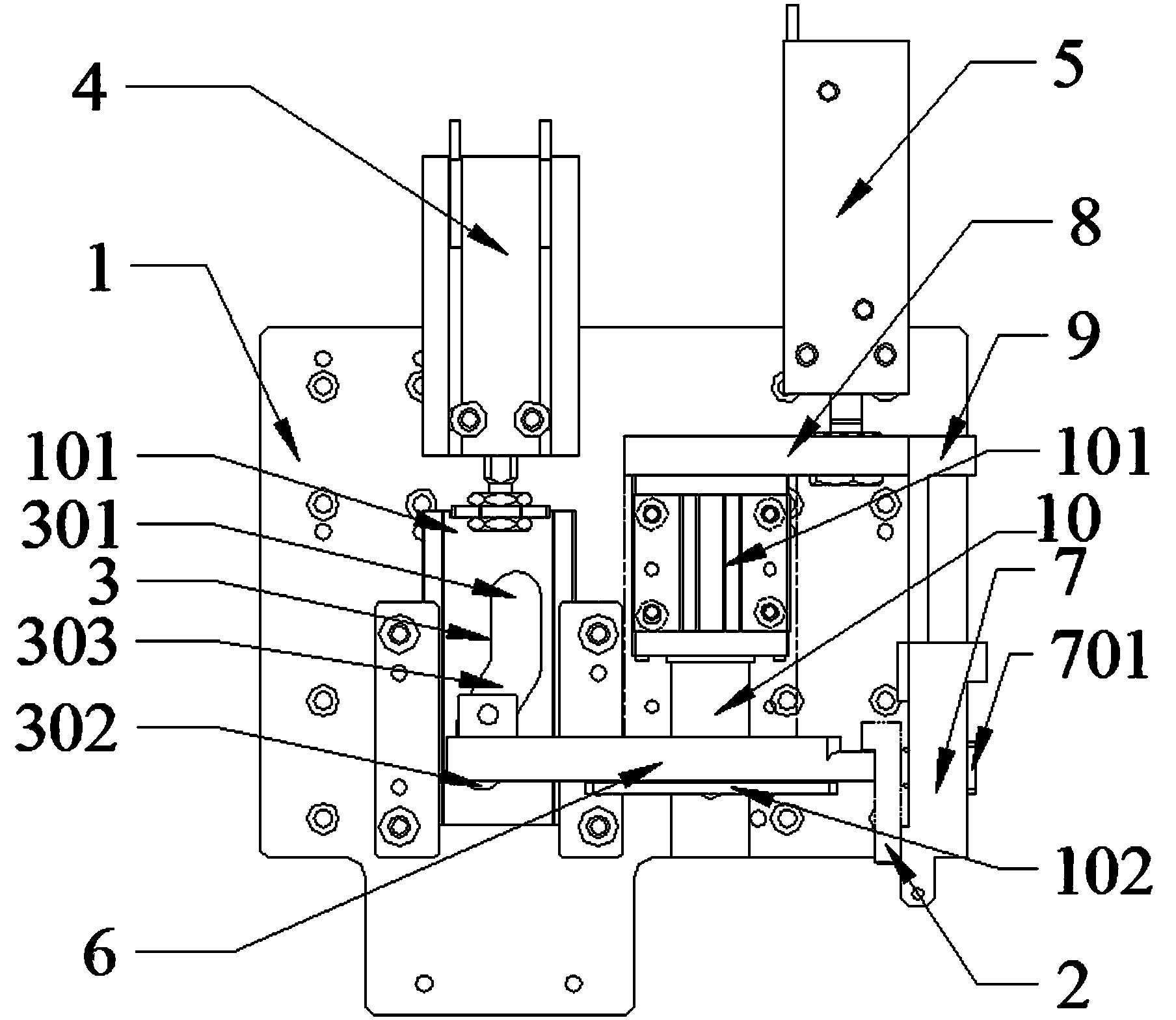

[0020] The workpiece press-fitting machine includes a fixed plate 1 on which a receiving groove 101 is fixed, and also includes: a clamping device for clamping the workpiece 2, a sliding part that slides in the receiving groove 101 and provides the sliding track 3 of the clamping device , the pushing device that pushes the workpiece 2 to the specified position, and the driving device that provides the power of the clamping device and the pushing device. As a preference, the workpiece 2 is an "L" shaped workpiece 2 .

[0021] The sliding part is a cam, and the sliding track 3 on the sliding part consists of: a clamping track 301, a loosening track 302, a transition track connecting the clamping track 301 and a relaxing track 302, the clamping track 301 is close to the workpiece 2, and the loosening track 302 Move away from workpiece 2.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com