Floor block, wall panel and assembling method of floor block and wall panel

An assembly method and a technology of floor boards, which are applied to floors, coverings/linings, buildings, etc., can solve problems such as complex procedures, long construction periods, and difficulty in ensuring neatness, and achieve improved uniformity, uniform gap sizes, and The effect of fast splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

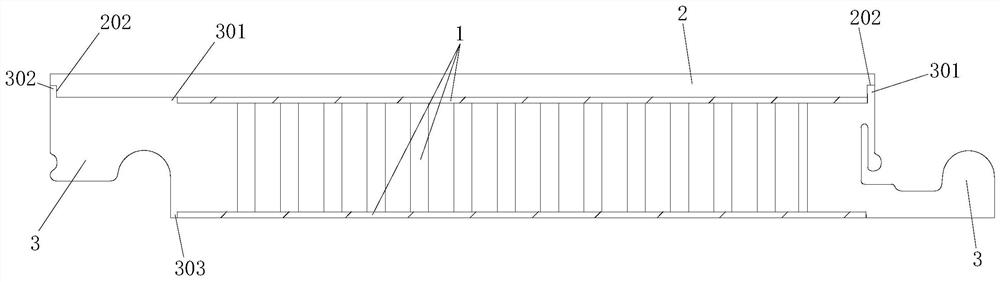

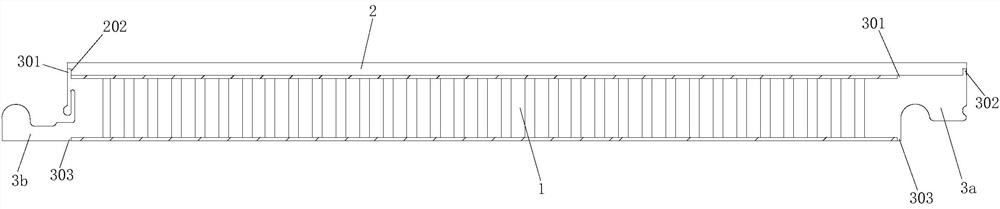

[0090] Figure 1 to Figure 6 A preferred embodiment of the floorboards of the present application is shown. Like most of the existing floorboards, the outer contour of the floorboards is roughly rectangular, and each side of the floorboards is provided with a The buckles that are connected together (commonly known as floor buckles).

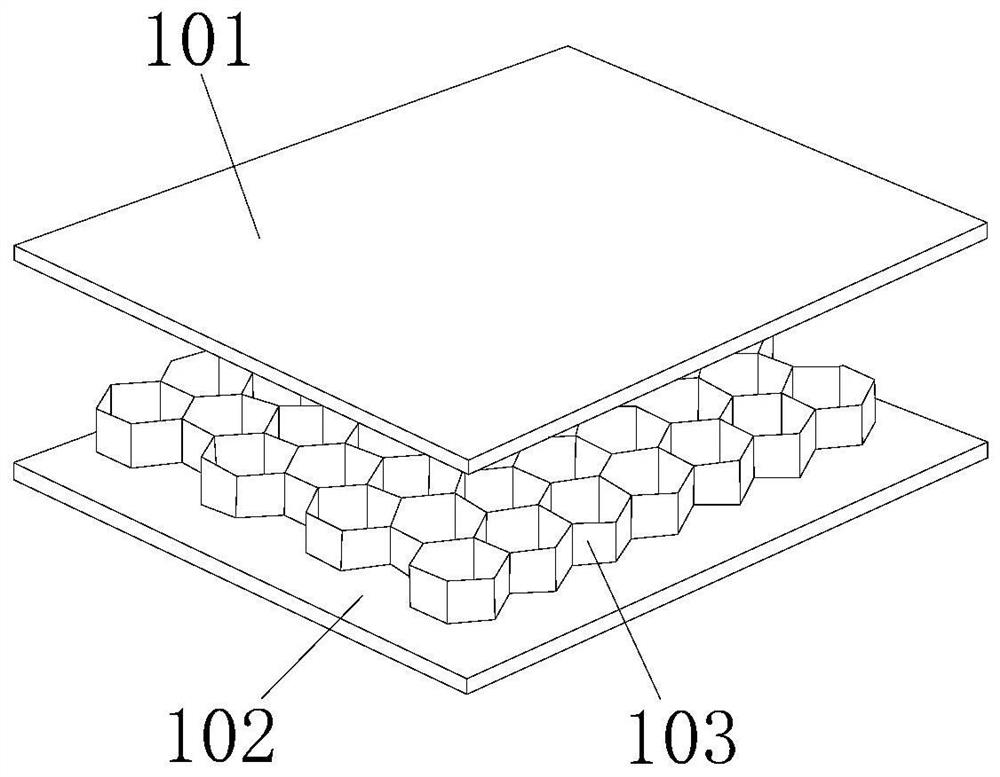

[0091] Different from the traditional floor boards, the floor boards of this embodiment are mainly composed of a lower honeycomb substrate 1 and an upper deck 2. The lower honeycomb substrate 1 and the upper facing layer 2 are rectangular structures, both of which have two long sides arranged in parallel and two short sides arranged in parallel. And each side of the honeycomb substrate 1 is fixedly connected with a buckle 3, a total of four buckles 3, two of the four buckles 3 are male buckles 3a, and the other two are female buckles 3b. Specifically, one long side and one short side of the honeycomb substrate 1 are respectively fixedly connect...

Embodiment 2

[0121] Figure 7 and Figure 8 Shown is the second preferred embodiment of this floorboard of the present application, and the structure of this floorboard and embodiment one floorboard is basically the same, and the main difference is:

[0122] All buckles 3 are female buckles 3b, and the positioning protrusion 301 of each buckle 3 protrudes from the upper surface of the upper plate body 101 and abuts against the side of the finish layer 2 in the horizontal direction. The second positioning protrusion 302 of the first embodiment is not additionally provided on all buckles 3 .

Embodiment 3

[0124] Figure 9 to Figure 10 Shown is the third preferred embodiment of this floorboard of the present application, and the structure of this floorboard is basically the same as that of Embodiment 1 floorboard, the main difference is:

[0125] All buckles 3 are male buckles 3a, and each buckle 3 includes a second positioning protrusion 302 protruding upwards and horizontally abutting against the side edge of the finish layer.

[0126] Under normal circumstances, the floor boards of embodiment two and embodiment three need to be used in conjunction with each other to form a large-area floor system paved on the ground.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com