Drilling machine tool for round timber tip

An end and machine tool technology, which is applied in the field of log end drilling machine tools, can solve the problems of high operation difficulty, low production efficiency, and inability to clamp and process, and achieve firm clamping, high production efficiency, and accurate processing positions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

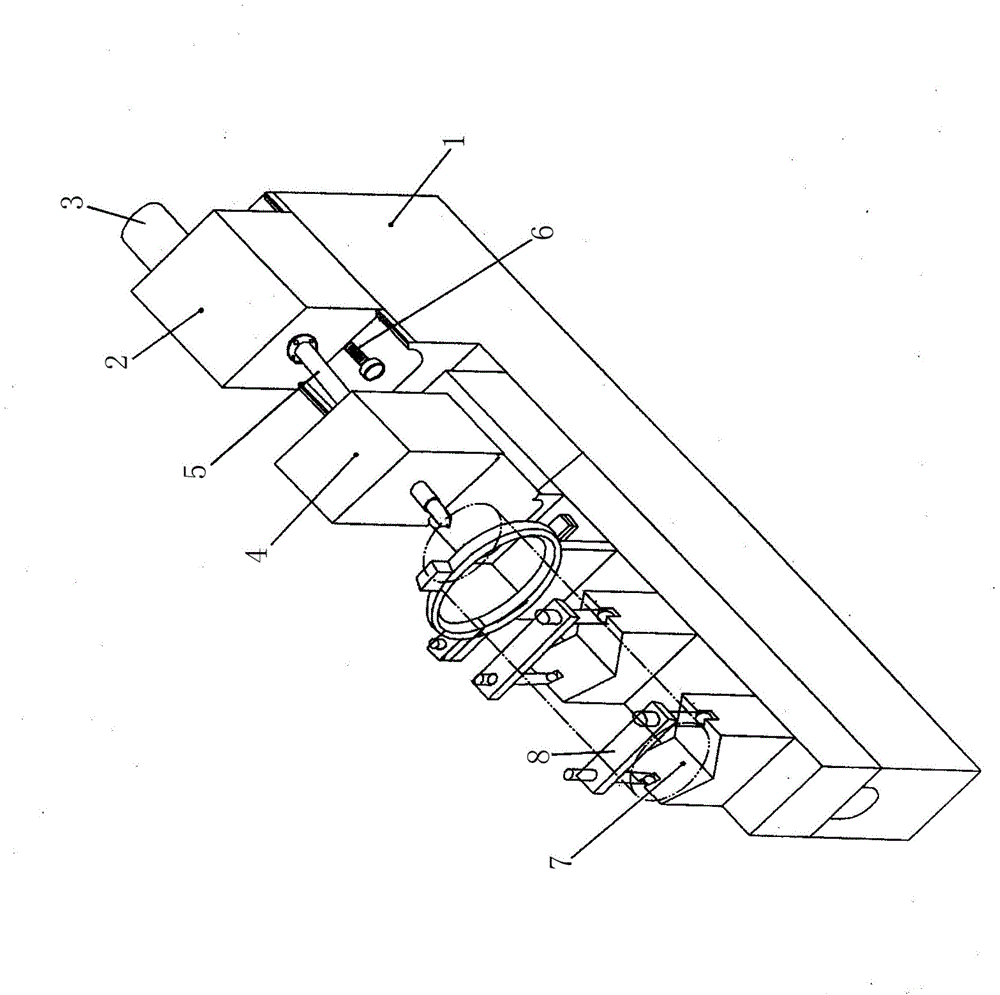

[0008] Such as figure 1 As shown, the present invention supports the main engine head 2 through the guide rail at one end of the bed 1, the driving motor 3 is arranged on the upper part of one side of the main engine head 2, and the drill pipe support block 4 is arranged on the inner side of the main engine head 2, and is connected to the main engine head 2. The drill pipe 5 on the top is supported by the drill pipe support block 4, and a propulsion screw 6 is provided at the bottom of the main machine head 2, and a plurality of clamp bases 7 are arranged on the other side of the bed 1, and the workpiece on the clamp base 7 is fixed. The center of the frame 8 and the center of the drill pipe 5 are on the same horizontal line. Through the above settings, the present invention uses the rotation of the propulsion screw 6 as the power to advance the main engine head 2, and the driving motor 3 drives the drill pipe 5 on the main engine head 2 to rotate. , Carry out deep hole proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com