Reduction and resourceful treatment process and equipment for oily sludge and emulsified sump oil

A treatment equipment and reduction technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of air pollution, incompleteness, and unacceptability by oil field and refinery owners, and achieve hazardous waste reduction and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

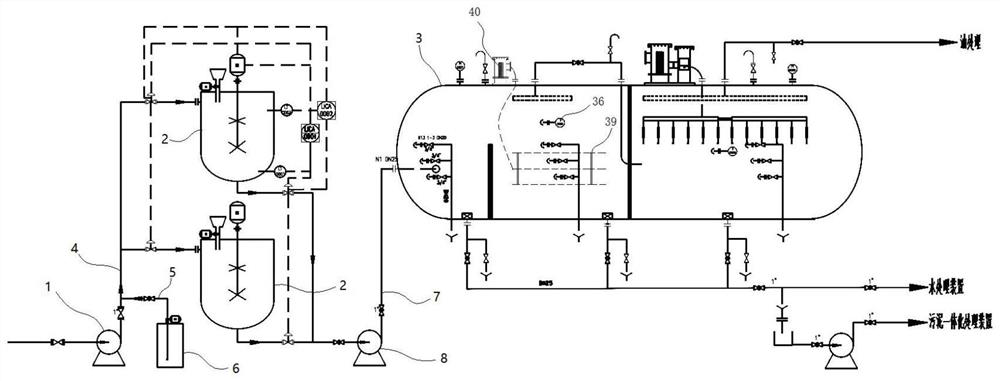

[0035] An oily sludge and emulsified waste oil reduction and recycling treatment equipment disclosed in this embodiment is characterized in that it includes a raw material pump 1, a material homogenization tank 2, and a frequency conversion electric field modification and electric field separation refining tank 3. The outlet of the raw material pump 1 communicates with the feed port of the material homogenization tank 2 through the first pipeline 4, and transports the sludge into the material homogenization tank 2, and the first pipeline 4 communicates with the demulsifier through the drug application pipeline 5 Storage tank 6, the demulsifier is stored in the demulsifier storage tank 6, and the demulsifier is mixed into the sludge through the application pipeline 5, and is input into the material homogenization tank 2 for mixing and homogenization, and the material homogeneity The discharge port of the tank 2 is communicated with the feed port of the variable frequency electri...

Embodiment 2

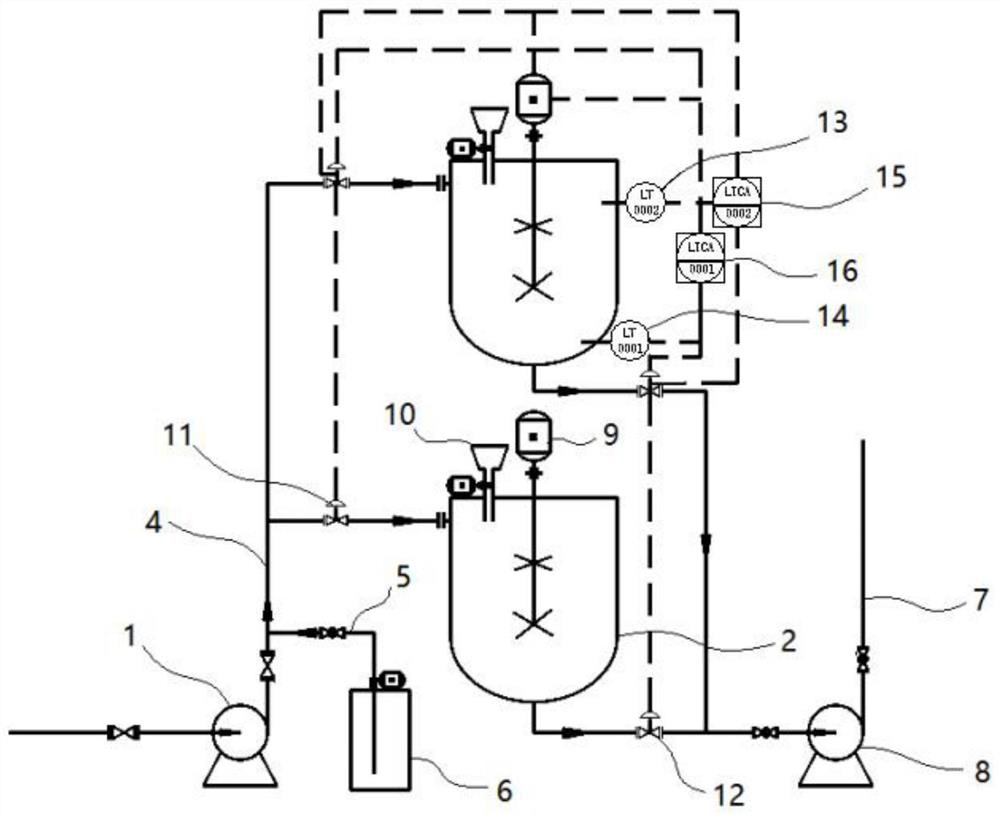

[0039] An oily sludge and emulsified waste oil reduction and recycling treatment equipment in this embodiment, wherein the material homogenization tank 2 is provided with a first solenoid valve 11 and a second solenoid valve 11 at the inlet and outlet respectively. Solenoid valve 12, material homogenization tank 2 is built with first liquid level sensor 13 and second liquid level sensor 14, and described first liquid level sensor 13 and second liquid level sensor 14 are respectively arranged in the material homogenization tank 2 The upper part and the lower part, the first liquid level sensor 13 interacts with the first solenoid valve 11, the second solenoid valve 12 and the stirring device 9 through the No. 1 LICA liquid level indication control alarm 15 to control the first solenoid valve 11 and the second solenoid valve 12 Switch with the stirring device 9, the second liquid level sensor 14 interacts with the first solenoid valve 11, the second solenoid valve 12 and the stir...

Embodiment 3

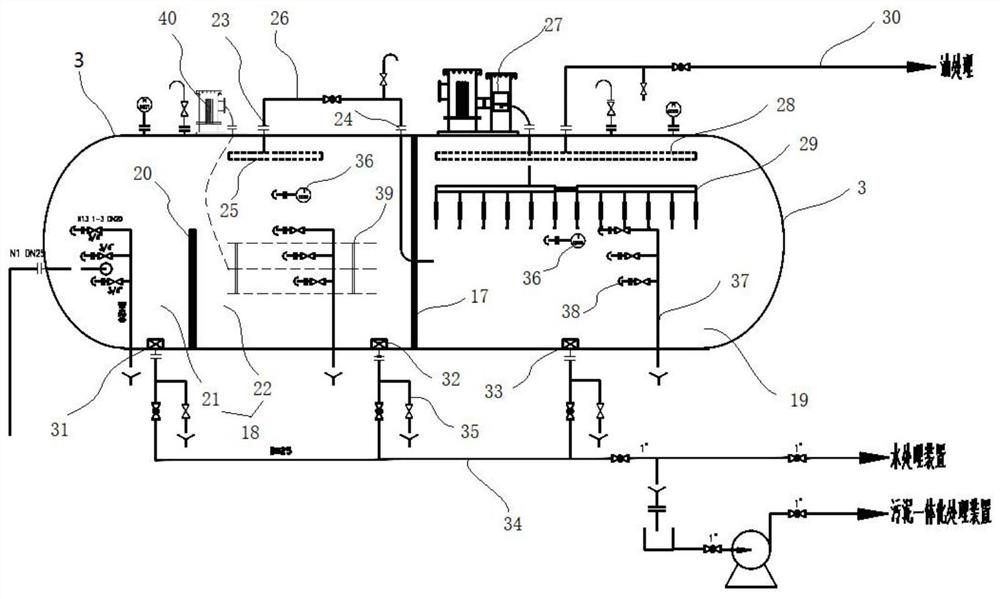

[0042] An oily sludge and emulsified waste oil reduction and recycling treatment equipment in this embodiment, wherein the variable frequency electric field modification and electric field separation refining tank 3 is a hollow horizontal tank, and a closed The separation plate 17 is used to separate and refine the electric field into a first chamber 18 and a second chamber 19. A partition 20 is arranged in the first chamber 18, and the partition 20 divides the first chamber 18 into two chambers. A connected chamber is respectively a material distribution chamber 21 and a variable frequency electric field modification chamber 22;

[0043] The top of the first chamber 18 is provided with an oil outlet 23 and an oil inlet 24, and its inner top is fixedly provided with a first oil collecting pipe 25, and the first oil collecting pipe 25 communicates with a first oil collecting pipe 26, so that The first oil collecting pipeline 26 leads out of the refining tank 3 for frequency con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com