Millet threshing device

A threshing device and millet technology, applied in the field of agricultural machinery, can solve the problems of unclean threshing and short threshing distance, and achieve the effects of increasing threshing efficiency, increasing rolling distance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

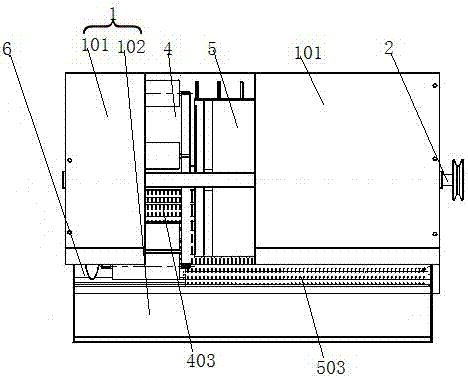

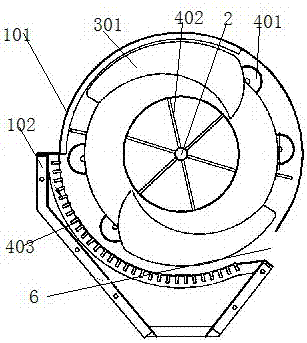

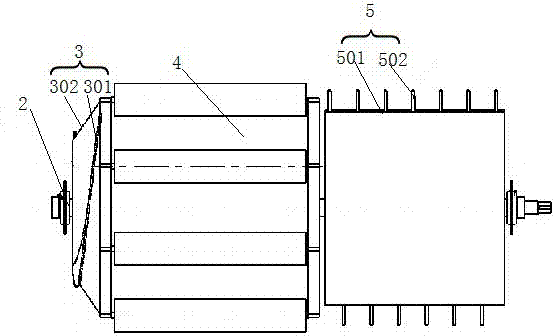

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as Figure 1~6 , a kind of millet threshing device, its technical solution is: comprising a housing 1, a drive shaft 2 rotatably arranged on the opposite side wall of the housing 1, and a cone for pushing ears of grain arranged on the drive shaft 2 The large-diameter end of the shaped front end assembly 3 and the conical front end assembly 3 is connected to the rotary threshing assembly 4 driven by the drive shaft 2 for threshing, and the rear end of the rotary threshing assembly 4 driven by the drive shaft 2 is used for separating millet grains and The vibration separation component 5 of impurities, the rotary threshing component 4 cooperates with the grid concave plate I403 for threshing, and the rotary threshing component 4 is composed of a plurality of threshing rollers 401 that are evenly distributed on the outside of the drive shaft 2 and parallel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com