Separation analyzing method for nitrogen-containing compounds in heavy oil

A technology for the separation and analysis of nitrogen compounds, applied in the direction of material separation, analysis materials, measuring devices, etc., can solve the problems of inability to judge the integrity of nitrogen compounds in the separation and purification effect, and achieve the effect of large sample processing capacity and reduced solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The fine-pore silica gel was dried in an oven at 120°C to obtain activated silica gel, which was placed in a desiccator and stored away from light for future use. Measure 80mL of hydrochloric acid solution and add it to 40g of the extracted silica gel, stir evenly, let it stand to dry, and the adsorbent turns slightly yellow to make acid-modified silica gel. Insert the absorbent cotton into the bottom of the Soxhlet extraction tube, put the acid-modified silica gel into the chromatographic column with a side tube, and extract with 50mL of dichloromethane for 30min until it is completely wetted and free of bubbles.

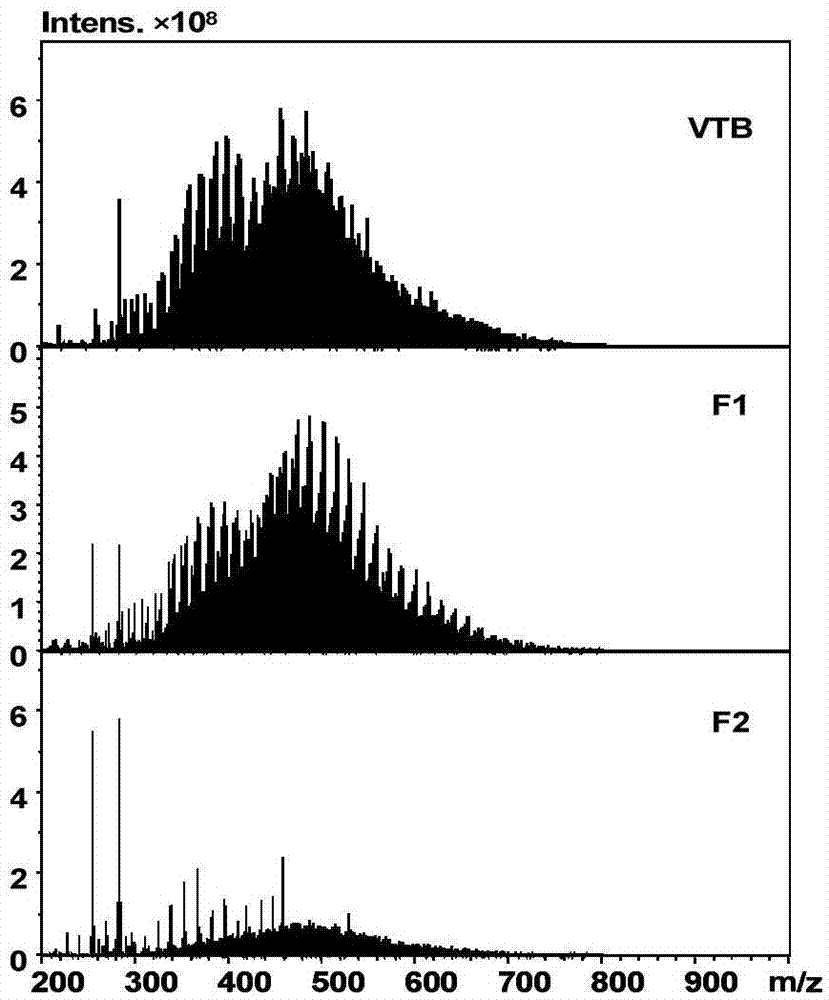

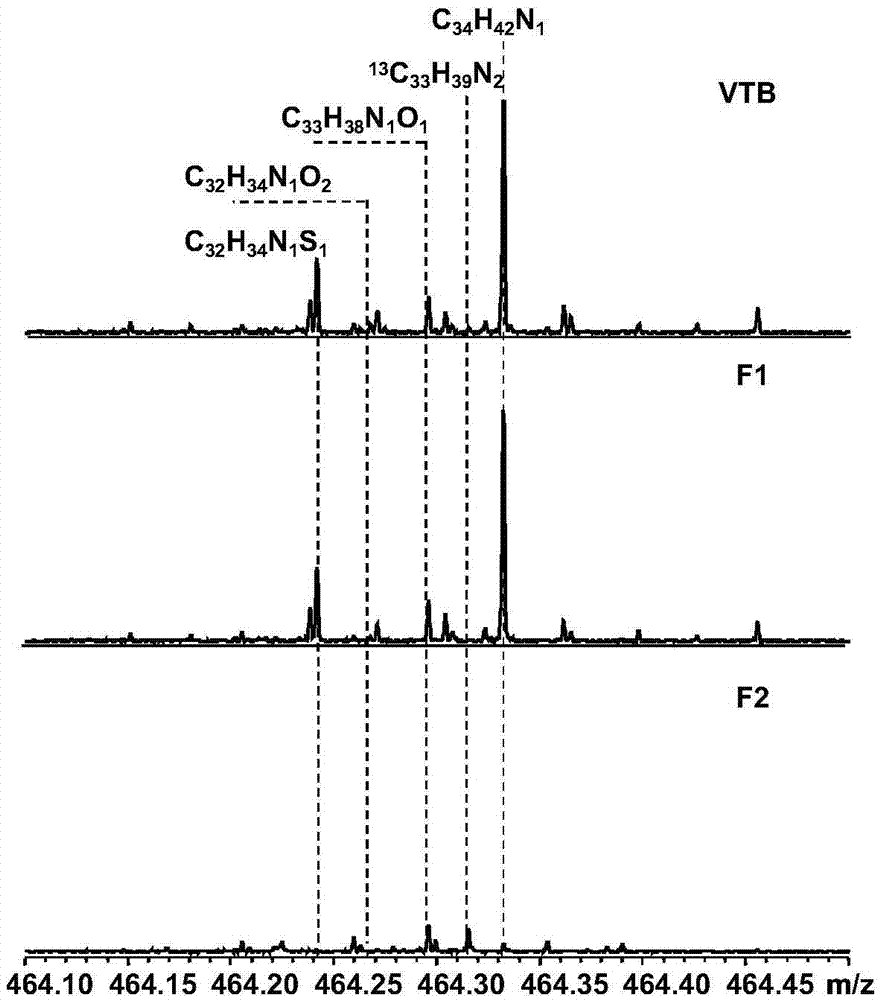

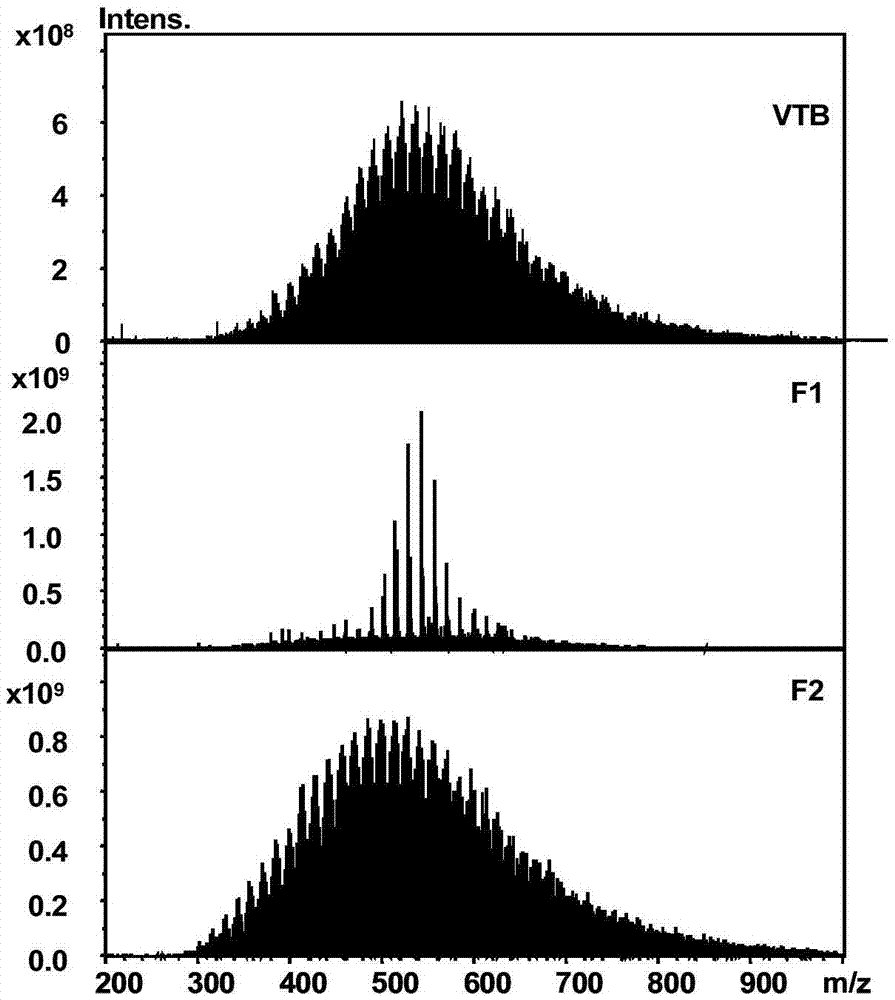

[0054] Weigh about 1g of VTB, dissolve it in 2mL of dichloromethane with ultrasonic vibration; fill 40 grams of acid-modified silica gel in a solid-phase extraction column (inner diameter of 28 mm, the same below) with side stream reflux; install the solid-phase extraction column On a solid phase extraction device with a heating and condensing system. Add 5...

Embodiment 2

[0059] This example is used to illustrate that the solid phase extraction method provided by the present invention rapidly separates colloids in Canadian oil sands bitumen vacuum residue (distillation range>524°C) (colloid separation method refers to SH / T 0509-92) and Preparation of non-alkaline components and alkaline components in colloids.

[0060] Weigh 1 gram of the colloidal component (colloid separation according to SH / T 0509-92) sample of Canadian oil sand bitumen vacuum residue (distillation range >524°C), dissolve it in 2 ml of dichloromethane with ultrasonic vibration; Pack 20 grams of acid-modified silica gel in a solid-phase extraction column (inner diameter of 28 mm, the same below) with side stream reflux; the following steps are the same as described in Example 1.

[0061] After adopting rotary evaporator to dry up the solvent in the separation product containing non-basic component and basic component, weigh, obtain non-basic component Resin-F1 and basic compo...

Embodiment 3

[0064] This example is used to illustrate the rapid separation of Liaohe vacuum residue (distillation range>500°C, referred to as LHVR) by the solid phase extraction method provided by the present invention, and to prepare the non-alkaline component (LHVR-F1 ) and alkaline components (LHVR-F2).

[0065] Weigh 1 gram of Liaohe vacuum residue sample, dissolve it in 2 milliliters of dichloromethane with ultrasonic vibration; fill 40 grams of acid-modified silica gel in a solid-phase extraction column (inner diameter 28 mm, the same below) with side stream reflux; The steps are the same as described in Example 1.

[0066] After using a rotary evaporator to evaporate to dryness the solvent in the separated product containing non-basic components and basic components, weigh them, and obtain the sample mass distribution of non-basic components LHVR-F1 and basic components LHVR-F2 as 0.6205 Grams 0.3743 grams.

[0067] Using electrospray Fourier ion cyclotron resonance high-resoluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com