Non-excavation type PRB construction method for underground water pollution

A technology of groundwater pollution and construction method, which is applied in the field of trenchless PRB construction, can solve the problems of inability to meet the requirements of filler content in the reaction zone, affect the groundwater flow field, increase the cost of materials, etc., so as to achieve high construction efficiency and reduce formation. Disruption, effect of reducing disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

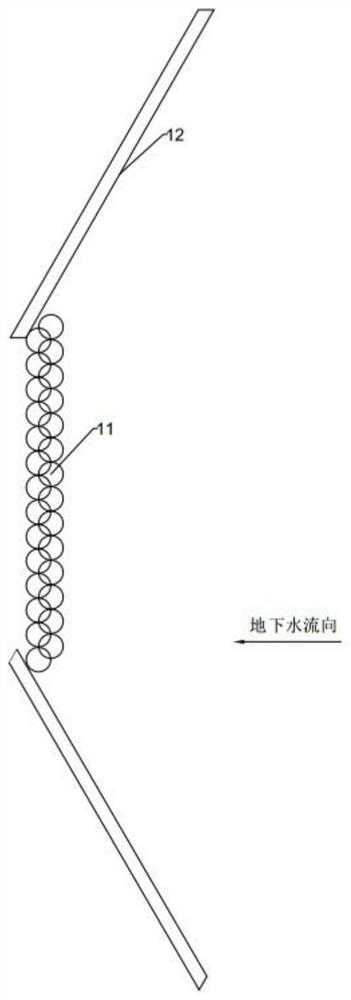

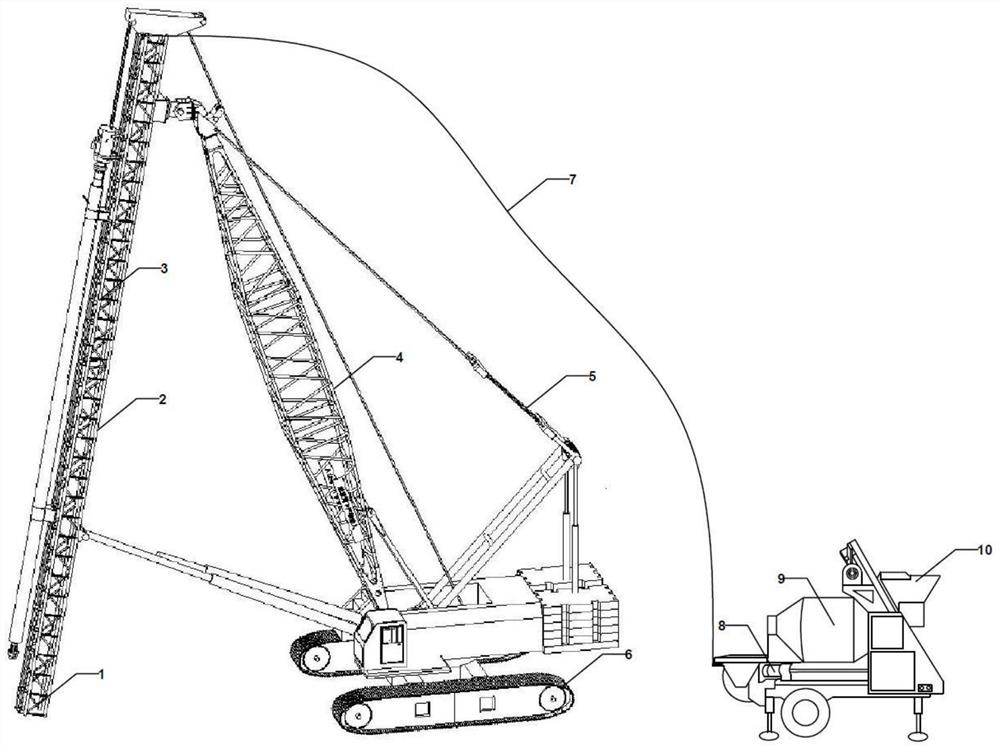

[0029] like Figure 1-2 As shown, the present invention provides a technical solution: a trenchless PRB construction method for groundwater pollution, comprising a reaction zone and a permeable reaction wall, and the reaction zone adopts a modified PRB integrated machine to realize drilling and material stirring With the function of forming a wall, the PRB integrated machine includes a drilling system, a background system and a feeding system. The feeding system mixes the background material with a conveying volume of 60-100m3 / h and a pumping pressure of 10-20Mpa. The drilling system The output shaft of the power head and the drilling tool are hollow, and the top port of the drill pipe is connected with the material conveying pipe; the feeding system includes the active material mixing background, the ground pump and the conveying pump pipe, and the long spiral of the PRB integrated machine forms a hole. The diameter is 400mm~1000mm, the hole depth is not more than 30m, and th...

Embodiment 2

[0036] In this example, a copper and zinc waste processing plant in Inner Mongolia is selected. The groundwater of this plant is slightly polluted, and the stratum is mainly fine sand. According to the construction method of the present invention, a field test and pilot test are carried out. The project PRB permeable reaction wall adopts a funnel-water guide gate It is about 30m long, 1m wide, the reaction zone is 10m long, and the water stop zone is 20m long.

[0037] The PRB permeable reaction wall technology is applied in the aquifer of the plant area. The project mainly includes: retaining wall 11, reaction wall 12 and the construction of the feeding background. The thickness of the retaining wall 11 is about 600mm, and the diameter of the opening of the reaction wall 12 is about 600-700mm. For the specific construction method, see figure 1 ,Specific steps are as follows:

[0038] In the direction of groundwater flow, a guide gate type retaining wall is built, and the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com